Advanced supporting system for bolt-mesh supporting and supporting method

A technology of advanced support and anchor net support, which is applied in earth square drilling, mine roof support, mining equipment, etc., and can solve problems such as support rollover, support deflection, and impact on the service life of the support.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

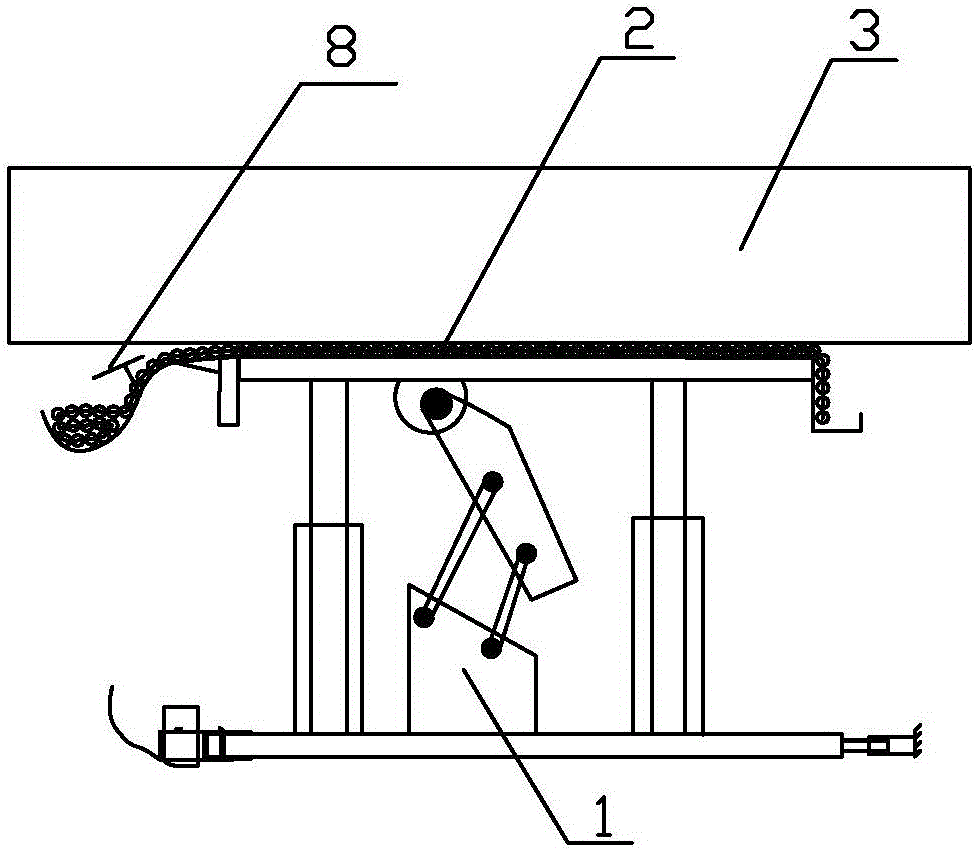

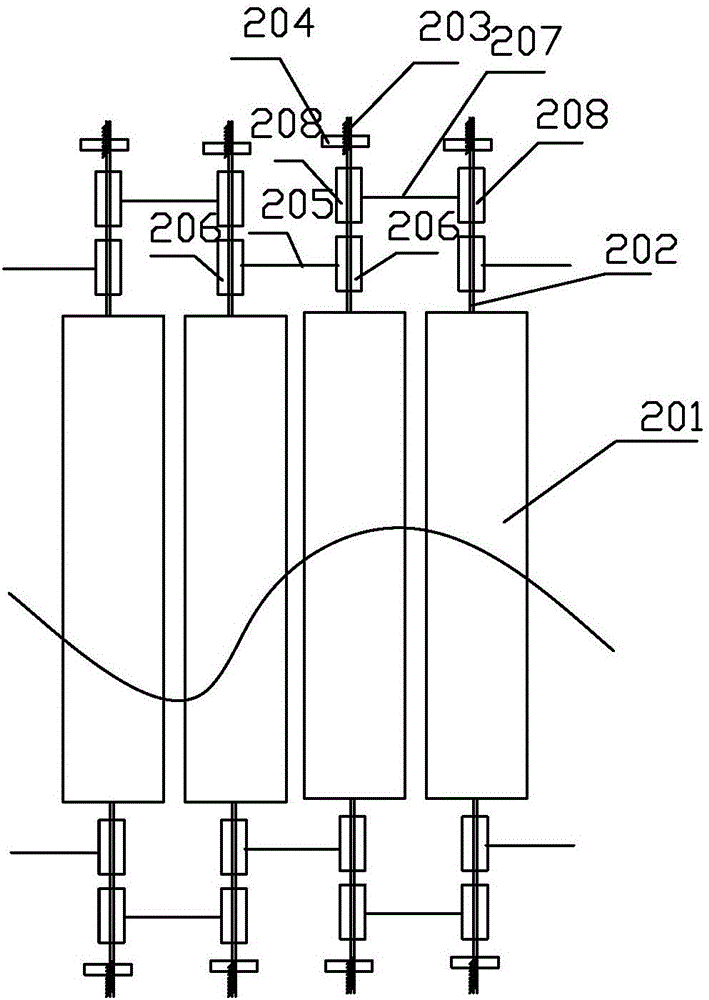

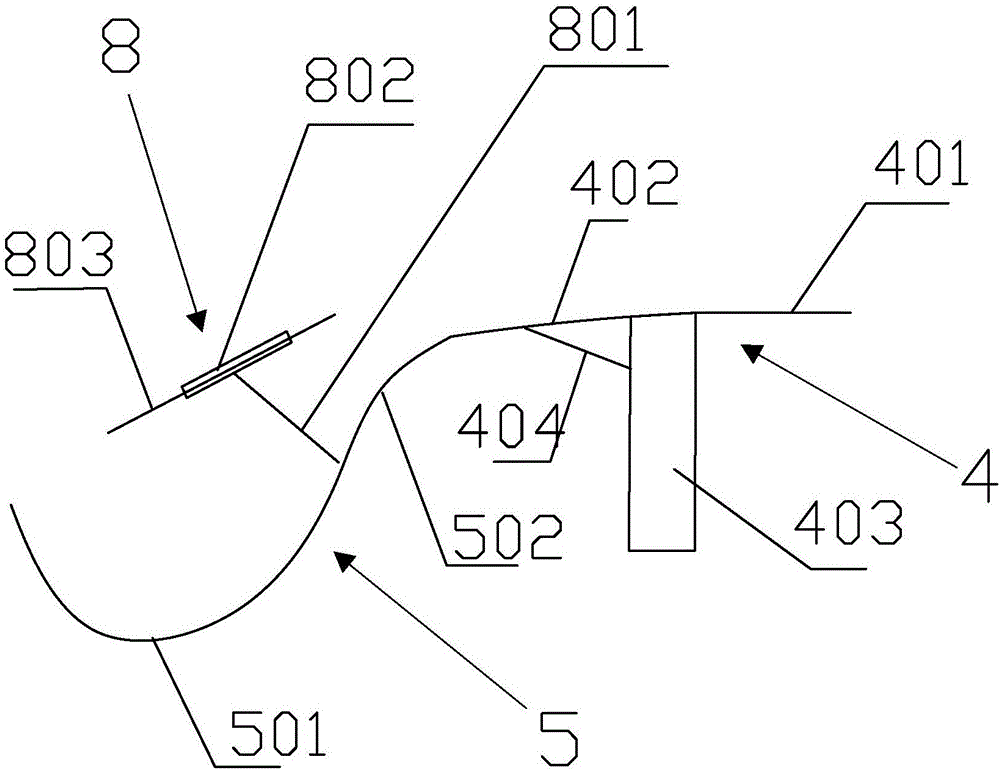

[0054] Such as Figure 1 to Figure 10 As shown, an advanced support system for anchor net support includes a roof support body and a bottom plate support body. The roof support body includes an advanced hydraulic support 1 and a cylindrical pressure-bearing row 2. The cylindrical pressure-bearing row 2 is composed of multiple Two cylindrical rollers 201 are formed in series in sequence, and the cylindrical pressure-bearing row 2 is arranged between the top beam of the leading hydraulic support 1 and the roadway roof 3, and the cylindrical rollers 201 roll when the leading hydraulic support 1 advances; A cylindrical pressure-bearing row 2 is laid between the top beam of the leading hydraulic support 1, so that the pressure can be directly carried in the form of rolling friction, and the leading hydraulic support 1 is pushed from the back through the jack, so that there is no need for pressure relief and re-pressurization, directly Advance like this, can hardly cause any damage ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com