Coating compound machine and compound technology of film

A laminating machine and film technology, applied in layered products, lamination devices, lamination and other directions, can solve the problems that the release film cannot be reused, increase the cost of film lamination, low production efficiency, etc., and achieve strong structural reliability, Easy to operate and use, improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

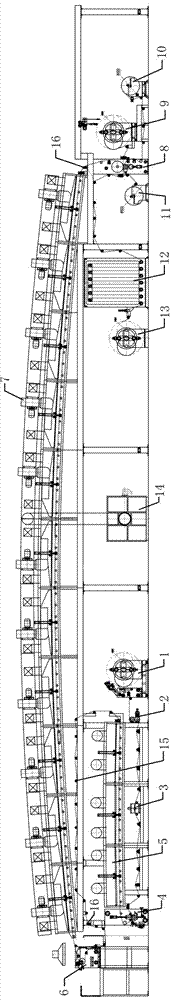

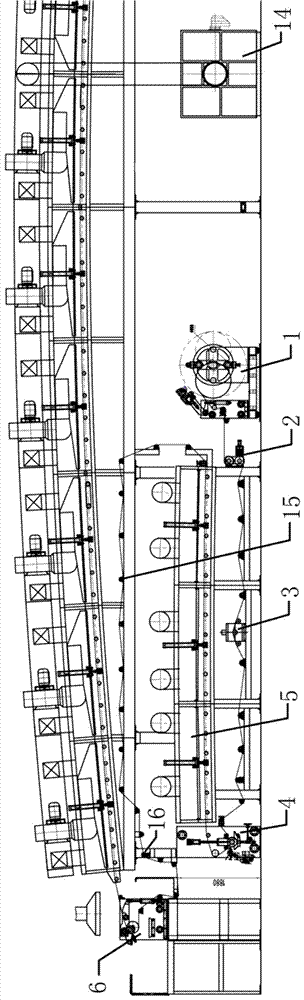

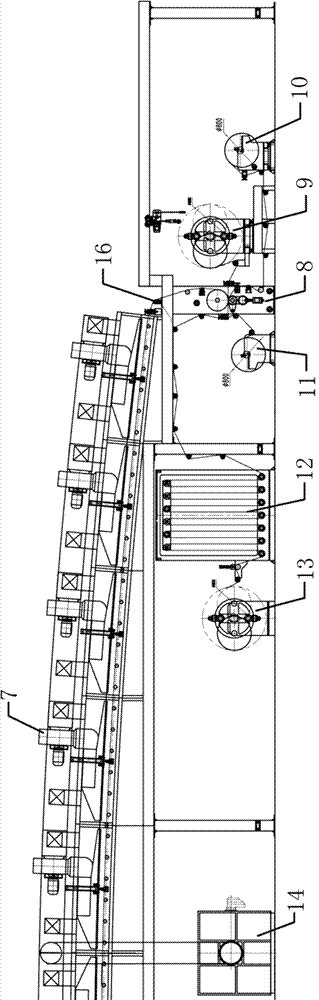

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0023] Such as Figure 1-3 Shown, a kind of film coating compound machine, it comprises substrate unwinding device 1, traction device 2, corona treatment device 3, anilox coating device 4, lower oven 5, comma scraping device 6, upper oven 7 , composite device 8, dipped fiber unwinding device 9, glass fiber Teflon unwinding device 10, glass fiber Teflon rewinding device 1311, storage rack 12 and rewinding device 13; lower oven 5 and upper oven 7 Connected with the hot blast stove 14; the base material is unwound from the base material unwinding device 1 and is pulled by the traction device 2 and then passes through the corona treatment device 3, the anilox coating device 4, the lower oven 5, the comma scraping device 6, and the upper oven 7. Composite device 8, the dipped fiber layer is unwound from the dipped fiber unwinding device 9 and composited with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com