Super-deep hole double-tube drilling directional drilling rig

A directional drilling rig and ultra-deep hole technology, applied in directional drilling, percussion drilling, rotary drilling and other directions, to achieve the effect of improving climbing ability, high overall strength and improving coal mining efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing this embodiment will be further described

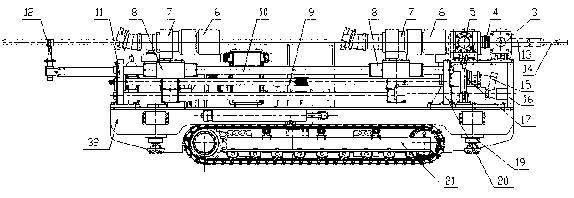

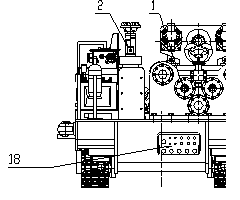

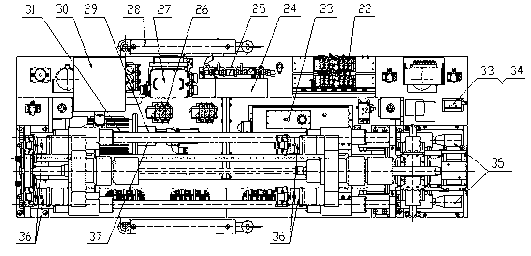

[0021] Depend on Figure 1-2It can be seen that the front vehicle frame 32 is based on the front vehicle, and each mechanism component is fixed on it with a connecting piece. Wherein both sides are equipped with walking device 21 and ground anchor cylinder 28; its front and rear respectively two lower supporting oil cylinders 19, each upper supporting oil cylinder 2 in the left front and left rear, two front supporting oil cylinders 35 in the front, respectively used for stabilizing the drilling rig, Provide support guarantee for drilling. Front vehicle frame 32 right sides arrange front holder 3, blocking device 4, shackle 5, holder 6, speed reducer 7, pulley 8, double motor 36 and support bar mechanism 12 successively from front to back. Wherein the holder 3 is fixed on the bracket 16 on the front frame 32 with a connecting piece; the blocking device 4 is fixed on the shackle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com