Adverse feedback conveying system for working face of underground coal mine

A conveying system and working face technology, applied in mining equipment, underground transportation, mining equipment, etc., can solve the problems of complexity, poor adaptability of monitoring equipment, and difficulty in collecting working information, so as to prevent pressure slippage, improve coal mining efficiency, The effect of reducing equipment wear and power loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

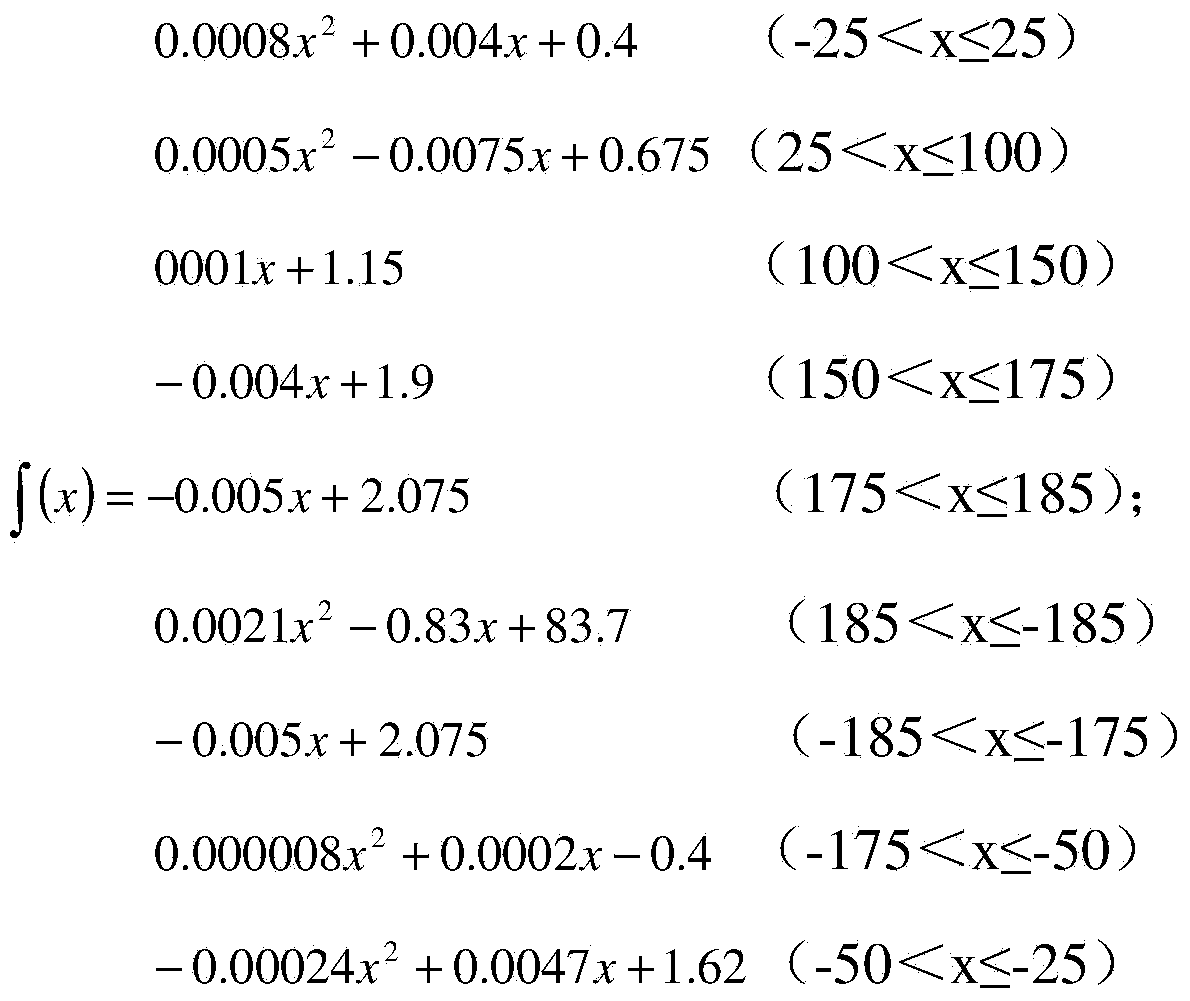

Method used

Image

Examples

Embodiment Construction

[0040] The invention provides a reverse feedback conveying system for coal mine underground working face equipment, which includes a coal shearer, a scraper conveyor, a loader, a crusher, and a belt conveyor, and also includes a control box, which is connected to the belt conveyor respectively. machine, crusher, loader and scraper conveyor, and also includes a coal volume detection device installed on the loader, which is connected with the control box to provide information on the coal volume of the loader, and also includes coal mining The shearer positioning device is connected with the control box so as to provide the position and forward direction information of the shearer relative to the scraper conveyor.

[0041] It also includes a driving part monitoring device, which is respectively connected with the driving part of the transfer machine and the driving part of the scraper conveyor to obtain their torque information, and the driving part monitoring device is also conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com