Precise cutting device for polytetrafluoroethylene casing pipes of instruments and meters

A polytetrafluoroethylene, precision cutting technology, applied in metal processing and other directions, can solve the problems of difficult casing, precise control of casing cutting length, clamping, etc., to reduce frictional resistance, avoid movement, easy disassembly and maintenance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

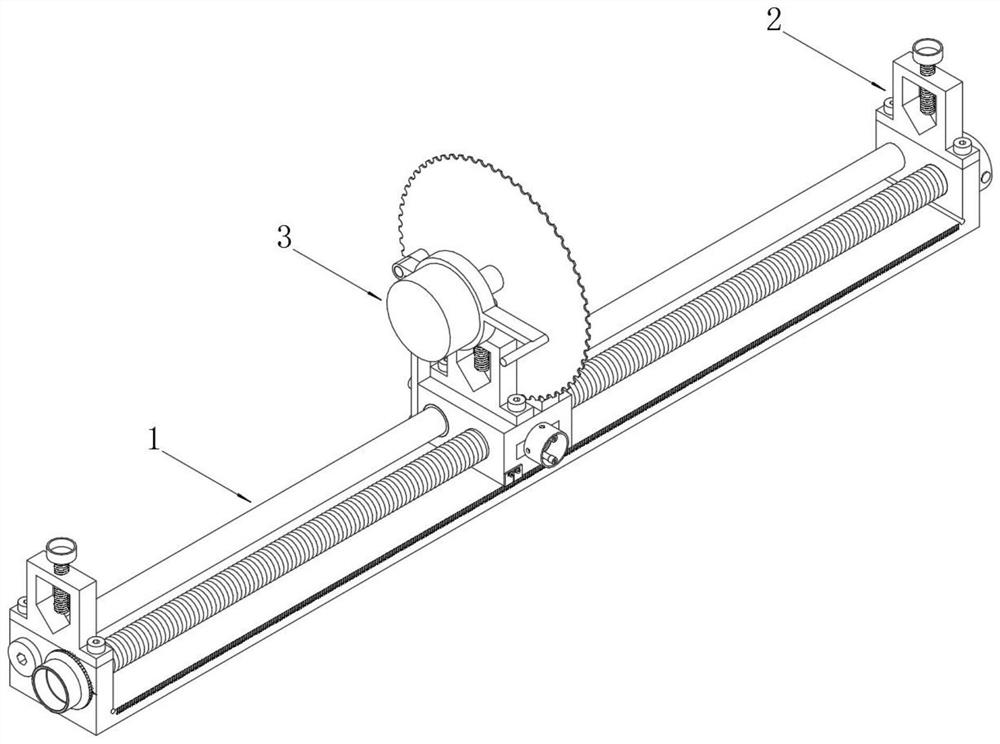

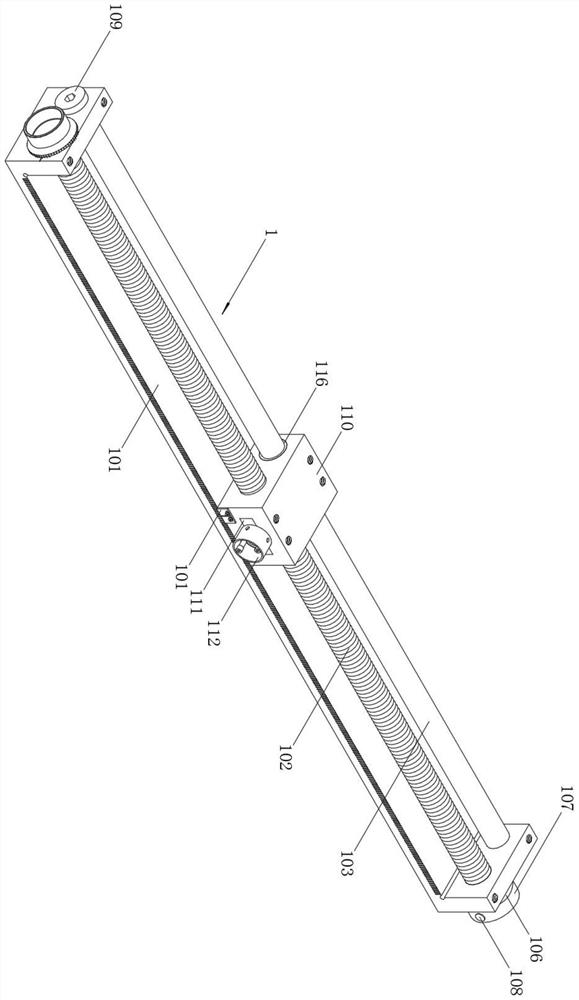

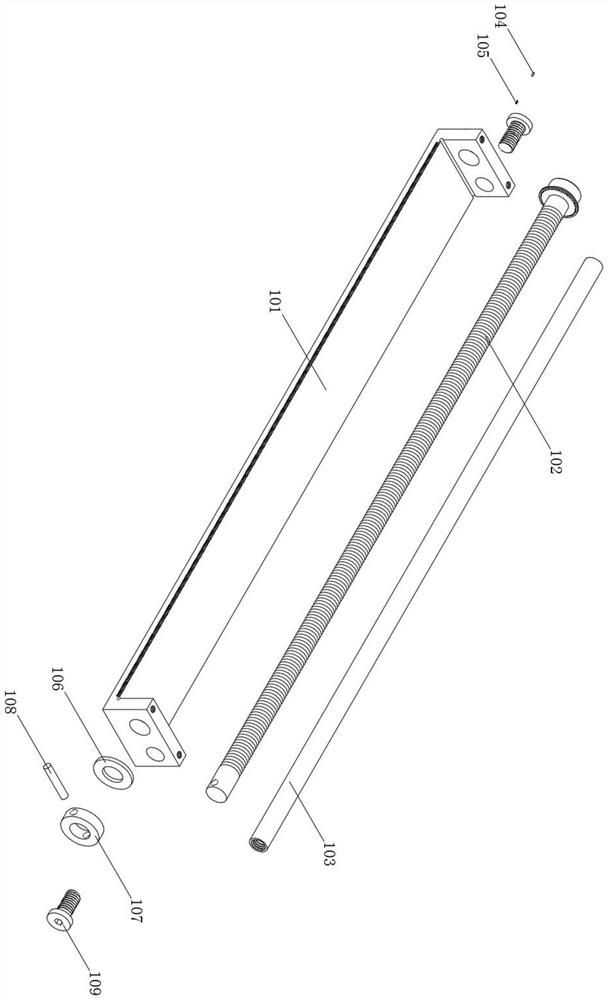

[0035] refer to figure 1 , a precision cutting device for polytetrafluoroethylene casing for instrumentation, including a cutting length control assembly 1, a pipe fixing assembly 2, and a cutting assembly 3; the cutting length control assembly 1 includes a base 101, a threaded shaft 102, and a sliding shaft 103 , end ring 107, slide block 110, engaging block 111, puller 112, copper sleeve 116, locking screw 117 and adjustable scale plate 119; the tube fixing assembly 2 includes a fixing table 201, a fixing table thread 202 and a jacking screw 203 ; the cutting assembly 3 includes a rod screw 301 , a vertical rod 302 , a rotating rod 303 , a motor 304 and a cutting b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com