Self-expanding locking interface implant package

An implant and self-expanding technology, applied in the fields of implantology, medical science, dentistry, etc., can solve the problems of excessive occlusal pressure around the artificial teeth, shaking of the abutment (artificial teeth), long time-consuming and low efficiency, etc., to improve the implantation efficiency. The effect of success rate, increased risk of fracture resistance, and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

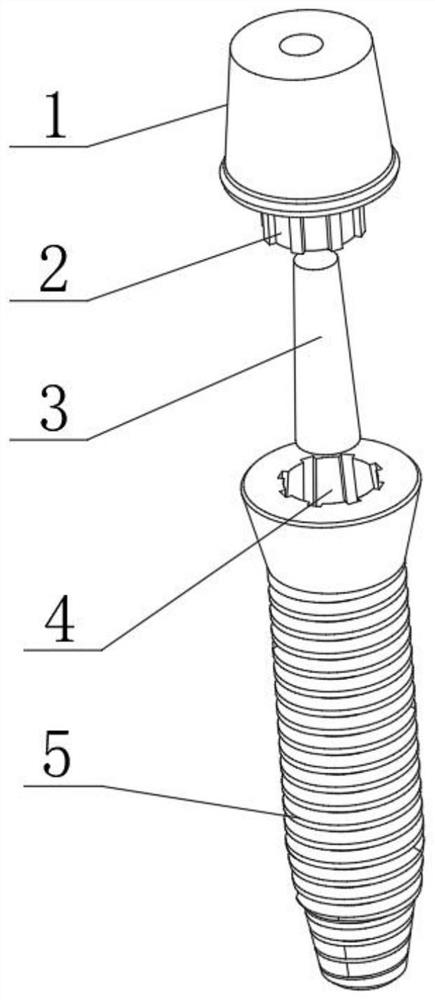

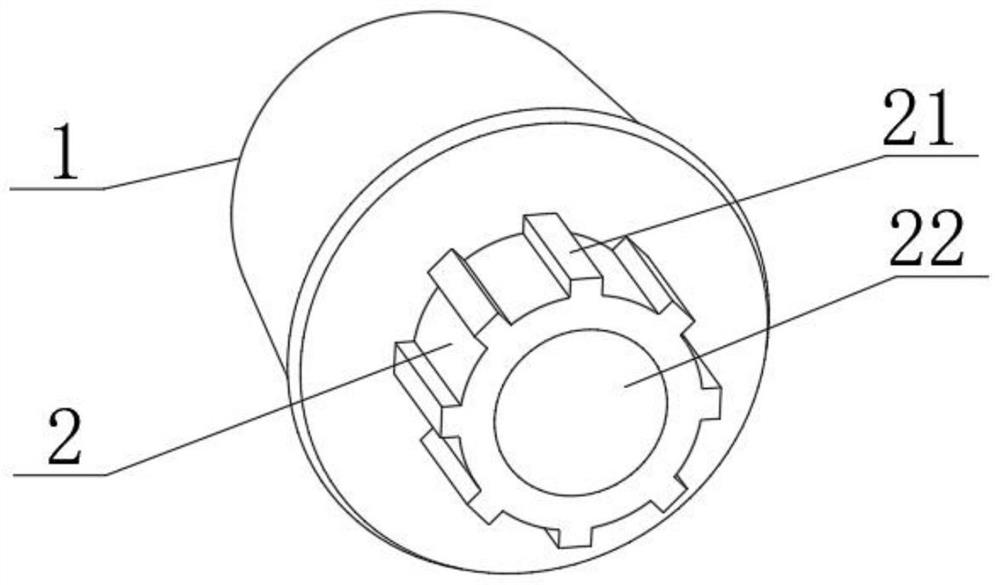

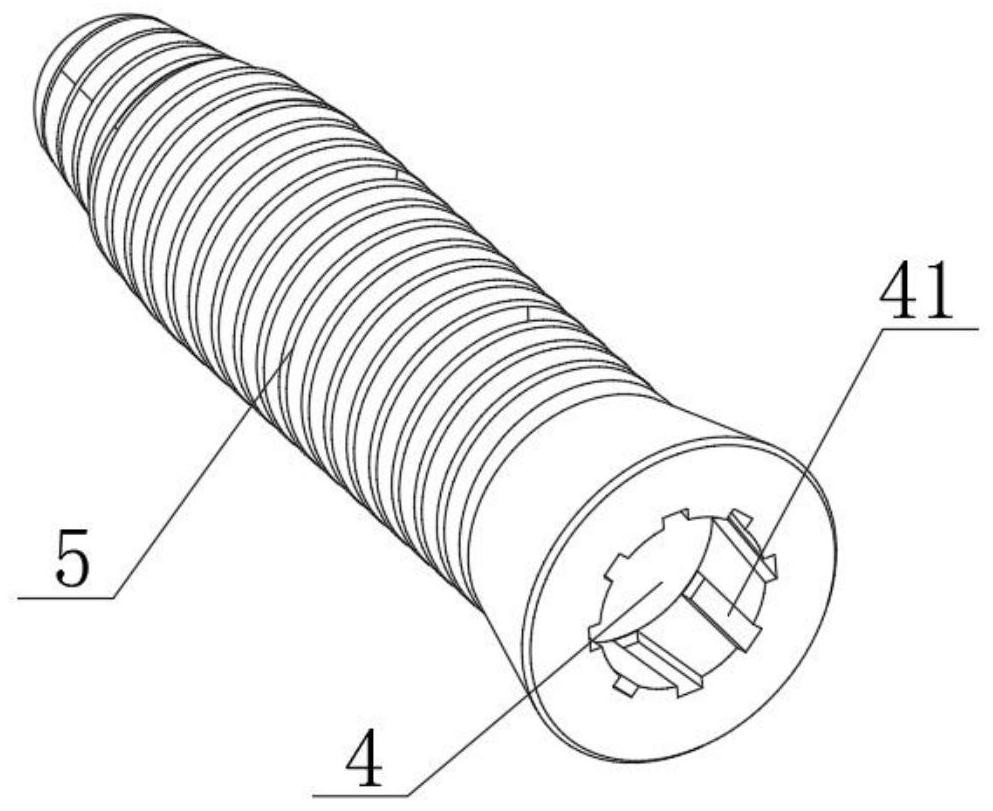

[0032] Such as Figure 1-Figure 4 As shown, the self-expanding locking interface implant set of this embodiment includes an implant 5 and an abutment 1, an inner groove body 4 is provided at one end of the implant 5, and an outer convex tube body 2 is formed at one end of the abutment 1, The protruding tube body 2 is an elastic part, and a hole 22 is formed in it; it also includes an inlay 3, which is used for nested fitting with the hole body 22, and the protruding tube body 2 is elastically deformed during the fitting process. , so that the outer convex pipe body 2 and the inner groove body 4 are fitted in a nested manner to form an elastic connection structure.

[0033] Such as Figure 4 and Figure 5 As shown, an outer conical surface 31 is formed on the outside of the inlay 3, and a corresponding inner conical surface 23 is formed on the inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com