Seal device for pulse valve

A technology of sealing device and pulse valve, applied in valve device, valve operation/release device, lift valve, etc., can solve the problems of valve air leakage and increased energy consumption of dust removal system, to prevent leakage, increase impact resistance, The effect of meeting the bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

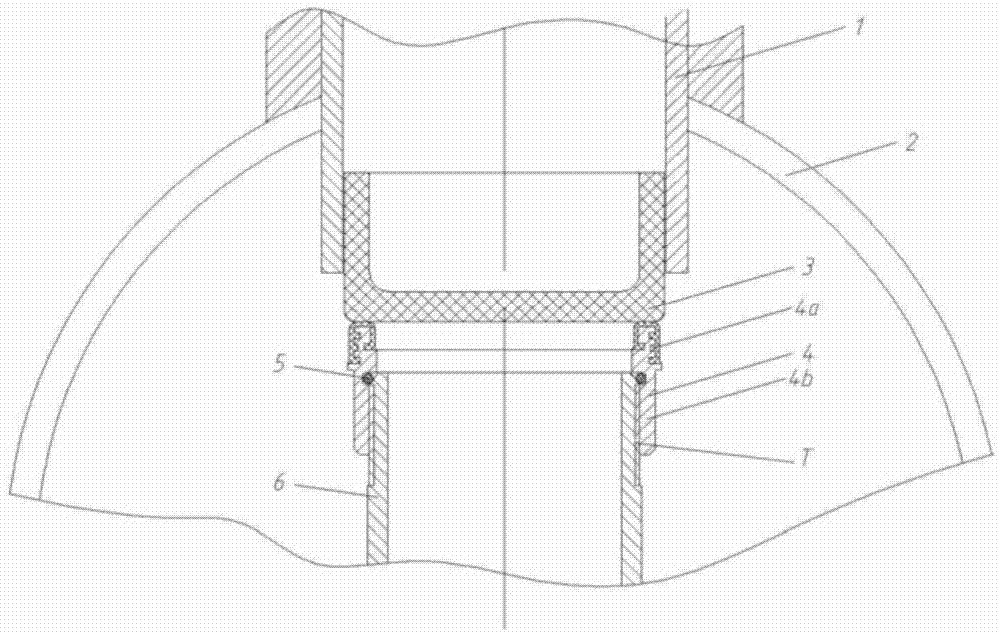

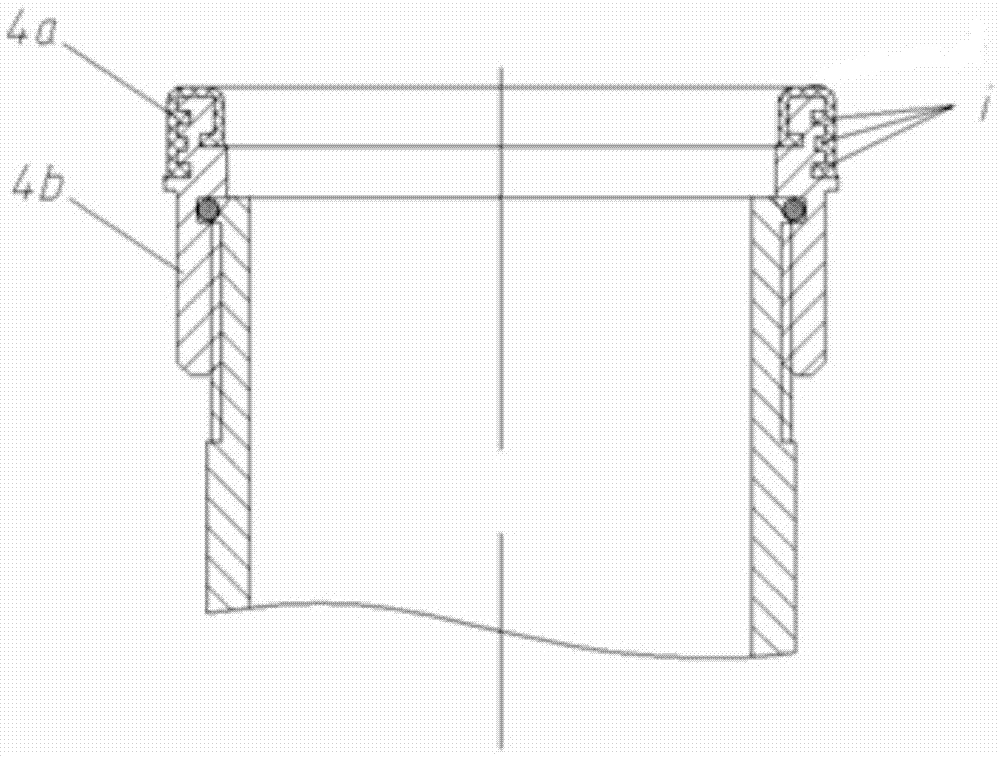

[0024] Such as figure 1 As shown, it is a schematic diagram of the installation of the sealing device 4 and the pulse valve. The pulse valve includes a valve body 1, an air bag 2 and a blowing pipe 3. The valve body 1 is installed on the air bag 2. The sealing device 4 Installed in the air bag 2 of the pulse valve. The sealing device 4 includes a vulcanized rubber layer 4a and a skeleton 4b, such as figure 2 As shown, a zigzag groove i is set above the skeleton 4b, which matches the inner wall of the vulcanized rubber layer 4a, so that the vulcanized rubber layer 4a covers the upper part of the skeleton 4b, and passes through the vulcanized rubber layer 4a and the valve flap 3 of the pulse valve. The sealing is achieved by adhering to the contact, and the skeleton 4b is fixed on the blowing pipe 6 of the pulse valve through the thread T,

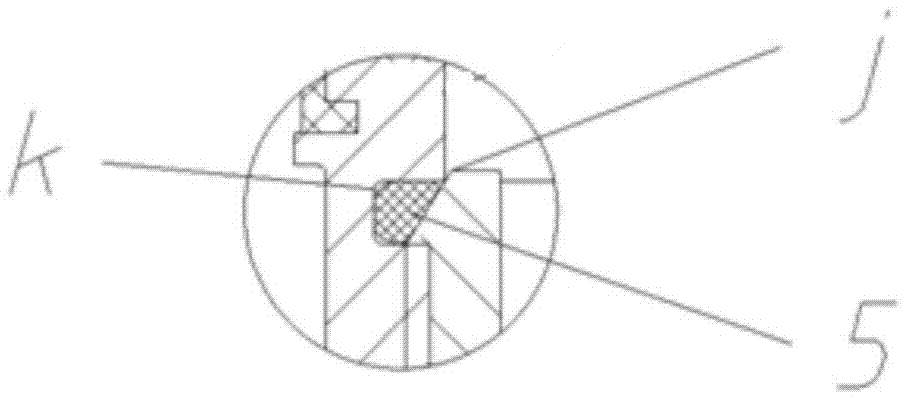

[0025] Such as image 3 As shown in the partial enlarged view of the sealing device 4, the upper end of the frame 4b is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com