Film bulk acoustic wave resonator, preparation method and film bulk acoustic wave filter

A thin-film bulk acoustic wave and resonator technology, applied in the fields of thin-film bulk acoustic wave resonators, fabrication, and thin-film bulk acoustic wave filters, can solve the problems of unfavorable integration, difficult operation, difficult stacking integration, etc. The effect of strong performance and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

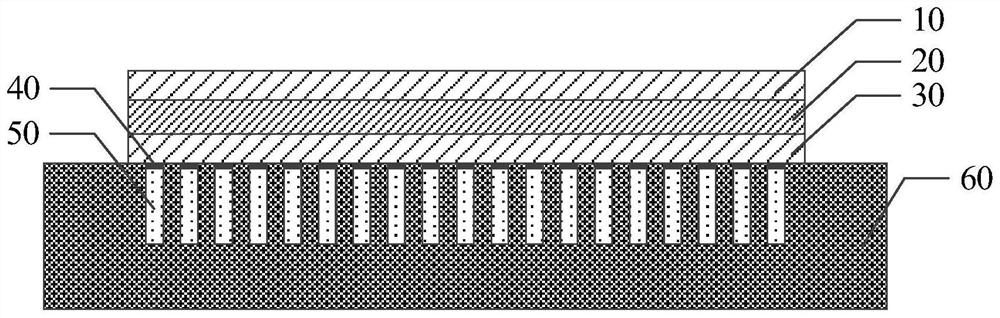

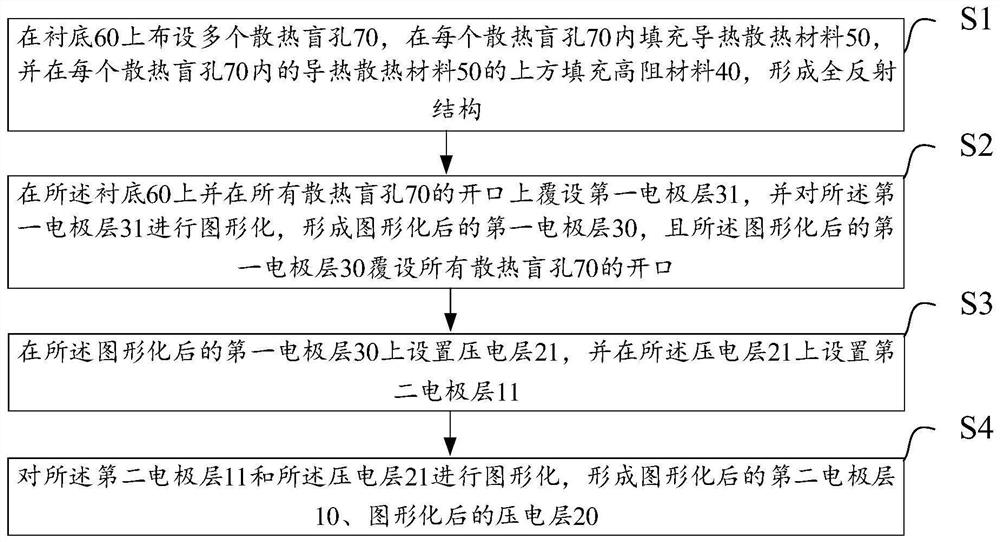

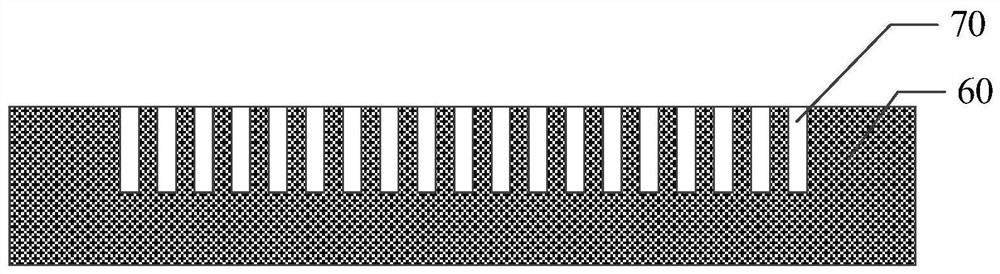

[0061] Prepare the total reflection structure on the substrate 60, and fill the thermally conductive and heat-dissipating material 50 and the high-resistance material 40 in each heat dissipation blind hole 70, so that a kind of thin film bulk acoustic wave resonator of the present application can maintain the original high Q value At the same time, it also solves the temperature influence of the traditional film bulk acoustic resonator due to insufficient conduction and heat dissipation capabilities, and has strong structural reliability, which is conducive to integration and simple preparation process.

[0062] Wherein, the material of the substrate 60 is Si, SiC or sapphire.

[0063] Wherein, the heat-conducting and heat-dissipating material 50 includes at least one of graphite, graphene, graphite oxide, copper, gold, silver, aluminum, diamond and silicon with high thermal conductivity.

[0064] Wherein, the high resistance material 40 includes at least one of silicon dioxid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com