Improved advance support body and using method thereof

A technology of advanced support and support body, which is used in earth-moving drilling, mine roof support, mining equipment, etc., can solve the problems of roadway personnel safety hazards, support deflection, and unstable walking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

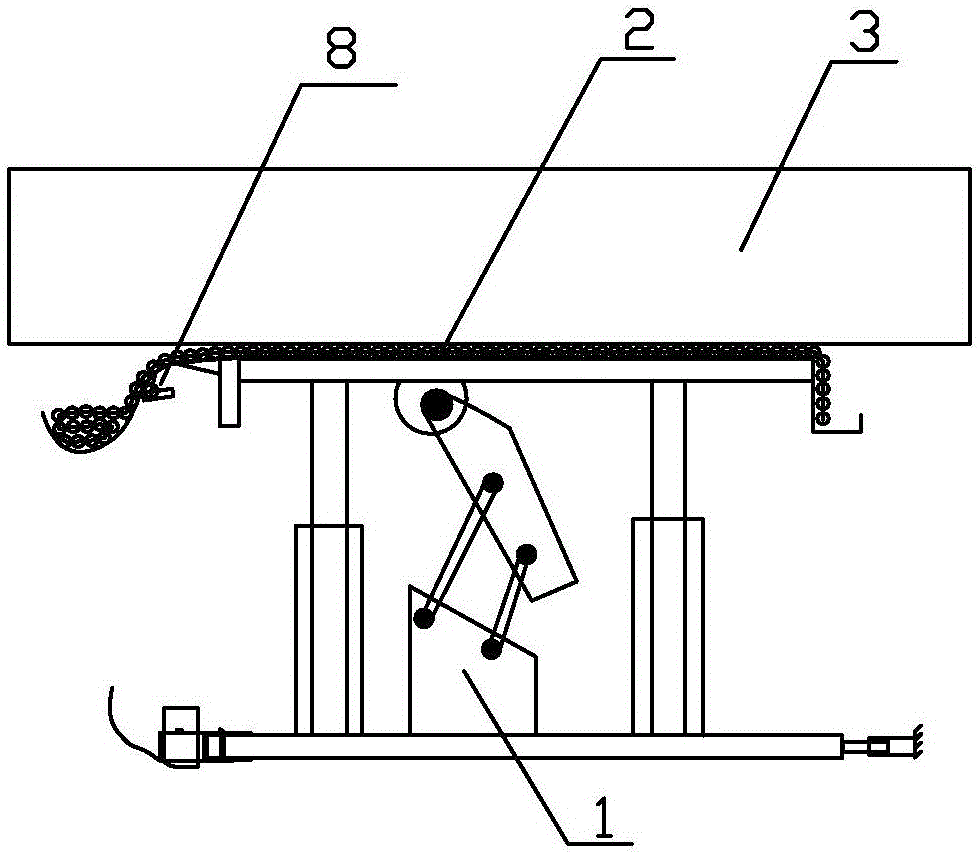

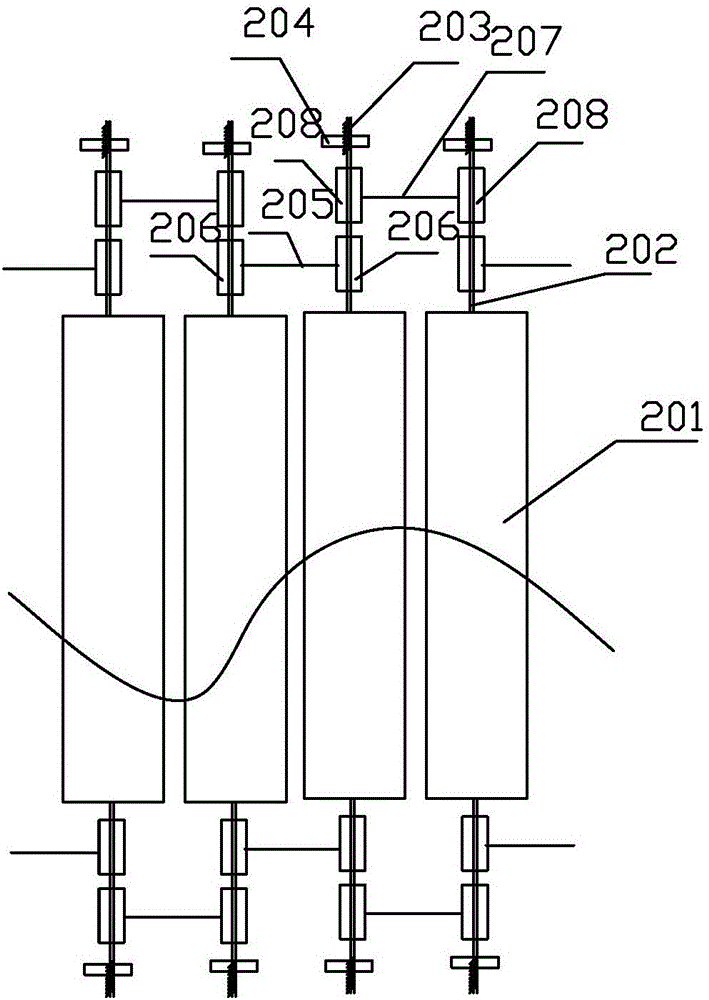

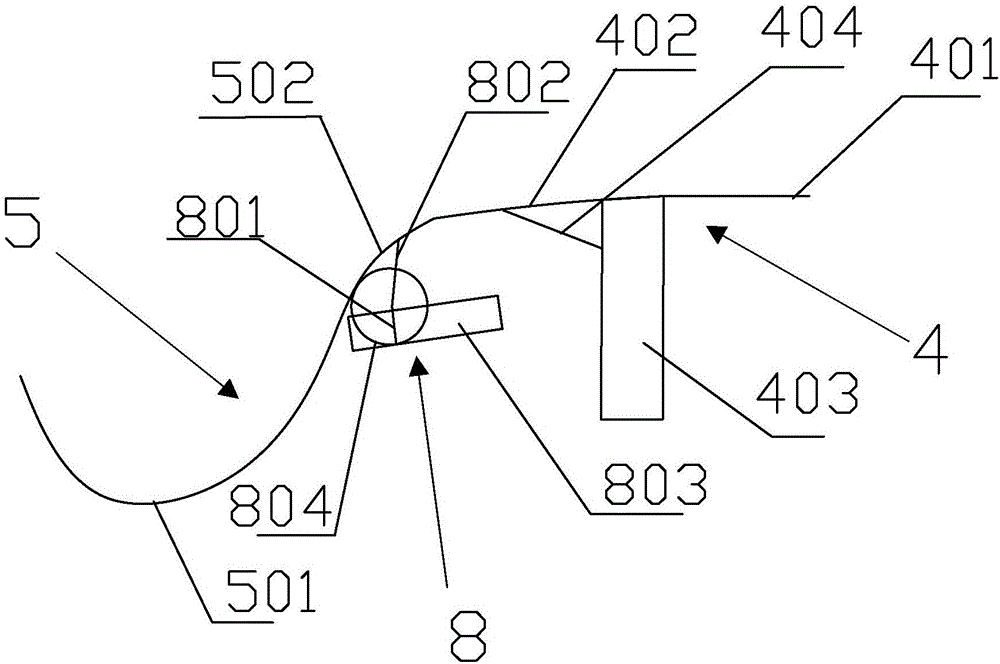

[0055] Such as Figure 1 to Figure 10 As shown, an improved advanced support body includes a roof support body and a bottom plate support body. The roof support body includes an advanced hydraulic support 1 and a cylindrical pressure-bearing row 2. The cylindrical pressure-bearing row 2 is composed of a plurality of cylindrical rollers 201 are formed in series in sequence, and the cylindrical pressure-bearing row 2 is arranged between the top beam of the leading hydraulic support 1 and the roadway roof 3, and the cylindrical roller 201 rolls when the leading hydraulic support 1 advances; when the roadway roof 3 and the leading hydraulic support A cylindrical pressure-bearing row 2 is laid between the top beams of 1, so that the pressure can be directly carried in the form of rolling friction, and the leading hydraulic support 1 can be pushed from behind through the jack, so that there is no need to release and repressurize, and it can be pushed forward directly in this way , w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com