Coal mining roadway

A technology of roadway and coal seam, applied in the field of coal mining, can solve the problems of damage to the side guard plate of the support, difficult support, large working face inclination, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

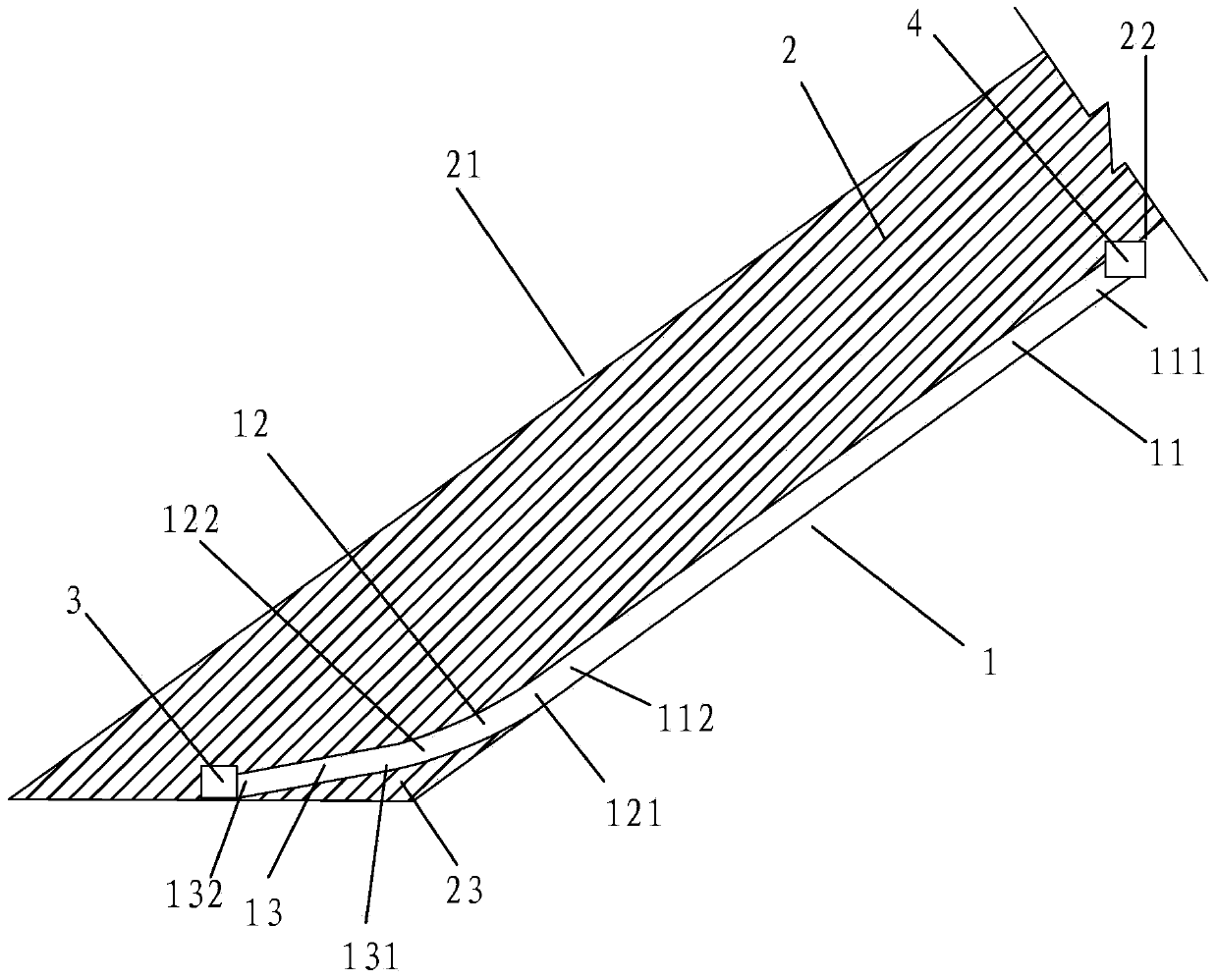

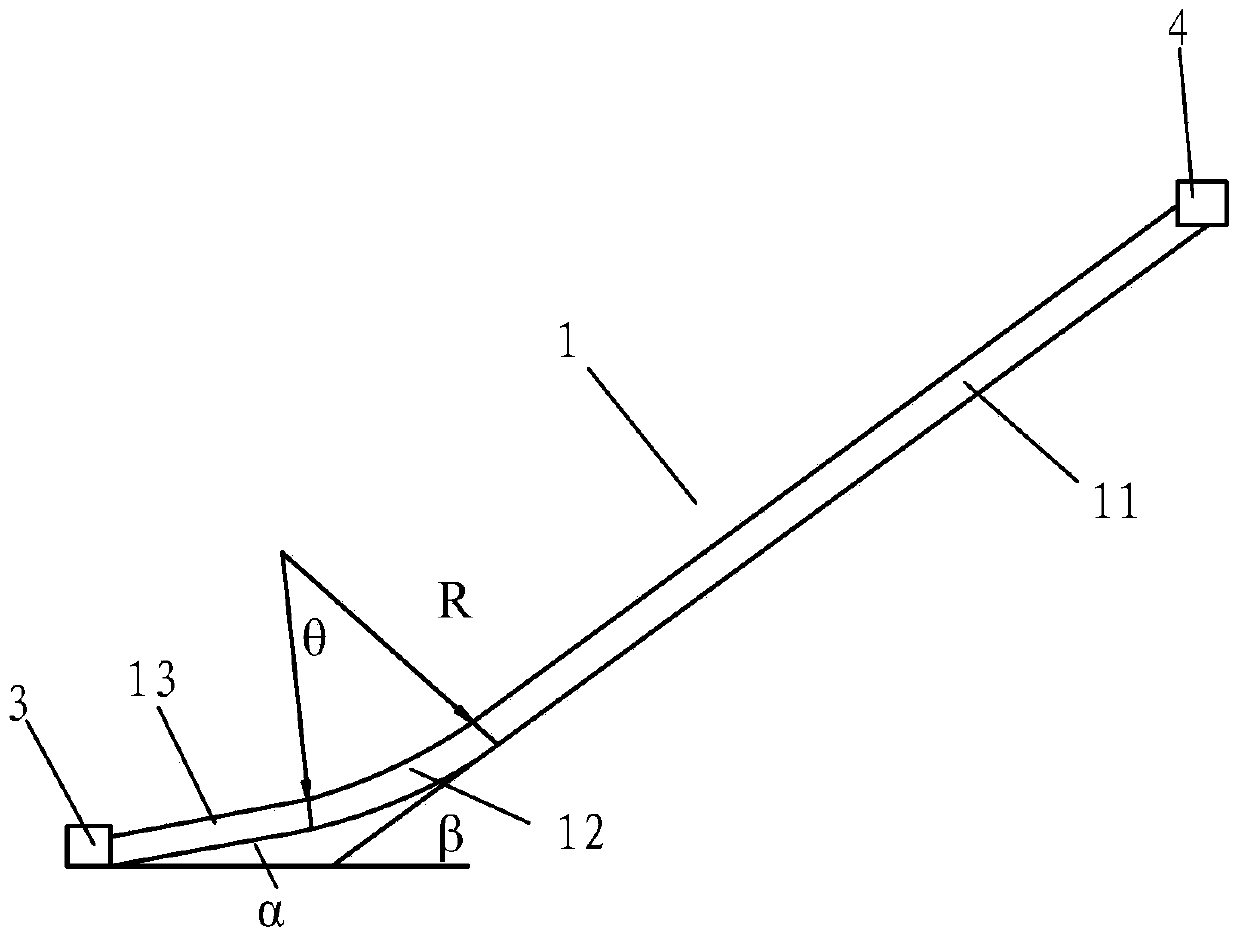

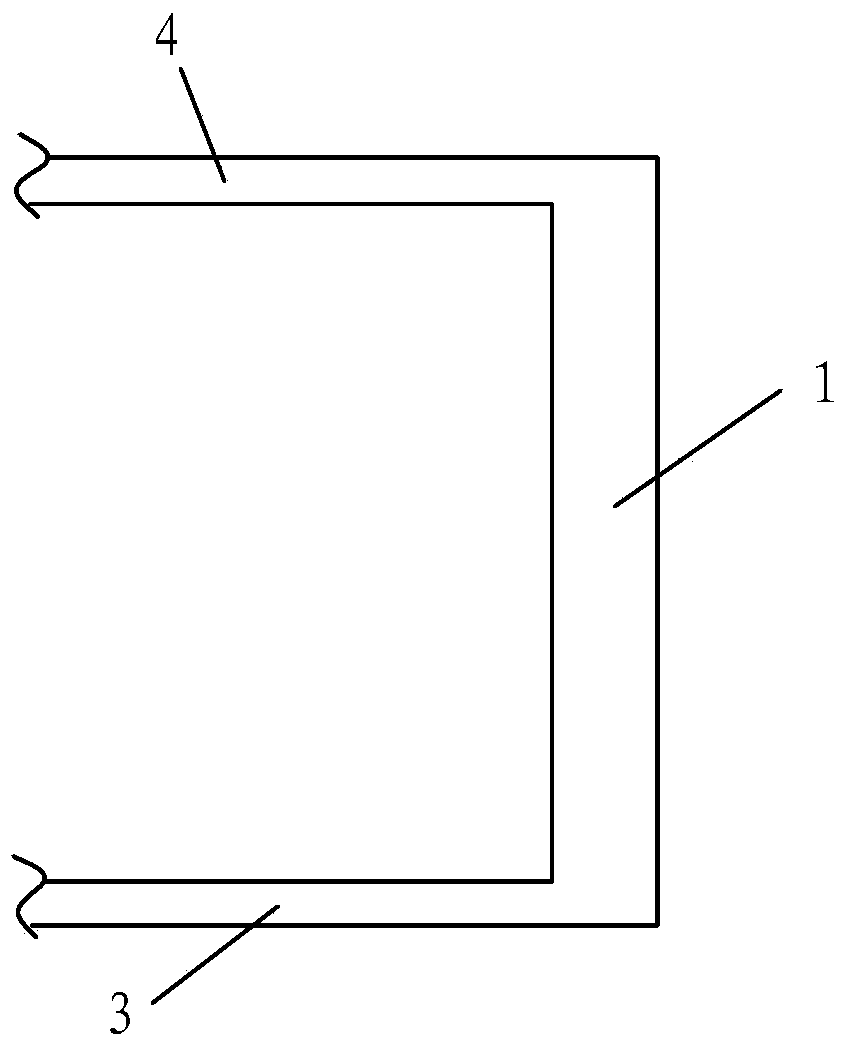

[0045] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

[0046] The coal mining roadway provided by the invention is mainly used in coal seam mining where the inclination angle of the coal seam is greater than or equal to 25°. The fully-mechanized caving face involved in the present invention is a comprehensive mechanized top-coal caving mining face, that is, on the basis of an ordinary fully-mechanized mining face with a sufficiently thick coal seam, a high-power scraper conveyor is erected from behind the hydraulic support, so as to use to carry the coal away. Fully-mechanized caving means that all equipment is comprehensively placed on the common fully-mechanized mining face. The fully mechanized mining face is the back mining face equipped with comprehensive mechanized equipment in underground coal mines.

[0047] Such as Figure 1-3 As shown, the present invention provides a coal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com