Walking belt type transferring system

A technology of walking belt and loader, which is used in cleaning devices, conveyors, conveyor objects, etc., can solve the problems of difficult disassembly and transportation, affecting coal mining progress, and small transportation capacity, and achieves improved transportation capacity, installation and disassembly transportation. Convenient, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

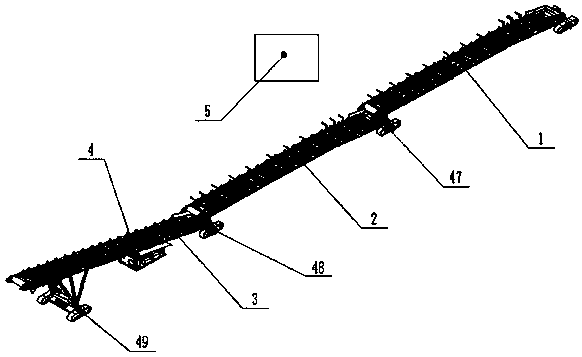

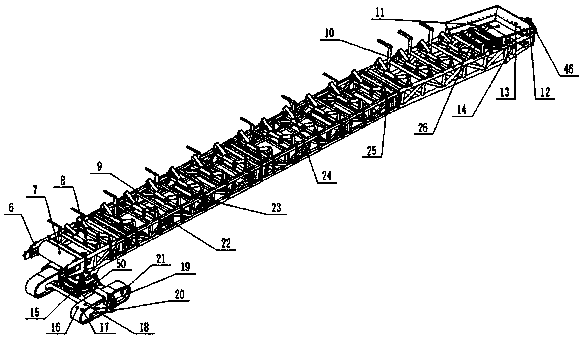

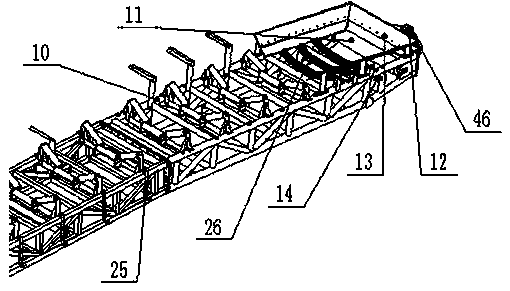

[0033] The present invention will be further described below with reference to the accompanying drawings and embodiments, and the mode of the present invention includes but not limited to the following embodiments.

[0034] The purpose of this embodiment is to design and develop a walking belt-type reloading system to solve the practical problems of the current models such as large structural size, low transportation capacity, small traction force, and difficulty in lateral moving. The design concept of centralized control and remote control of the whole machine, the unit adopts the design of the combination of the head, the middle frame, the tail of the machine, and the slewing walking mechanism. It can realize material receiving, reloading and traction synchronously, and it is an ideal auxiliary equipment for the operation line of side continuous coal mining machine.

[0035] see Figure 1~Figure 9 , the walking belt type continuous reloading system of the present embodimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com