Patents

Literature

74results about How to "Strong structural reliability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

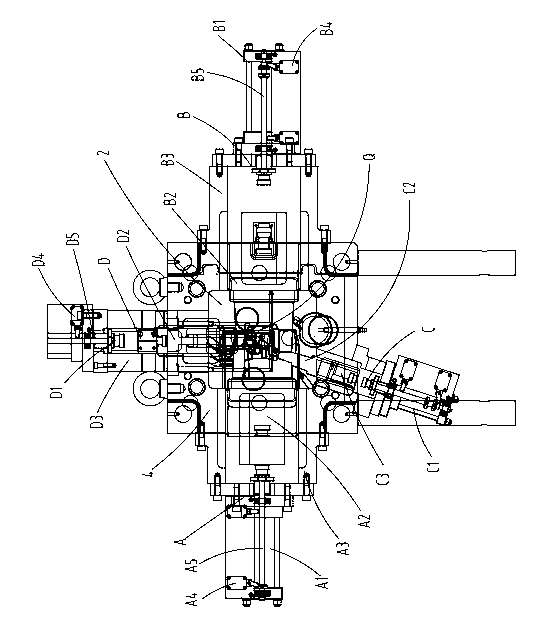

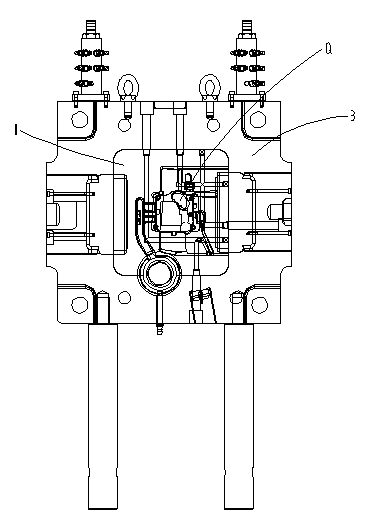

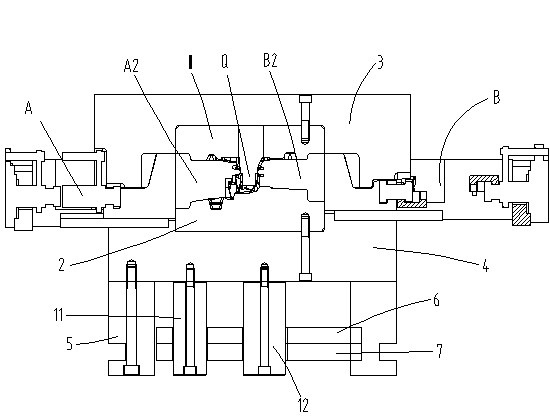

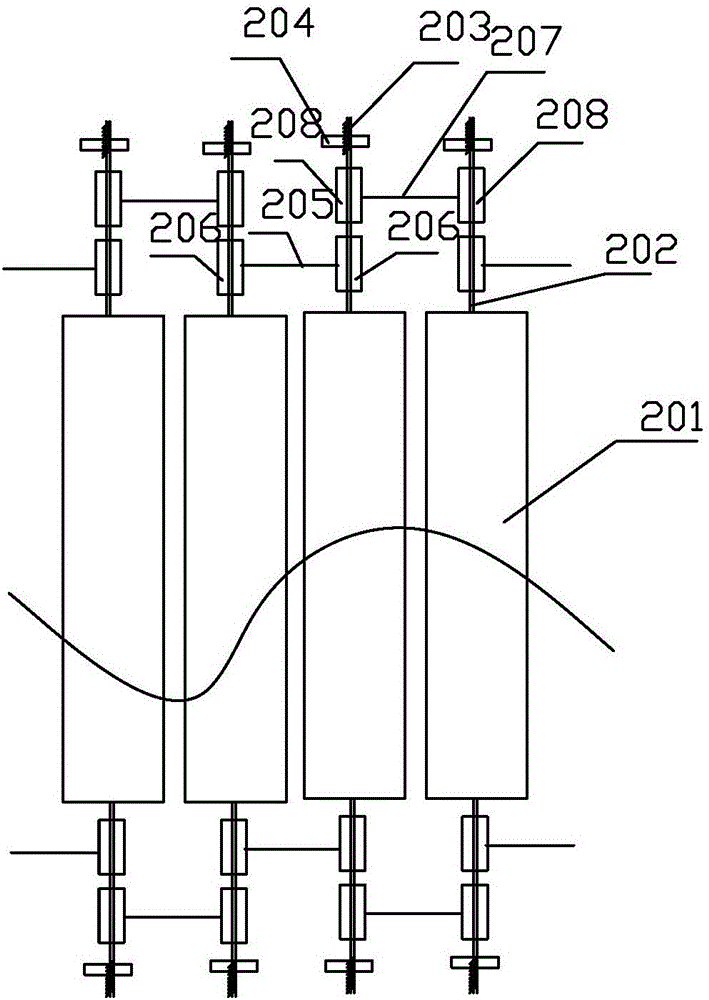

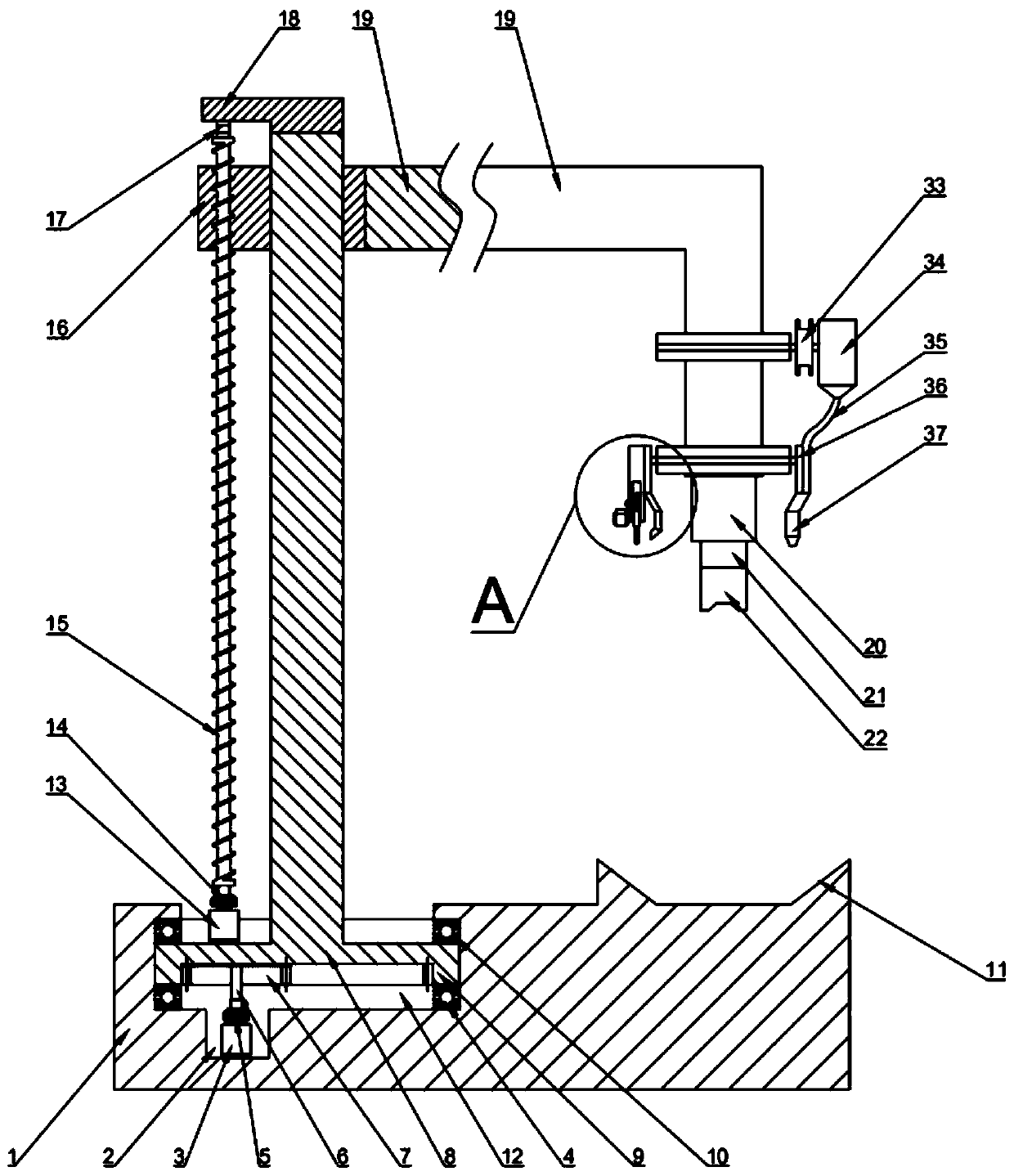

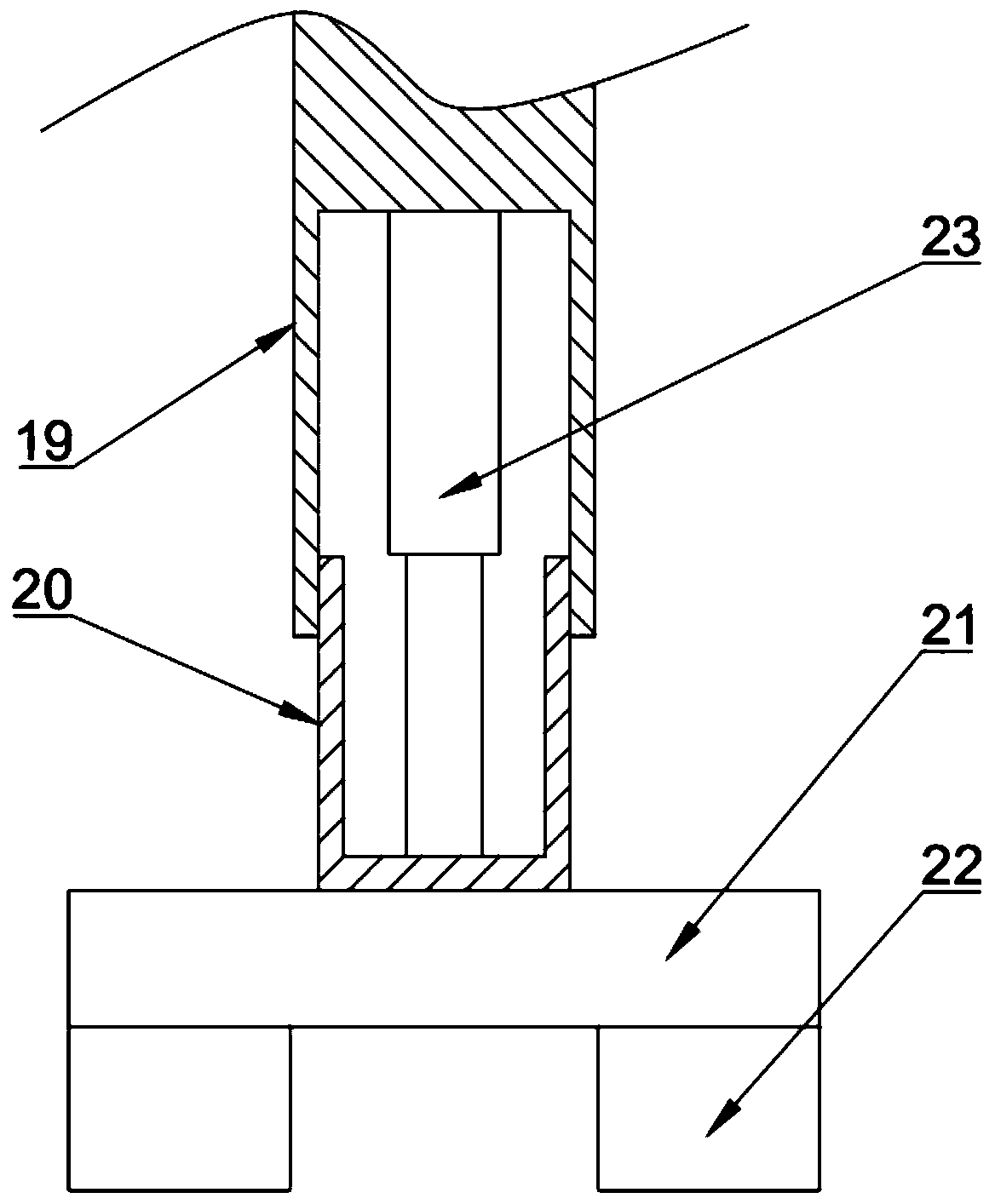

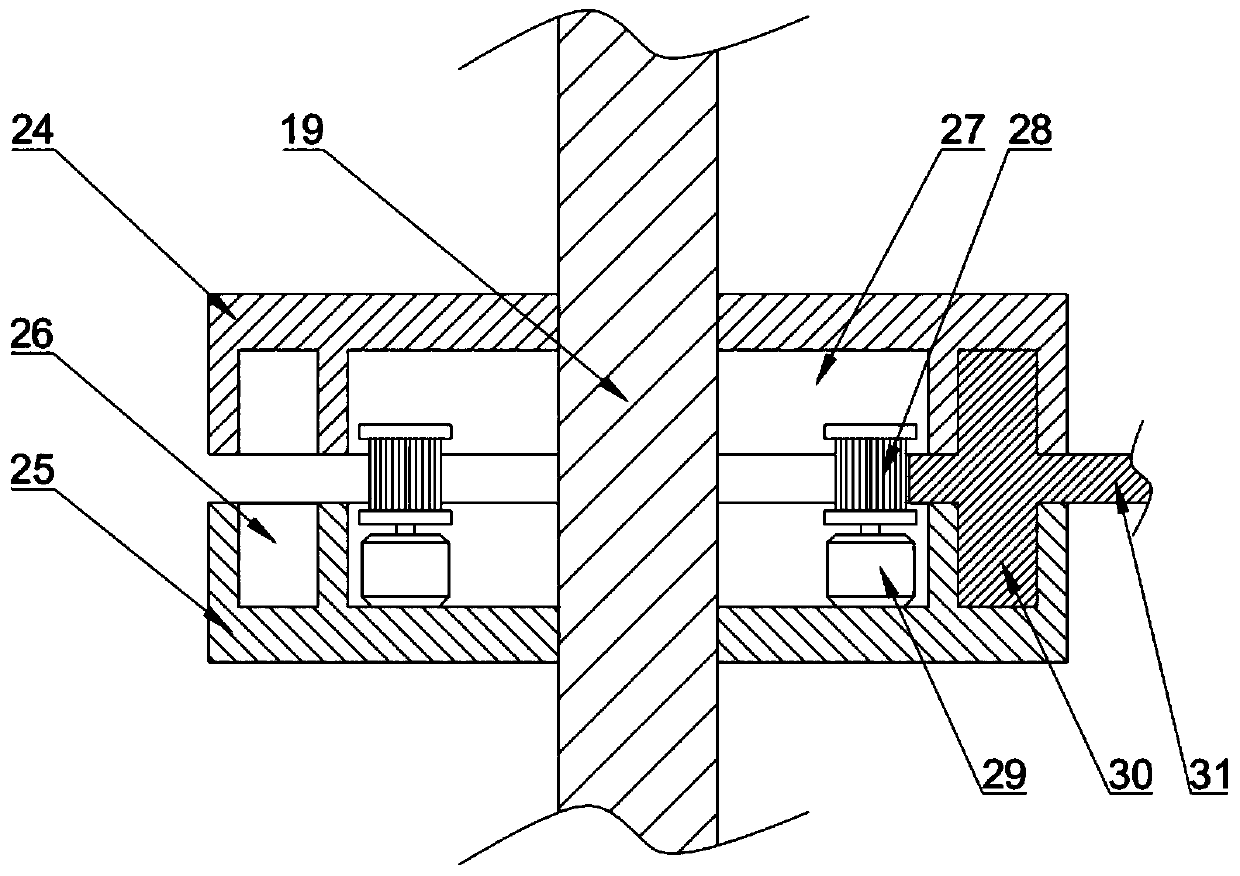

Metal pouring die of hydraulic core pulling structure

ActiveCN103273047AExtended service lifeImprove rigidityFoundry mouldsFoundry coresEngineeringAutomation

The invention discloses a metal pouring die of a hydraulic core pulling structure. The metal pouring die comprises an upper die frame, a lower die frame, an upper die core and a lower die core, wherein the upper die frame and the lower die frame are vertically fastened, the upper die core is embedded on the bottom face of the upper die frame, the lower die core is embedded on the top face of the lower die frame, the upper die core and the lower die core form a forming cavity of the metal pouring die when being vertically matched, a first-side core pulling component and a second-side core pulling component are allocated on the left side and the right side of the lower die frame respectively, and a third-side core pulling component and a fourth-side core pulling component are allocated on the front side and the rear side of the lower die frame respectively. According to forming complexity of the metal pouring die, the core pulling components are independently allocated on four sides of the die, so that the metal pouring die is reasonable in design, flexible to operate and suitable for convenient manufacturing of different models. The core pulling components are driven by hydraulic oil, so that the metal pouring die is high in automation degree, direct in control, high in working efficiency and low in labor cost. The metal pouring die is controlled by travel switches, and core pulling strokes are designed to be adjustable, so that the metal pouring die is convenient and fast to operate and wide in application range.

Owner:NINGBO HUASHUO MOLDING & MACHINE

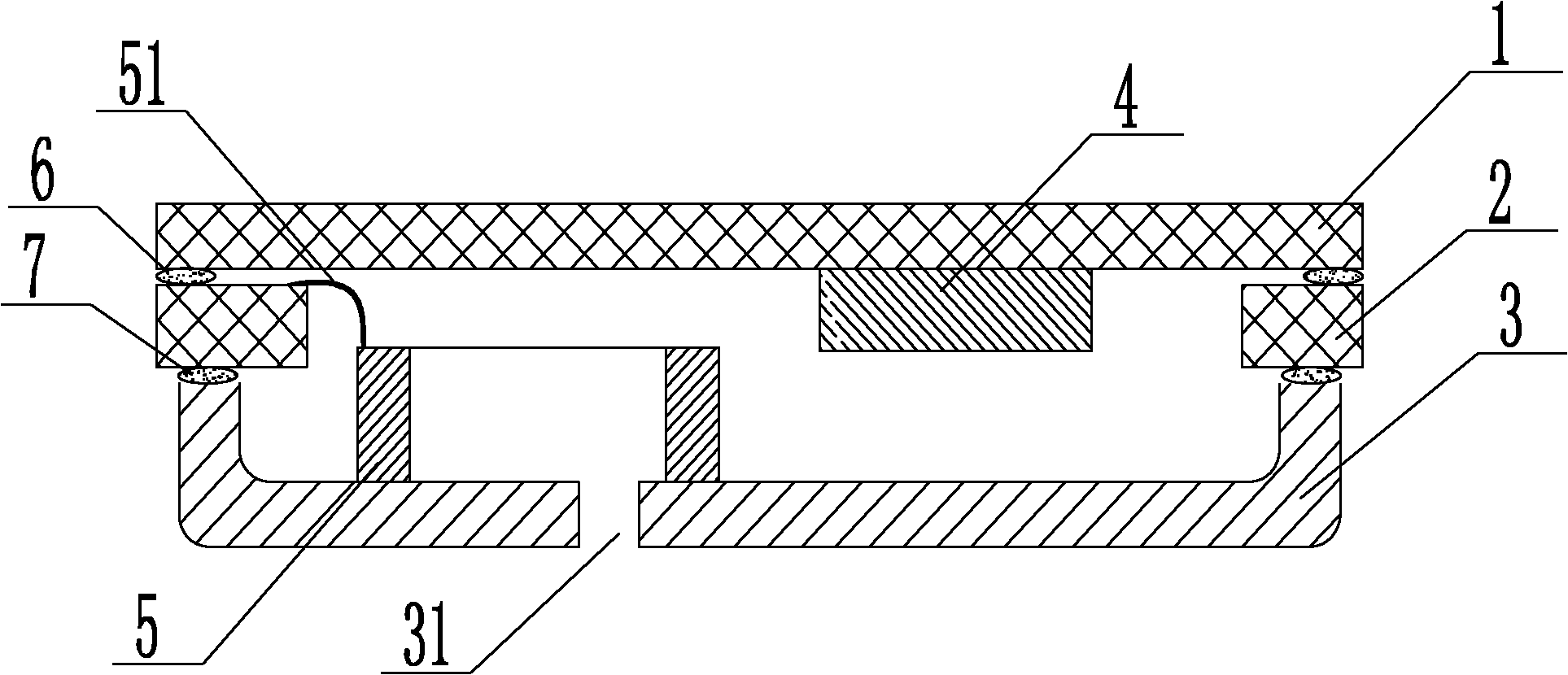

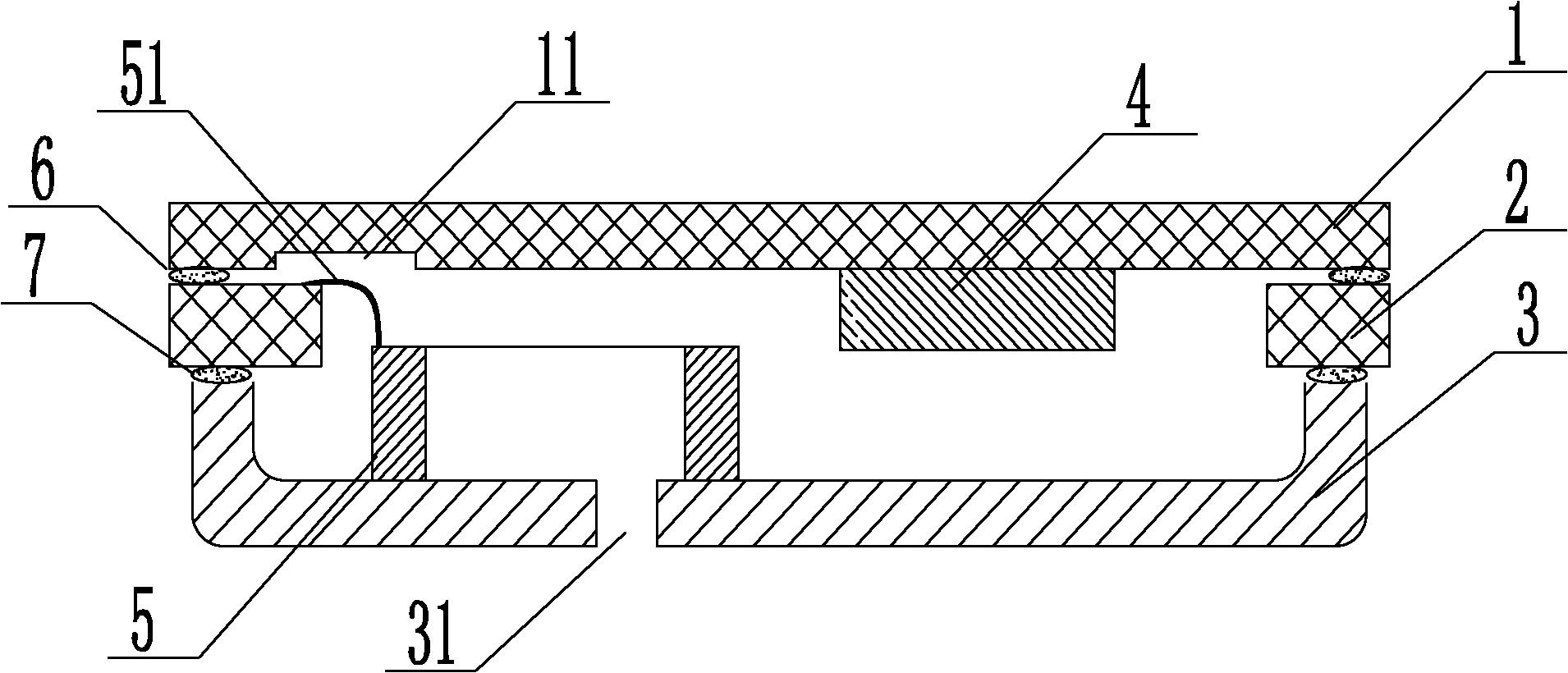

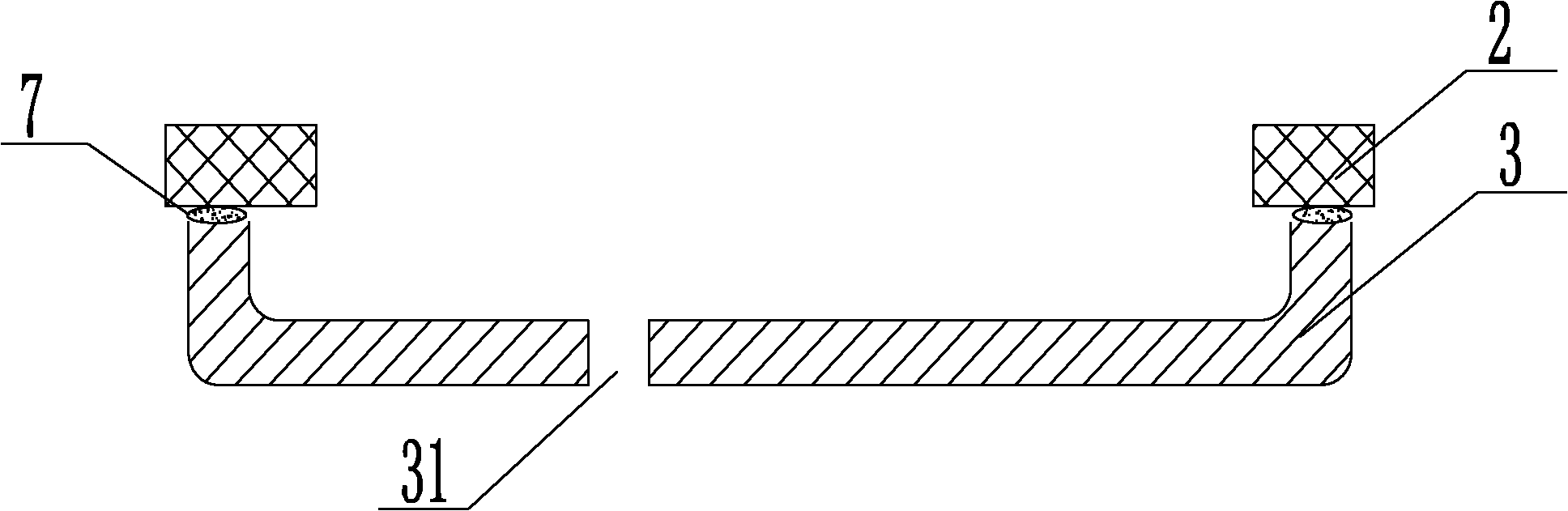

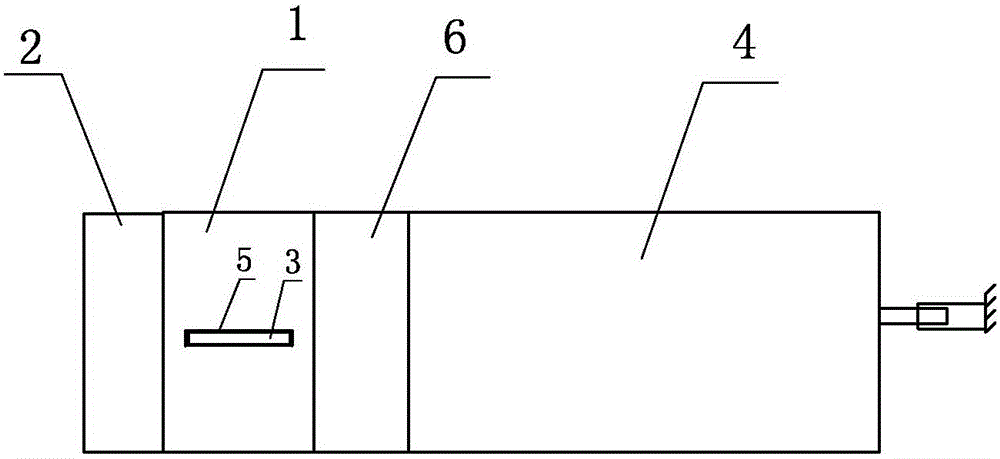

Micro-electromechanical system (MEMS) microphone and packaging method thereof

ActiveCN102595293AReduce manufacturing costStrong structural reliabilityElectrostatic transducer microphonesTransducer circuitsStructural reliabilityEngineering

The invention provides a micro-electromechanical system (MEMS) microphone and a packaging method of the MEMS microphone. The MEMS microphone comprises a circuit board substrate, a hollow circuit board frame, a cover, an MEMS acoustic chip and an application specific integrated circuit (ASIC) chip, wherein the circuit board substrate, the hollow circuit board frame and the cover form an MEMS microphone frame structure; the MEMS acoustic chip and the ASIC chip are arranged in the MEMS microphone frame structure; the circuit board substrate and the cover are fixedly arranged on the upper and lower surfaces of the circuit board frame respectively; the MEMS acoustic chip and the ASIC chip are arranged on the circuit board substrate and the cover respectively; and the chips on the cover are electrically connected with the circuit board frame through a metal wire. By the MEMS microphone and the packaging method of the MEMS microphone, the mounting positions of the MEMS acoustic chip and the ASIC chip of the MEMS microphone are flexibly regulated, and different design requirements can be met; and the MEMS microphone with the structure is low in manufacture cost and high in structural reliability.

Owner:WEIFANG GOERTEK MICROELECTRONICS CO LTD

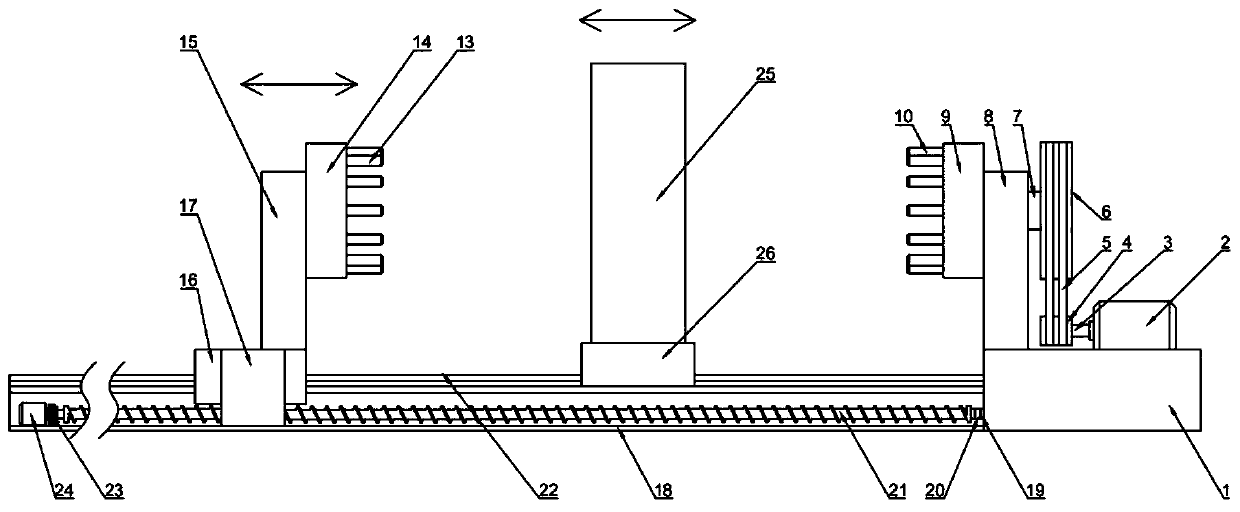

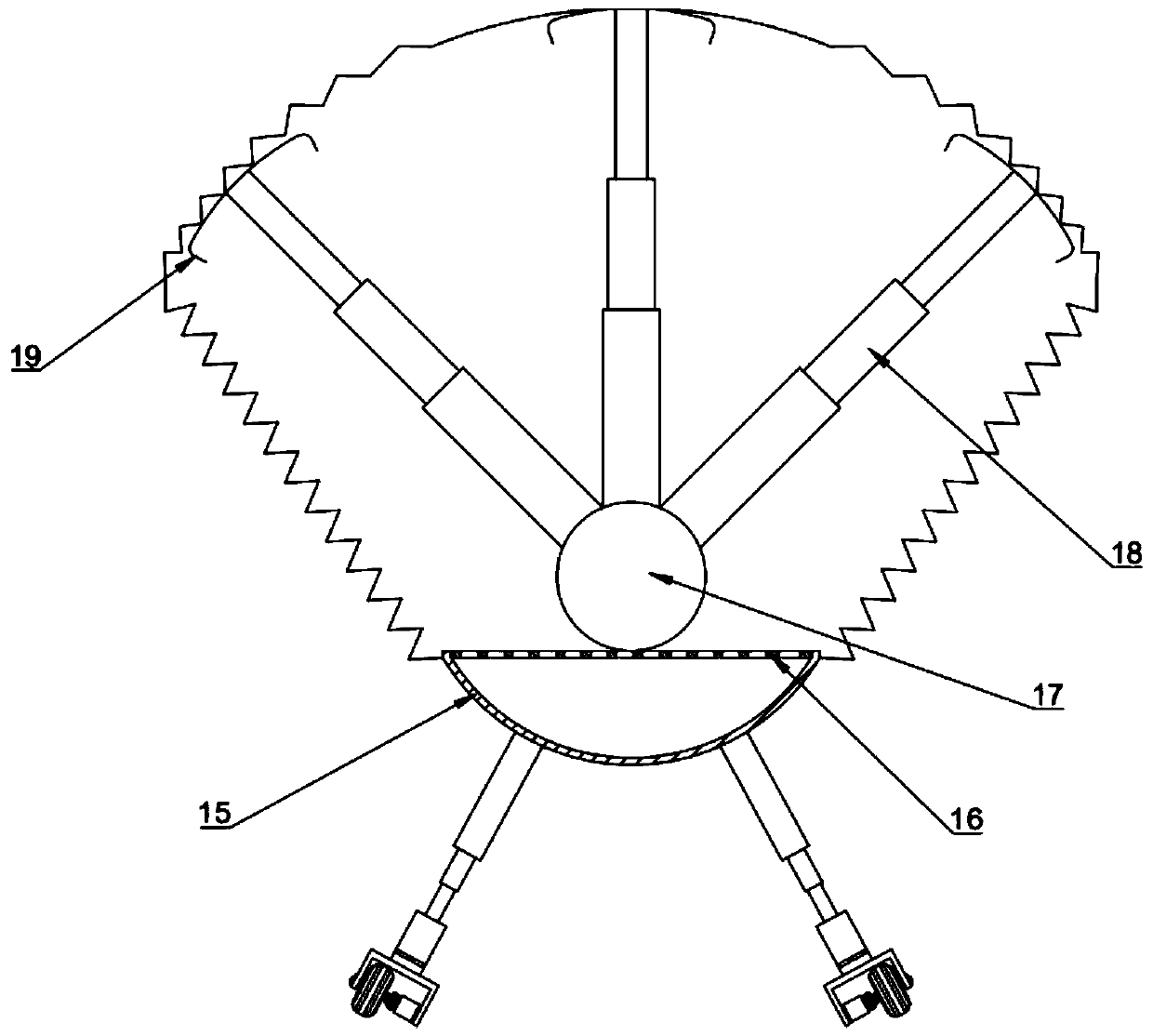

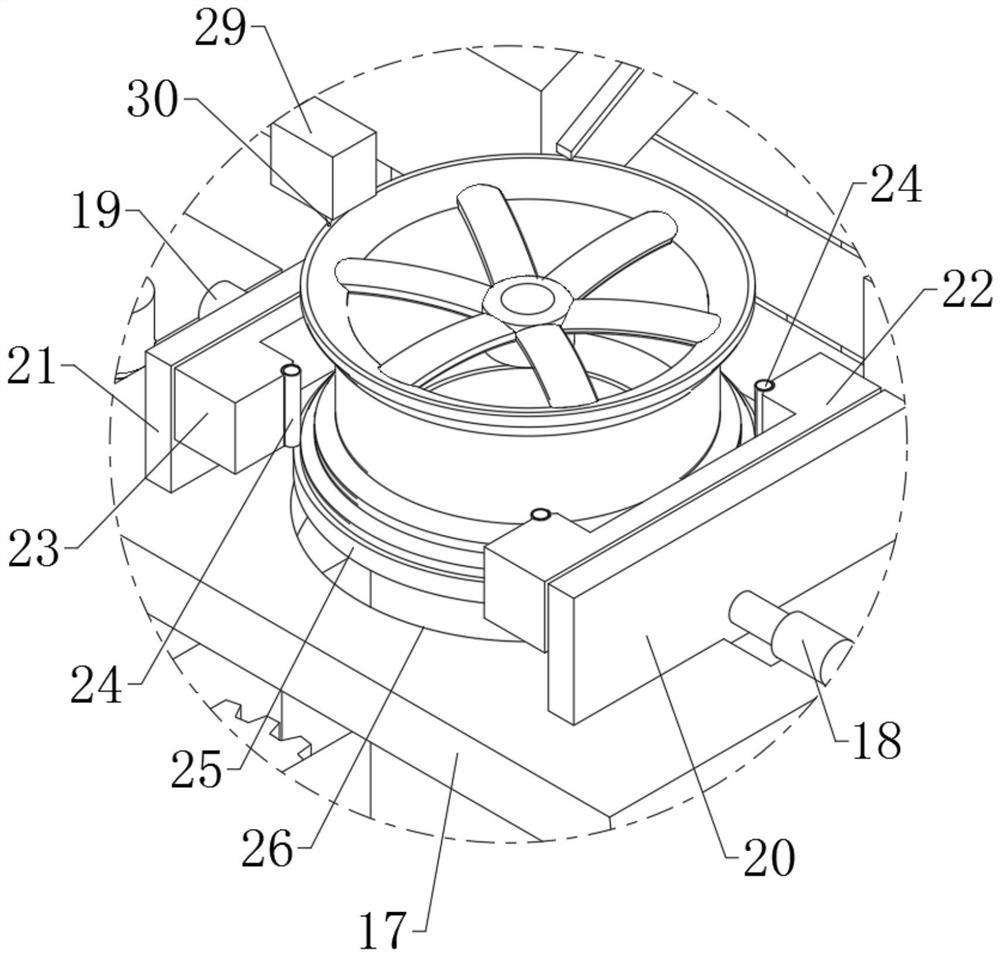

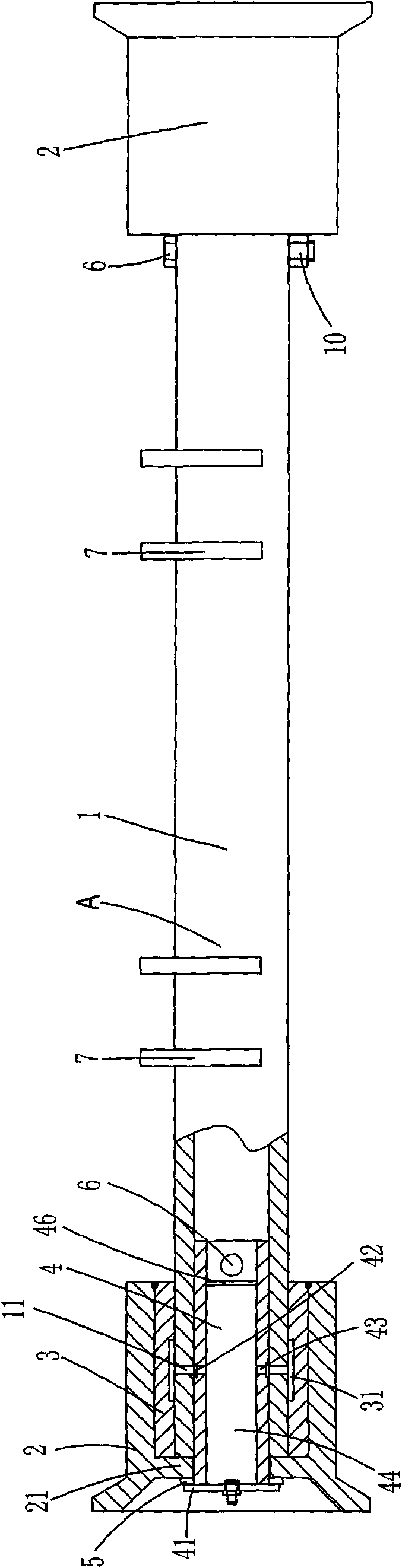

Automatic paint spraying device of wind power generation tower

InactiveCN110586385AImprove painting efficiencyStrong structural reliabilitySpraying apparatusStructural reliabilityDrive shaft

The invention discloses an automatic paint spraying device of a wind power generation tower, and relates to the field of the machine manufacturing industry. The automatic paint spraying device comprises a clamping and rotating mechanism and a concentrated paint spraying mechanism. The clamping and rotating mechanism comprises a fixed base, a rotating driving motor, a driving shaft, a driving beltwheel, a transmission belt, a driven belt wheel, a rotating shaft, a supporting base, a driving rotating plate, driving pin columns, a bearing, a motor installing groove, driven pin columns, a drivenrotating plate, a movable supporting base, a movable base, a clamping slider, a clamping slide rail, a clamping bearing pedestal, a clamping bearing, a clamping screw, a clamping harmonic reducer, a clamping driving motor and movable base slide grooves. Due to the design scheme, the automatic paint spraying device is suitable for the paint spraying process of the wind power generation tower, is high in structural reliability and automation degree, can conduct automatic clamping, rotating and paint spraying, greatly improves the paint spraying efficiency of the wind power generation tower and reduces the production cost.

Owner:QINGDAO TIANNENG HEAVY INDUSTRIES CO LTD

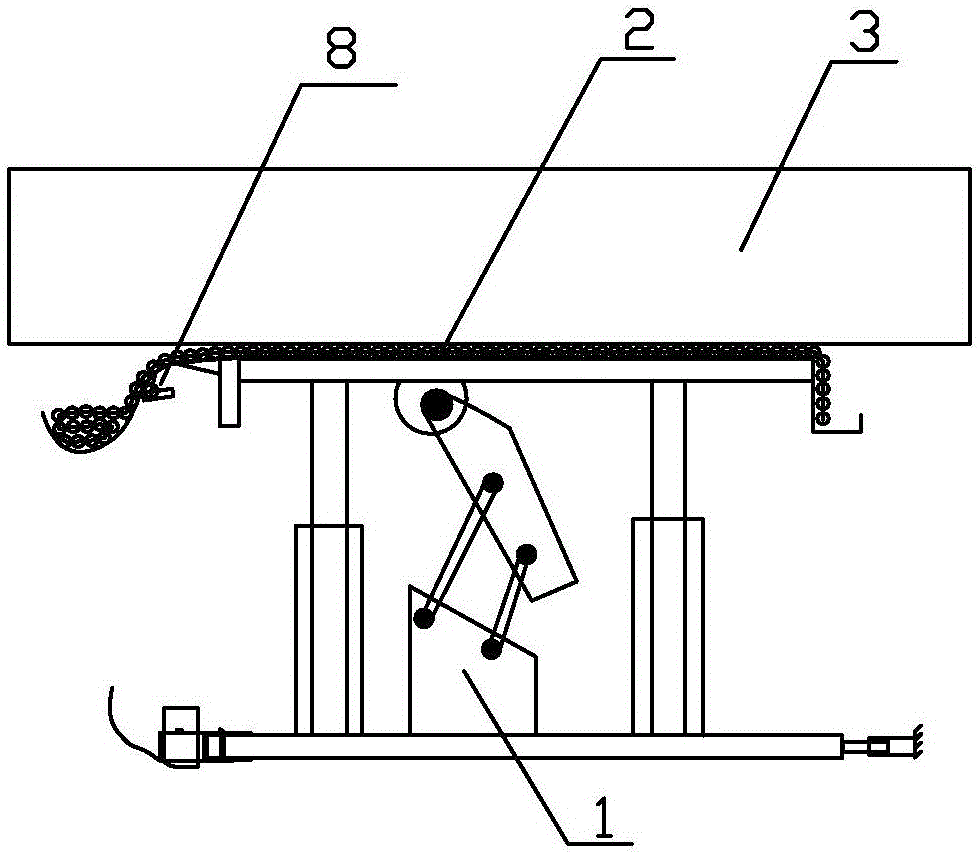

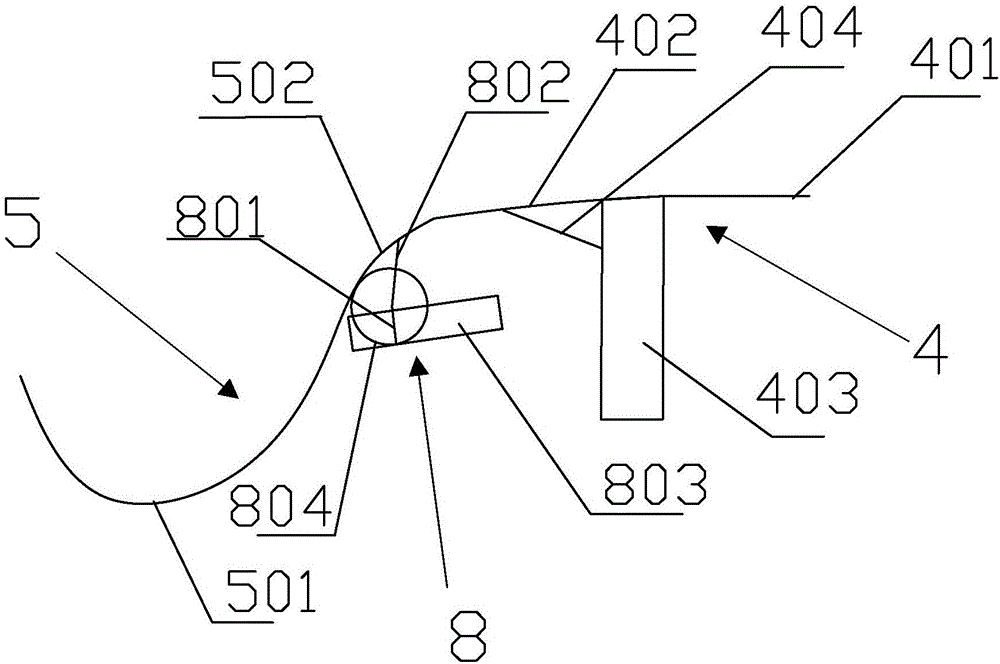

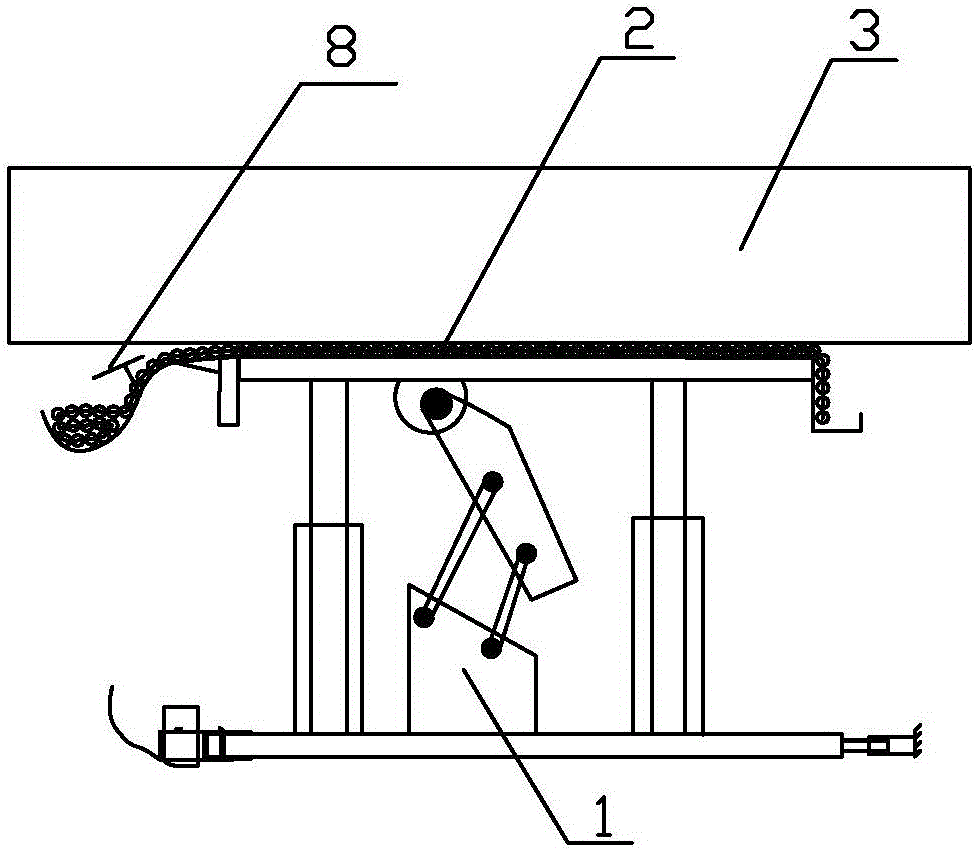

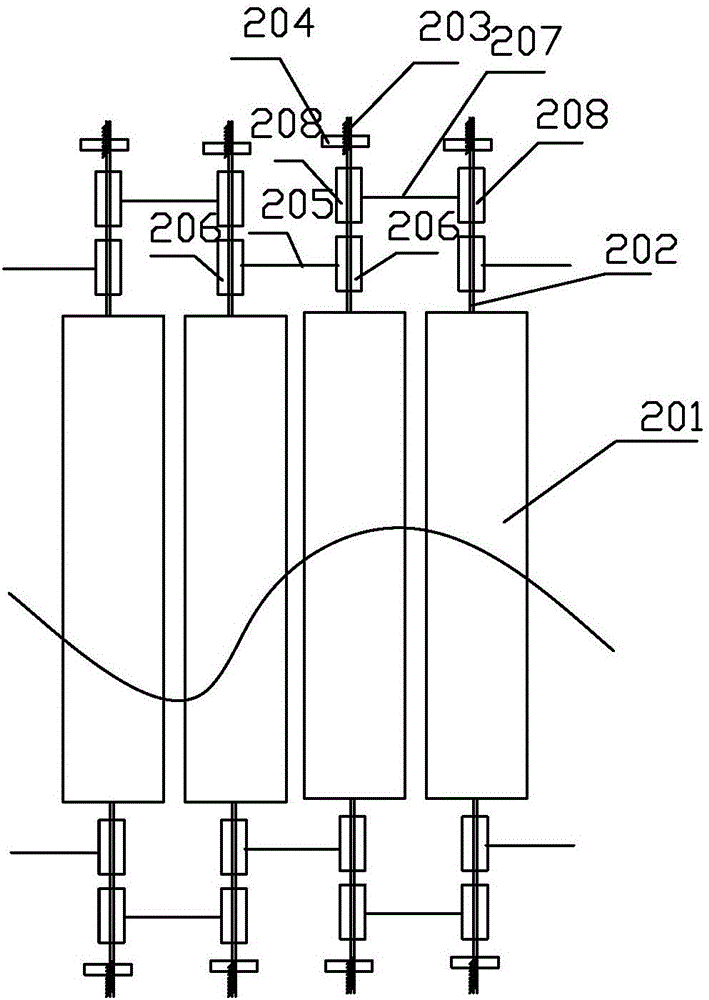

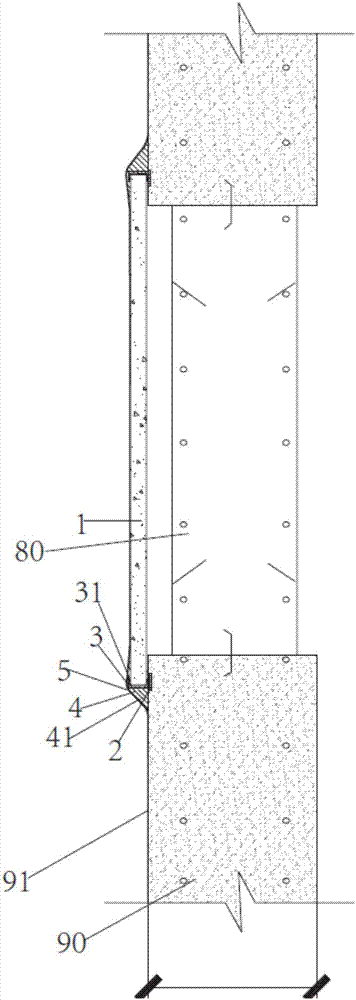

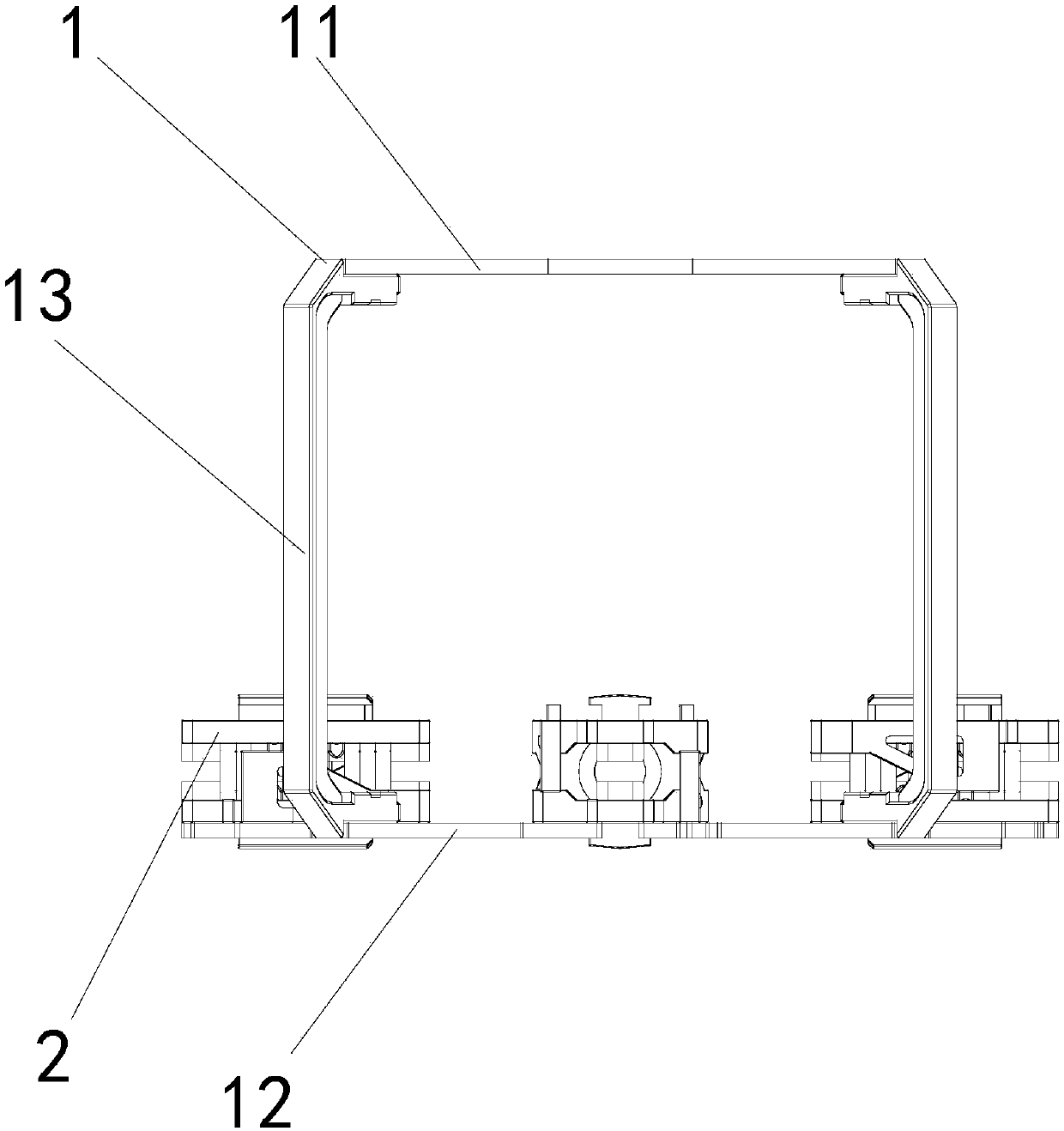

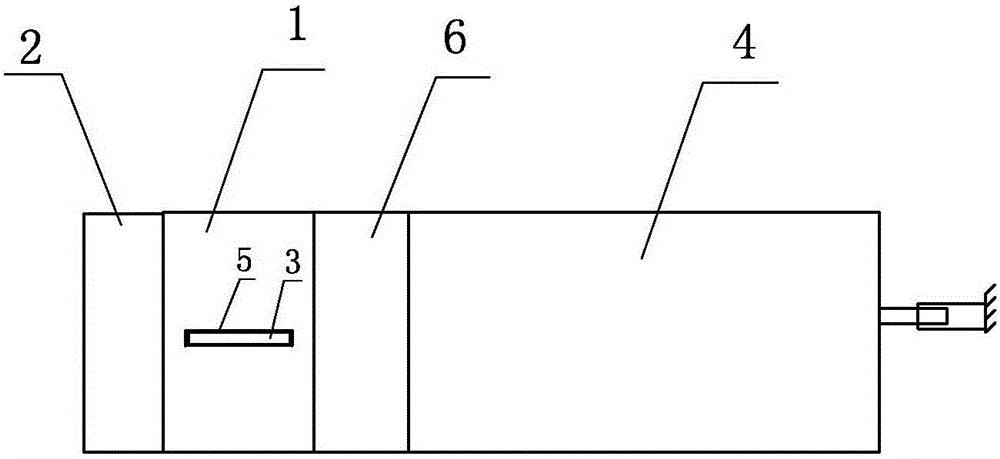

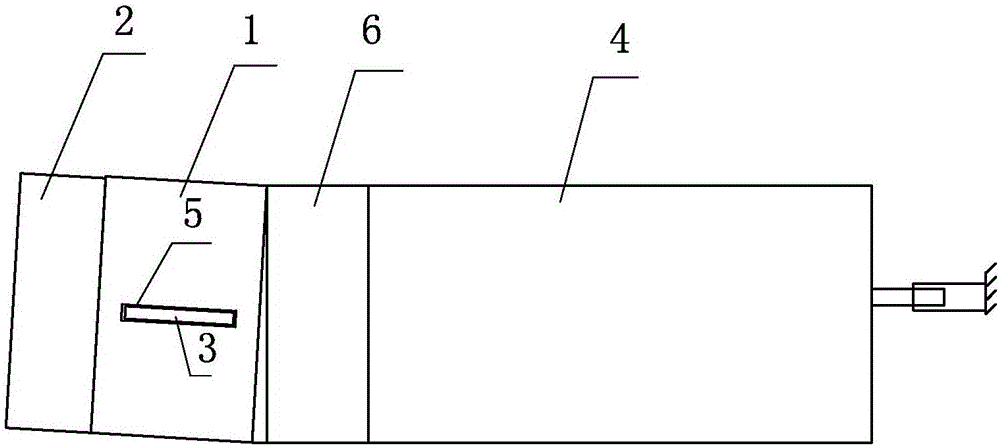

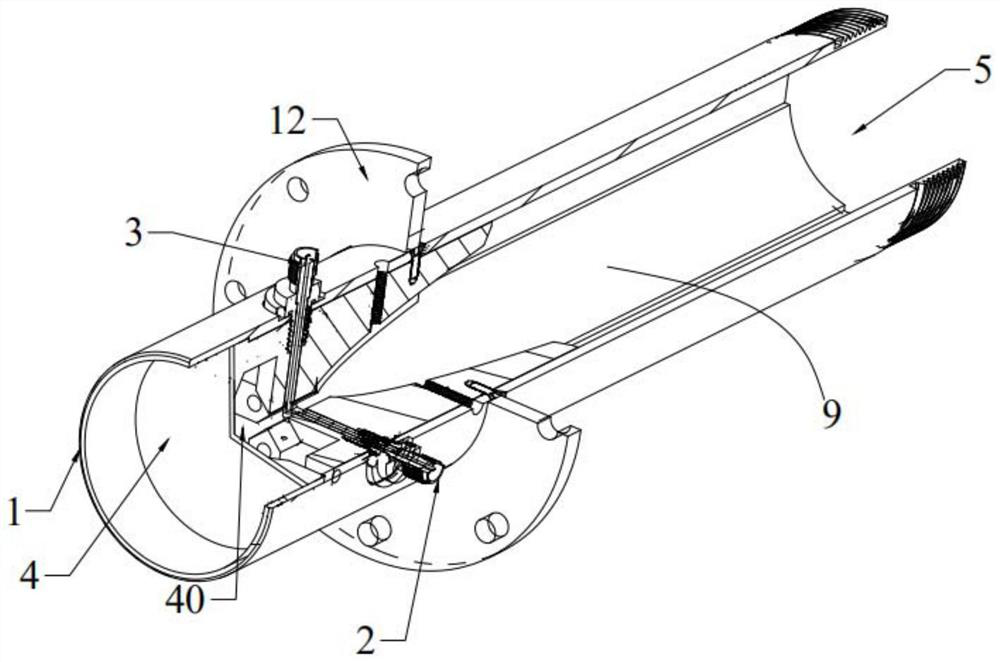

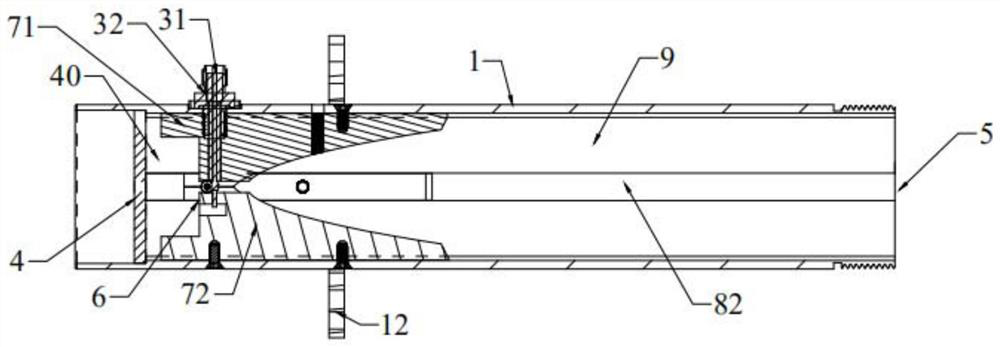

Improved advance support body and using method thereof

InactiveCN106285749AImprove production safetyImprove coal mining efficiencyMine roof supportsFuel tankEngineering

The invention discloses an improved advance support body. The improved advance support body comprises a roof support body and a floor support body; the roof support body comprises an advanced hydraulic support (1), a cylindrical pressure-bearing array (2) and a lubricating brush (8), wherein the lubricating brush (8) comprises a fixing rod (801), supporting rods (802), an oil tank (803) and a cylindrical brush (804); the floor support body comprises a bearing block (9), an anti-drilling bottom baffle plate (10) and a guide plate (11); the bearing block (9) is connected with the front end of a base of the advanced hydraulic support (1); a fixed groove (12) which penetrates vertically is formed in the middle of the bearing block (9). The improved advance support body disclosed by the invention has a simple structure, and is reliable and practical.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

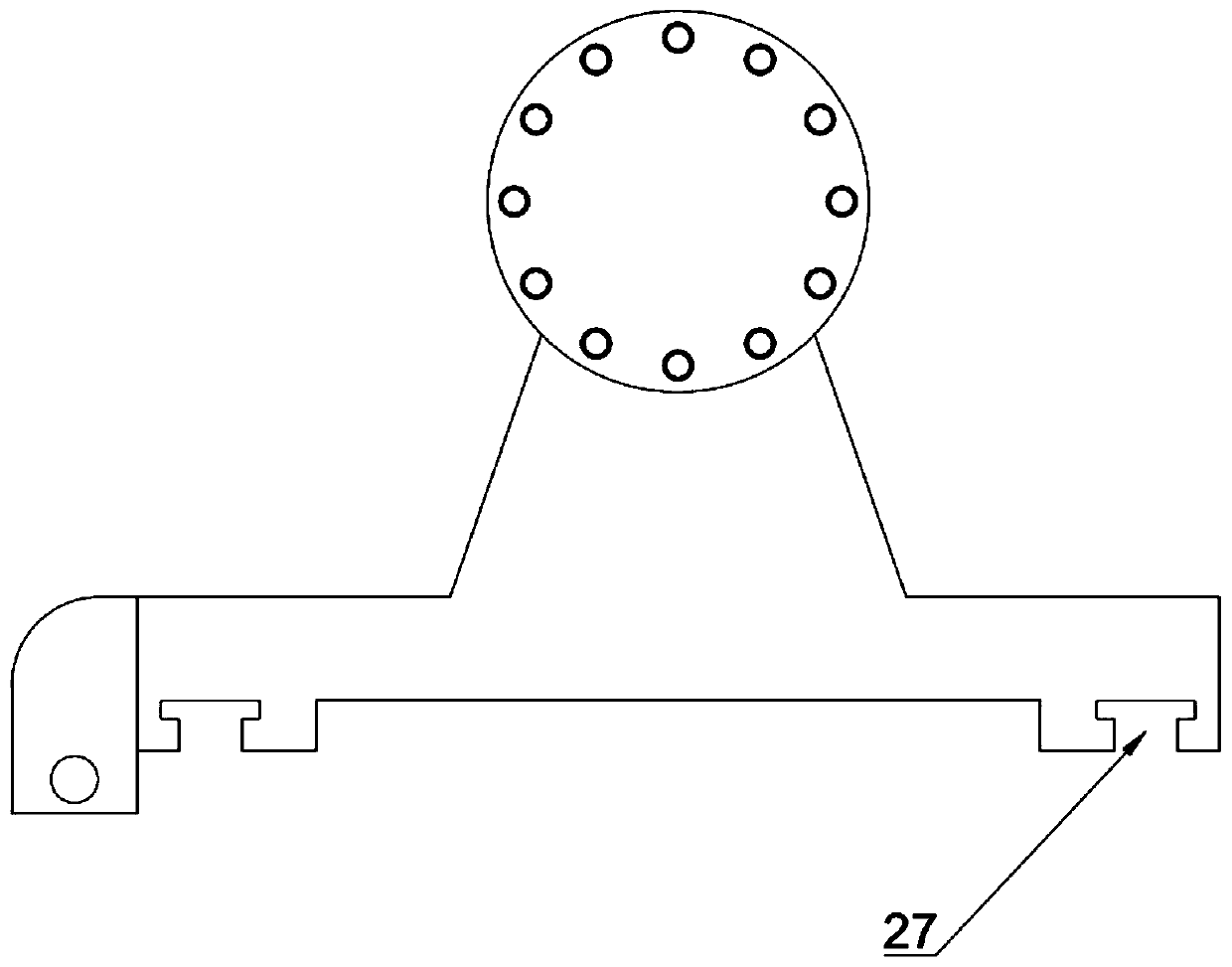

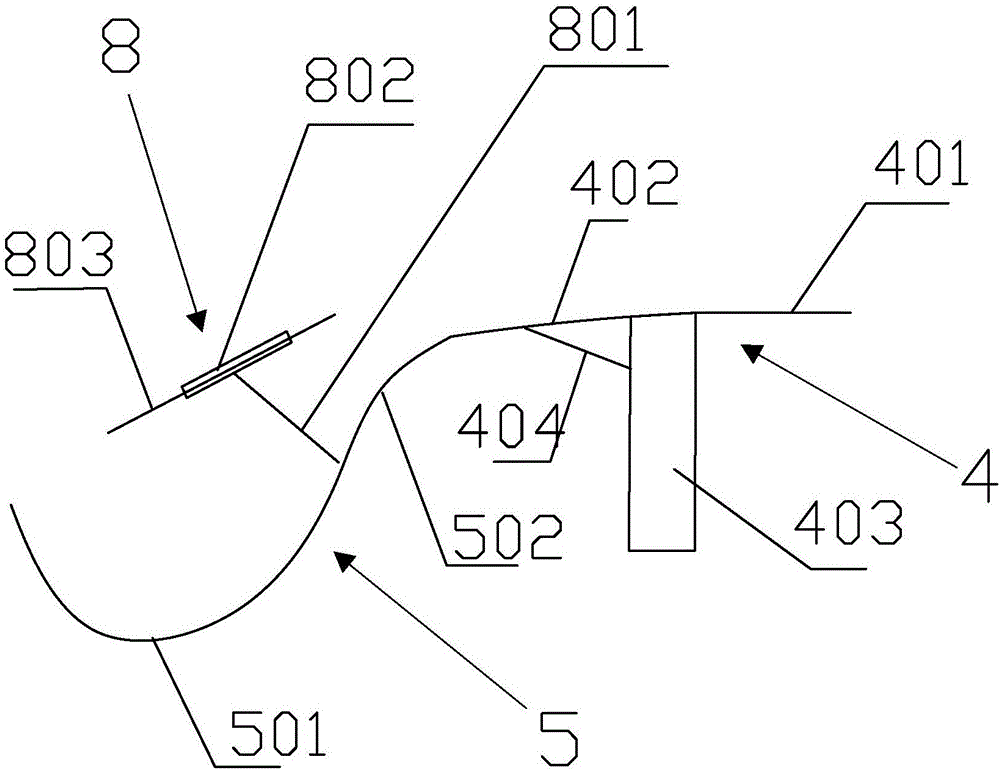

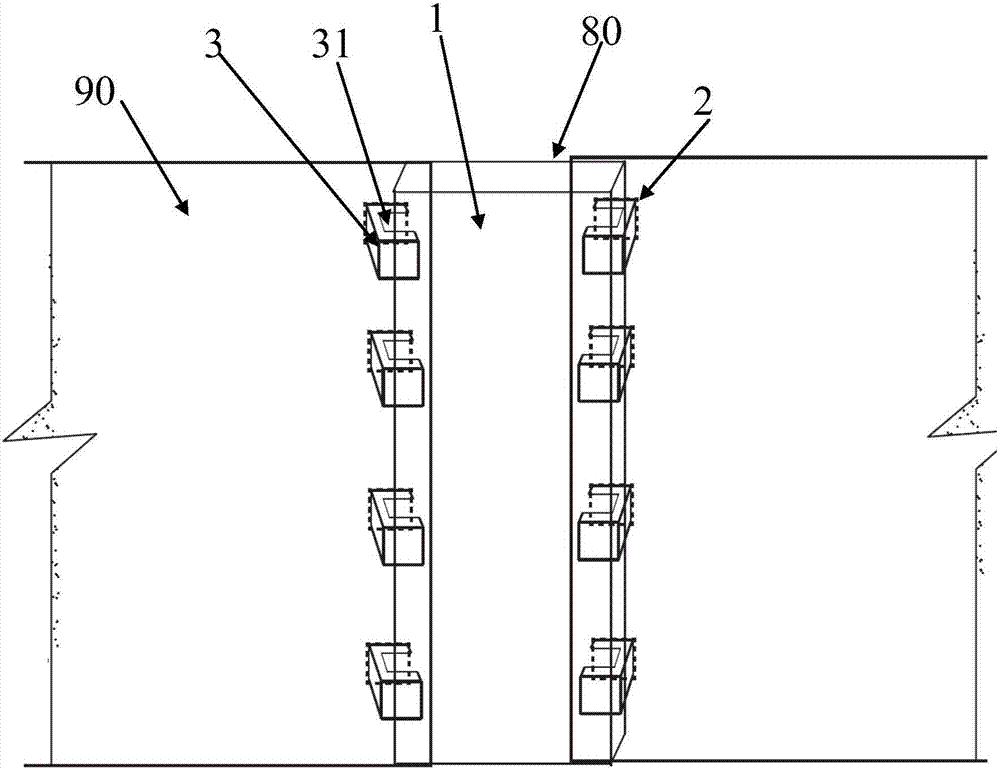

Advanced supporting system for bolt-mesh supporting and supporting method

ActiveCN106321135AImprove production safetyImprove coal mining efficiencyMine roof supportsSupporting systemEngineering

The invention discloses an advanced supporting system for bolt-mesh supporting. The advanced supporting system comprises a floor supporting body and a roof supporting body. The floor supporting body comprises a bearing block (9), a floor drilling preventing baffle (10) and a guiding plate (11), a vertically-through fixing groove (12) is formed in the middle of the bearing block (9), the guiding plate (11) is arranged in the fixing groove (12), and the floor drilling preventing baffle (10) is an arc plate. The roof supporting body comprises a front top beam protecting plate arranged at the front end of a top beam of an advanced hydraulic support (1), a rear top beam protecting plate arranged at the rear end of the top beam of the advanced hydraulic support (1), and a cylindrical pressure-bearing row (2), and the front top beam protecting plate comprises a plate-type pressure-bearing baffle (4) and a bar-type containing hopper (5). The advanced supporting system is simple in structure, low in cost and easy and convenient to operate.

Owner:ANHUI UNIV OF SCI & TECH

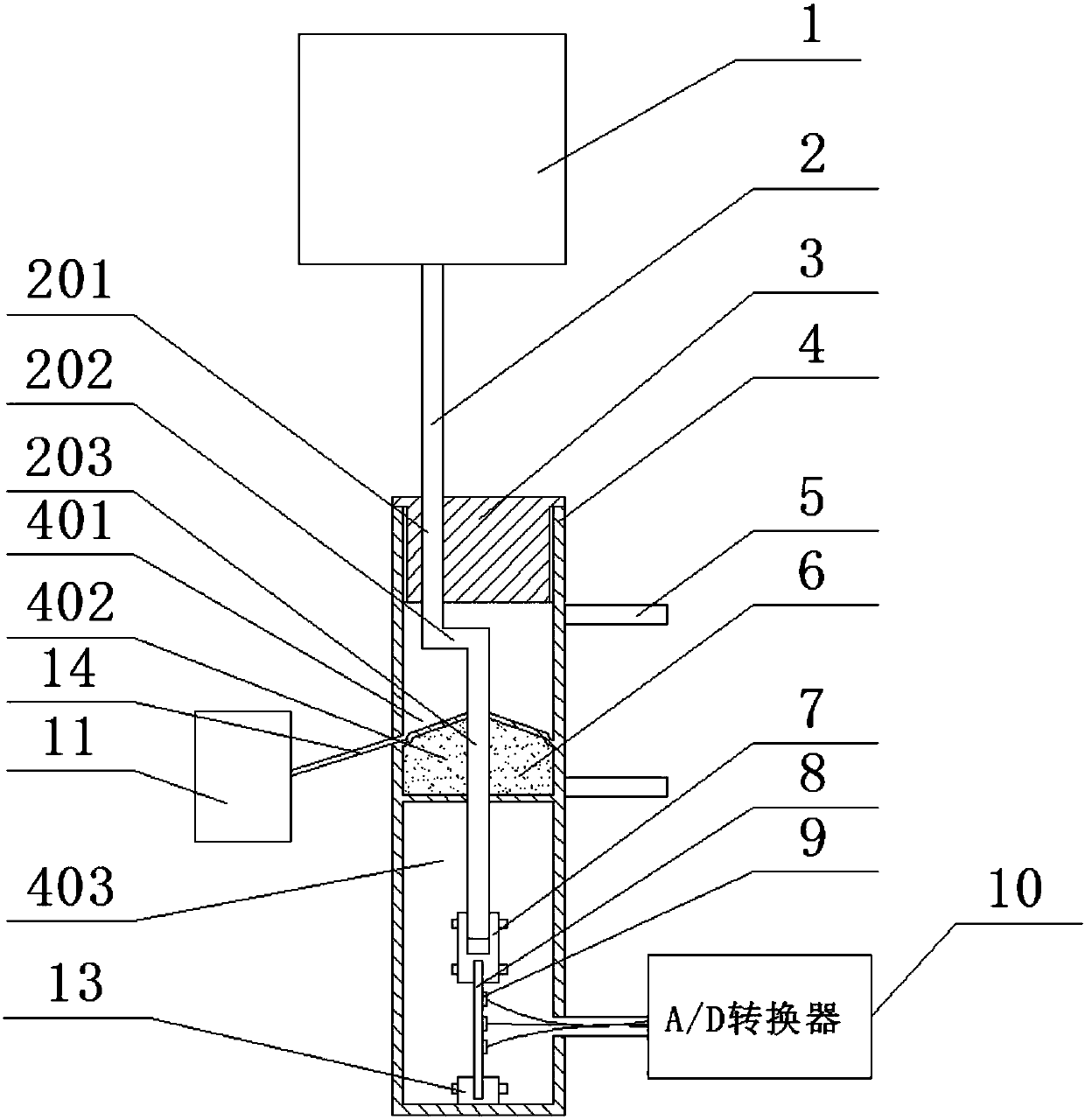

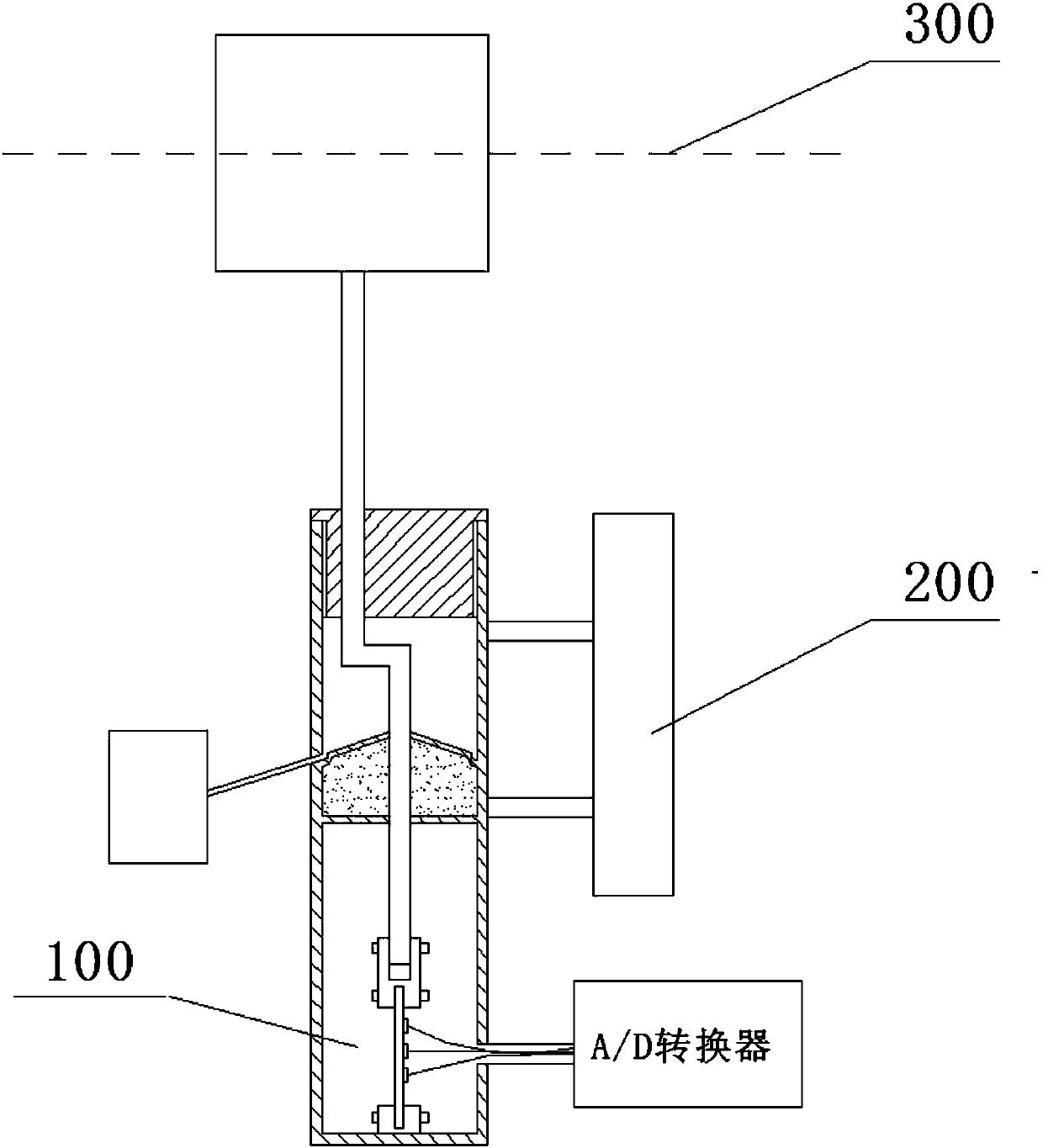

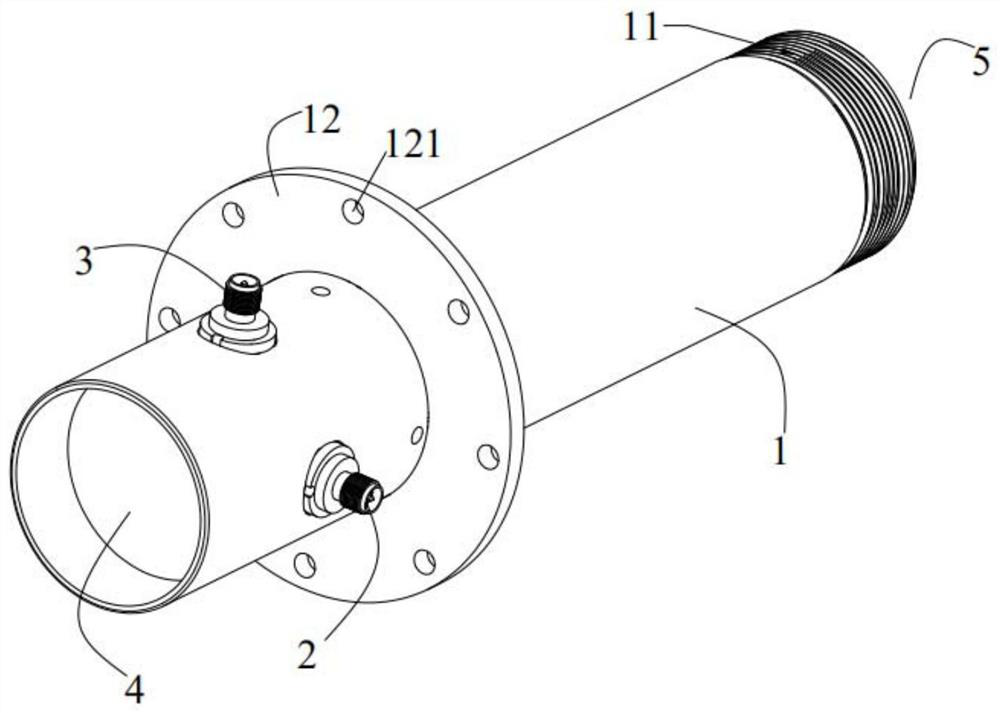

Ocean wave force monitoring device

ActiveCN107631826AEasy to installStrong structural reliabilityFluid pressure measurement by electric/magnetic elementsStructural reliabilitySurface ocean

An ocean wave force monitoring device disclosed by the present invention belongs to the signal monitoring technology field, and comprises a buoyancy column, a guiding rod, a sealing head, a sleeve, adrying agent, a fixing support, a connecting clamp, an elastic film, a strain gauge, a signal line, an A / D converter and a water storage tank. When the ocean waves pass the buoyancy column, and underthe action of the buoyancy, the buoyancy column drives the guiding rod to move up and down in a sliding cavity and further drives the elastic film connected at the bottom to telescope. According to the ocean wave force monitoring device provided by the present invention, the strain gauge on the elastic film real-timely outputs the strain signals of the elastic film, and the A / D convert converts anelectric signal into a digital signal to transmit to the monitoring device. Moreover, the ocean wave force monitoring device provided by the present invention is convenient to install, is strong in structure reliability and high in sensitivity, can adapt to the complex ocean environments, can monitor the ocean wave environments, and provides the good monitoring means for the ocean engineering construction.

Owner:OCEANOGRAPHIC INSTR RES INST SHANDONG ACAD OF SCI

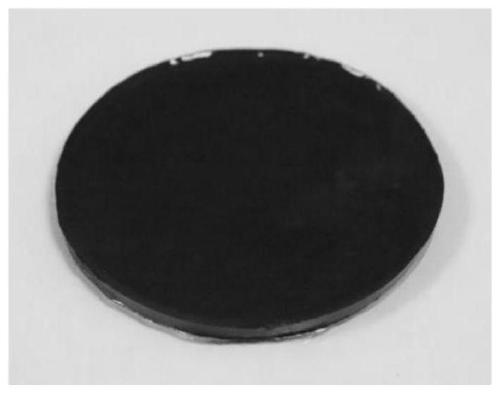

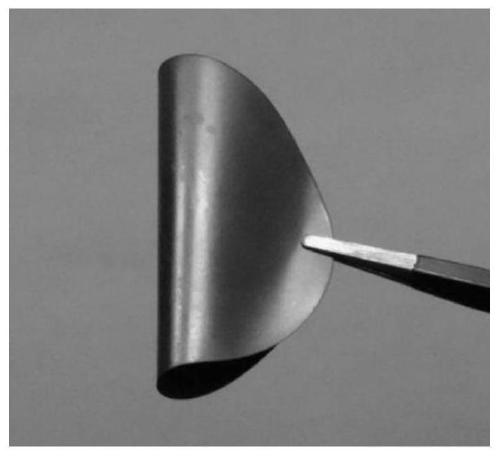

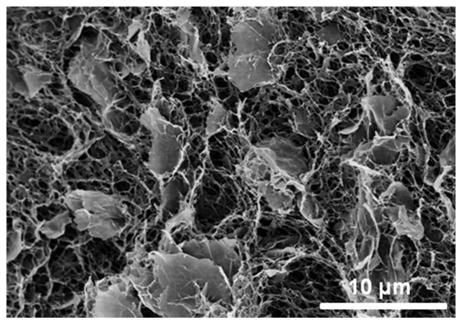

High-toughness high-thermal-conductivity PBONF-based composite film and preparation method thereof

The invention provides a high-toughness high-thermal-conductivity PBONF-based composite film and a preparation method thereof, and belongs to the technical field of heat-conducting composite materials. The high-toughness high-thermal-conductivity PBONF-based composite film comprises PBONF and a heat-conducting nano material; the PBONF forms a three-dimensional net structure, and the heat-conducting nano material is located in the three-dimensional net structure; the PBONF is in a forked geometrical shape. The high-toughness high-thermal-conductivity PBONF-based composite film has the advantages of low density, high toughness, high thermal conductivity and the like, can replace existing aviation aluminum alloy, reduces the weight of aerospace vehicles, and meanwhile, has higher heat dissipation efficiency and excellent structural reliability.

Owner:HUNAN UNIV

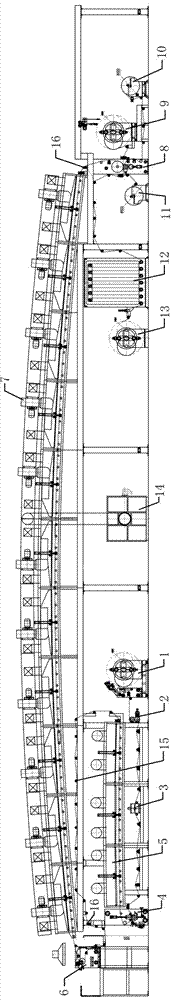

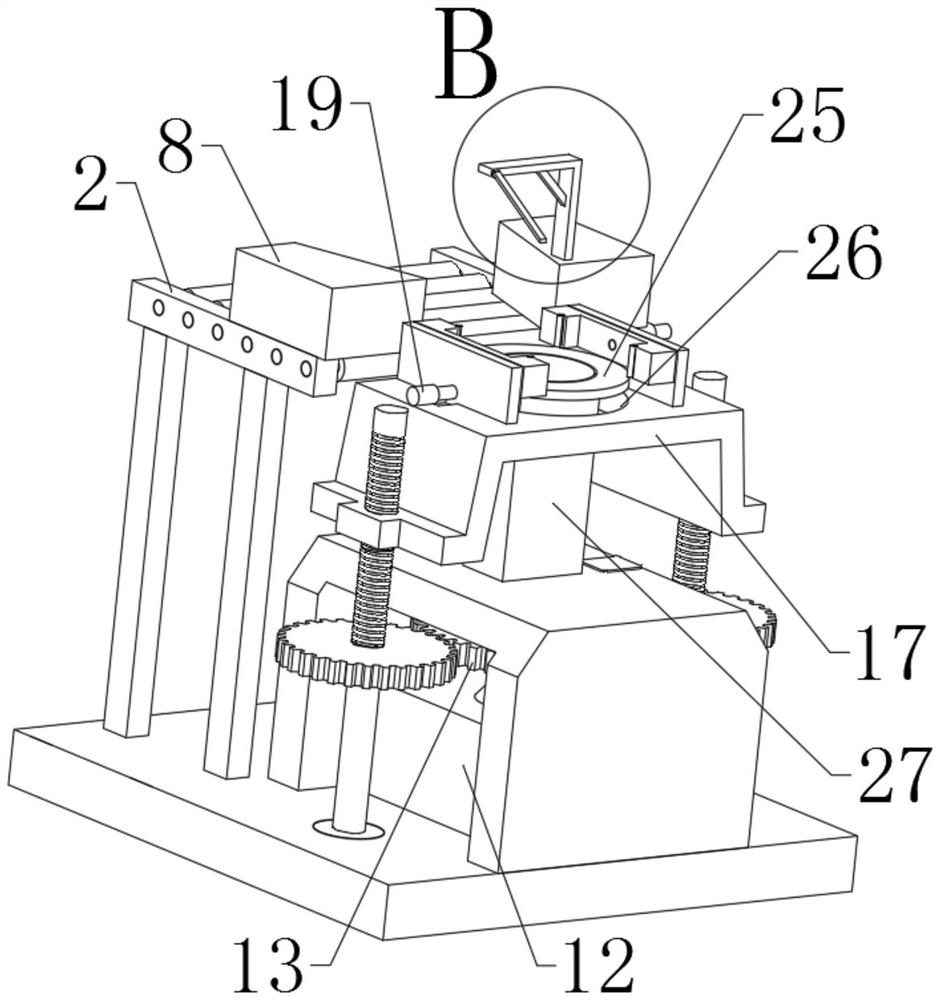

Automatic welding device for manhole door of wind power generation tower barrel

ActiveCN110576230AImprove welding efficiencyStrong structural reliabilitySoldering auxillary devicesStructural reliabilityDrive motor

The invention discloses an automatic welding device for a manhole door of a wind power generation tower barrel, and relates to the field of mechanical manufacturing industry. The device comprises a base, a tower barrel jaw, a complete machine rotating mechanism, a working arm lifting mechanism and an automatic welding mechanism; the complete machine rotating mechanism comprises a rotary driving motor mounting groove, a rotary driving motor, a bottom bearing, a harmonic reducer, a rotary driving shaft, a driving gear, a lifting guide column, a gear ring, a top bearing and a rotary mechanism mounting groove; and the working arm lifting mechanism comprises a lifting driving motor, a lifting harmonic reducer, a screw, a lifting sliding block, a screw bearing, a mounting block, a working arm, aworking arm moving part, a feeding connecting rod, an electromagnetic suction block and a hydraulic telescopic rod. According to the device, the design scheme is suitable for the welding process of the manhole door of the wind power generation tower barrel, strong in structural reliability, high in automation degree, and capable of achieving automatic clamping and welding, so that the welding efficiency of the manhole door of the wind power generation tower barrel is greatly improved, and the production cost is reduced.

Owner:广东天能海洋重工有限公司

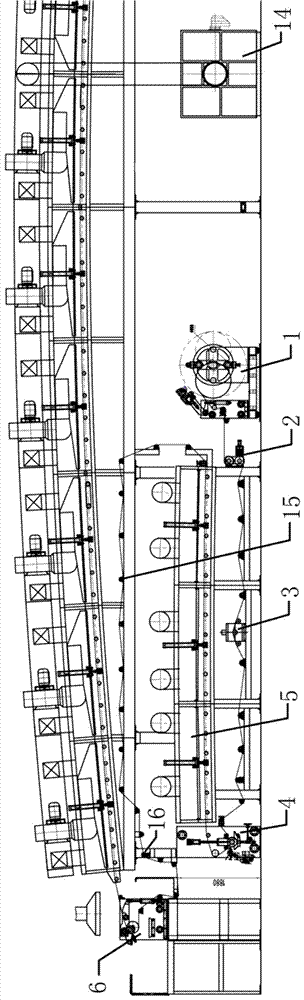

Coating compound machine and compound technology of film

PendingCN107336507AStrong structural reliabilityCompact layoutLaminationLamination apparatusHot blastHot air oven

The invention discloses a coating compound machine and a compound technology of a film. The coating compound machine comprises a base material unwinding device, a traction device, a corona treatment device, a screen coating device, a lower drying oven, a knife coating device, an upper drying oven, a compound device, a gum dipped fiber unwinding device, a glass fiber Teflon unwinding device, a glass fiber Teflon winding device, a storage rack and a winding device, wherein the lower drying oven and the upper drying oven are communicated with a hot blast heater. In the compound technology, a glass fiber Teflon layer is used for replacing a traditional disposable release film, the product cost is saved, and the production efficiency is improved.

Owner:东莞市安派电子有限公司

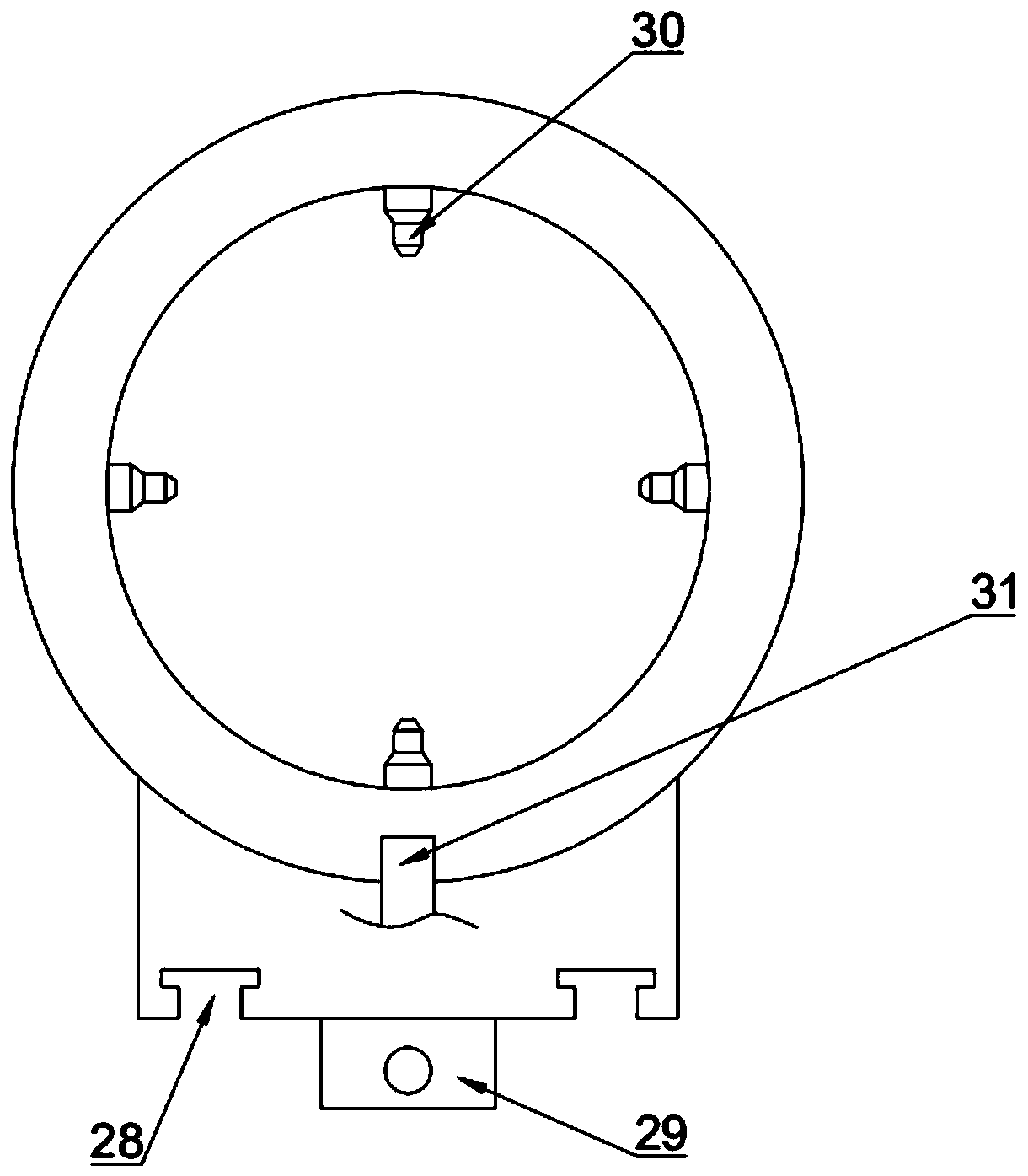

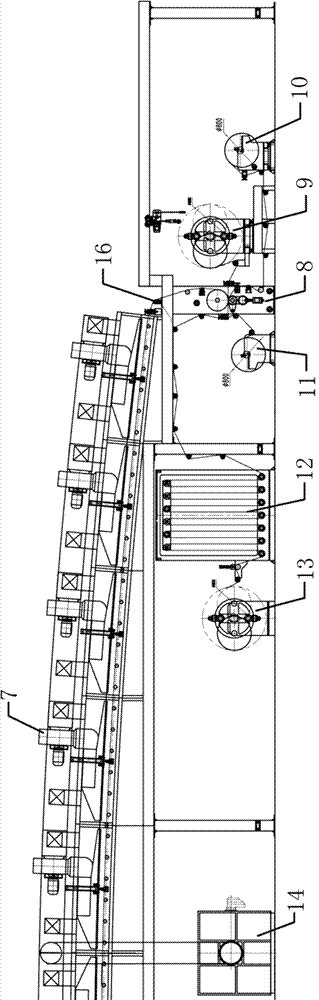

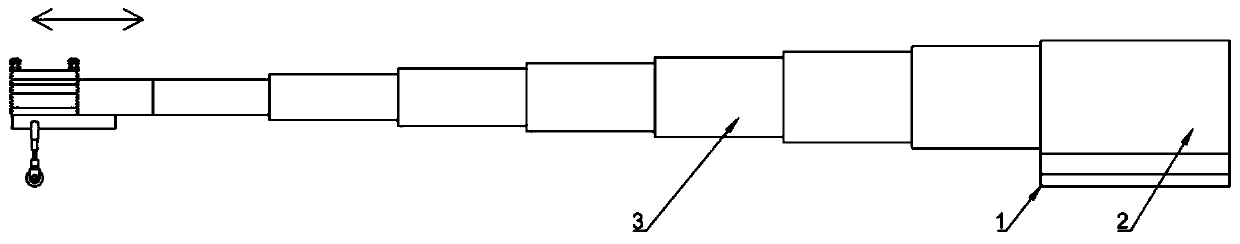

Telescopic wind power generation tower barrel inner wall sandblast cleaning machine

ActiveCN110509190AImprove blasting efficiencyStrong structural reliabilityBlast gunsAbrasive feedersStructural reliabilityHydraulic cylinder

The invention discloses a telescopic wind power generation tower barrel inner wall sandblast cleaning machine, and relates to the field of mechanical manufacturing industry. The machine comprises a base, a telescopic supporting arm mechanism, a machine head driving mechanism and a sand blasting machine head mechanism; the telescopic supporting arm mechanism comprises a fixing shell, and a moving telescopic arm; the machine head driving mechanism comprises a hydraulic supporting rod, a fixing shaft, a bearing, a wheel stand, a rotating shaft, a driving wheel, a driving motor, a driving harmonicspeed reducing device, a steering adjusting motor, a steering harmonic speed reducing device and a connecting shaft; and the sand blasting machine head mechanism comprises a telescopic outer cover, awaste barrel cover, a barrel cover pressing bolt, a waste barrel body, a partition plate, a main hydraulic cylinder, a hydraulic telescopic rod, a supporting piece, a sand hopper, a sand feeding pipe, a high-pressure air source, a nozzle, an air feeding pipe and an air inlet nozzle. The design scheme of the machine is suitable for wind power generation tower barrel inner wall sand blasting process, the structural reliability is high, the automation degree is high, the efficiency of wind power generation tower barrel inner wall sand blasting is greatly improved, and the production cost is reduced.

Owner:QINGDAO TIANNENG HEAVY INDUSTRIES CO LTD

Water-proofing and earthwork backfilling structure and method of late poured band coordinating with basement sidewall

InactiveCN107217686AAvoid pouringSimple working principleArtificial islandsProtective foundationBasementReinforced concrete

The invention discloses a structure for waterproofing and earth backfilling of a basement side wall post-cast belt, comprising a basement side wall, the side wall includes a post-cast belt extending in a vertical direction; wherein the structure further includes: a pre-embedded steel plate , it is pre-buried in the side walls on both sides of the post-casting belt during the construction of the basement side wall, and is exposed on the surface of the side wall; the channel steel parts are respectively welded on the pre-embedded steel plates on both sides of the post-casting belt, The pair of channel steel parts respectively form a slot with openings opposite to each other on both sides of the post-casting belt; the reinforced concrete prefabricated plate is inserted into the slot from top to bottom; waterproof coating is applied to the The seams between the channel steel parts and the pre-embedded steel plates, and the joints between both sides of the reinforced concrete prefabricated slab and the outer surface of the side wall; waterproof felt, which is laid outside the reinforced concrete prefabricated slab, and Cover the reinforced concrete prefabricated slab and waterproof coating. The invention also includes a construction method of the structure.

Owner:CHINA MCC20 GRP CORP

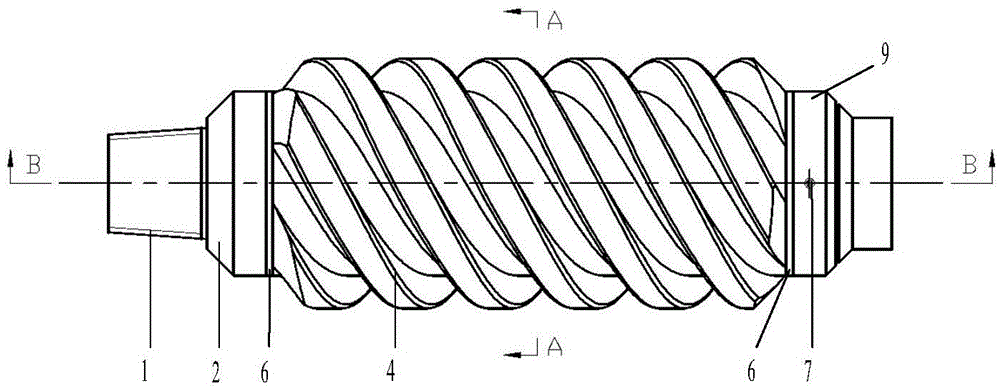

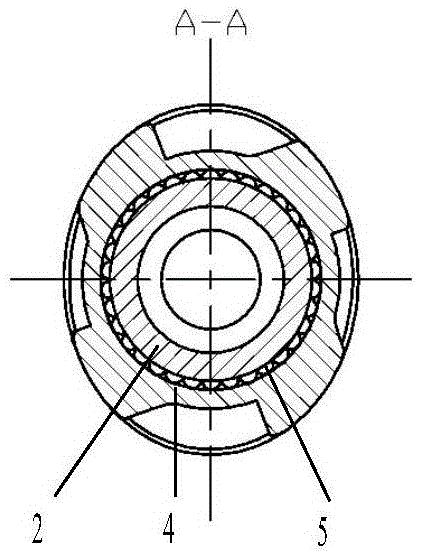

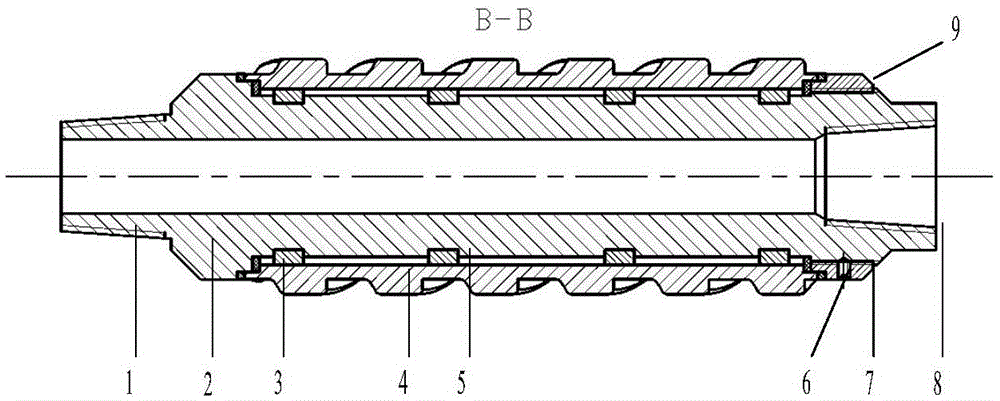

Drag-reducing and torque-reducing device

InactiveCN105604484AReduce contact stressReduce frictional resistanceDrilling rodsDrilling casingsStructural reliabilityTorque transmission

A drag-reducing and torque-reducing device for a pipe string comprises a body, a sliding sleeve, cylindrical rollers, a threaded locking ring, a tightening screw, metal abrasion-proof gaskets and seal rings, wherein four spiral ridges are longitudinally and uniformly distributed on the outer surface of the sliding sleeve in the circumferential direction; the outer contour of a cross section of the sliding sleeve is elliptical; four circles of roller grooves are formed in the surface of the body in the circumferential direction, are fully filled with the rollers, and are matched with the sliding sleeve; the sliding sleeve sleeves the body; the seal rings are arranged at two ends of the part, connected with the body, of the sliding sleeve; the sliding sleeve is limited by a shoulder at the male buckle end of the body and the threaded locking ring mounted at the female buckle end of the body; the threaded locking ring is fastened with the tightening screw; the metal abrasion-proof gaskets are arranged between the sliding sleeve, and the body and the threaded locking ring. The drag-reducing and torque-reducing device has the advantages that the structural reliability is high; loss in a drilling torque transmission process can be reduced; abrasion on the pipe string is reduced; vortex motion of the pipe string can be reduced to a certain extent; the work efficiency is further improved.

Owner:YANSHAN UNIV

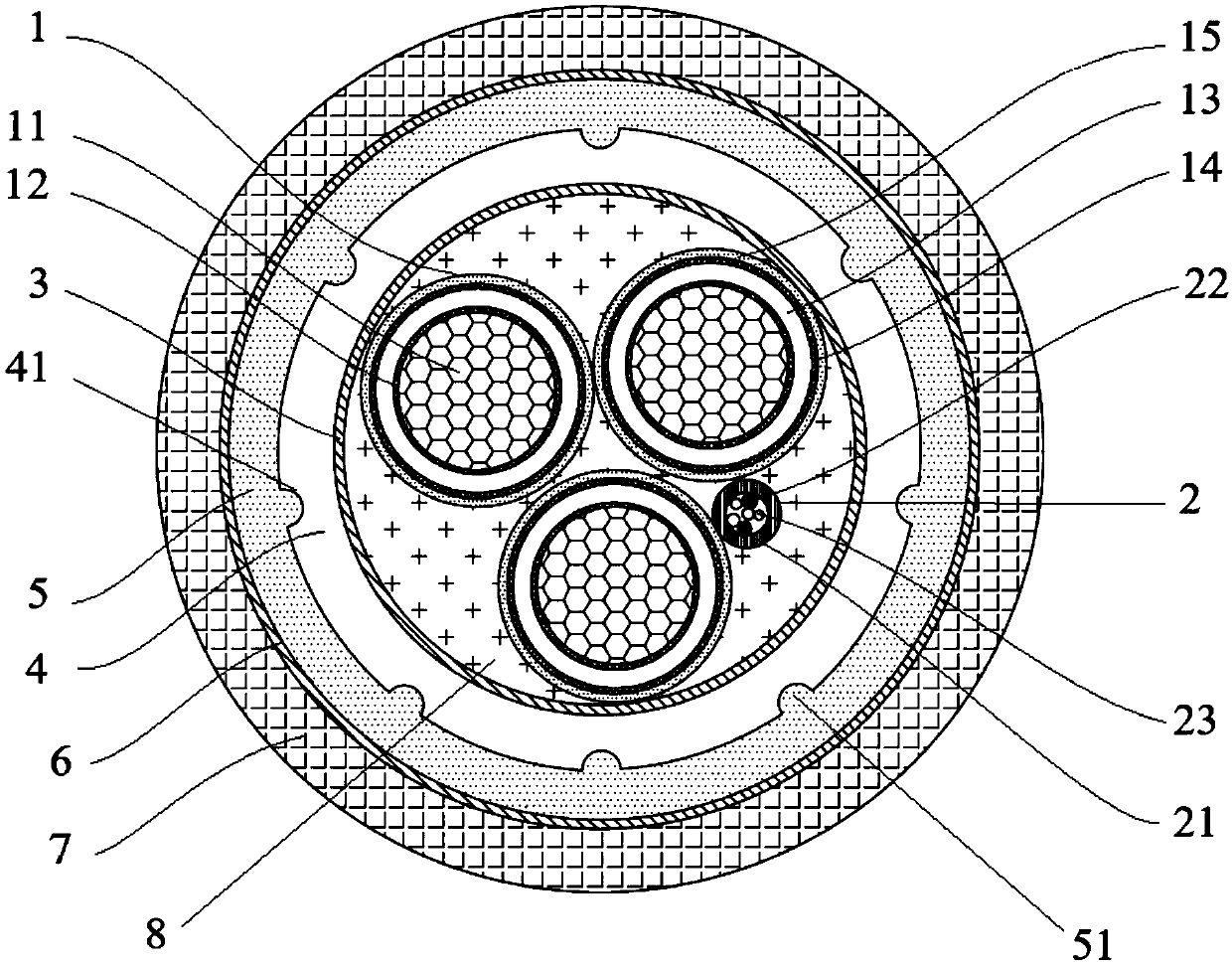

Manufacturing process of medium-voltage fireproof cable for intelligent early warning communication

InactiveCN109524172APlay a role in communicationEnsure normal communicationInsulating conductors/cablesCopper conductorElectric power transmission

The invention discloses a manufacturing process of a medium-voltage fireproof cable for intelligent early warning communication. The medium-voltage fireproof cable for intelligent early warning communication comprises a power transmission unit and an optical transmission unit, and the power transmission unit is formed by a copper conductor, a conductor shielding layer, an insulating layer and an insulating shielding layer which coats the outer surface of the copper conductor from inside to outside, and a metal shielding layer coating the outer surface of the insulating shielding layer. The power transmission unit and the optical transmission unit are wrapped by a wrapping tape to form a first winding layer, the outer surface of the first winding layer is coated with an oxygen barrier layer, and the outer surface of the oxygen barrier layer is coated with a refractory layer. The outer surface of the refractory layer is coated with a second winding layer, and an outer sheath is extrudedon the outer surface of the second winding layer. The prepared cable has good heat insulation and flame retardant performance and is used for a distributed optical fiber temperature measuring system to achieve the purpose of timely detecting a disaster and emitting an early warning in the early stage of fire, and a time guarantee is provided for escape and disaster relief.

Owner:JIANGSU HENGTONG POWER CABLE

Demoulding device

Owner:NINGBO HUABAO PLASTICS & RUBBER MOLD

Positioning middle sliding door buffering device

Owner:SUZHOU SHENGDE PRECISION ELECTRIC

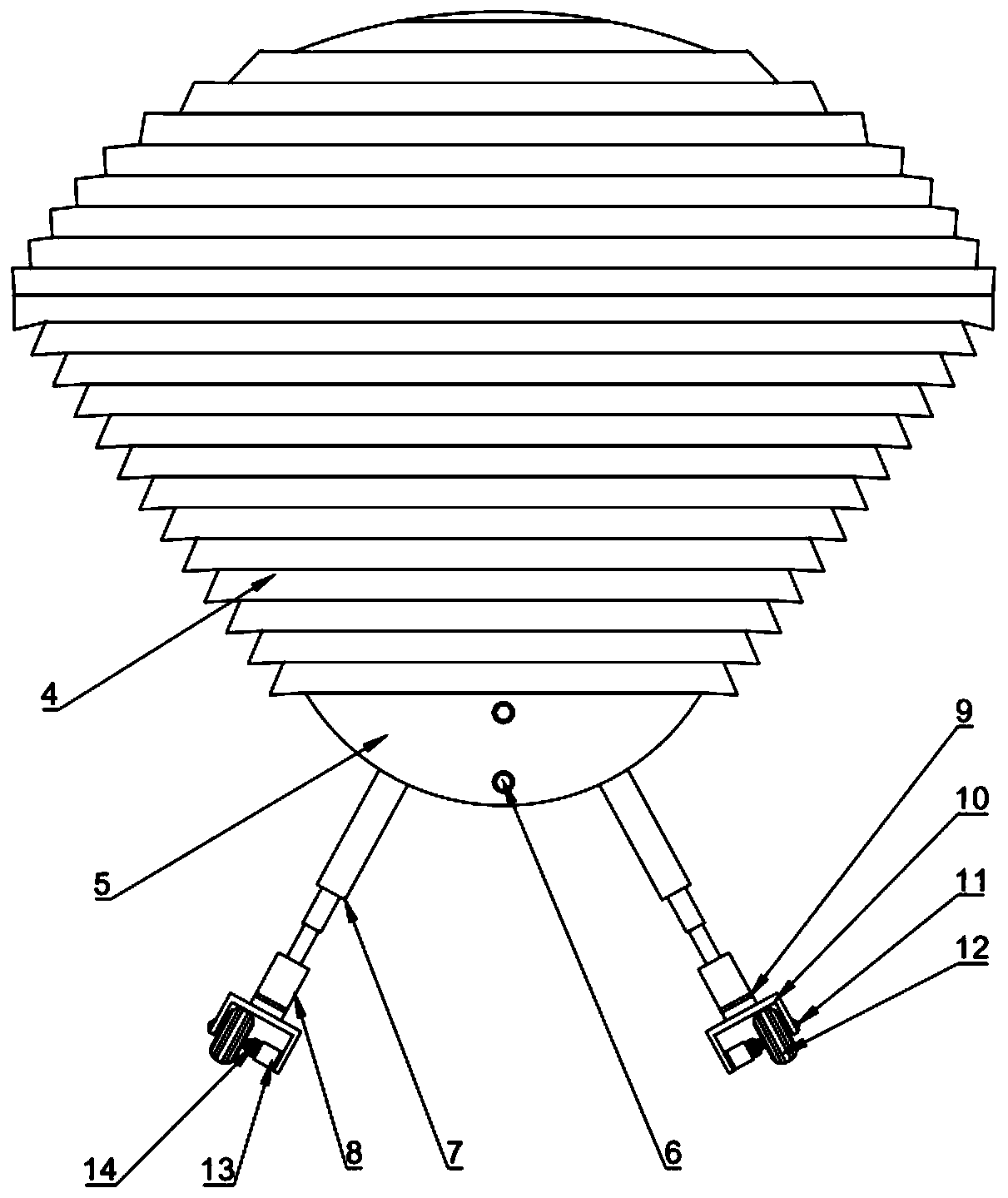

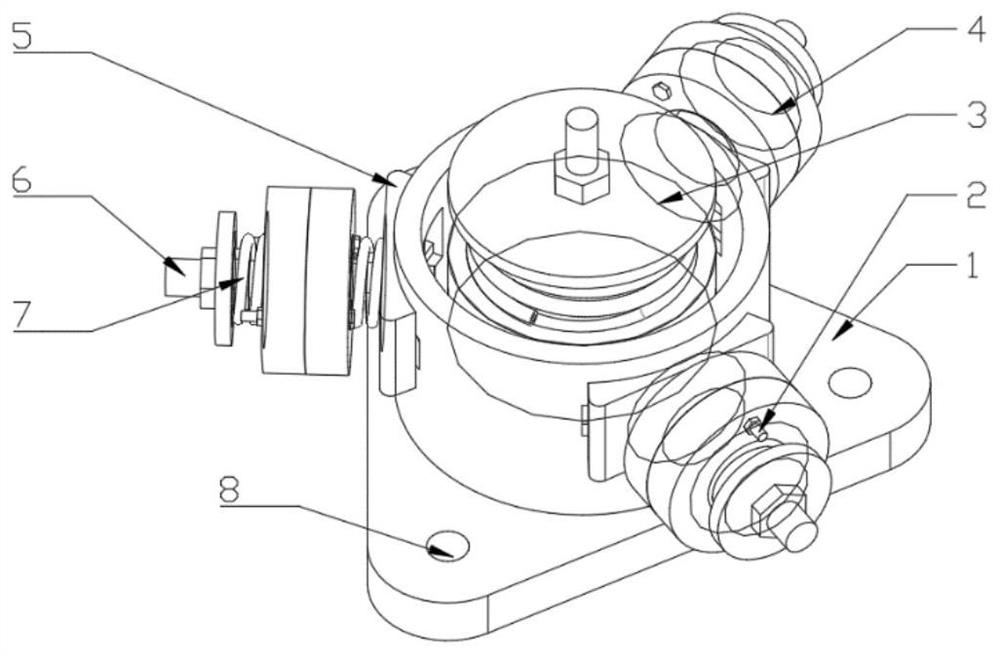

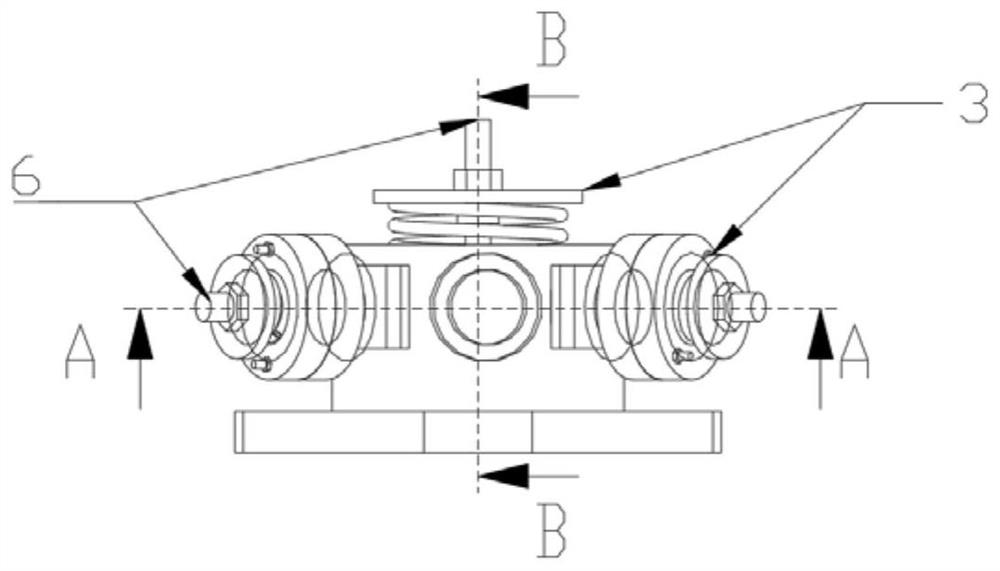

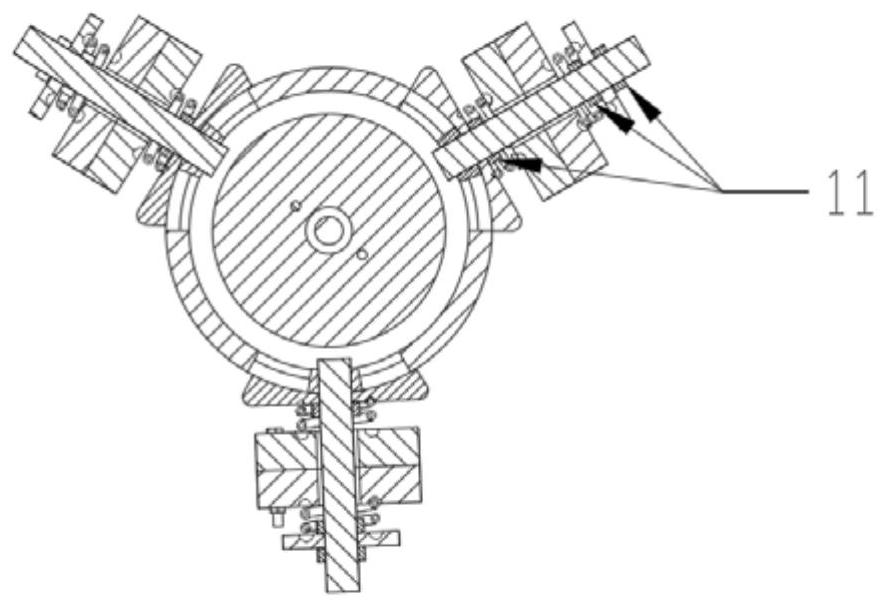

Multidirectional adjustable tuning dynamic damper

ActiveCN113464603AGood vibration reduction effectGood vibration dampingSpringsNon-rotating vibration suppressionClassical mechanicsDamper

The invention relates to a multidirectional adjustable tuning dynamic damper. The multidirectional adjustable tuning dynamic damper comprises an installation supporting seat (1) and a plurality of mass spring damping pieces, the mass spring damping pieces are vertically or horizontally installed on the installation supporting seat (1), and each mass spring damping piece comprises an adjustable mass block (4) and a hollow damping spring (7). Vibration with different frequencies in different directions is controlled by adjusting the quantity and the installation positions of the mass spring damping pieces on the installation supporting seat (1), selecting the mass of the adjustable mass blocks (4) and selecting the rigidity of the hollow damping springs (7). Compared with the prior art, the multidirectional adjustable tuning dynamic damper has a good vibration damping effect on vibration of different frequency bands in multiple directions of a main vibration system, can adjust the direction and the inherent frequency of the mass spring damping pieces according to different modal shapes and modal frequencies of the main vibration system, and has the advantages of being easy to install, high in structural reliability, good in adjustability, small in occupied size, and good in vibration reduction effect.

Owner:SHANGHAI UNIV OF ENG SCI

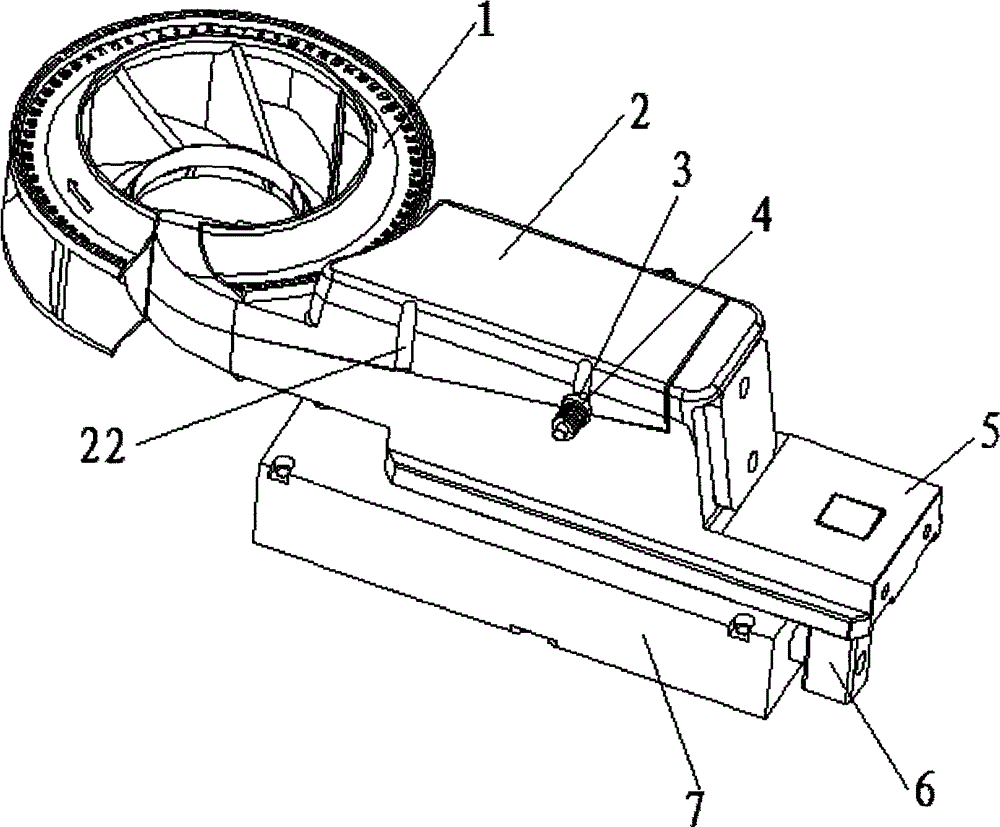

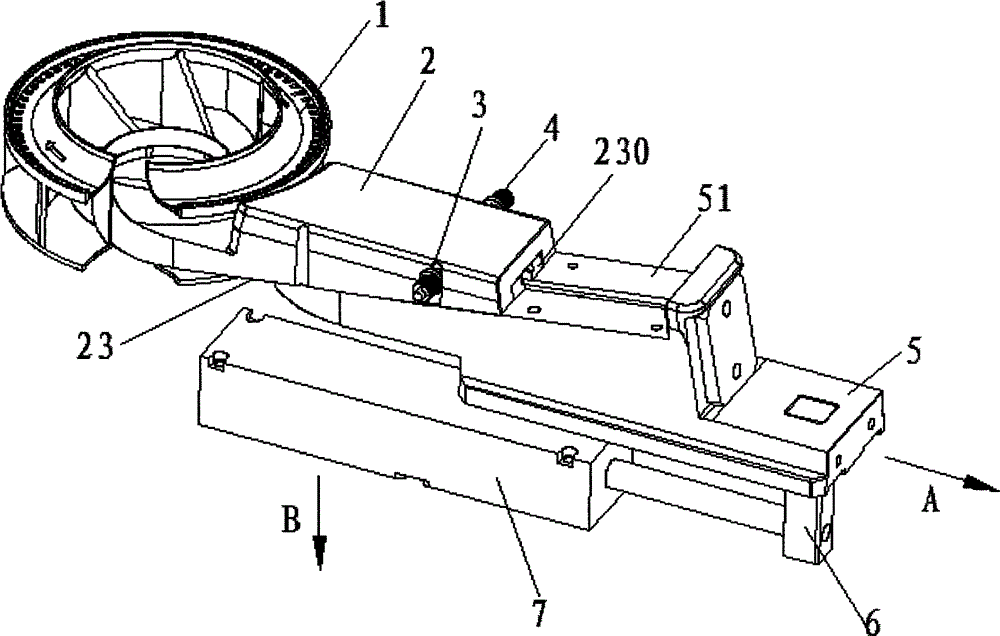

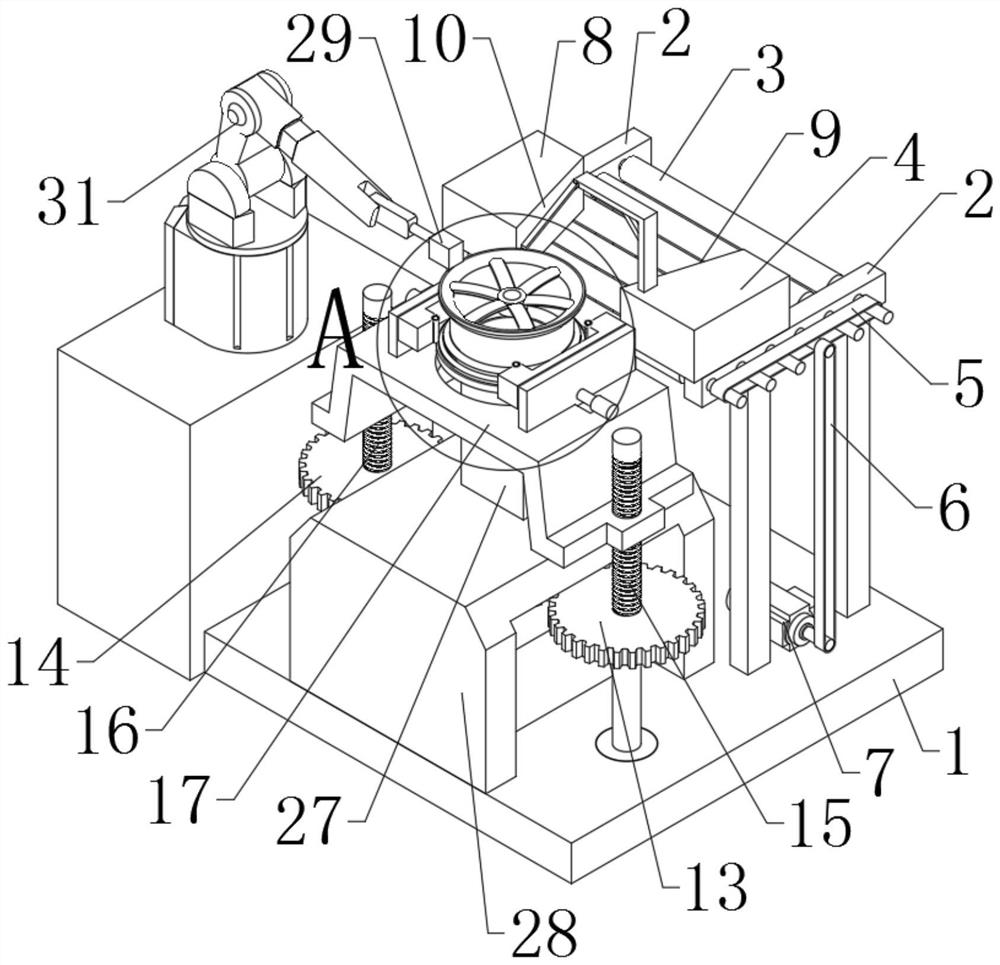

Device for detecting deformation of outer edge of hub blank

ActiveCN112729154AShorten detection timeImprove work efficiencyUsing optical meansStructural engineeringMechanical engineering

The invention relates to a device for detecting deformation of the outer edge of a hub blank. The device comprises a detection table provided with a conveying unit, a clamping unit and a detection unit on a base, a guide plate for guiding a hub is arranged at an outlet of the conveying unit, the detection table of the detection unit is arranged at an outlet of the guide plate, and a hub to be detected can be placed on the detection table, a probe of the detection unit can be in contact with the outer edge of the hub for detection; a lifting clamping unit can clamp the hub blank on the detection table, a turning unit is arranged on a guide plate of the conveying unit, a turning rod of the turning unit is located on the lifting stroke of the hub blank clamped by the clamping unit, and the lifting clamping unit can be matched with the turning rod to drive the hub blank to turn over. Through cooperation of the liftable clamping unit and the turning rod, the upper edge and the lower edge of the hub can be detected at a time, the detection time is reduced, and the working efficiency is improved.

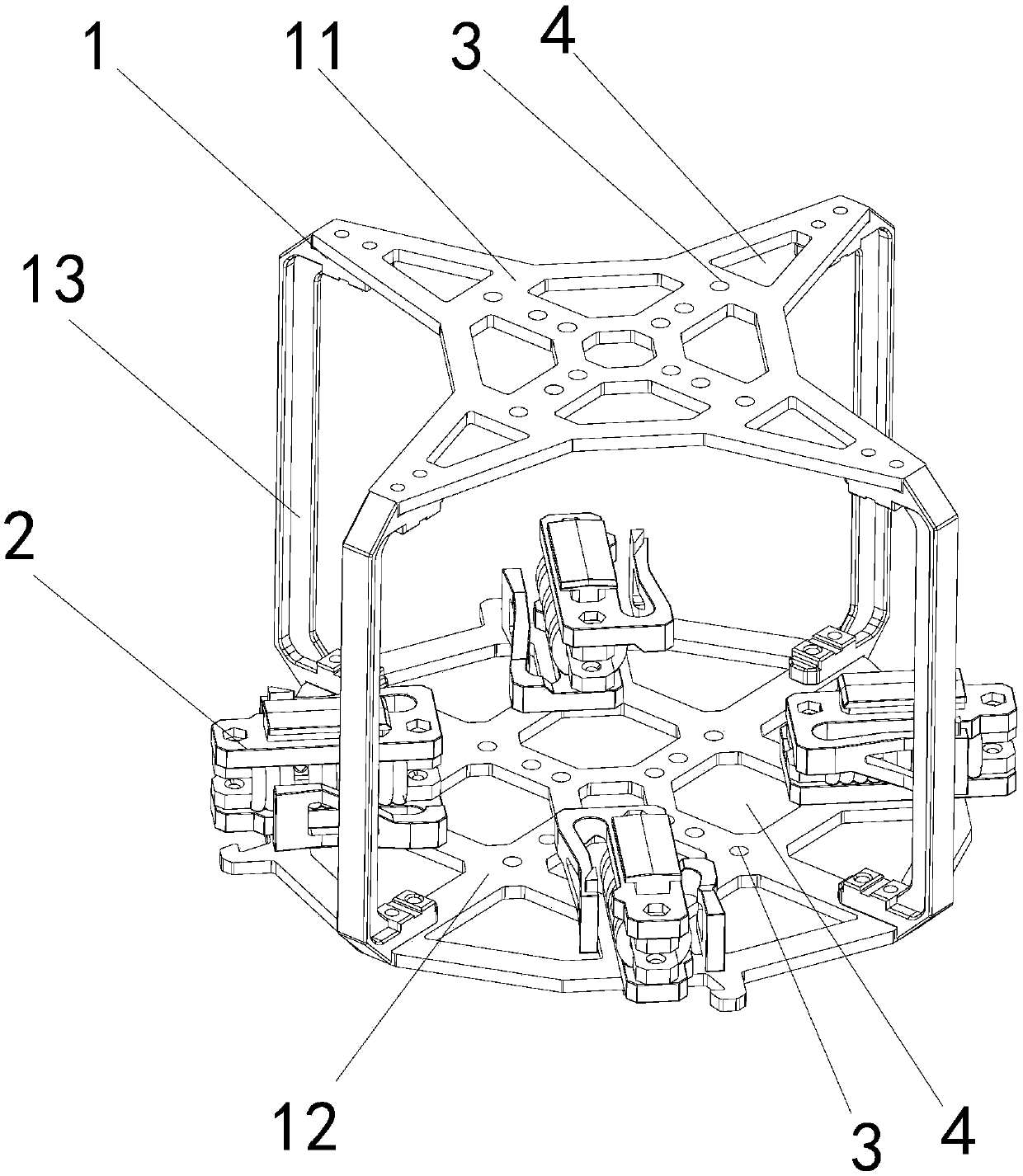

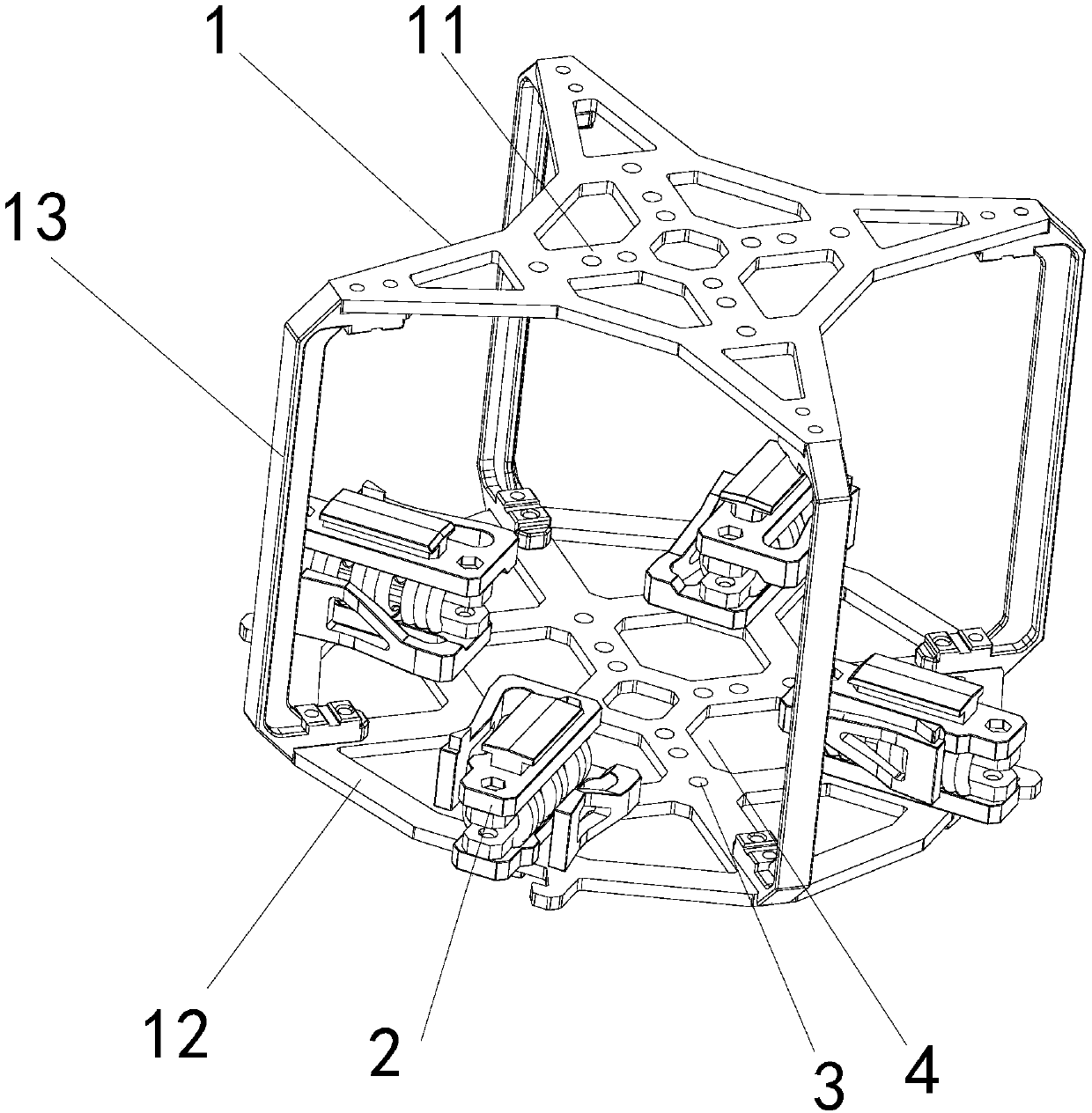

Unmanned aerial vehicle damping connecting rod system and unmanned aerial vehicle

PendingCN107640310AMeet the design requirementsEasy to replaceFuselage framesEngineeringUnmanned air vehicle

The invention discloses an unmanned aerial vehicle damping connecting rod system and an unmanned aerial vehicle. The unmanned aerial vehicle damping connecting rod system comprises a connecting rod assembly and a plurality of damping components arranged on the connecting rod assembly; the connecting rod assembly comprises an upper support frame, a lower support frame, and a plurality of vertical rods; the upper support frame and the lower support frame are arranged from top to bottom in the vertical direction; edges between the upper support frame and the lower support frame are connected by the plurality of vertical rods; the vertical rods are respectively perpendicular to the upper support frame and the lower frame; each damping component comprises two quick dismounting plates with L-shaped cross sections, a middle support piece, and a plurality of O-shaped damping rings; the plurality of damping components are mounted on the top surface of the lower support frame and are sequentially arranged at intervals in the circumferential direction of the lower support frame; one end of each damping component is pointed to the center of the lower support frame. The unmanned aerial vehicledamping connecting rod system and the unmanned aerial vehicle, provided by the invention, have the relatively prominent damping effect, and quick mounting and dismounting of the damping components arerealized.

Owner:北京沃氏航空科技有限公司

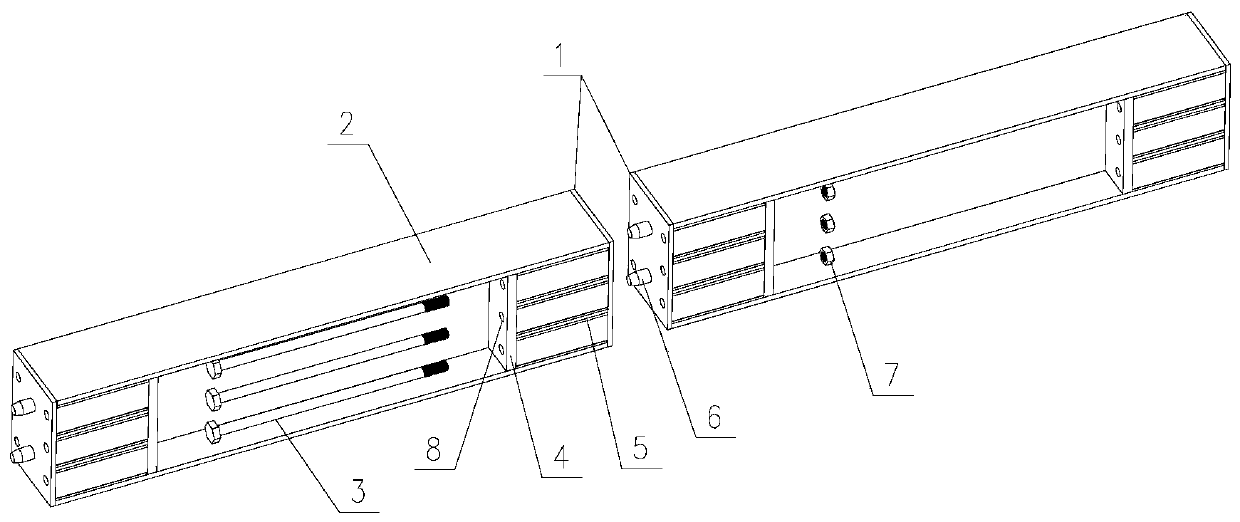

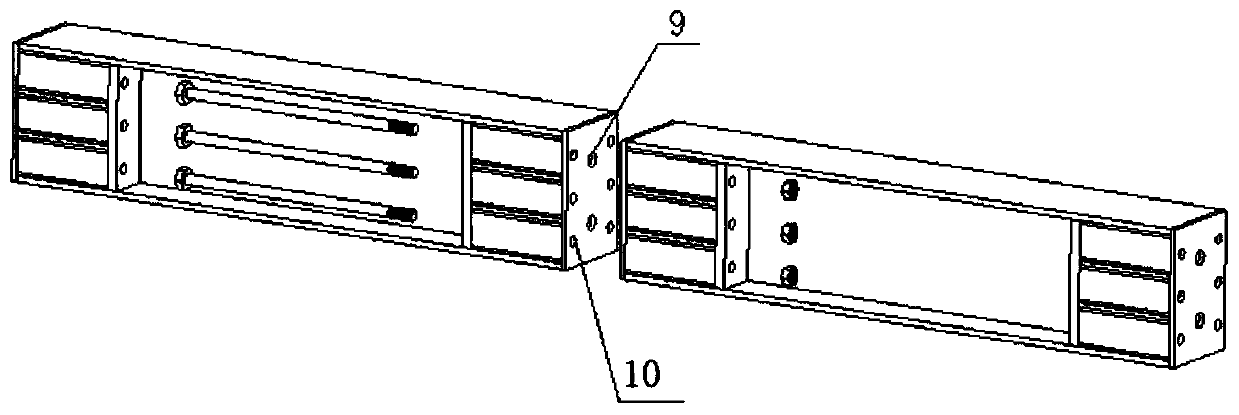

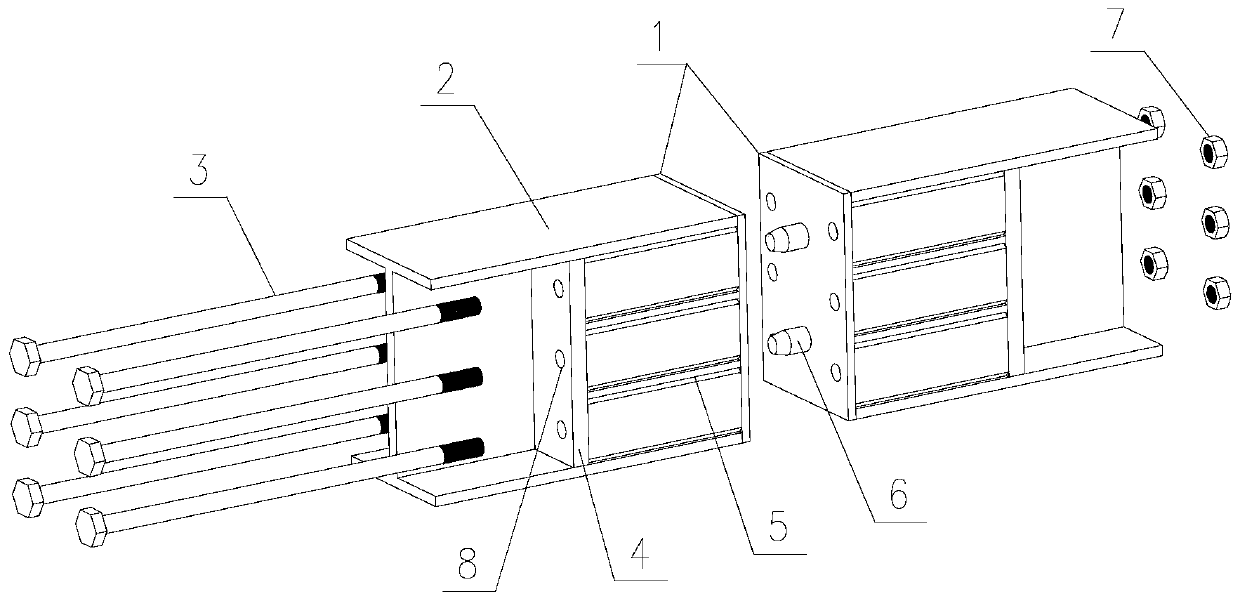

Box-type connecting joint

PendingCN111395149AStrong structural reliabilityPrecise positioningBridge structural detailsStructural engineeringMechanical engineering

The invention, which belongs to the technical field of emergency bridge equipment, discloses a box type connecting joint comprising a joint main body, end sealing plates, transverse reinforcing ribs and positioning pins. The two end sealing plates are fixed to the two longitudinal ends of the joint main body respectively, so that two symmetrical rectangular cavities with openings in the side facesare formed in the two sides of a web of the joint main body, and the side faces are opposite to the web. The two positioning pins respectively and correspondingly penetrate through two positioning pin holes of one end sealing plate of the joint main body and then are fixedly connected with the web plate of the joint main body; two transverse reinforcing ribs parallel to the end sealing plates arefixed to the two ends in each rectangular cavity respectively. The distances between the two transverse reinforcing ribs and the end sealing plates at the corresponding ends are equal. Therefore, a problem of accurate positioning in the modular bridge splicing process is solved; and the joint is simple in structure, high in operability and convenient to disassemble and assemble.

Owner:CHINA HARZONE IND CORP

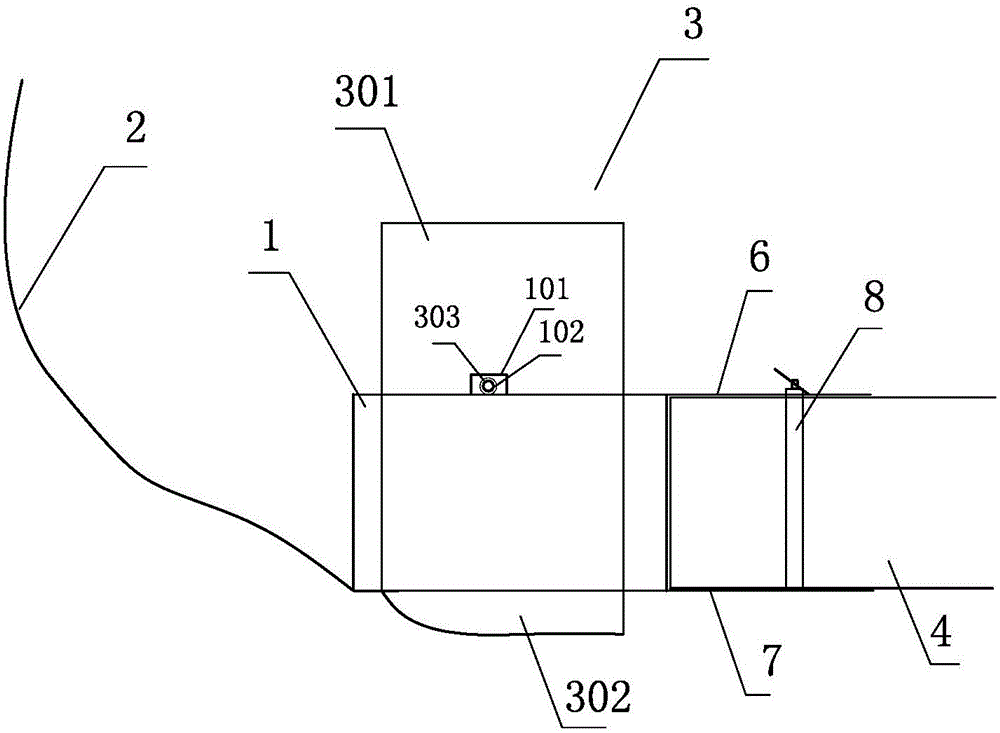

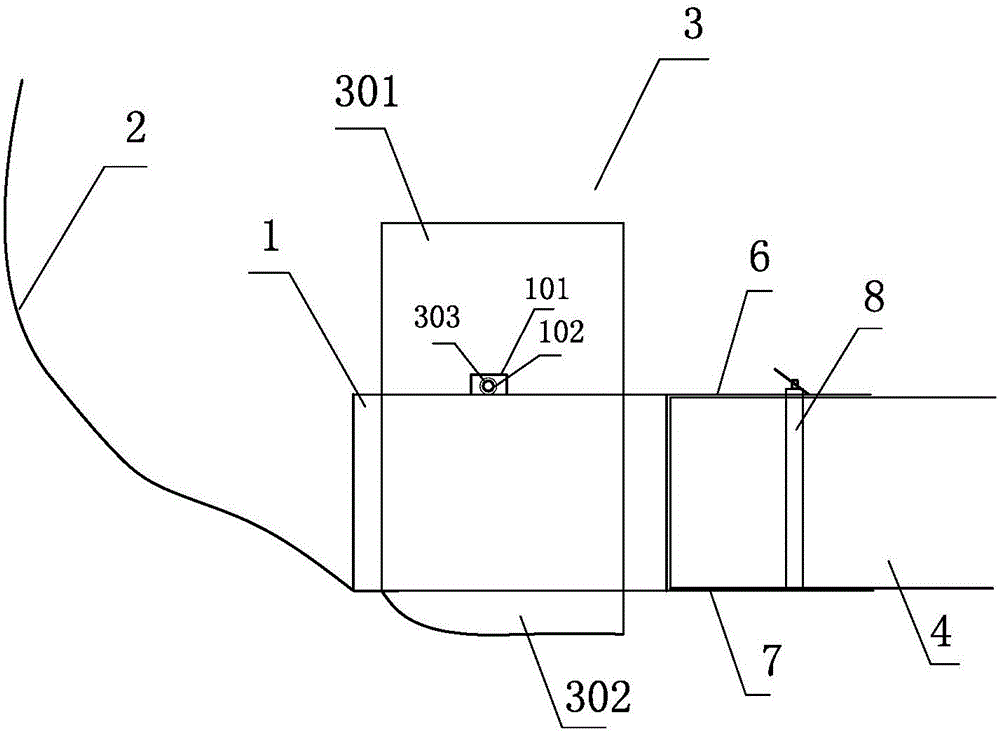

Apparatus and method for accurately positioning hydraulic fore-support moving route

InactiveCN106121702AThe device is safe and reliableImprove coal mining efficiencyMine roof supportsCoal miningEngineering

The invention discloses an apparatus for accurately positioning a hydraulic fore-support moving route. The apparatus comprises a load bearing block (1), a bottom-drilling-preventive baffle (2) and a guide plate (3), wherein the guide plate (3) comprises a first fixed plate (301) and a cutting part (302) connected to the bottom of the first fixed plate (301), a fixed hole (303) is formed in the first fixed plate (301), the distance between the fixed hole (303) and the bottommost end of the cutting part (302) is H+280 mm, H is the thickness of a fore-support base, and the unit of H is mm. The apparatus is safe, practical, simple and reliable, and is capable of improving the coal mining efficiency and the safety production work of a coal mine.

Owner:孙姗姗

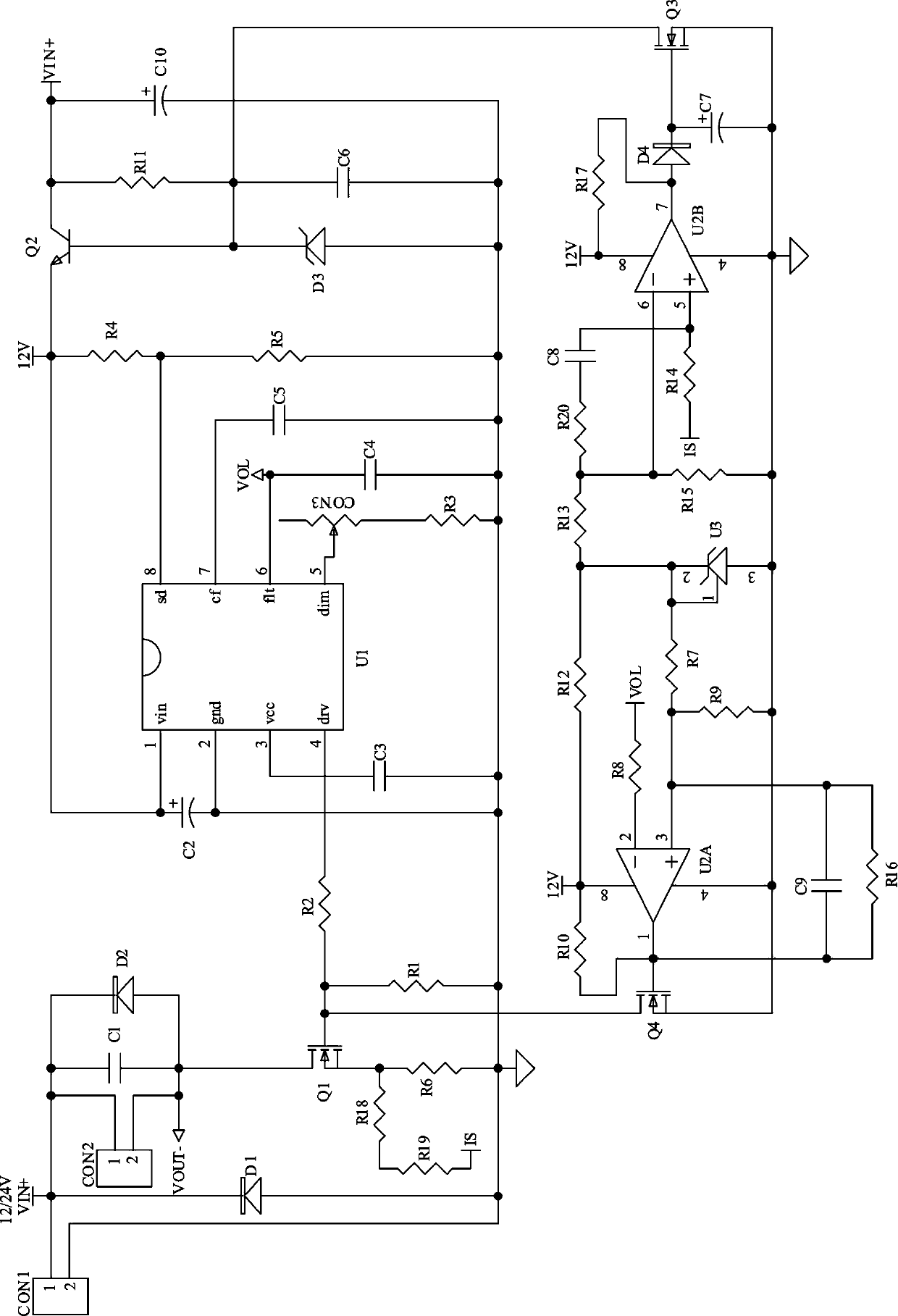

Overload protection and short circuit recoverable PWM dimmer

PendingCN109640494AStrong structural reliabilityPowerfulElectrical apparatusElectric light circuit arrangementEngineeringReverse connection

The invention discloses an overload protection and short circuit recoverable PWM dimmer which comprises a PWM modulation circuit, an overcurrent detection circuit, an undervoltage protection circuit and an input and output anti-reverse-connection protection circuit. The overload protection and short circuit recoverable PWM dimmer has the advantages of high reliability of circuit structure and powerful functions, and PWM modulation, overcurrent detection, VCC undervoltage protection and input and output anti-reverse-connection protection can be achieved.

Owner:LETARON ELECTRONICS

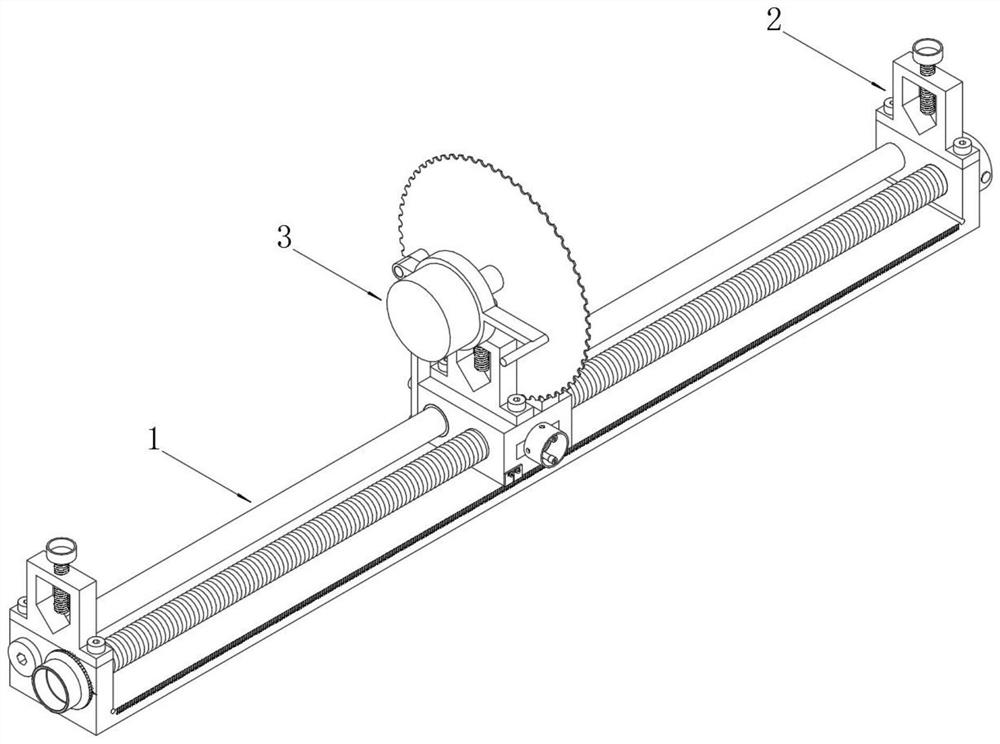

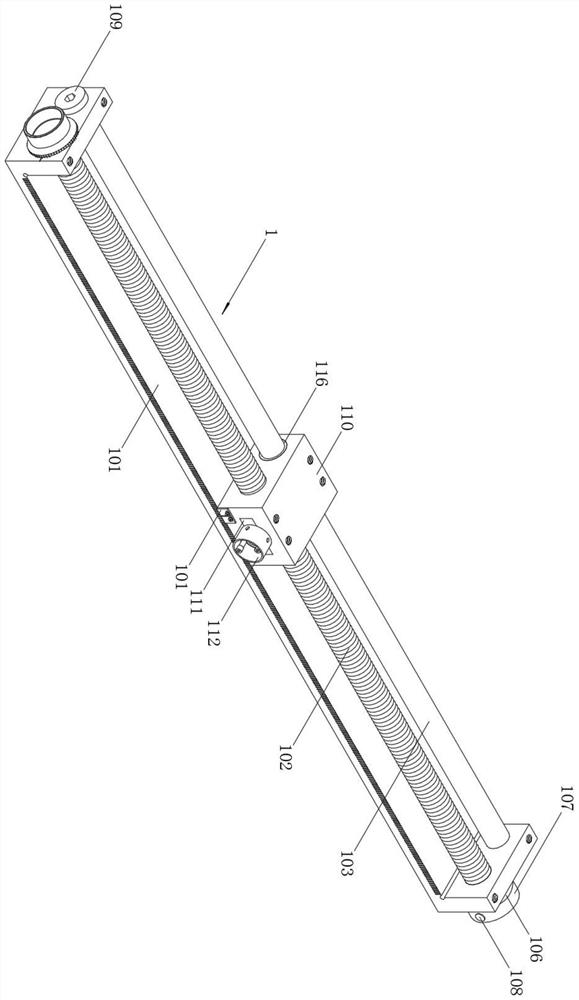

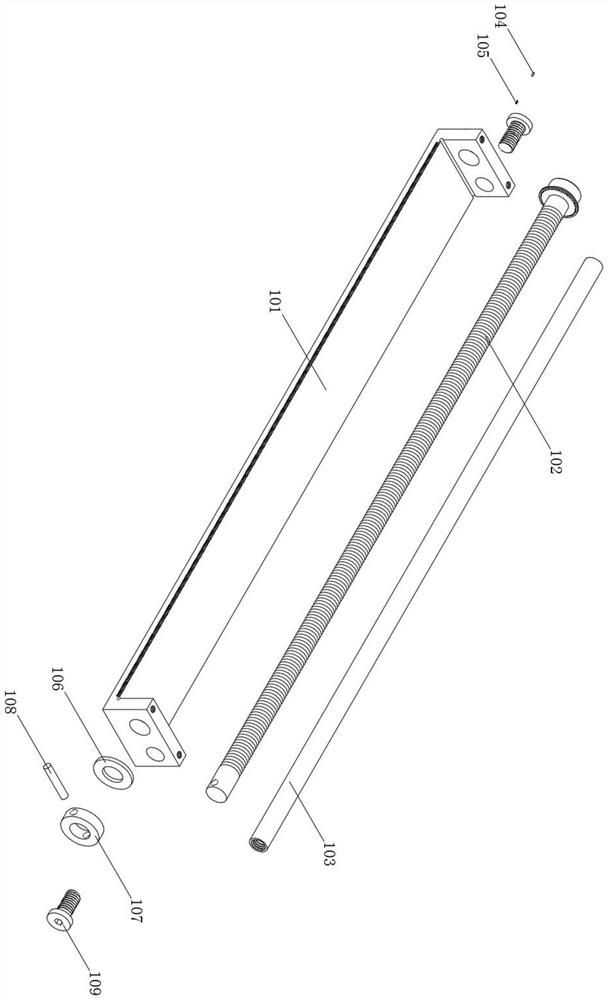

Precise cutting device for polytetrafluoroethylene casing pipes of instruments and meters

ActiveCN113290599AAdjust the movement distanceControl lengthMetal working apparatusTetrafluoroethyleneElectric machinery

The invention discloses a precise cutting device for polytetrafluoroethylene casing pipes of instruments and meters. The precise cutting device comprises a cutting length control assembly, a pipe fixing assembly and a cutting assembly; the cutting length control assembly comprises a bottom table, a threaded shaft, a sliding shaft, an end ring, a sliding block, a meshing block, a pull cylinder, a copper sleeve, a locking screw and an adjustable scale plate; the pipe fixing assembly comprises a fixing table, a fixing table thread and a puller screw; the cutting assembly comprises a rod screw, a vertical rod, a rotating rod, a motor and a cutting piece; under-table scales are formed in the edge of the horizontal part of the cutting length control assembly; table shaft holes and table thread shaft holes are formed in the vertical parts of the two ends of the bottom table; the tops of plate-shaped parts at the two ends of the bottom table are each provided with two table top screws; and the end of one of the plate-shaped structures of the bottom table is provided with a spring groove and table top scales. The precise cutting device for the polytetrafluoroethylene casing pipes of the instruments and meters can adapt to casing pipes with different diameters, can precisely control the length of the cut casing pipes, and is suitable for being widely used and popularized.

Owner:江苏益佳通新能源科技有限公司

Device for preventing side slipping of support base and using method

InactiveCN106401630APrevent sideslipImprove production safetyMine roof supportsEngineeringCoal mining

The invention discloses a device for preventing side slipping of a support base. The device comprises a bearing block (1), an anti-drilling bottom baffle (2) and a guiding plate (3). The guiding plate (3) comprises a first fixing plate (301) and a cutting part (302). A fixing hole (303) is formed in the first fixing plate (301), and the distance between the fixing hole (303) and the bottommost end of the cutting part (302) is H+220 mm, wherein H is the thickness of the forepoling base, and the unit of H is millimeter; and the guiding plate (3) stretches deep into a soft bottom plate to achieve the sliding prevention and side moving prevention effects of a forepoling. The structure is practical, simple and reliable, and coal mining efficiency and safety production of a coal mine are improved.

Owner:孙姗姗

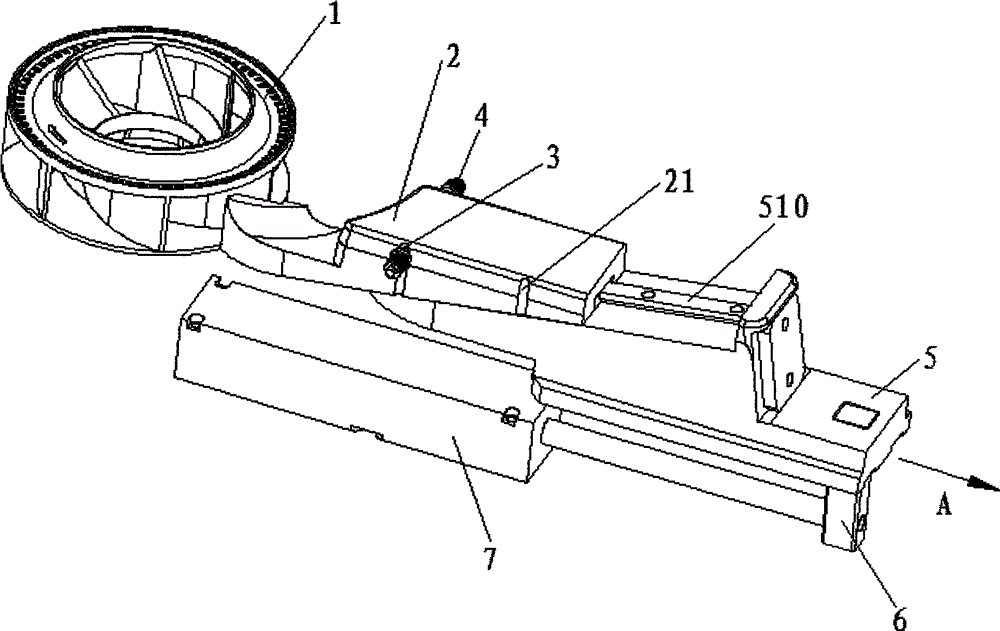

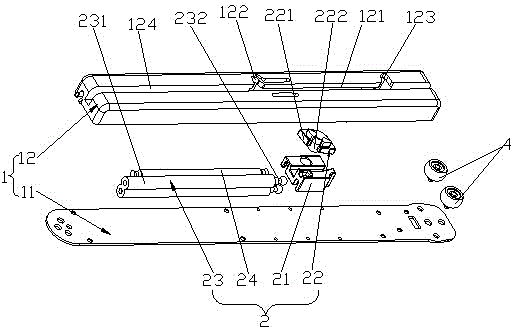

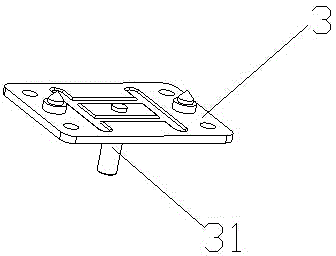

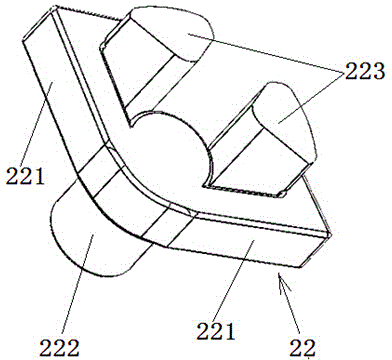

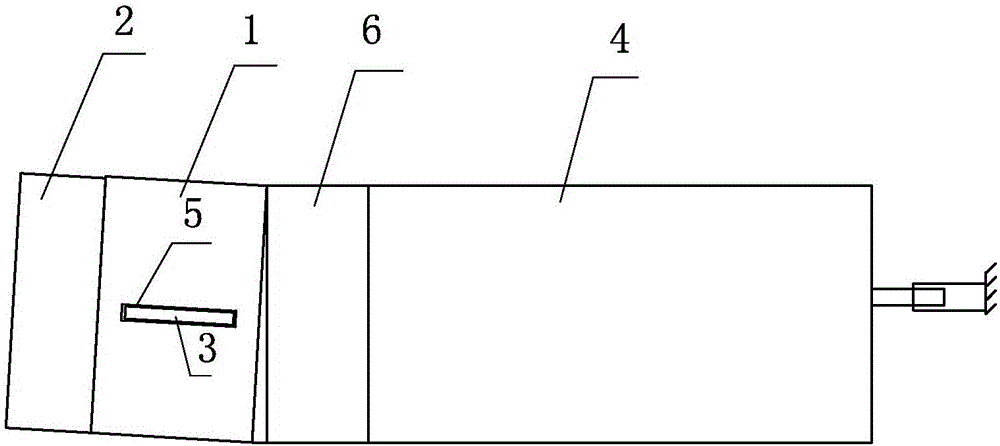

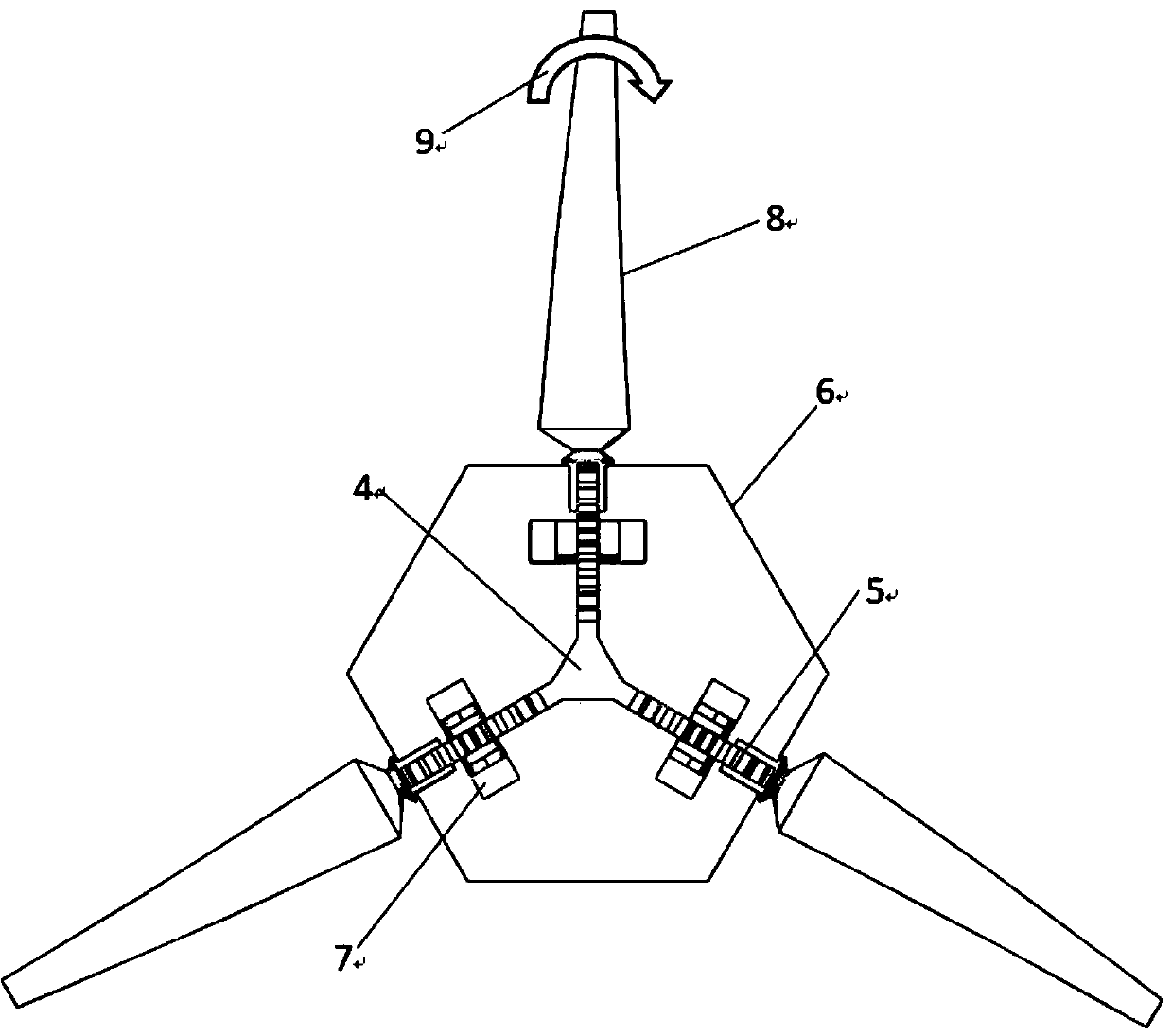

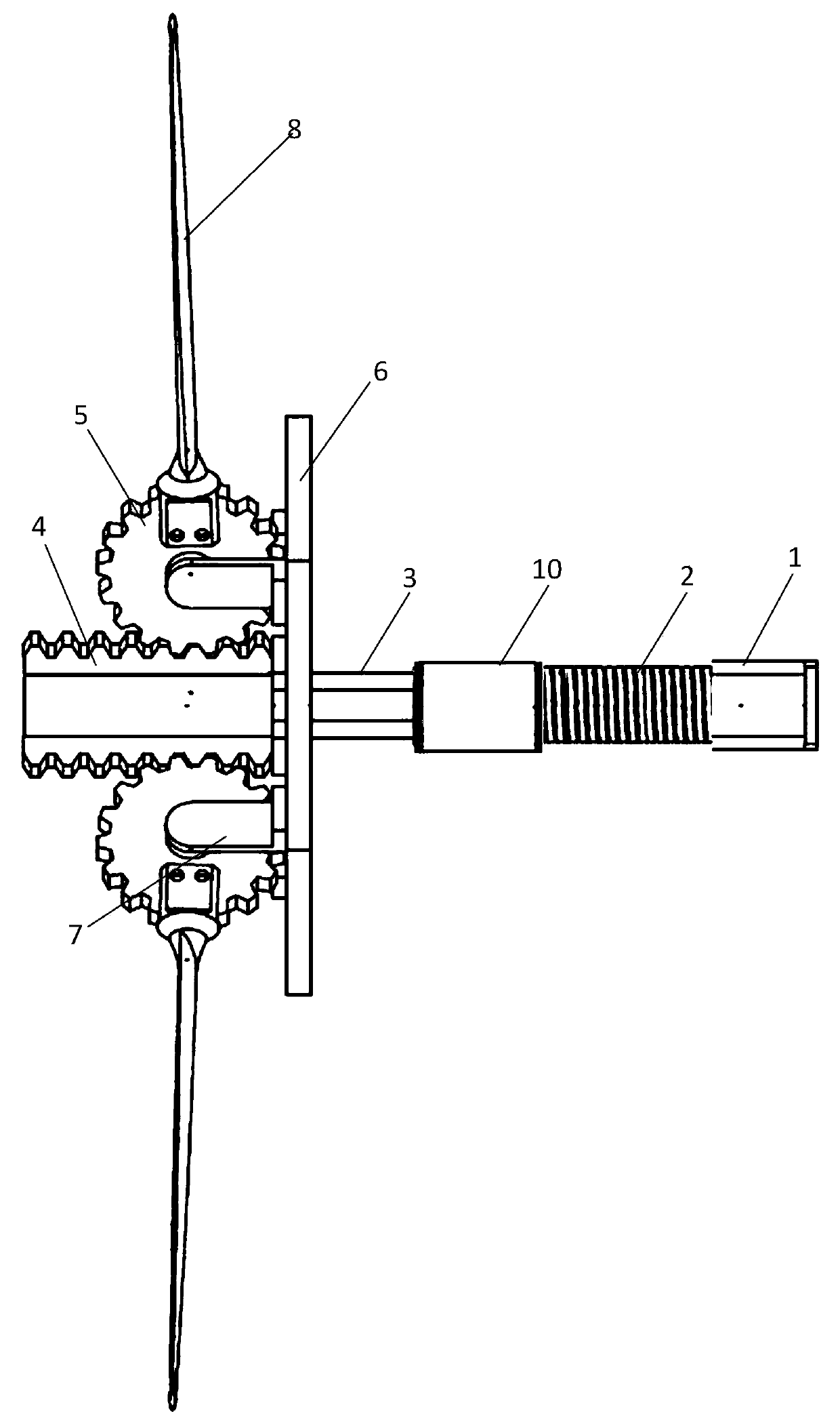

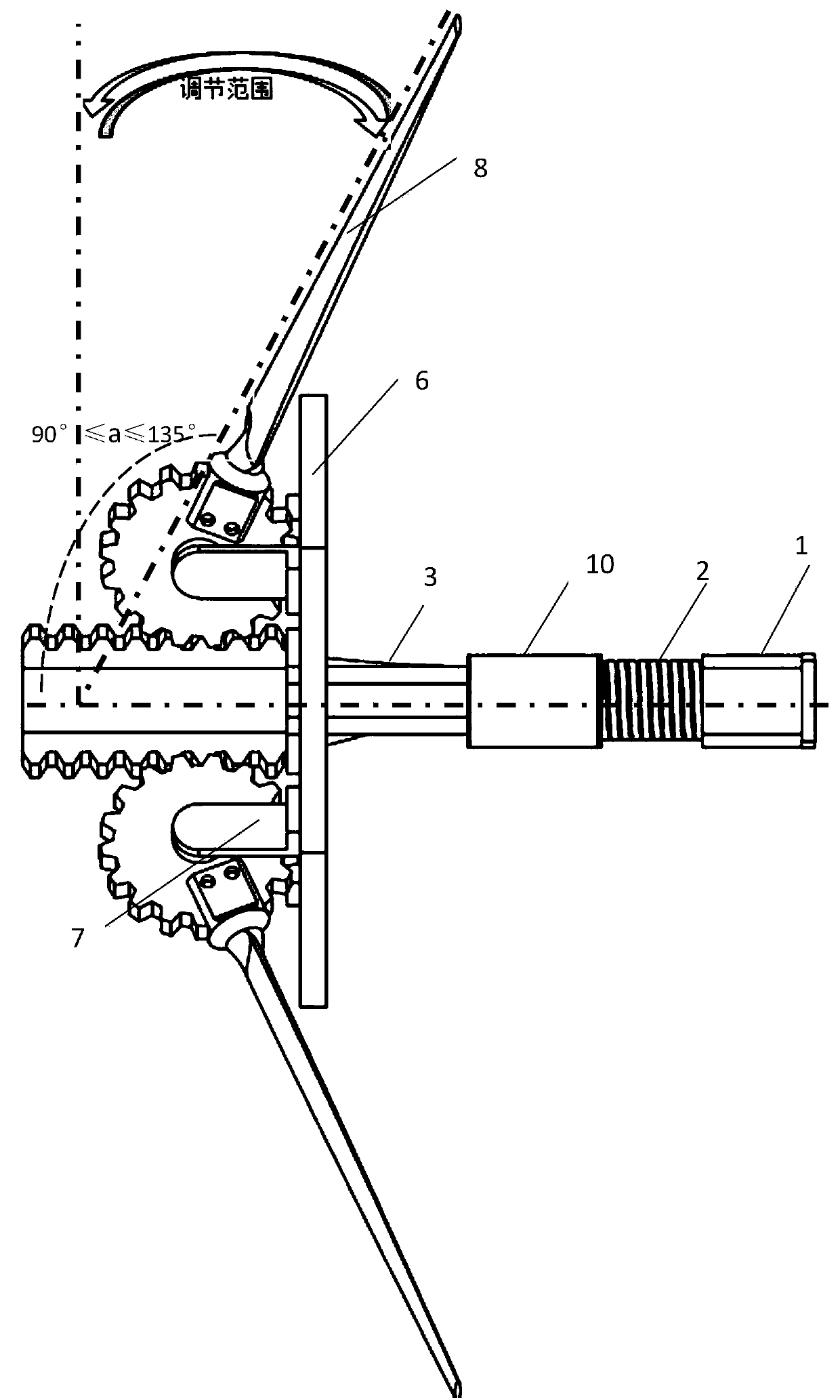

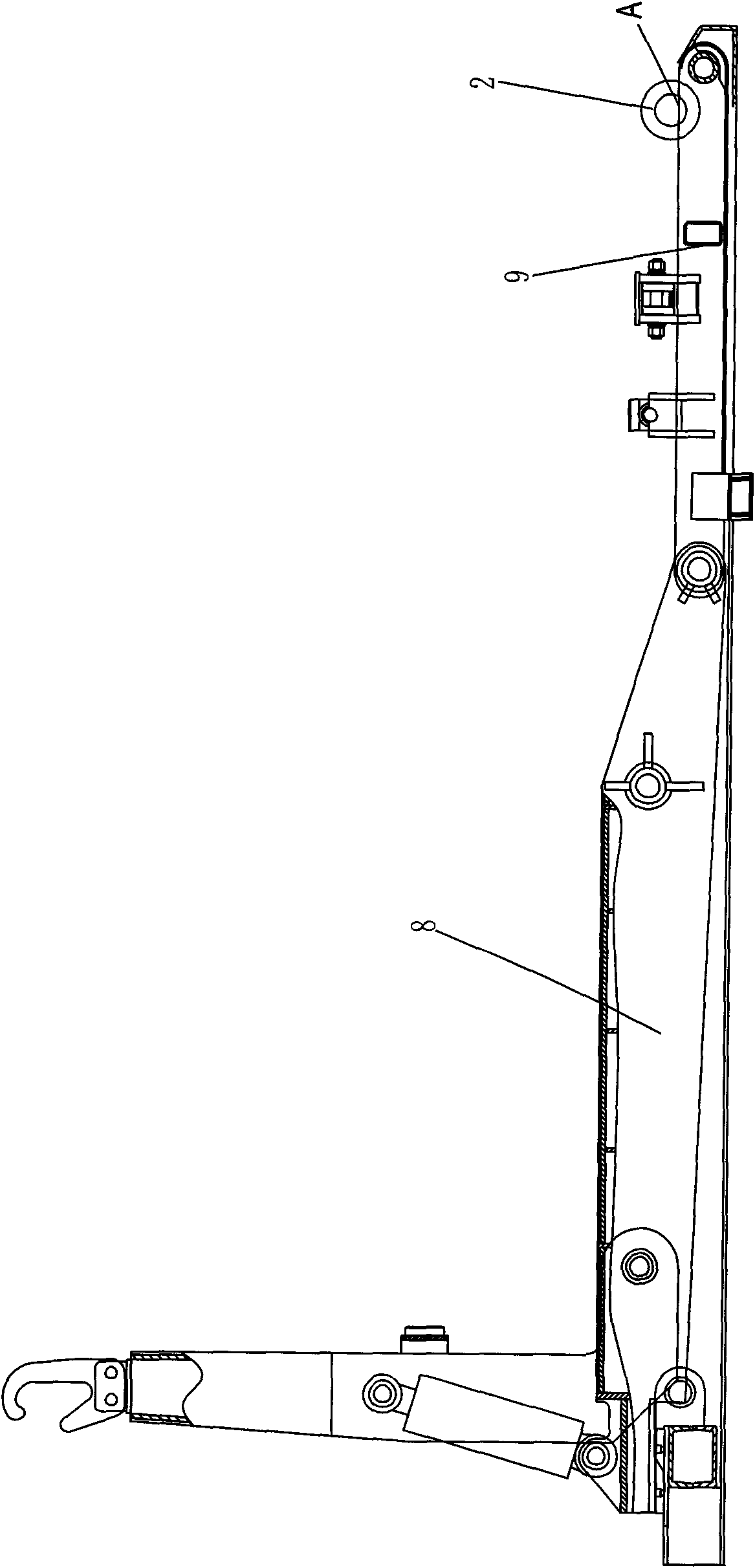

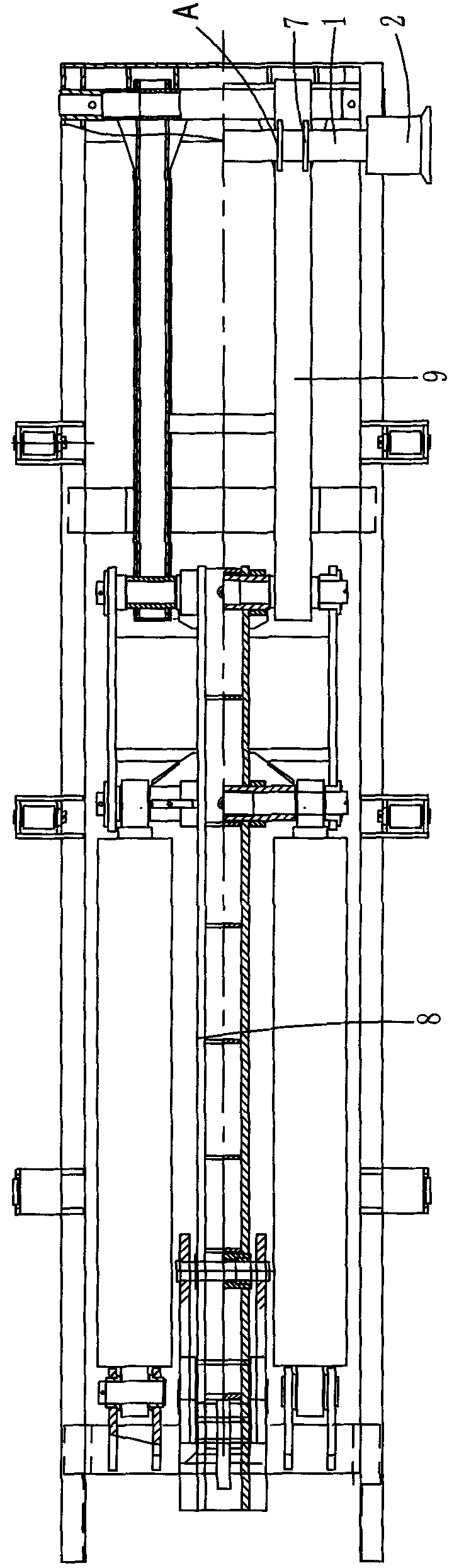

Special power adjusting device for the fan

PendingCN108678903ASimple structureEven by forceWind motor controlMachines/enginesEngineeringPower regulation

The invention discloses a special power adjusting device for a fan. The special power adjusting device for the fan comprises a power mechanism for outputting rotary motion, a driving guide rod (3) used for converting the rotary motion into linear motion, and a transmission mechanism used for converting the linear motion into turning motion, wherein the power mechanism is fixedly connected with thedriving guide rod (3), the driving guide rod (3) is controlled to move linearly in the axis direction of the power mechanism; the other end of the driving guide rod (3) penetrates after through a support I (6) and then is fixedly connected with the transmission mechanism; and the transmission mechanism is installed on the support I (6) through supports II (7), a plurality of blades (8) are installed on the supports II (7), and all the blades (8) are synchronously rotated under the coordination of the power mechanism and the transmission mechanism, According to the special power adjusting device for the fan, the included angle between the blades and the horizontal direction is changed, then the wind receiving area of the fan blades under different conditions is changed, and the obvious effect of power regulation is achieved.

Owner:TSINGHUA UNIV TIANJIN HIGH END EQUIP RES INST LUOYANG ADVANCED MFG IND RES & DEV BASE

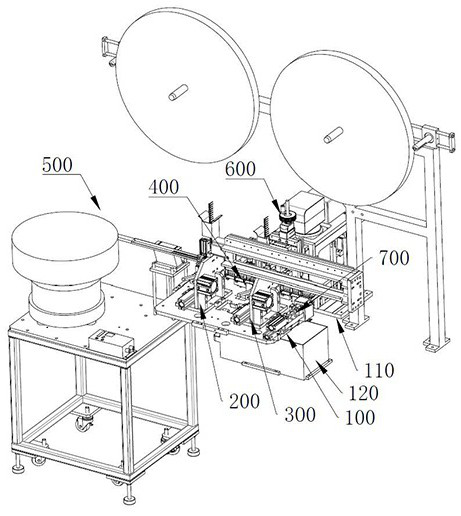

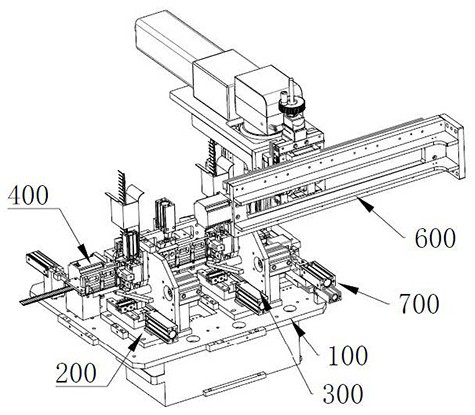

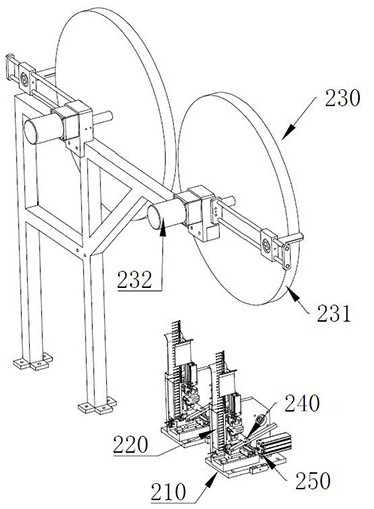

Full-automatic laser cutting welding equipment and process

ActiveCN111940928AImprove work efficiencyHigh degree of automationWelding/cutting auxillary devicesAuxillary welding devicesPhysicsEngineering

The invention relates to the technical field of laser cutting welding and intelligent equipment, in particular to full-automatic laser cutting welding equipment and process. The equipment comprises aworkbench, a first feeding guide device, a second feeding guide device, a pushing device installed at the portion, located at one side of the first feeding guide device and one side of the second feeding guide device, of the workbench, a vibration feeding device connected to one side of the pushing device, a laser cutting device arranged above the pushing device and a welding device positioned below the laser cutting device, wherein the first feeding guide device and the second feeding guide device are mounted on the workbench. Laser cutting is adopted for cutting a power connection sheet, thecutting effect is good, the stability is good, the follow-up connection problem is prevented, the welding device is arranged to conduct spot welding on the cut position, and the quality is guaranteed.

Owner:济南镭迈机械科技有限公司

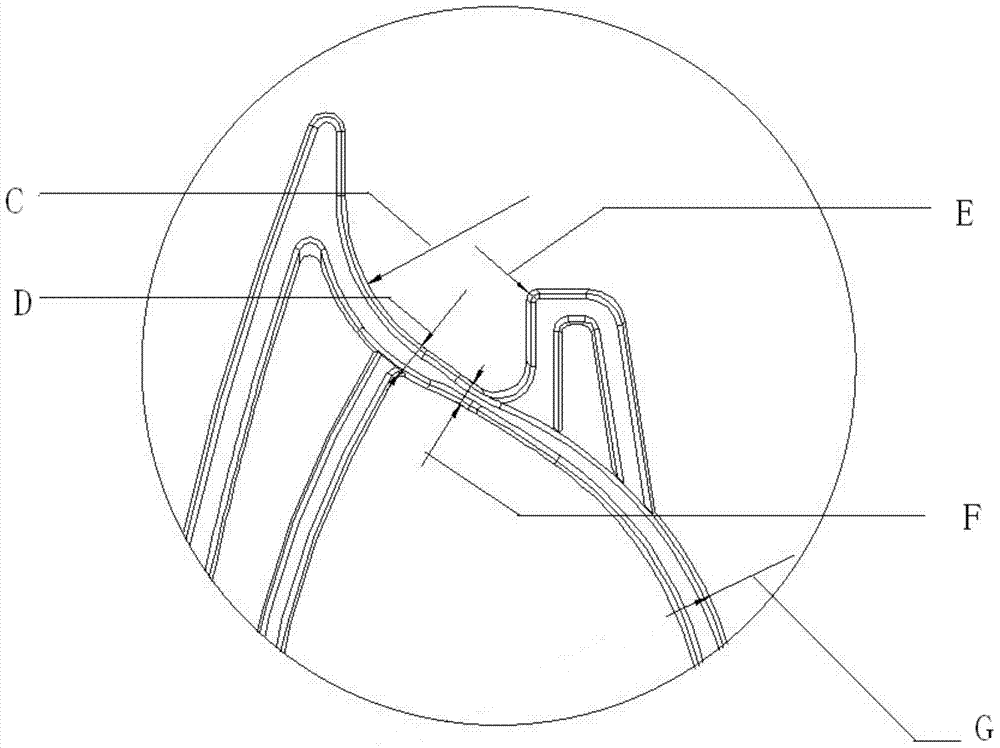

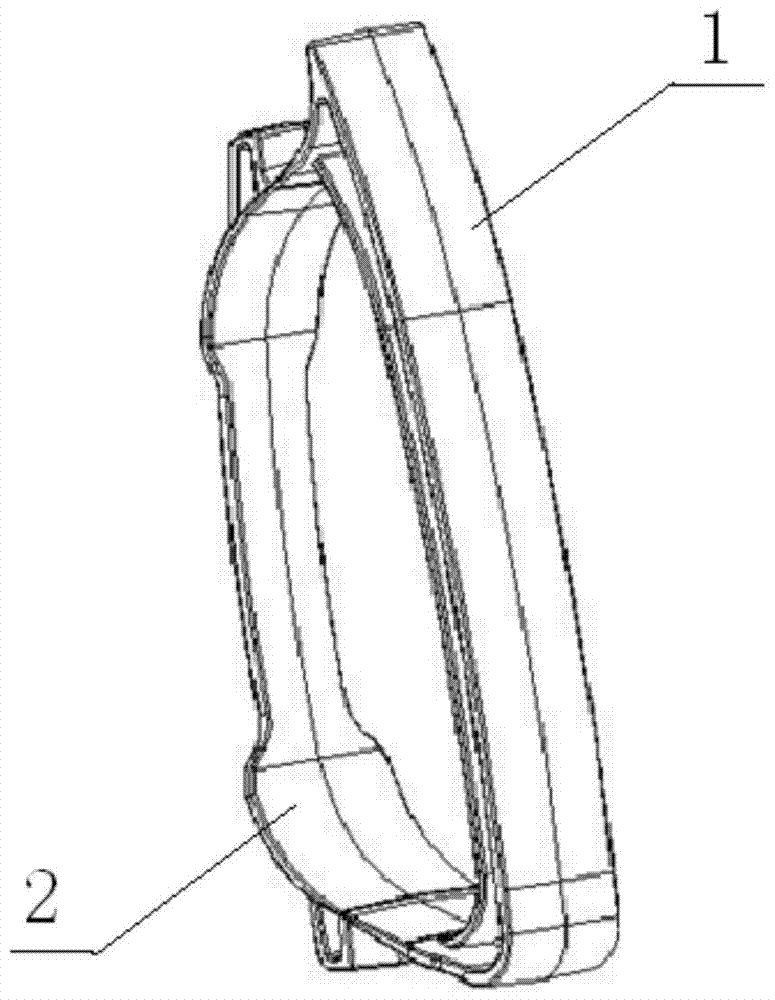

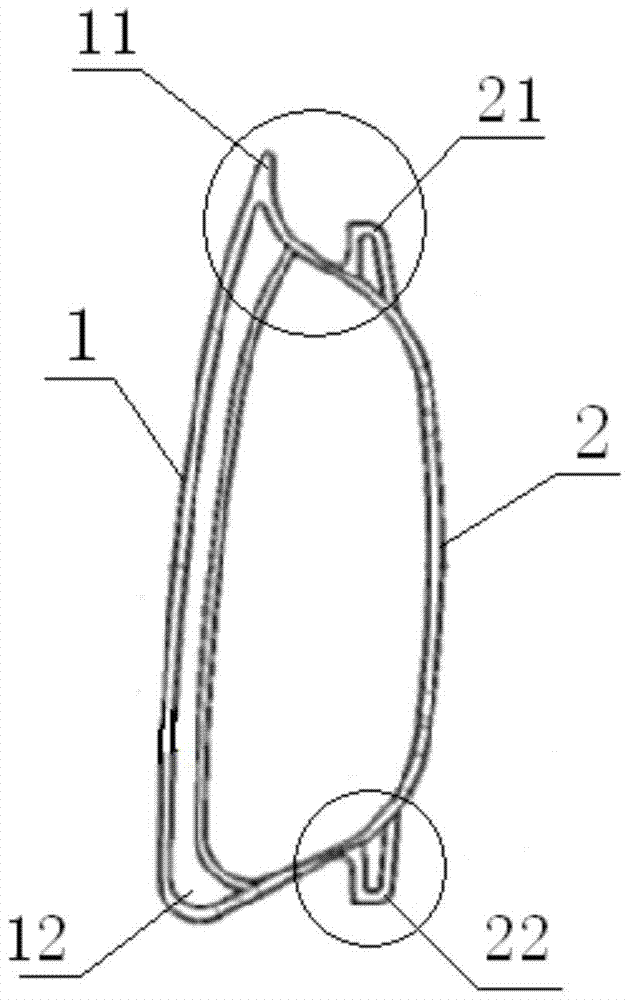

A kind of modified springback implanted handle and manufacturing process method

ActiveCN105035479BStrong structural stabilityStrong structural reliabilityKitchen equipmentContainer handlesBottleBiomedical engineering

The invention discloses a modified springback implanted handle and a manufacturing process, wherein the modified rebounded implanted handle includes an outer handle rod part and an inner rod part connected with the outer handle rod part; the outer handle rod part It is connected with the inner rod to form an oval handle shape; the outer handle rod is used as the handle to directly hold the contact part, and the outer surface of the outer handle rod is the grip surface of the handle; the inner rod is used as an oil bottle body, and the inner surface of the inner rod is the contact surface of the bottle body; wherein, the top of the outer handle rod is provided with an upper raised part, and the bottom of the outer handle rod is provided with a lower raised part; the inner rod The top of the portion is provided with an upper implant portion, and the bottom of the inner stem portion is provided with a lower implant portion. The modified springback provided by the invention is implanted into the handle, which greatly improves the rebound performance of the handle and ensures that both the drop index and the cold resistance index meet the technical requirements.

Owner:SHANDONG LUHUA GROUP

A waveguide coaxial converter

ActiveCN113097676BSolve insufficient bandwidthMeet the requirements of the new generation communication systemCoupling devicesConvertersElectrical conductor

The invention discloses a waveguide coaxial converter, which comprises: a device body, an excitation terminal and a feed source terminal are arranged in the device body; a second ridge wave conductor and a first ridge wave conductor, and the second ridge wave conductor and the first ridge wave conductor are alternately located in the device body along the direction from the excitation end to the feed source end, and the second ridge wave conductor and the first ridge wave conductor are provided with matching structures; A short circuit board, the short circuit board is located in the device body close to the excitation end, and a zigzag short circuit rear cavity is formed between the short circuit board and the matching structure. The technical scheme of the present invention optimizes the structure between the double-ridge waveguide and the short circuit board, realizes the broadband and dual-polarization design of the waveguide-coaxial converter; solves the insufficient bandwidth of existing products, and can realize a relative bandwidth of more than 30% .

Owner:广东省蓝波湾智能科技有限公司

Box loading wheel mechanism of box pulling device

InactiveCN102069985BReasonable designEven by forceRefuse vehiclesStructural reliabilityWear resistant

The invention discloses a box loading wheel mechanism of a box pulling device. The mechanism comprises a run-through shaft and a roller, wherein the run-through shaft is fixedly connected with the upper end on the rear side of a turning frame of the box pulling device; a wear-resistant ring is tightly arranged on the inner side in the middle cavity of the roller; the inner wall of the wear-resistant ring is sleeved on external circles of the two ends of the run-through shaft and is in running fit with the external circles; an inward convex baffle ring body is arranged outside the middle cavity of the roller; the inner surface of the baffle ring body is contacted with the outer end face of the run-through shaft; a connecting pin is penetrated in the middle of the two ends of the run-through shaft; the rear end head of the connecting pin is provided with a convex ring; a spacer ring is arranged between the inner surface of the convex ring and the outer surface of the baffle ring body; the front end head of the connecting pin is provided with a bolt member; and the bolt member is also inserted into the two sides of the run-through shaft. Due to adoption of the overall structure, long-span rigid connection is realized on the two sides during box loading, so the structure has high reliability; the wear-resistant ring structure is lined in the roller, so the flexibility of the roller during running is improved and the service life of the entire member is prolonged; the axial relative moment of the roller is limited by using the connecting pin and the bolt member, so the structure of the mechanism is simple; and an oil storage ring is internally arranged to prolong the service life of the mechanism.

Owner:阮志华

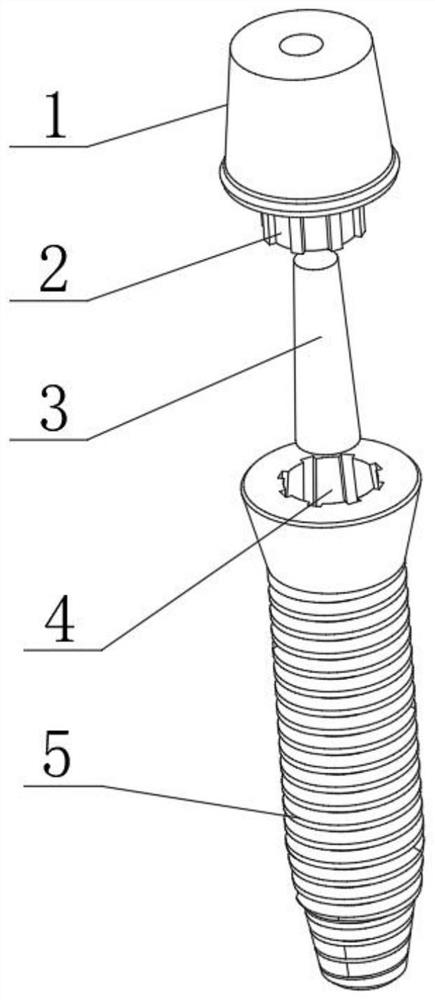

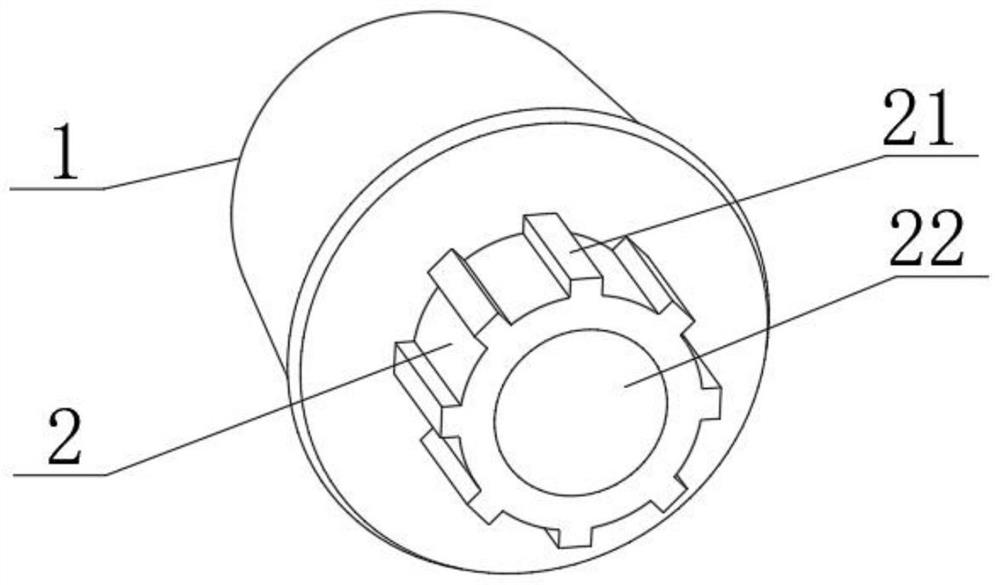

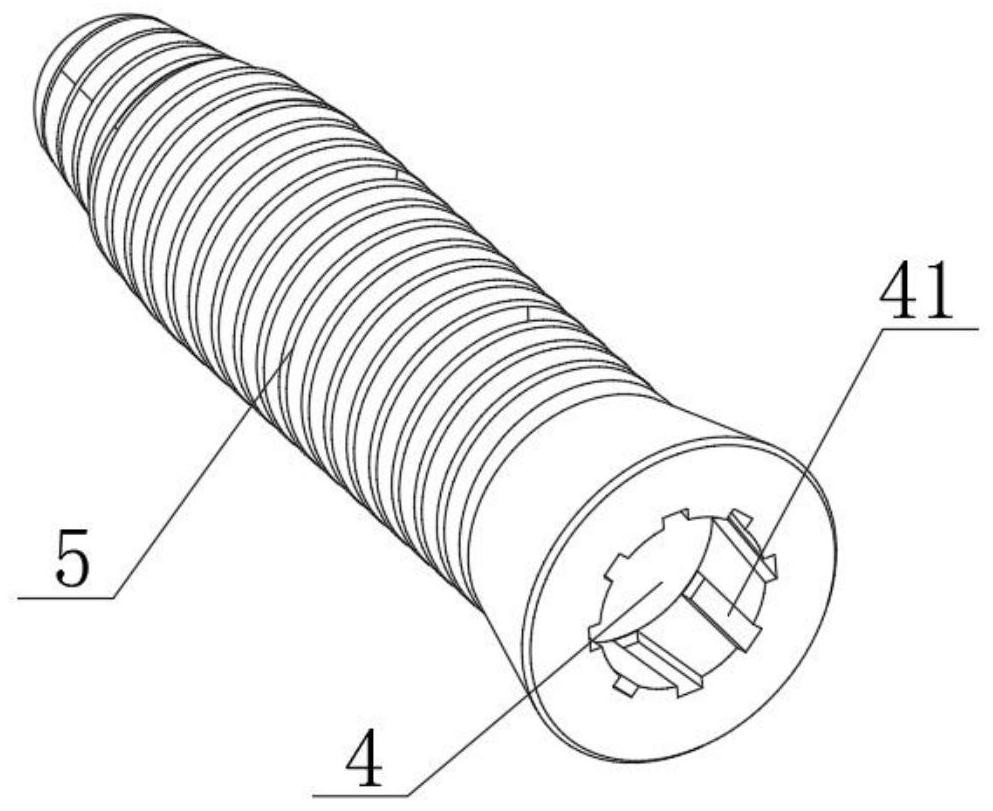

Self-expanding locking interface implant package

The invention provides a self-expanding locking interface implant package. The self-expanding locking interface implant package comprises an implant and an abutment, one end of the implant is provided with an inner concave groove body, an outer convex pipe body is formed at one end of the abutment, an elastic piece, and internally provided with a hole body; the self-expanding locking interface implant package also comprises an embedded body, the embedded body is used for being matched with the hole body in a nested mode, after the outer convex pipe body is elastically deformed in a matching process, and the outer convex pipe body and the inner concave groove body are matched in a nested mode to form an elastic connecting structure; an outer conical surface is formed on an outer side of the embedded body and a corresponding inner conical surface is formed on an inner side of the hole body; and when the inner conical surface is sleeved from a large-diameter end of the inner conical surface to a small-diameter end of the outer conical surface in an axial direction, a size of the outer convex pipe body is gradually expanded in a radial direction, and after the sleeving is completed, the outer convex pipe body and the inner concave groove body are connected in a complementary mode. By means of an elastic nesting fit of the embedded body and the outer convex pipe body, the outer convex pipe body and the inner concave groove body form the complementary concave-convex combined type elastic connecting structure, the abutment can be effectively prevented from disengaging, structural reliability is high, and stability is good.

Owner:JIANGYIN JINTAIKE BIOTECH

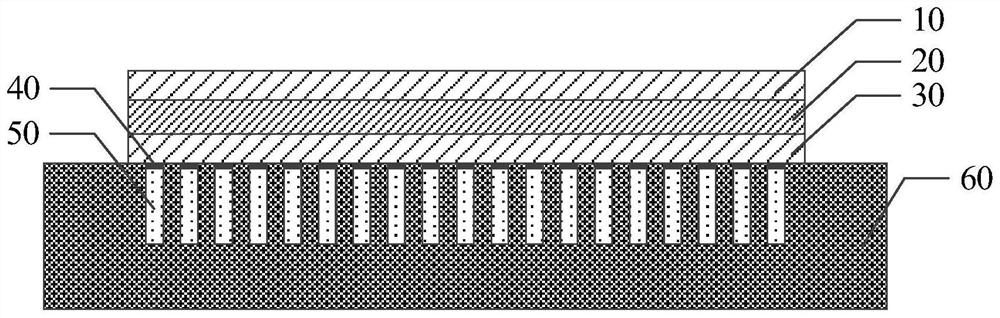

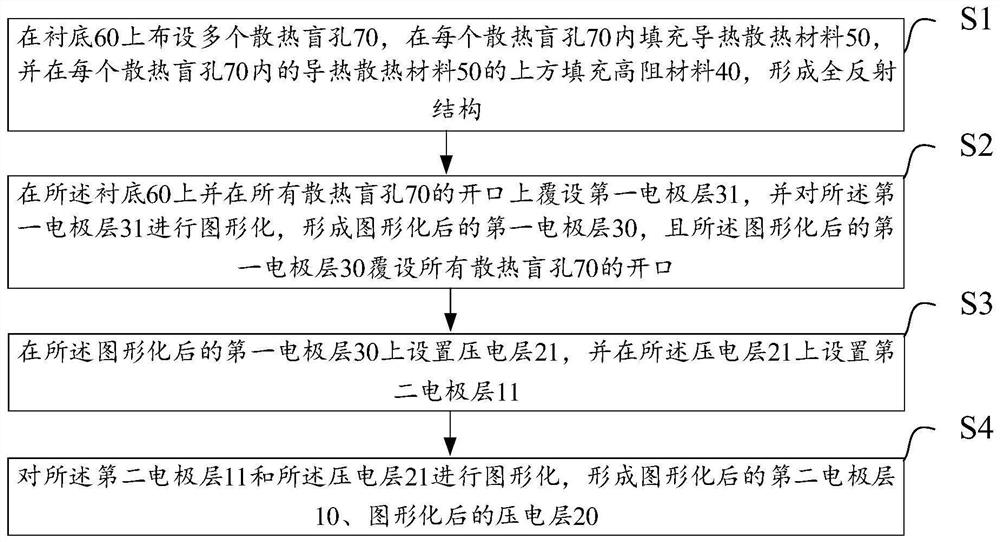

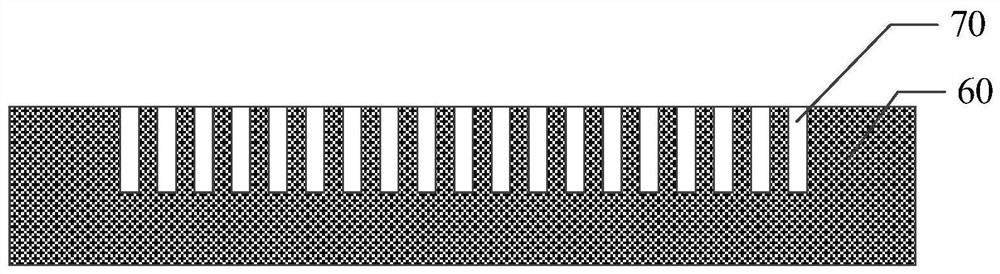

Film bulk acoustic wave resonator, preparation method and film bulk acoustic wave filter

PendingCN114006598AAvoid temperature effectsSimple preparation processImpedence networksThin-film bulk acoustic resonatorThin membrane

The invention relates to a film bulk acoustic wave resonator, a preparation method and a film bulk acoustic wave filter. The film bulk acoustic wave resonator comprises a patterned second electrode layer, a patterned piezoelectric layer, a patterned first electrode layer and a substrate which are sequentially stacked, wherein a plurality of heat dissipation blind holes are formed in the substrate, each heat dissipation blind hole is filled with a heat conduction and dissipation material, a high-resistance material is filled above the heat conduction and dissipation material in each heat dissipation blind hole to form a total reflection structure, and the patterned first electrode layer covers openings of all the heat dissipation blind holes. According to the film bulk acoustic wave resonator, the total reflection structure is prepared on the substrate, and each heat dissipation blind hole is filled with the heat conduction and dissipation material and the high-resistance material, so that the original high Q value is maintained, the temperature influence caused by insufficient heat conduction and dissipation capability of a traditional film bulk acoustic wave resonator is solved, and the film bulk acoustic wave resonator is high in structural reliability, facilitates integration, and simple in preparation process.

Owner:北京航天微电科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com