High-toughness high-thermal-conductivity PBONF-based composite film and preparation method thereof

A composite film and high thermal conductivity technology, applied in the field of thermal conductive composite materials, can solve the problems of low thermal conductivity and toughness, and achieve the effects of high thermal conductivity, high heat dissipation efficiency and low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The present invention also provides a preparation method of the high toughness and high thermal conductivity PBONF-based composite film described in the above technical solution, comprising the following steps:

[0041] (1) Methanesulfonic acid, trifluoroacetic acid and poly-p-phenylene benzobisoxazole micron fibers are mixed, and sodium salt is added to obtain a dispersion of sodium salt and PBONF;

[0042] (2) mixing methanesulfonic acid, trifluoroacetic acid and thermally conductive nanomaterials to obtain a dispersion of thermally conductive nanomaterials;

[0043] (3) Mix the dispersion liquid of sodium salt and PBONF in the step (1) with the dispersion liquid of the thermally conductive nanomaterial in the step (2), pour the dispersion liquid after the uniform mixing into the mould, and cover the The mold is sealed and forms a gel after standing;

[0044] (4) carry out solvent exchange with the gel of described step (3) and water, obtain high toughness and high t...

Embodiment 1

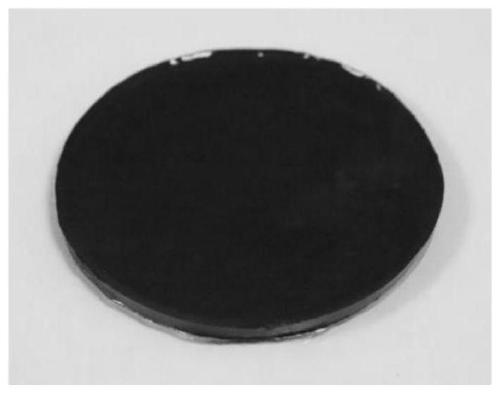

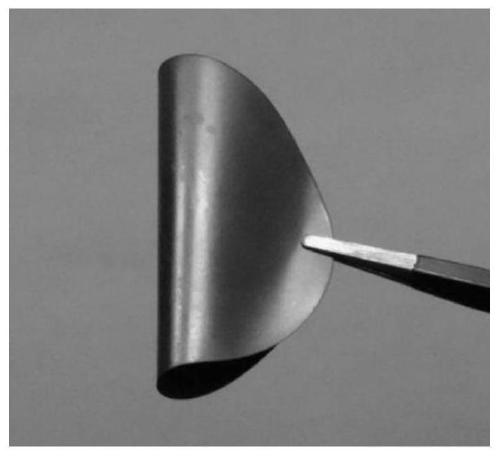

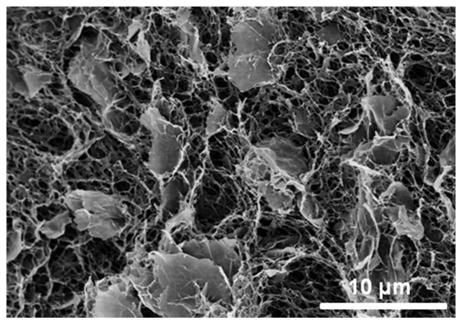

[0060] GNS / PBONF Composite Film

[0061] (1) Weigh 0.216g of commercialized poly-p-phenylenebenzobisoxazole micron fiber, add it to the mixed acid of 7mL methanesulfonic acid and 7mL trifluoroacetic acid, stir mechanically for 8h, then add 1.5g sodium sulfate to form PBONF dispersion containing sodium sulfate;

[0062] (2) Weigh 0.216g of GNS, add it into the mixed acid of 11mL methanesulfonic acid and 11mL trifluoroacetic acid, and ultrasonicate for 3h under the power of 400W to form a uniform GNS dispersion;

[0063] (3) Mix the sodium sulfate-containing PBONF dispersion prepared in step (1) with the GNS dispersion prepared in step (2), mechanically stir it for 2 hours at a speed of 1000 rpm, pour it into a flat-bottomed plastic dish with a diameter of 5.5 cm, and place it in the plastic Cover the dish with a layer of plastic wrap, and let it stand at 5°C for 8 hours to convert into a gel;

[0064] (4) Soak the gel in step (3) in distilled water, trifluoroacetic acid, meth...

Embodiment 2

[0069] Different from Example 1, the mass fraction of GNS is 40%; the thickness of the obtained PBONF-based composite film is 24 μm, and its tensile toughness is 42.4MJ / m 3 , the thermal conductivity is 87.2W / mK, and the density is 1.47g / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com