Fully mechanized coal mining face coal rock identification device and method

A fully-mechanized mining face and coal-rock identification technology, applied in earthwork drilling, testing machinery, cutting machinery, etc., can solve problems such as inability to adjust height adaptively, achieve the effect of improving efficiency and reliability, and improving work accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The technical solution of the present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments of the description:

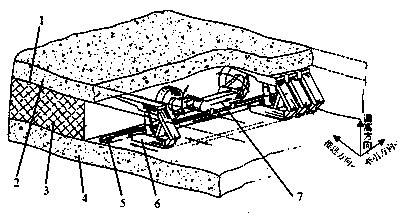

[0054] Such as figure 1 As shown, the scraper machine 5 is the running track of the coal shearer 7, and the coal shearer 7 reciprocates on the scraper machine 5 to cut the coal seam 3, and the coal lumps fall onto the scraper machine 5 to be transported out of the working face, and the coal mining When cutting, the drum of machine 7 adjusts the mining height according to the coal-rock boundary line 1, and the scraper machine 5 moves the coal shearer 7 in the advancing direction to form a goaf, and at the same time, the oil cylinder at the bottom of the scraper machine 5 pulls the hydraulic support 6 Complete the support of the goaf, reciprocating operation, and complete the mining of coal.

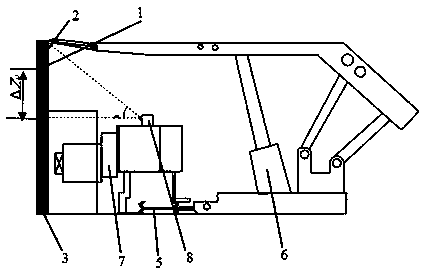

[0055] Such as figure 2 As shown, the inertial navigation device 9 and the explosion-proof box 8 are instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com