Roadway roof support device and support method

A technology of roadway roof and support device, which is applied in tunnels, tunnel linings, temporary shields, etc., can solve the problems of steel belts falling and hurting people, complicated construction procedures, and inadequate coordination, so as to increase the support density and improve the roof. The effect of supporting strength and increasing safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

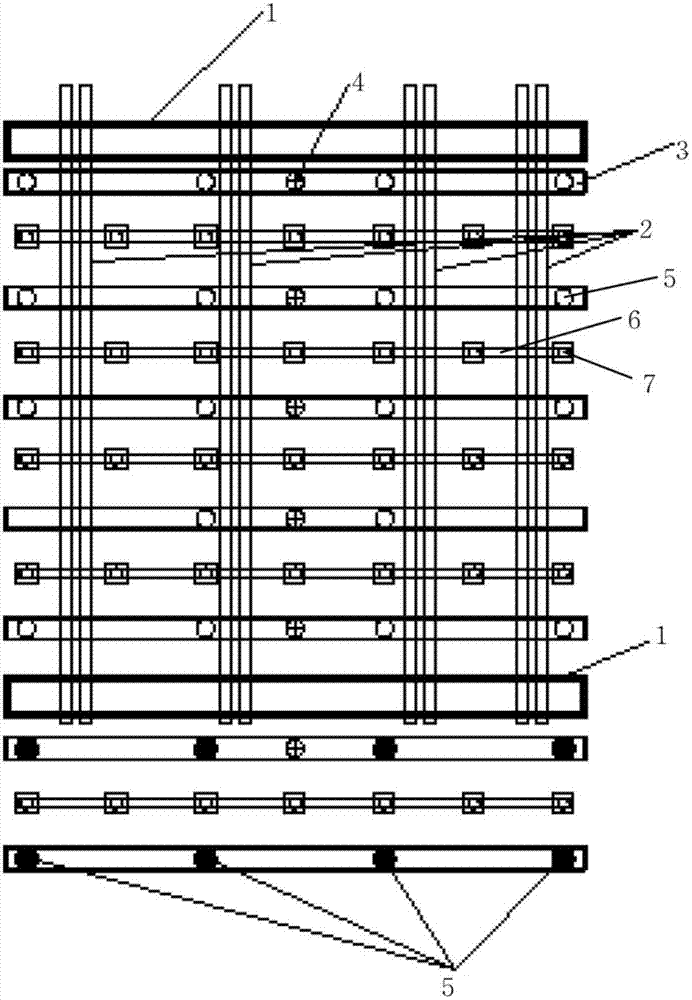

[0026] Such as figure 2 As shown, the present invention adopts the method of separate support of the anchor cable 5 and the anchor rod 7 to support the roadway roof, the anchor cable 5 cooperates with the T140 steel belt 3 for support, and the anchor rod 7 cooperates with the trapezoidal steel beam 6 for support. Concrete device and implementation method are as follows:

[0027] Anchor cable 5 and anchor rod 7 are separated, anchor cable 5 cooperates with T140 steel belt 3 for support, and anchor rod 7 cooperates with trapezoidal steel beam 6 for support, including the following steps:

[0028] Step 1, before the excavation construction, place the T140 steel belt 3 and trapezoidal steel beam 6 used for roof support in parallel with the beam 1 of the advanced temporary support device on the longitudinal beam 2 of the advanced temporary support device, according to the center line of the roadway, the specified Adjust the position of the T140 steel belt 3 and the trapezoidal st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com