Hydraulic drilling and bursting exploitation method for ultra-thin coal seam

A technology of ultra-thin coal seam and mining method, applied in the field of hydraulic drilling and blasting mining of ultra-thin coal seam, can solve the problems of high excavation rate of 10,000 tons, poor economic benefit, low coal recovery rate, etc. The effect of improving coal mining efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

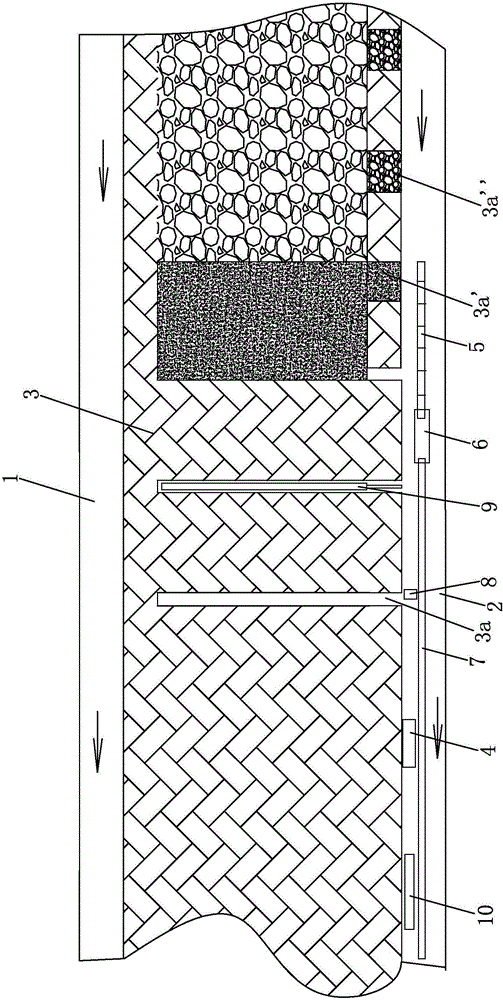

[0019] Such as figure 1 As shown, a very thin coal seam hydraulic drilling and blasting mining method is characterized in that it comprises the following steps:

[0020] Step a: Excavate wind tunnel 1 and mechanical tunnel 2 in the extremely thin coal seam, and make wind tunnel 1 and mechanical tunnel 2 form independent ventilation, water supply, power supply and other systems, wherein mechanical tunnel 2 is located below wind tunnel 1, and mechanical tunnel 2 The coal seam area between the wind lane 1 is the coal mining face 3 . In this case, the coal seam mining adopts the method of retaining coal pillars along the goaf with double lanes. This method is an existing mature technology, and the air lane 1 and machine lane 2 can be well supported and ensure the safety of all operators. After the wind lane 1 and machine lane 2 are dug and set up, place the fol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com