Environment-friendly device for uniformly spraying paint on automobile parts in all directions

A technology of auto parts and environmental protection equipment, applied in the direction of injection devices, etc., can solve problems such as color leakage, health effects, sneezing, etc., and achieve the effects of reducing chemical components, improving safety performance, and ensuring physical health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

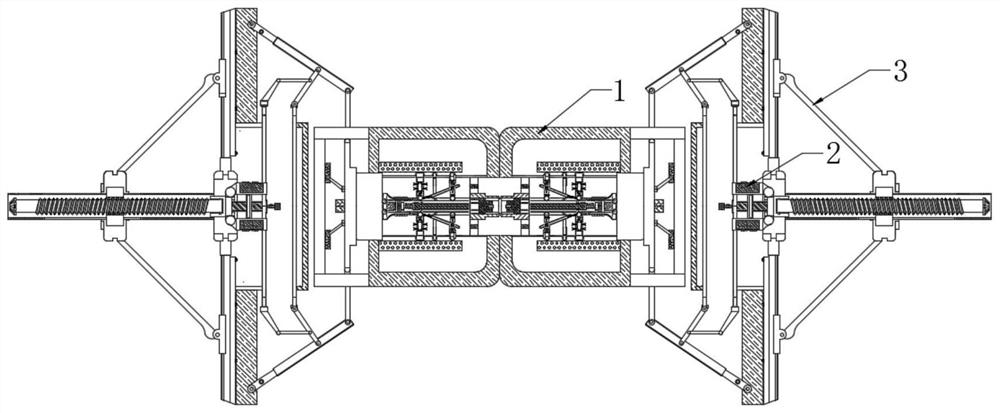

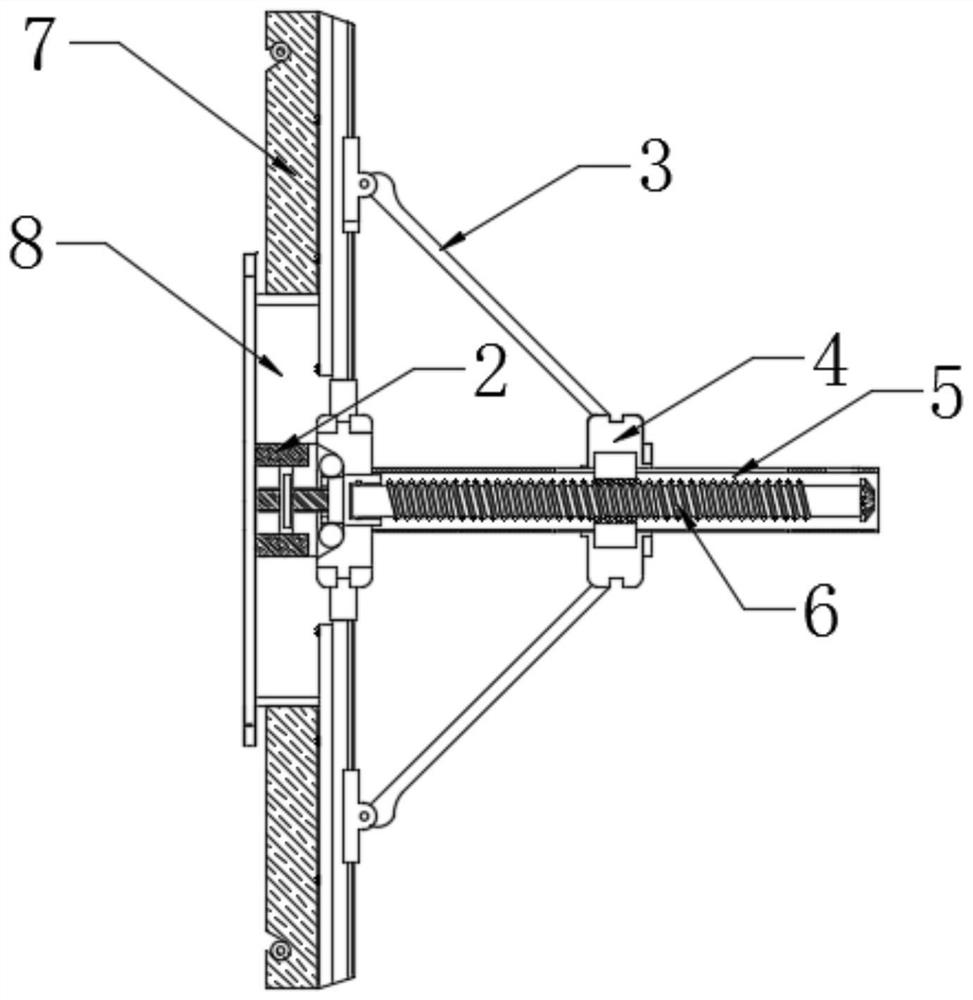

[0027] see Figure 2-Figure 3 ,

[0028] An environmental protection equipment for uniformly painting auto parts in an all-round way, including a main body 1, a metal seat 2, the left and right sides of the main body 1 are movably connected with a stay 3, the center of the stay 3 is movably connected with a fixed seat 4, and the inner side of the fixed seat 4 is movable A frame 5 is installed, a transmission rod 6 is movably installed at the center of the frame 5, a screw rod 7 is movably connected to the outside of the stay 3, a frame 8 is fixedly connected to the outside of the screw rod 7, and a handle is movably connected at the center of the frame 8 and one end away from the fixed seat 4 pole 9.

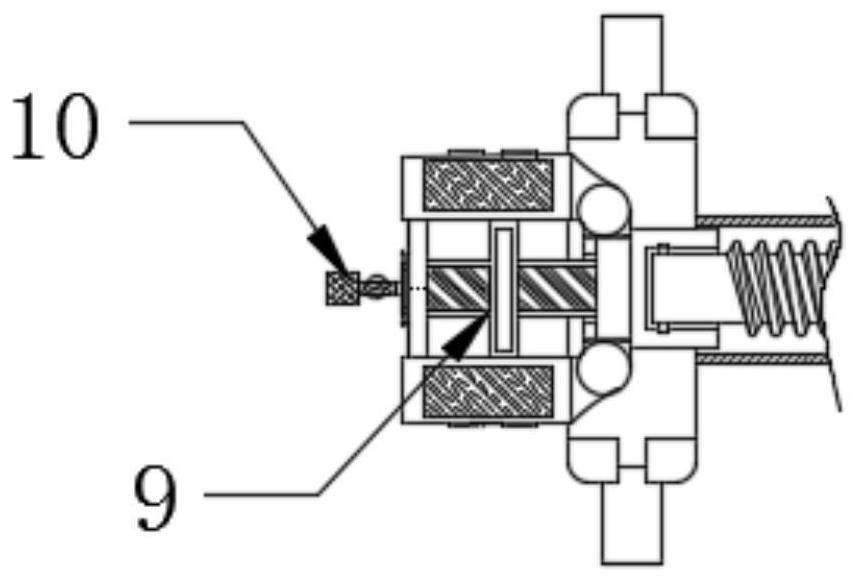

[0029] Further, the metal base 2 includes a workpiece 10, the left end of the workpiece 10 is fixed with a balance frame 11, and the upper end of the balance frame 11 is movably connected with a push block 12, and there are two push blocks 12 in a cylindrical shape. With stabi...

Embodiment 2

[0032] see Figure 5 , an environmental protection equipment for uniformly painting auto parts in all directions, including a main body 1, a metal seat 2, the left and right sides of the main body 1 are movably connected with a stay 3, the center of the stay 3 is movably connected with a fixed seat 4, and the inner side of the fixed seat 4 A frame 5 is movably installed, a transmission rod 6 is movably installed at the center of the frame 5, a screw 7 is movably connected to the outside of the stay 3, a frame 8 is fixedly connected to the outside of the screw 7, and the center of the frame 8 and one end away from the fixed seat 4 is movably connected to a Handle rod 9.

[0033] Further, it also includes a middle bar 13, the top of the middle bar 13 is movably connected with a protective block 14, the bottom of the protective block 14 is movably connected with an auxiliary bar 15 located inside the pushing block 12, and the left end of the auxiliary bar 15 is movably connected ...

Embodiment 3

[0038] see Figure 1-5 :

[0039] An environmental protection equipment for uniformly painting auto parts in an all-round way, including a main body 1, a metal seat 2, the left and right sides of the main body 1 are movably connected with a stay 3, the center of the stay 3 is movably connected with a fixed seat 4, and the inner side of the fixed seat 4 is movable A frame 5 is installed, a transmission rod 6 is movably installed at the center of the frame 5, a screw rod 7 is movably connected to the outside of the stay 3, a frame 8 is fixedly connected to the outside of the screw rod 7, and a handle is movably connected at the center of the frame 8 and one end away from the fixed seat 4 pole 9.

[0040] Further, the metal base 2 includes a workpiece 10, the left end of the workpiece 10 is fixed with a balance frame 11, and the upper end of the balance frame 11 is movably connected with a push block 12, and there are two push blocks 12 in a cylindrical shape. With stability an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com