Drag-reducing and torque-reducing device

A pipe string and sliding sleeve technology, applied in the field of machinery, can solve the problems of wear of drill pipe and casing, large friction torque of drill string, and reduction of mechanical penetration rate, so as to reduce pipe string wear, improve fatigue life, and reduce frictional resistance. and wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

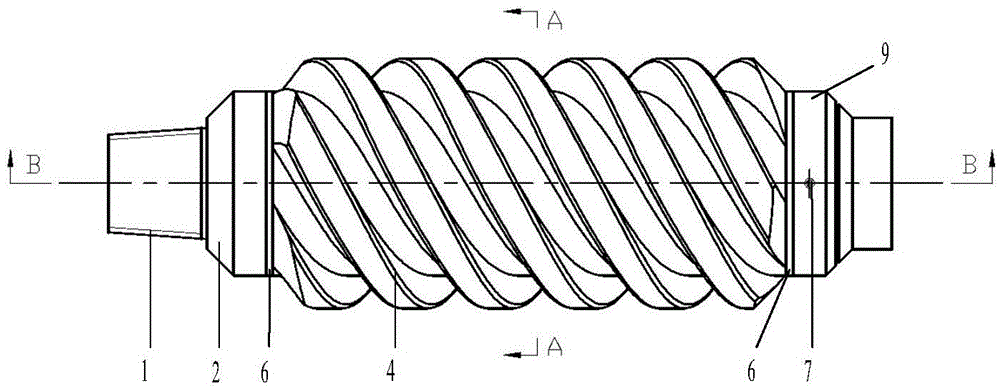

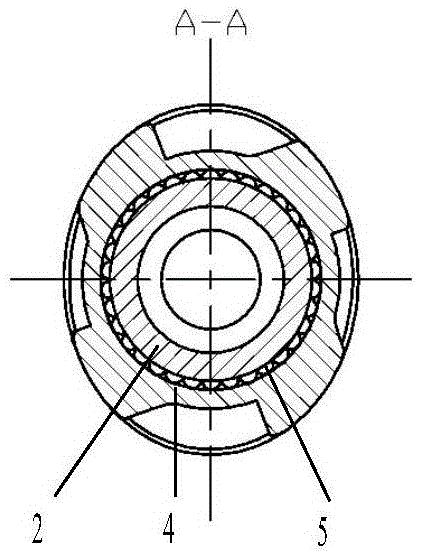

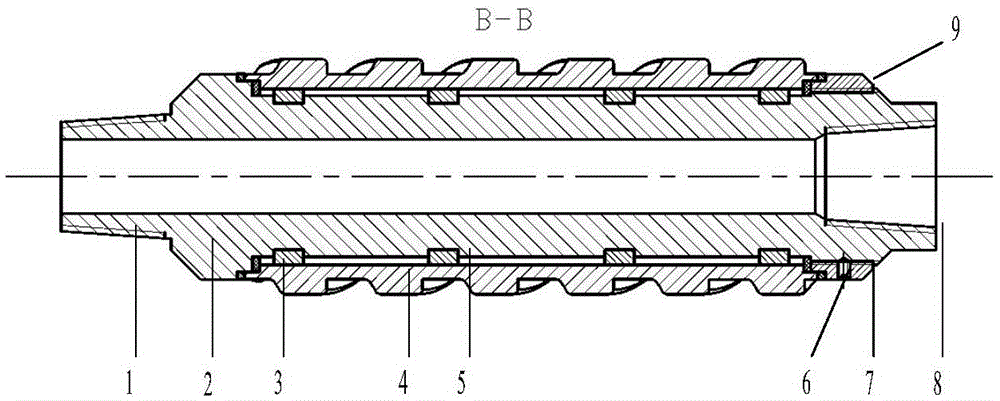

[0014] exist figure 1 , figure 2 and image 3 In the schematic diagram of the pipe string drag and torque reducer shown, the outer surface of the sliding sleeve 4 is provided with four helical ribs uniformly distributed longitudinally along the circumference, and the cross-sectional outer contour of the sliding sleeve is elliptical, as shown in figure 2 As shown; the surface of the body 2 is provided with four roller grooves along the circumference, the roller grooves are filled with cylindrical rollers 5 and matched with the sliding sleeve, the sliding sleeve is placed outside the body, and the two ends connected between the sliding sleeve and the body There is a sealing ring 3, and the sliding sleeve is respectively limited by the shoulder at one end of the male body 1 and the threaded locking ring 9 installed at the end of the female buckle 8. The threaded locking ring is tightly fixed by the set screw 7, and the sliding sleeve is connected with the body and the thread. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com