Box-type connecting joint

A technology for connecting joints and boxes, which is applied to bridge parts, bridges, buildings, etc., to achieve precise positioning, strong joint structure reliability, and easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below with reference to the accompanying drawings and examples.

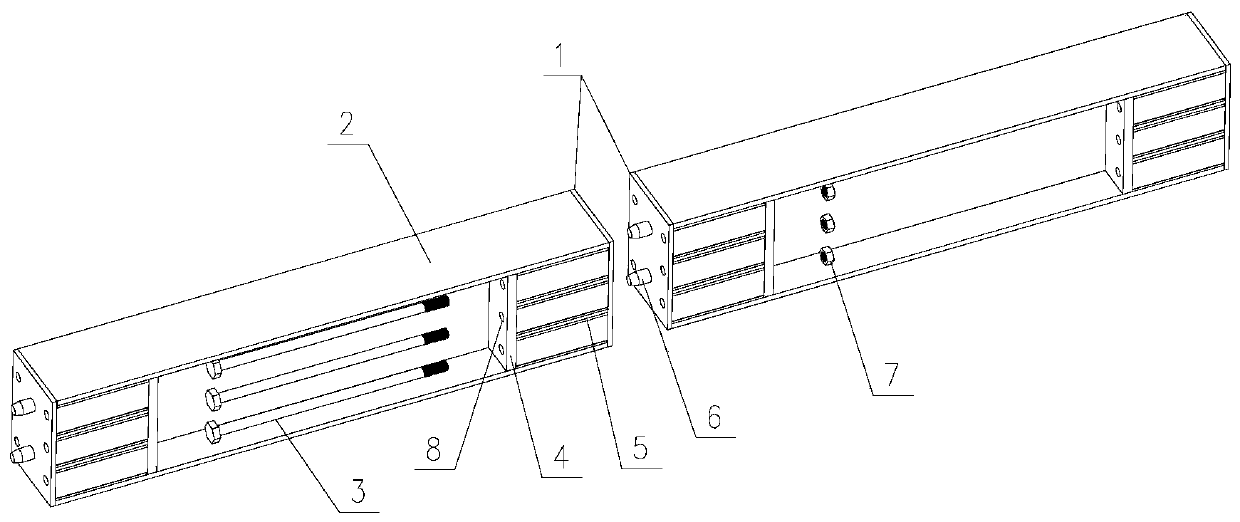

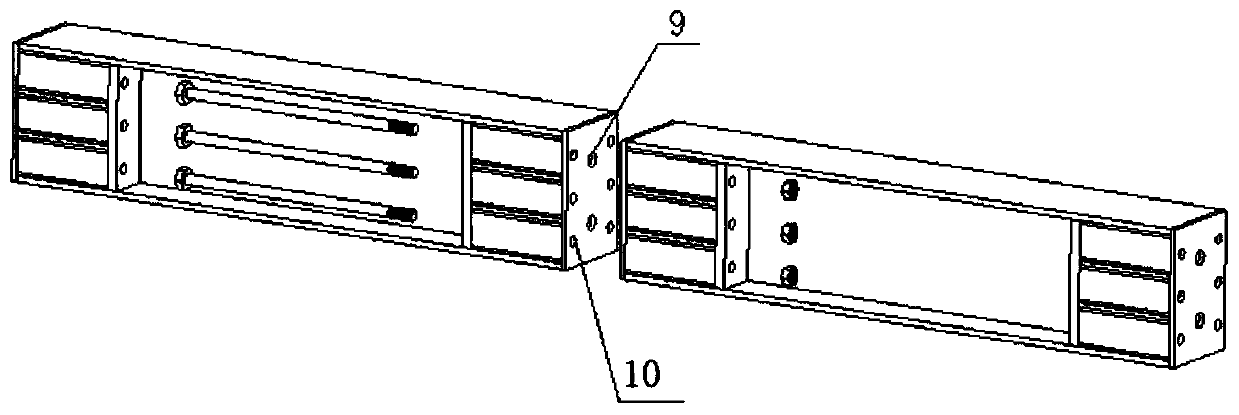

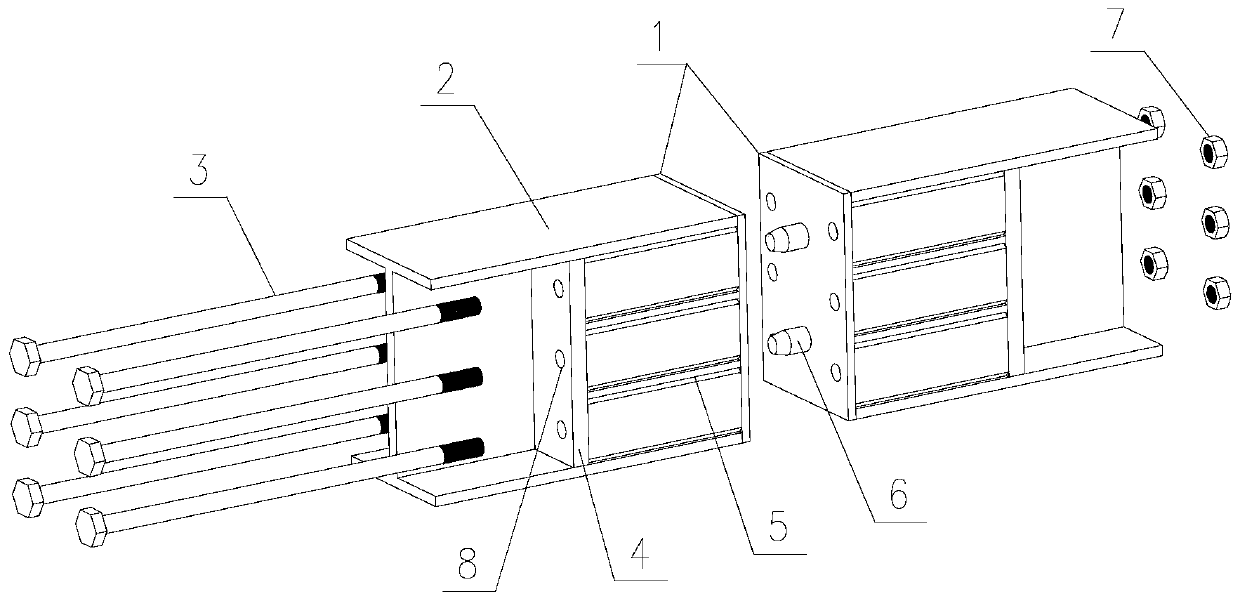

[0022] This embodiment provides a box-type connecting joint, see the attached Figure 1-3 , including: joint main body 2, end sealing plate 1, transverse reinforcement rib 4, longitudinal reinforcement rib 5 and positioning pin 6;

[0023] The joint body 2 is an I-shaped beam;

[0024] The two end sealing plates 1 are respectively fixed on the longitudinal ends of the joint body 2 by welding, so that the two sides of the web of the joint body 2 form a rectangular cavity with openings on two symmetrical sides (surfaces opposite to the web); and each The end sealing plate 1 is processed with three bolt through holes B10 arranged side by side in the vertical direction and two positioning pin holes 9 opposite to the web of the joint body 2, which communicate with the corresponding rectangular cavity;

[0025] After the two positioning pins 6 respectively pas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com