Water-proofing and earthwork backfilling structure and method of late poured band coordinating with basement sidewall

A post-pouring belt and basement technology, which is applied to underwater structures, infrastructure engineering, water conservancy projects, etc., can solve the problems affecting the site construction layout and construction progress, prolonging the construction period, etc., so as to facilitate the layout and utilization and shorten the construction period , making convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

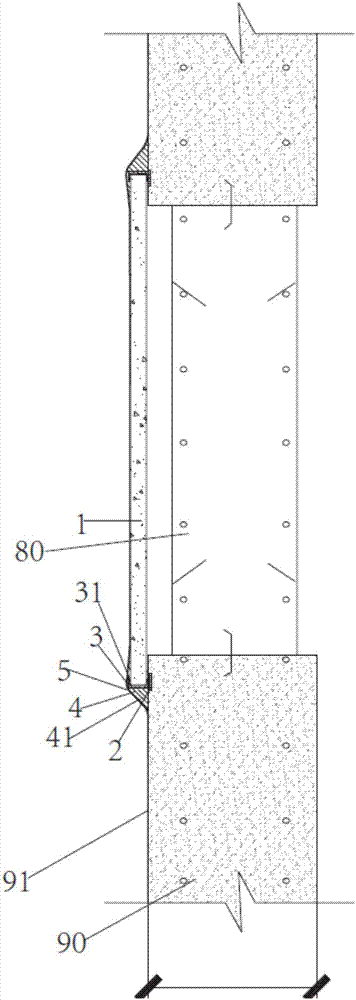

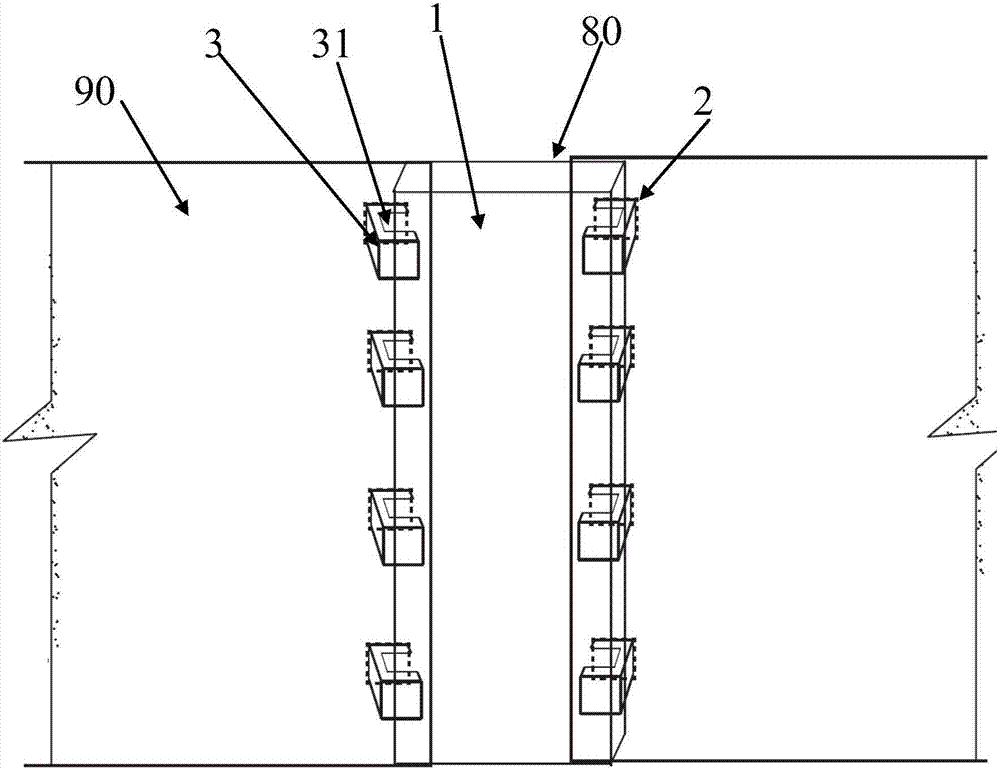

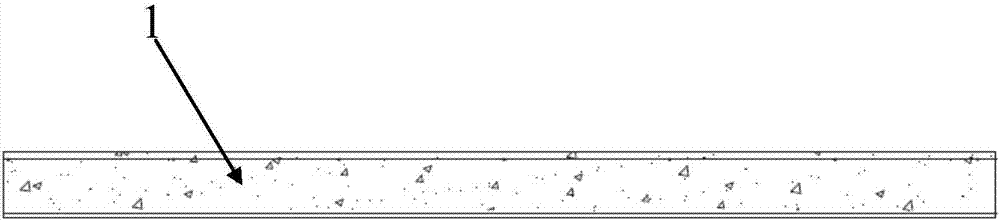

[0050] combine figure 1 As shown, it is a waterproof and earthwork backfilling structure with basement side wall post-cast tape according to an embodiment of the present invention, including basement side wall 90 and side wall outer surface 91, which includes post-cast tape 80 extending in the vertical direction. The structure includes: pre-embedded steel plates 2, which are directly pre-embedded in the side walls 90 on both sides of the post-casting belt 80 during the pouring construction of the basement side walls 90, and are exposed on the outer surface 91 of the side walls. The channel steel parts 3 are welded on the pre-embedded steel plates 2 on both sides of the post-casting band 80, and the pair of channel steel parts 3 respectively form a slot 31 with an opening opposite to each other on both sides of the post-casting band 80 (combined with figure 2 shown). The reinforced concrete precast panel 1 is inserted into the slot 31 from top to bottom, so that the reinforce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com