Method for manufacturing die pressing wheel disc

A roulette and molding technology, applied in the direction of manufacturing tools, wood compression, wood processing appliances, etc., can solve the problems of large waste, low efficiency and high production cost, and achieve the effect of reducing dust pollution and saving wood resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A method for preparing a molded wheel disc, comprising the following process steps:

[0043] a. Chip the raw materials with a moisture content below 25% to a length of 20mm;

[0044] b. Crushing the chipped raw materials to 15 meshes;

[0045] c. Dry the crushed raw materials to a moisture content of 4%;

[0046] d. Add glue to the dried raw materials and mix well;

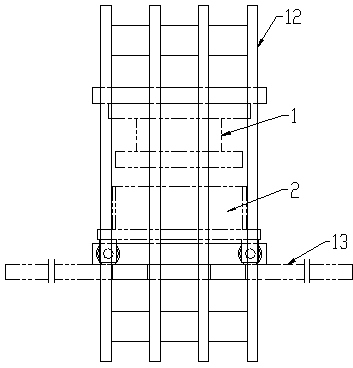

[0047] e. Weigh according to the weight of the size of the roulette, add the raw materials into the mould, and hot-press the roulette on the mould.

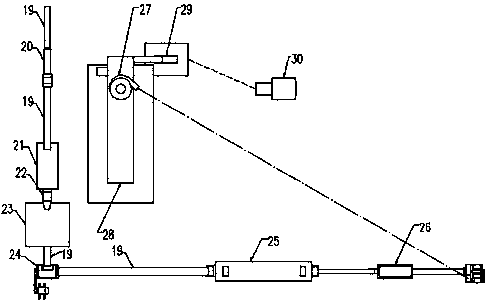

[0048] In the step a, the raw material is transported to the chipper for chipping by a conveyor.

[0049] The present invention also includes a step of removing impurities. The step of removing impurities is to transport the chipped raw materials to a vibrating screen to remove bulk materials, silt, and slag powder, and transport the cleaned raw materials to a wood chip silo.

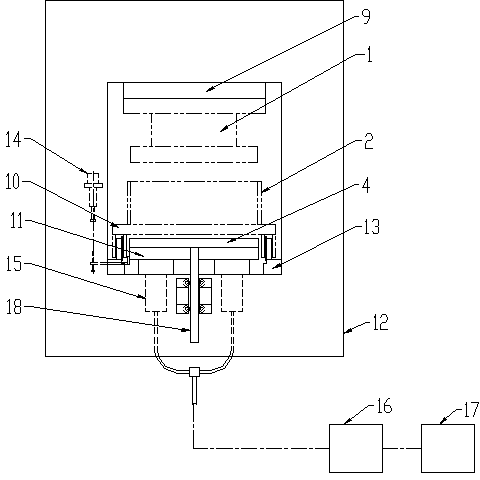

[0050] The raw materials in the wood chip silo are sent to the hammer crusher f...

Embodiment 2

[0065] A method for preparing a molded wheel disc, comprising the following process steps:

[0066] a. Chip the raw materials with a moisture content below 25% to a length of 30mm;

[0067] b. Crushing the chipped raw materials to 20 meshes;

[0068] c. Dry the crushed raw materials to a moisture content of 5%;

[0069] d. Add glue to the dried raw materials and mix well;

[0070] e. Weigh according to the weight of the roulette, add the raw materials into the mold, and heat-press the roulette on the mold.

[0071] In the step a, the raw material is transported to the chipper for chipping by a conveyor.

[0072] The present invention also includes a step of removing impurities. The step of removing impurities is to transport the chipped raw materials to a vibrating screen to remove bulk materials, silt and slag powder, and transport the cleaned raw materials to a wood chip silo.

[0073] The raw materials in the wood chip silo are sent to the hammer crusher for crushing af...

Embodiment 3

[0082] A method for preparing a molded wheel disc, comprising the following process steps:

[0083] a. Chip the raw materials with a moisture content below 25% to a length of 25mm;

[0084] b. Crushing the chipped raw materials to 17 meshes;

[0085] c. Dry the crushed raw materials to a moisture content of 4.5%;

[0086] d. Add about 20% urea-formaldehyde resin glue with a solid content of more than 55% to the dried raw materials and mix evenly. The amount of glue is determined according to the raw materials required for the size of the wheel;

[0087] e. Weigh according to the weight of the roulette, add the raw materials into the mold, and heat-press the roulette on the mold.

[0088] In the step a, the raw material is transported to the chipper for chipping by the conveyor, and the belt conveyor can be selected as the movement machine, but it is not limited to the belt conveyor.

[0089] The present invention also includes the step of removing impurities. The step of re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com