Ceramic core accurate positioning device for complex hollow turbine blade

A technology of turbine blades and ceramic cores, which is applied in the field of precise positioning devices for ceramic cores for complex hollow turbine blades, can solve the problems of not having an automatic reversing structure, unfavorable positioning of the turbine, and not having structural functions, etc., to achieve improved stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

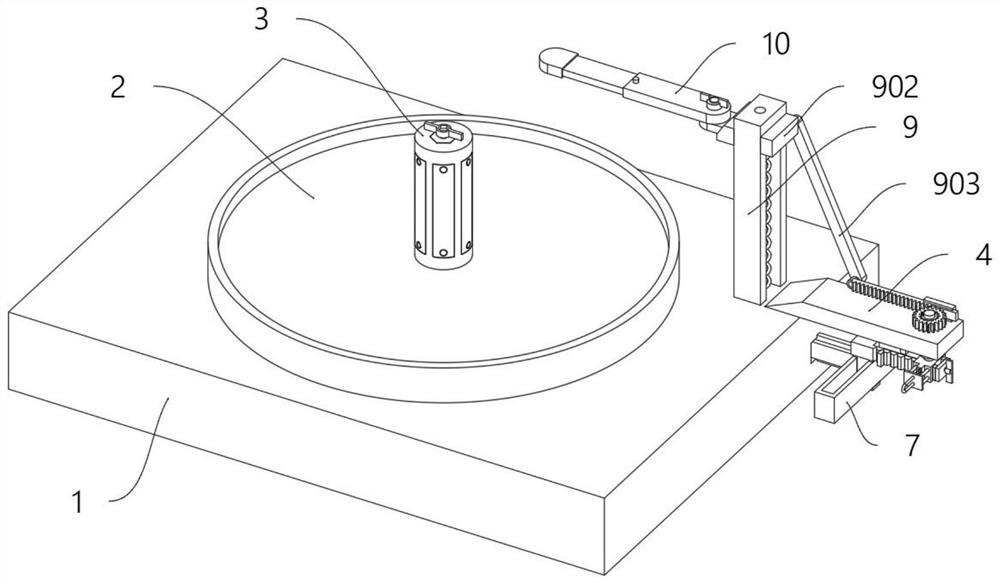

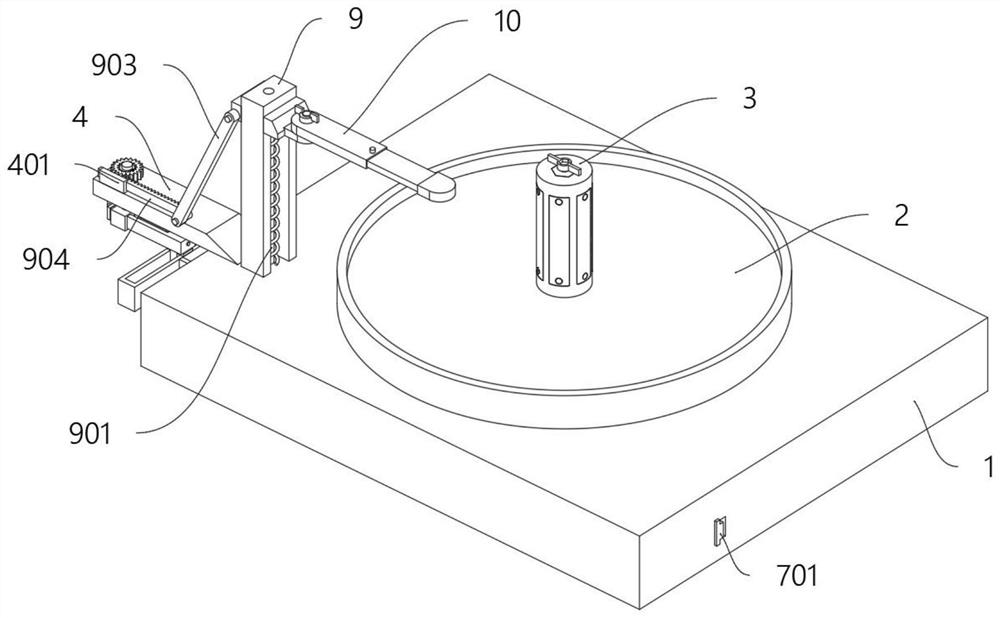

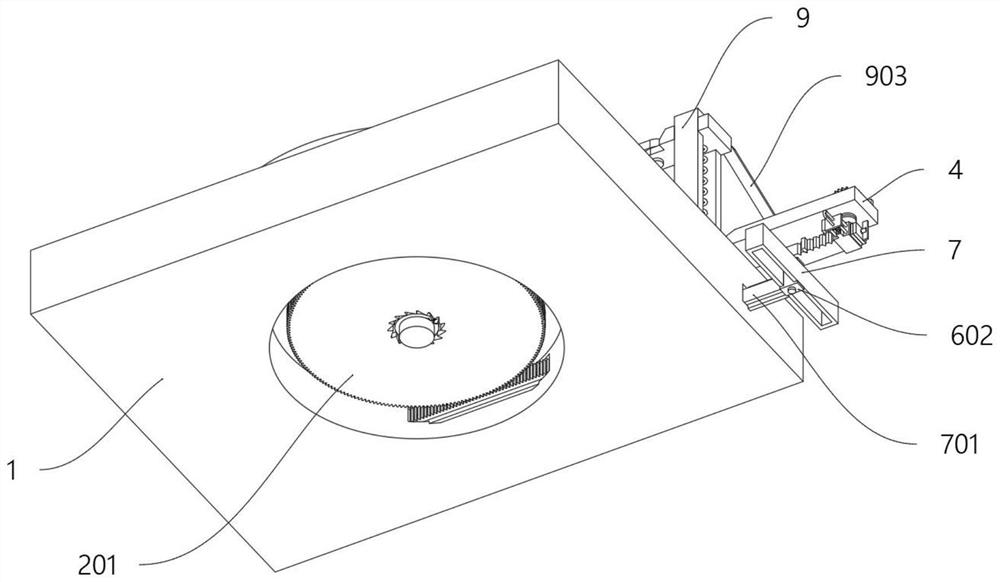

[0032] Example: Please refer to Figure 1 to Figure 8 :

[0033] The present invention proposes a device for precise positioning of ceramic cores for complex hollow turbine blades, which includes: a base 1, a revolving bracket 2 is installed in the middle of the top of the base 1 through a tapered roller bearing, and an inner shaft is fixed at the outer end of the bottom rotating shaft of the revolving bracket 2. Ratchet gear A201, the bottom of the base 1 is provided with a circular groove; the centering device 3 is fixedly arranged in the middle of the top of the revolving bracket 2; the middle of the centering device 3 is provided with a hexagonal through hole, and the centering device 3 The upper and lower ends of the interior are fixed with hexagonal pieces 301; the outside of the centering device 3 is provided with a vertical groove, and the outer end of the hexagonal piece 301 is provided with a spring rod A302 and passes through the vertical groove; the frame bar 4, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com