Micro-electromechanical system (MEMS) microphone and packaging method thereof

A packaging method and microphone technology, which are applied to sensor parts, sensors, electrostatic transducer microphones, etc., can solve the problems of high production cost, poor reliability, and difficulty in implementation, and achieve low cost, low manufacturing cost, and reliable structure. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

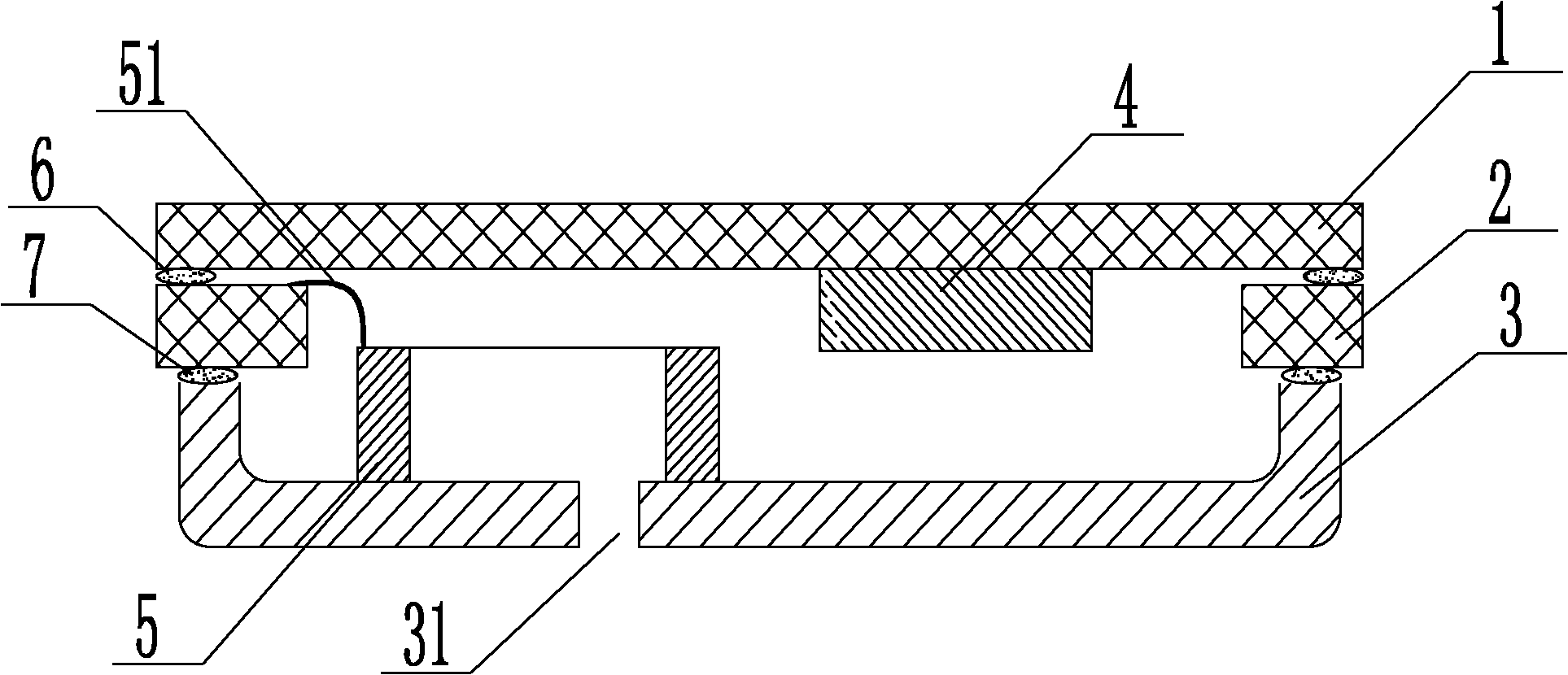

[0030] figure 1 It is a structural schematic diagram showing Embodiment 1 of the MEMS microphone according to the present invention.

[0031] Such as figure 1 As shown, the MEMS microphone related to the present invention includes a circuit board substrate 1, a circuit board frame 2 and a grooved cover 3 forming a MEMS microphone frame structure, wherein the circuit board frame 2 hollowed out in the middle and the grooved cover 3 are combined to form a MEMS microphone The slot-shaped shell, the circuit board substrate 1 and the slot-shaped cover 3 are respectively fixedly installed on the upper and lower surfaces of the circuit board frame 2, and the slot-shaped cover 3, the circuit board frame 2 and the circuit board substrate 1 are combined to form the cavity of the MEMS microphone structure.

[0032] Wherein, the trough-shaped cover 3 is made of metal.

[0033] The ASIC chip and the MEMS acoustic chip are respectively arranged on the circuit board substrate 1 and the tro...

Embodiment 2

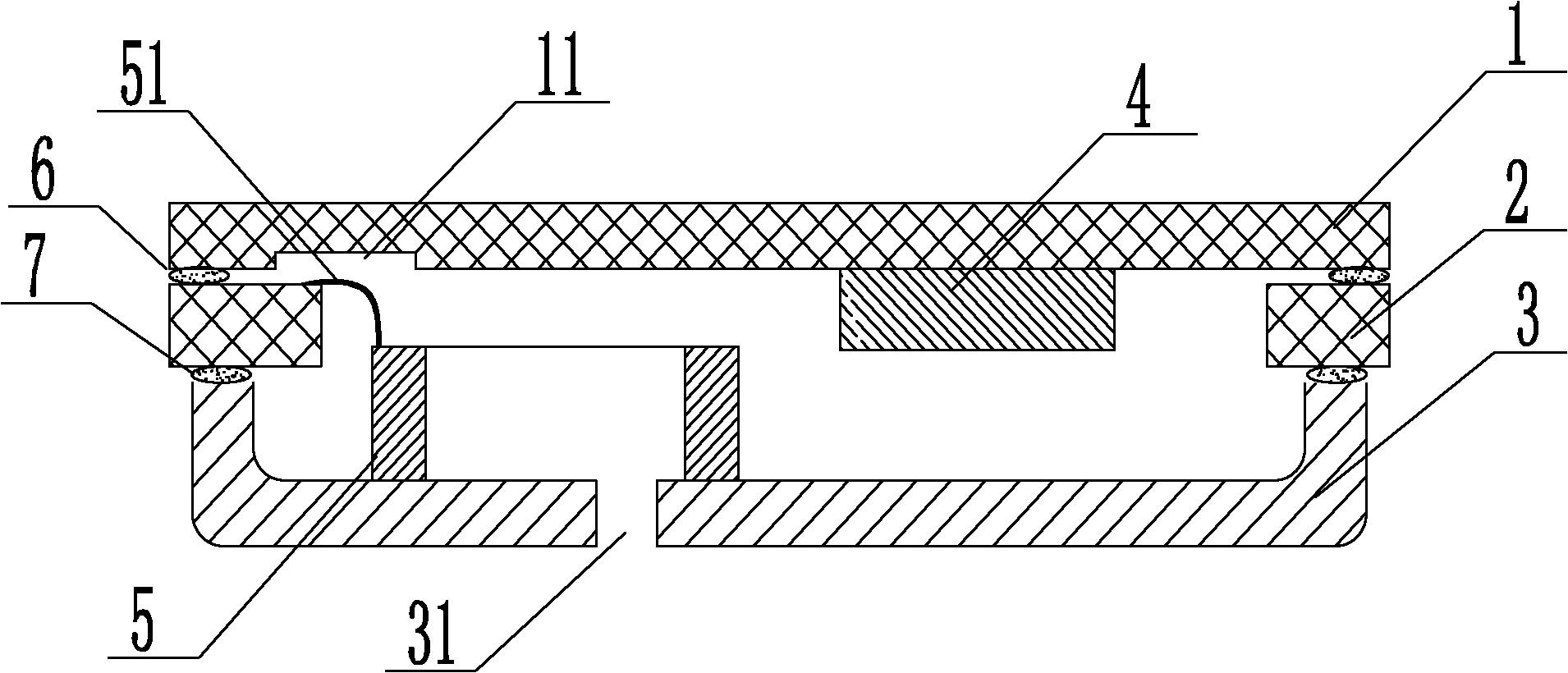

[0043] figure 2 It is a structural schematic diagram showing Embodiment 2 of the MEMS microphone of the present invention.

[0044] On the basis of the first embodiment above, the present invention can also make the following figure 2 Another improvement shown in figure 2 In the MEMS microphone packaging structure shown, the circuit board substrate 1 is provided with a recess 11 for accommodating the metal wire 51 at a position close to the metal wire 51 . The setting of the recess 11 can facilitate the connection and fixation of the metal wire 51, so that the metal wire 51 will not be affected by the packaging of the circuit board substrate 1 and the circuit board frame 2, and reduce the product height of the MEMS microphone as a whole.

[0045] And, the ASIC chip 4 (or MEMS acoustic chip 5) that is arranged on the circuit board substrate 1 is arranged on the side of the circuit board substrate 1 away from the recess 11, so that it can ensure that the distribution is arr...

Embodiment 3

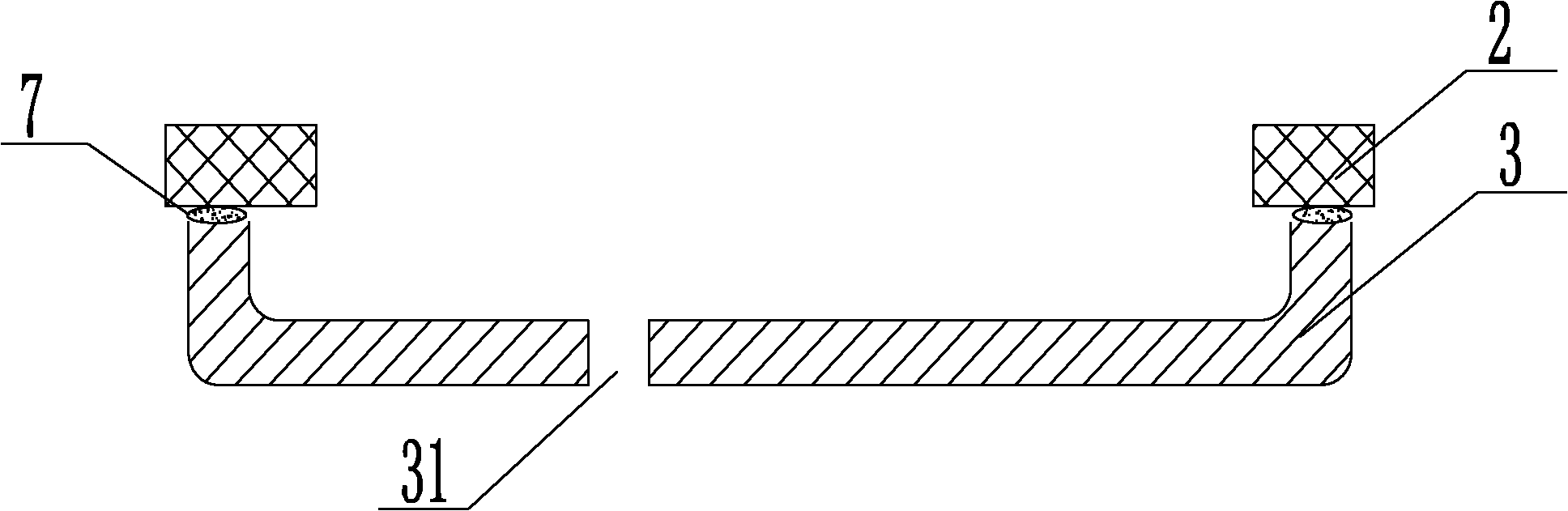

[0060] Figure 7 It is a structural schematic diagram showing Embodiment 3 of the MEMS microphone of the present invention.

[0061] On the basis of the first embodiment above, the present invention can also make the following Figure 7 Another improvement shown in Figure 7 Among them, the MEMS microphone includes a groove-shaped housing composed of a circuit board frame 2 hollowed out in the middle and a flat metal cover 3. One surface of the circuit board frame 2 is fixedly mounted on the cover 3, and the other surface is fixedly mounted on a circuit board. On the substrate 1, the cover 3, the circuit board frame 2 and the circuit board substrate 1 constitute the cavity structure of the MEMS microphone, the ASIC chip 4 is installed on the surface of the circuit board substrate 1 inside the cavity, and the cover 3 inside the cavity is installed on the surface The MEMS acoustic chip 5, the electrodes of the MEMS acoustic chip 5 are connected to the circuit board frame 2 thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com