Patents

Literature

109results about How to "Eliminate exposure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

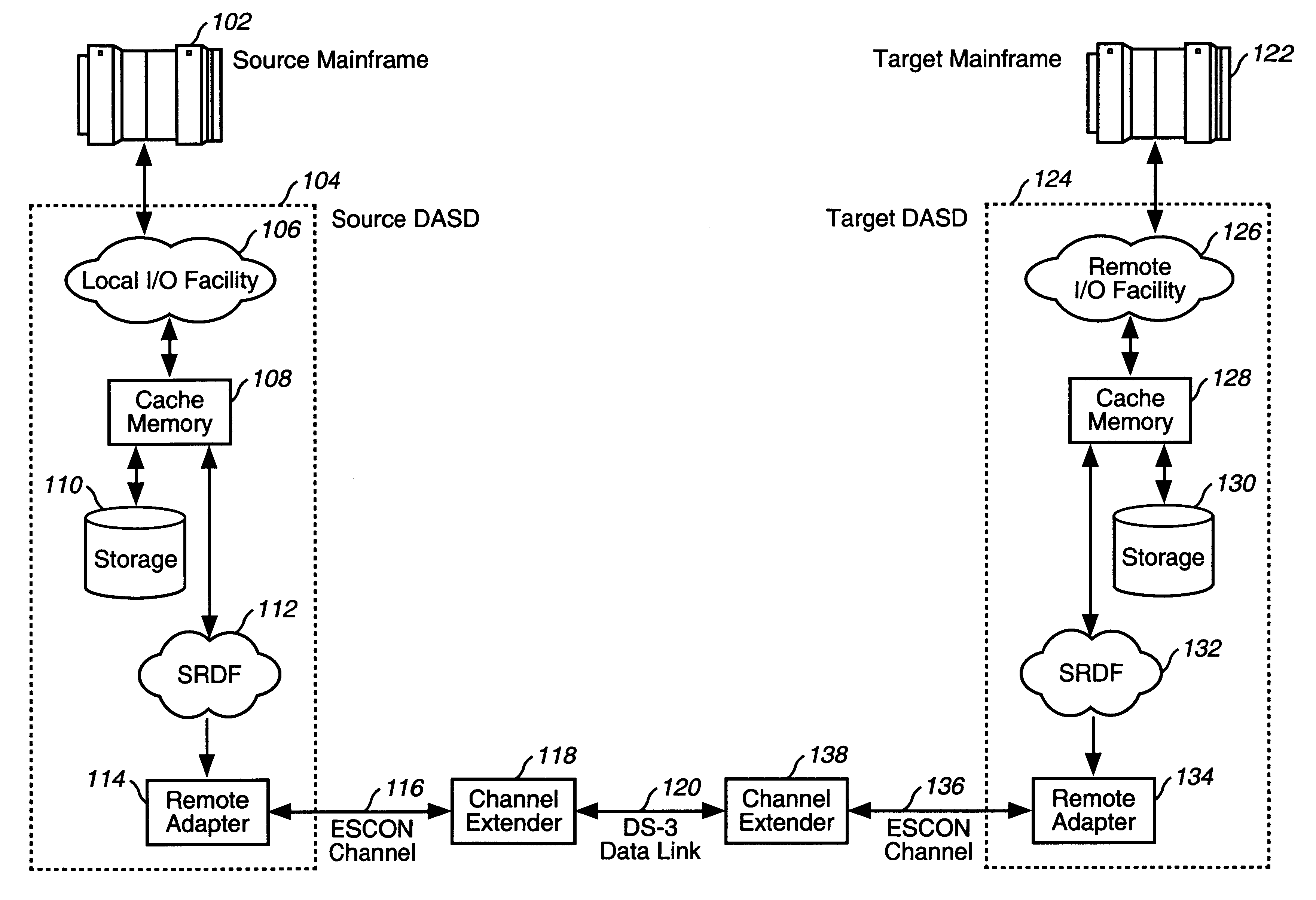

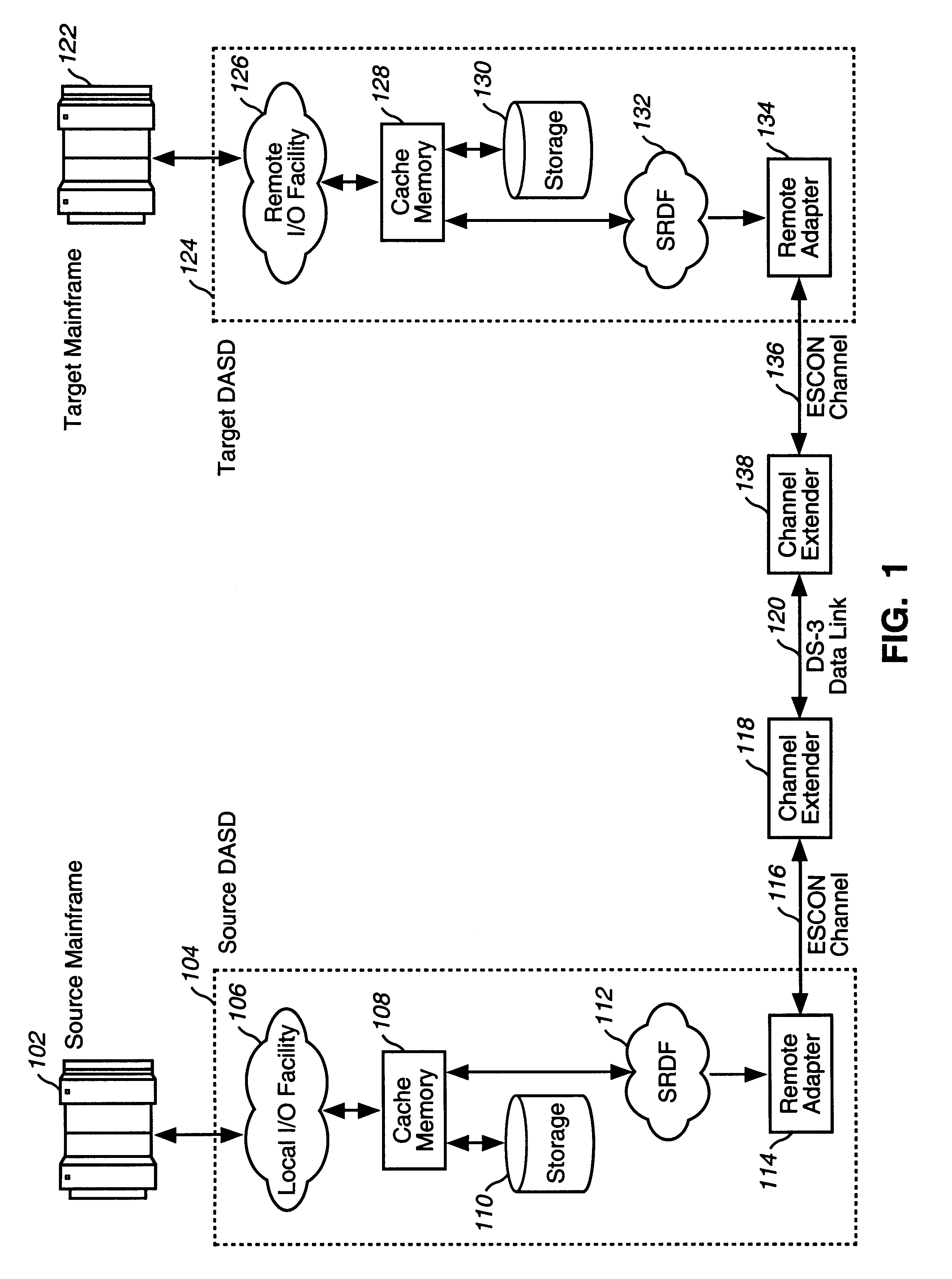

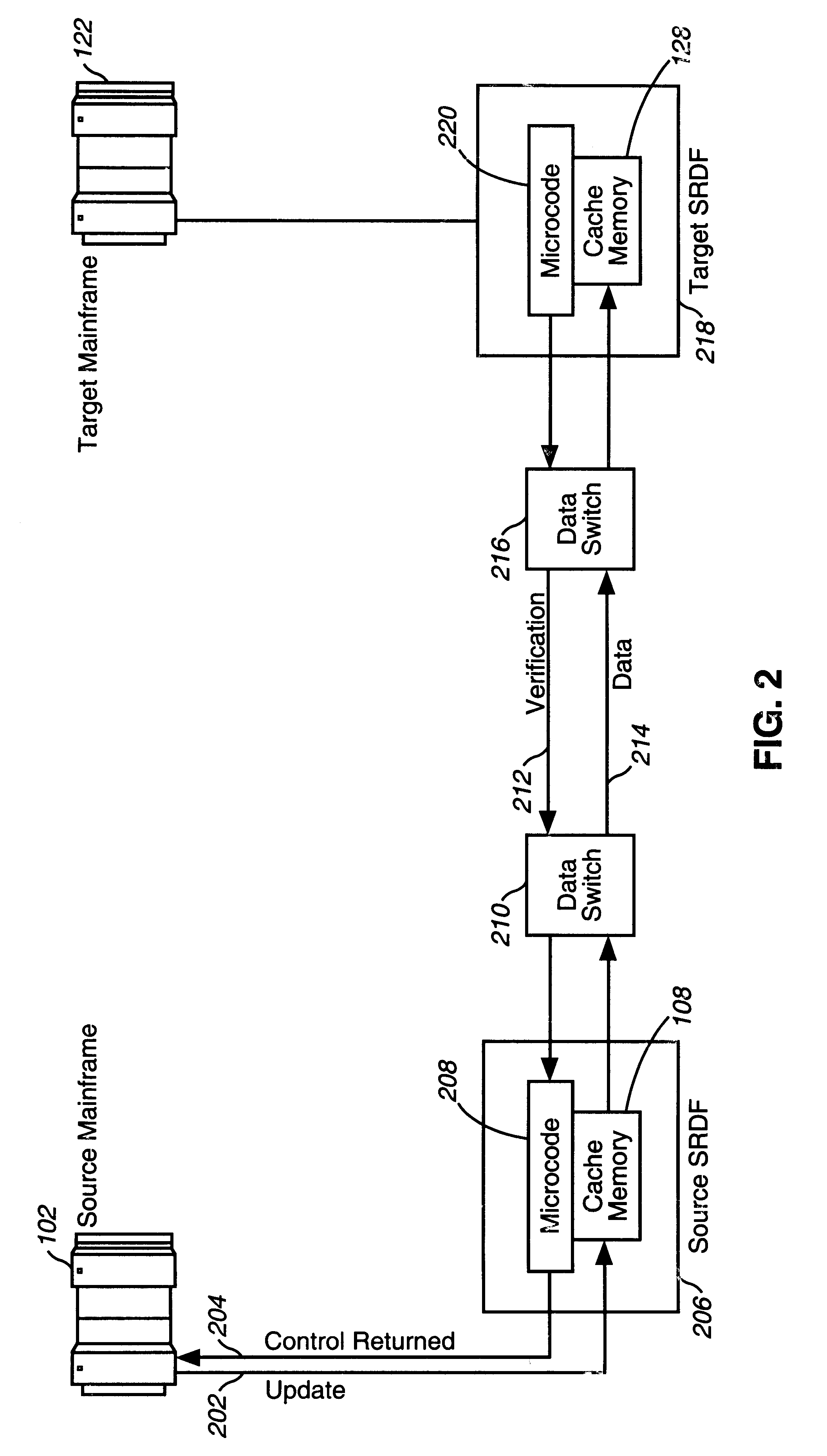

Data center migration method and system using data mirroring

InactiveUS6405294B1Save resource costLow costInput/output to record carriersRedundant operation error correctionSystem usageApplication software

A method and system for migrating computer applications and volumes of data from a source DASD connected to a source computer system to a target DASD connected to a target computer system. The method comprises ensuring data integrity on the source DASD, initiating one or more processes to mirror all data and all data updates from the source DASD to the target DASD, ensuring synchronization of data updates to the source DASD by the source computer system with data updates to the target DASD, deactivating all applications executing on the source computer system, mirroring one or more remaining data updates to the source DASD by the source computer system to the target DASD, disconnecting the source computer system and the source DASD from the target computer system and the target DASD; and bringing the target computer system and the applications executing on the target computer system on-line.

Owner:VERIZON PATENT & LICENSING INC

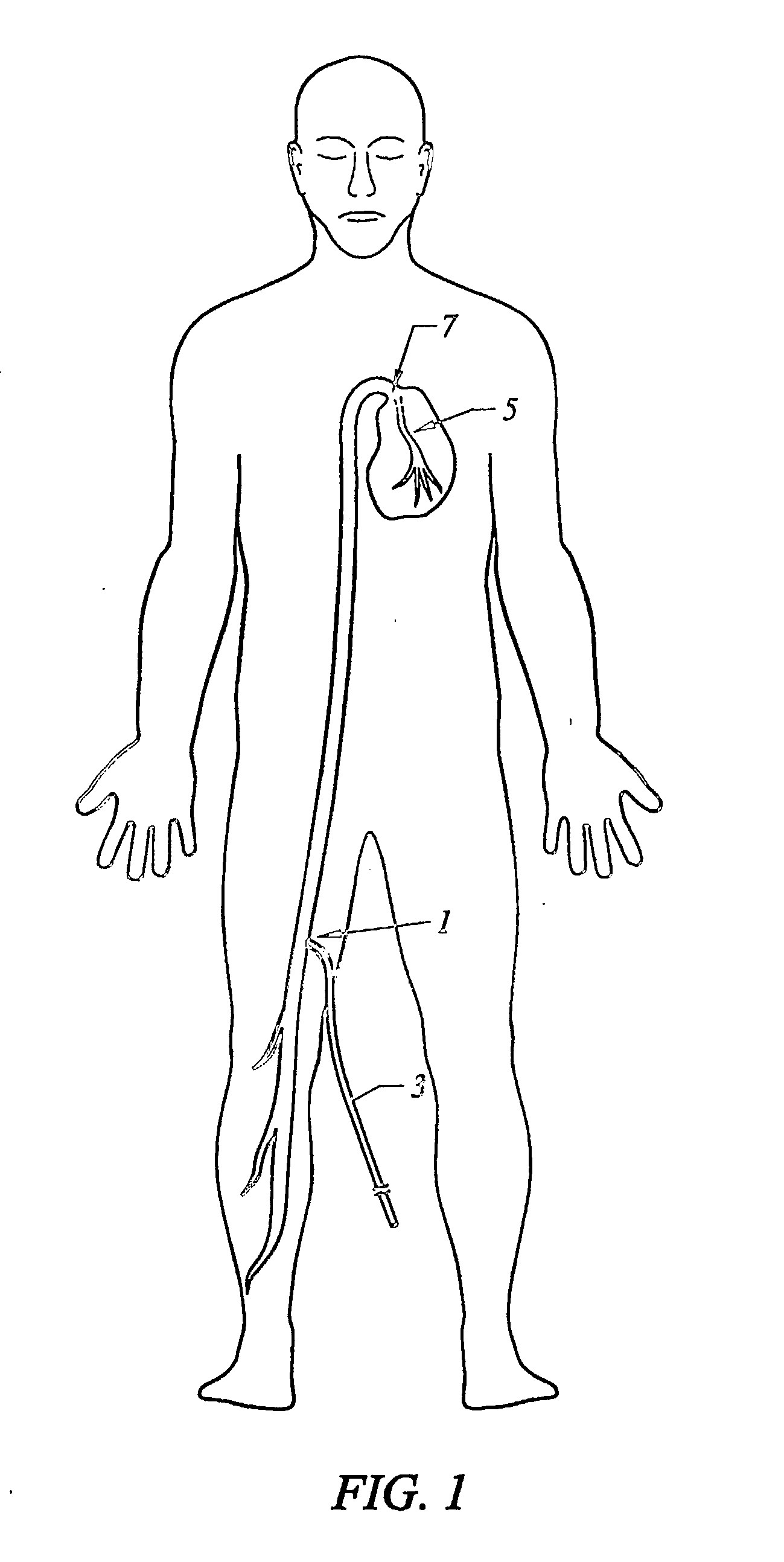

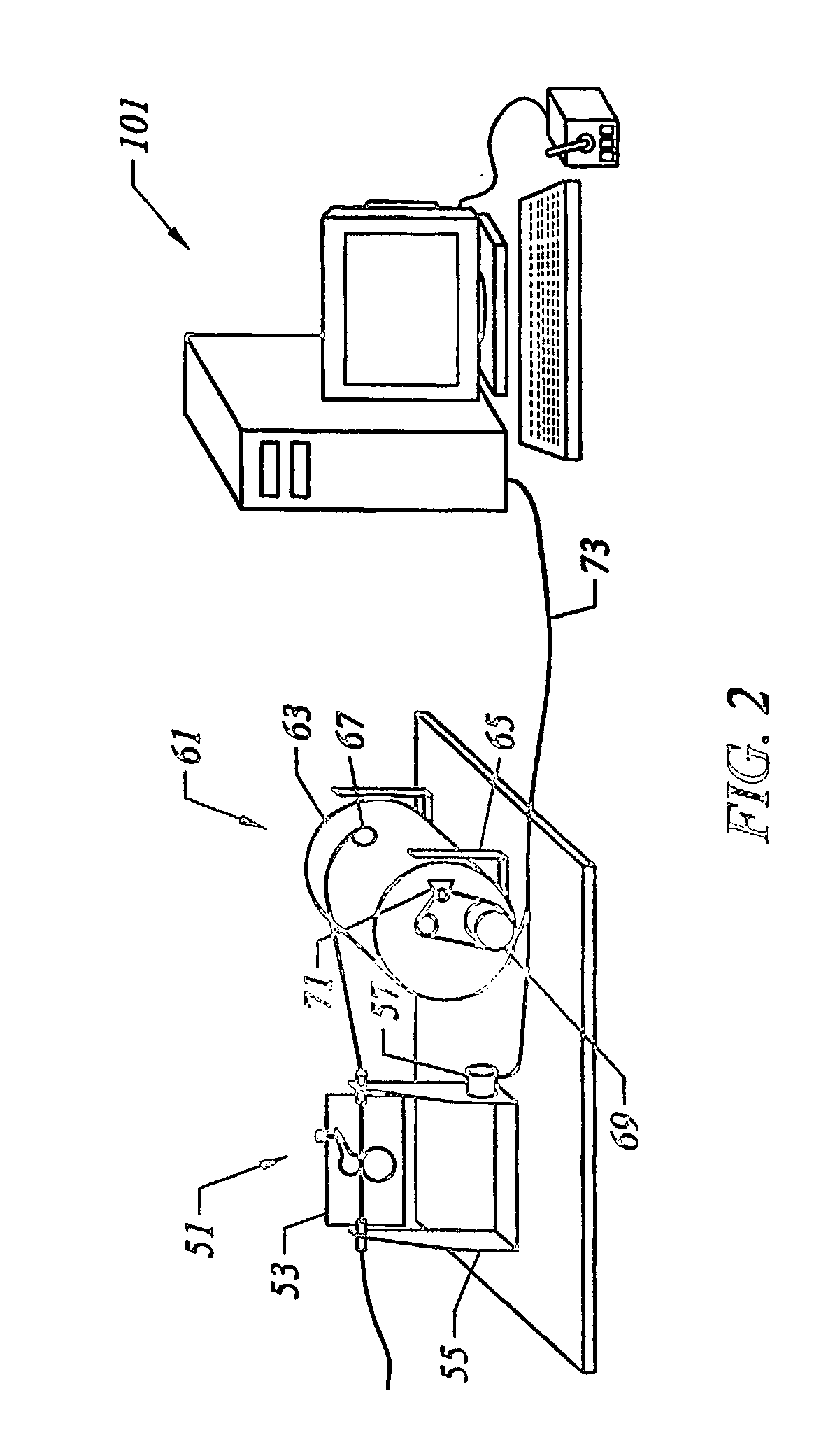

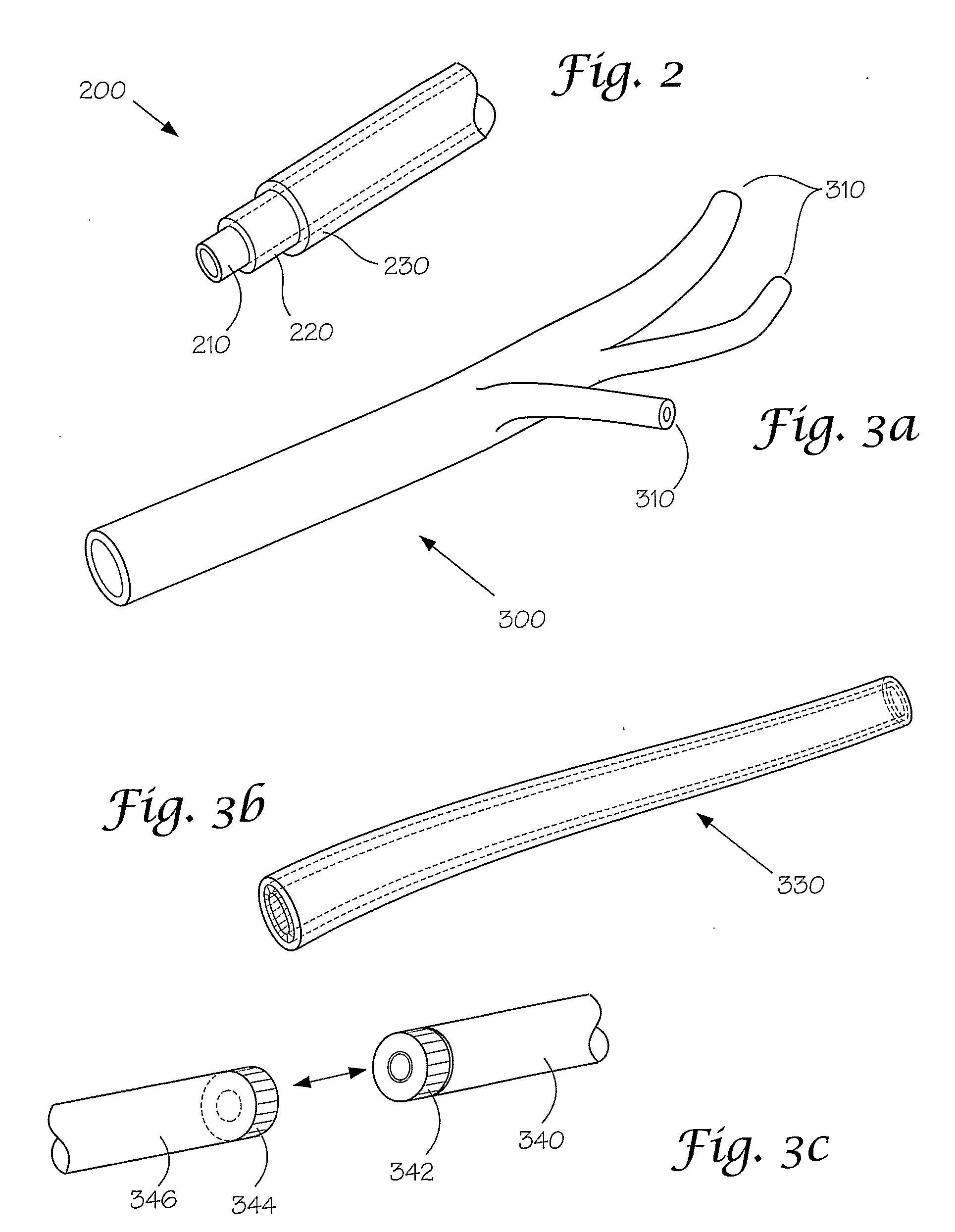

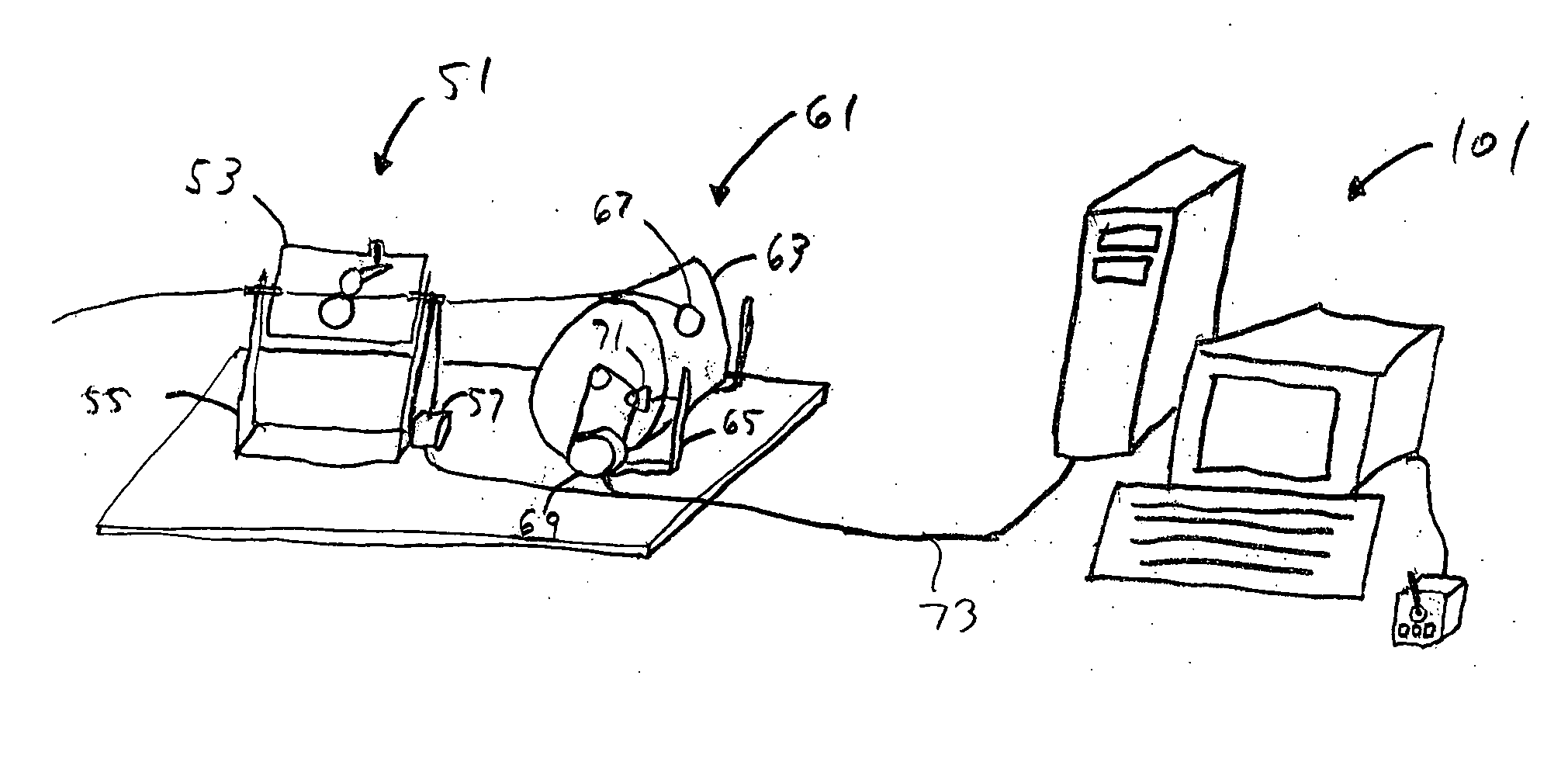

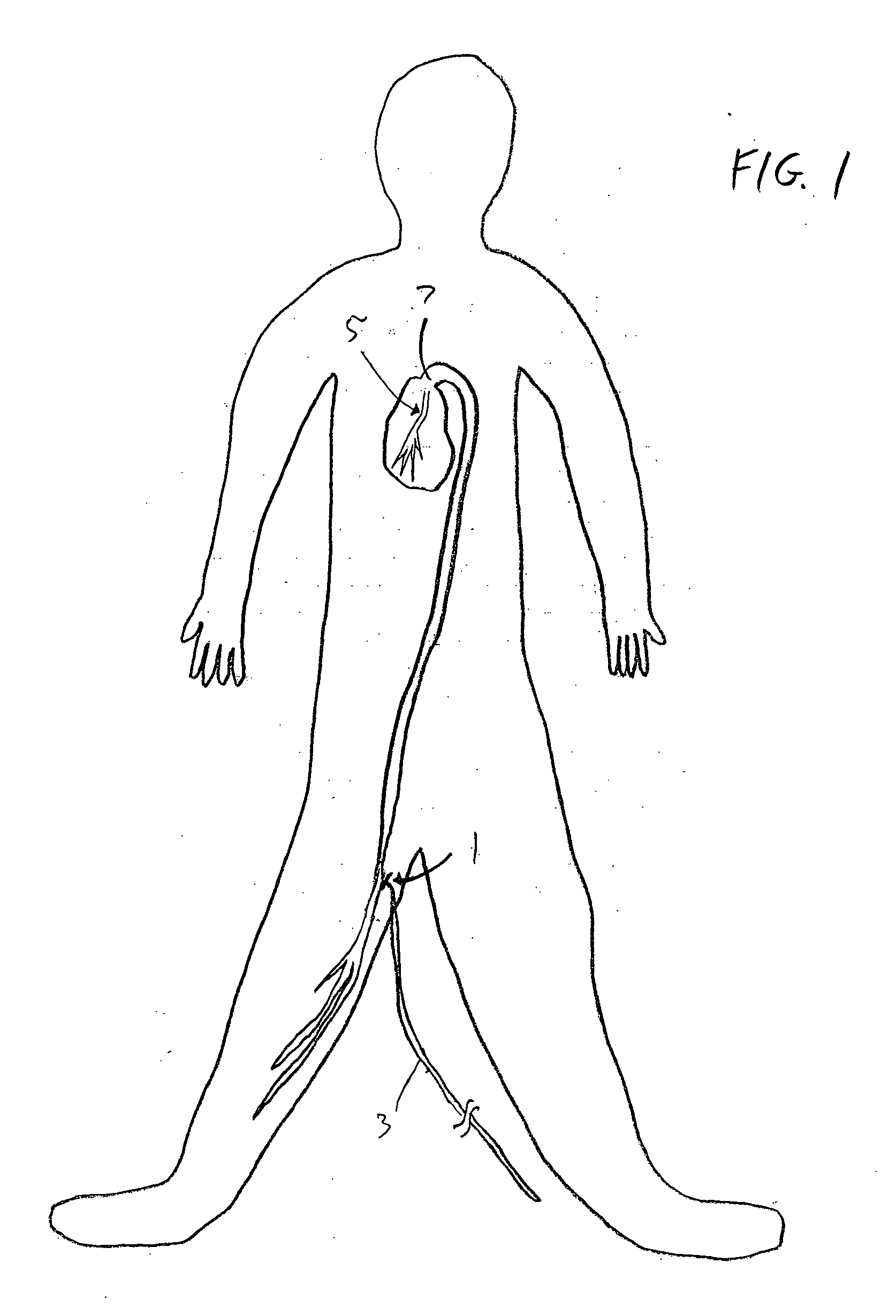

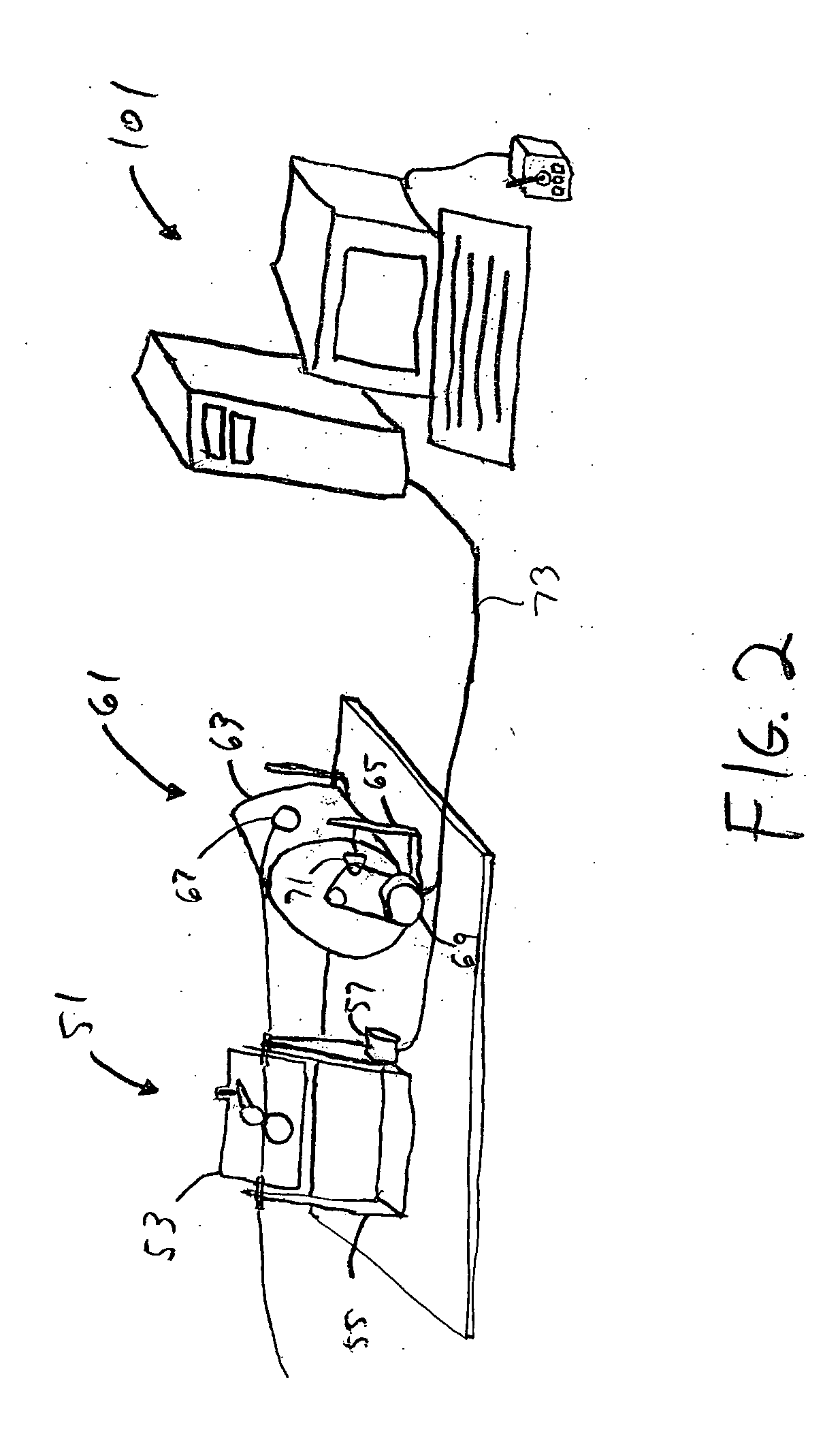

Computer assisted manipulation of catheters and guide wires

InactiveUS20060146010A1Ability to manipulate minimally invasive surgical toolsEliminate exposureEar treatmentCatheterGraphicsGraphical user interface

Owner:SCHNEIDER M BRET

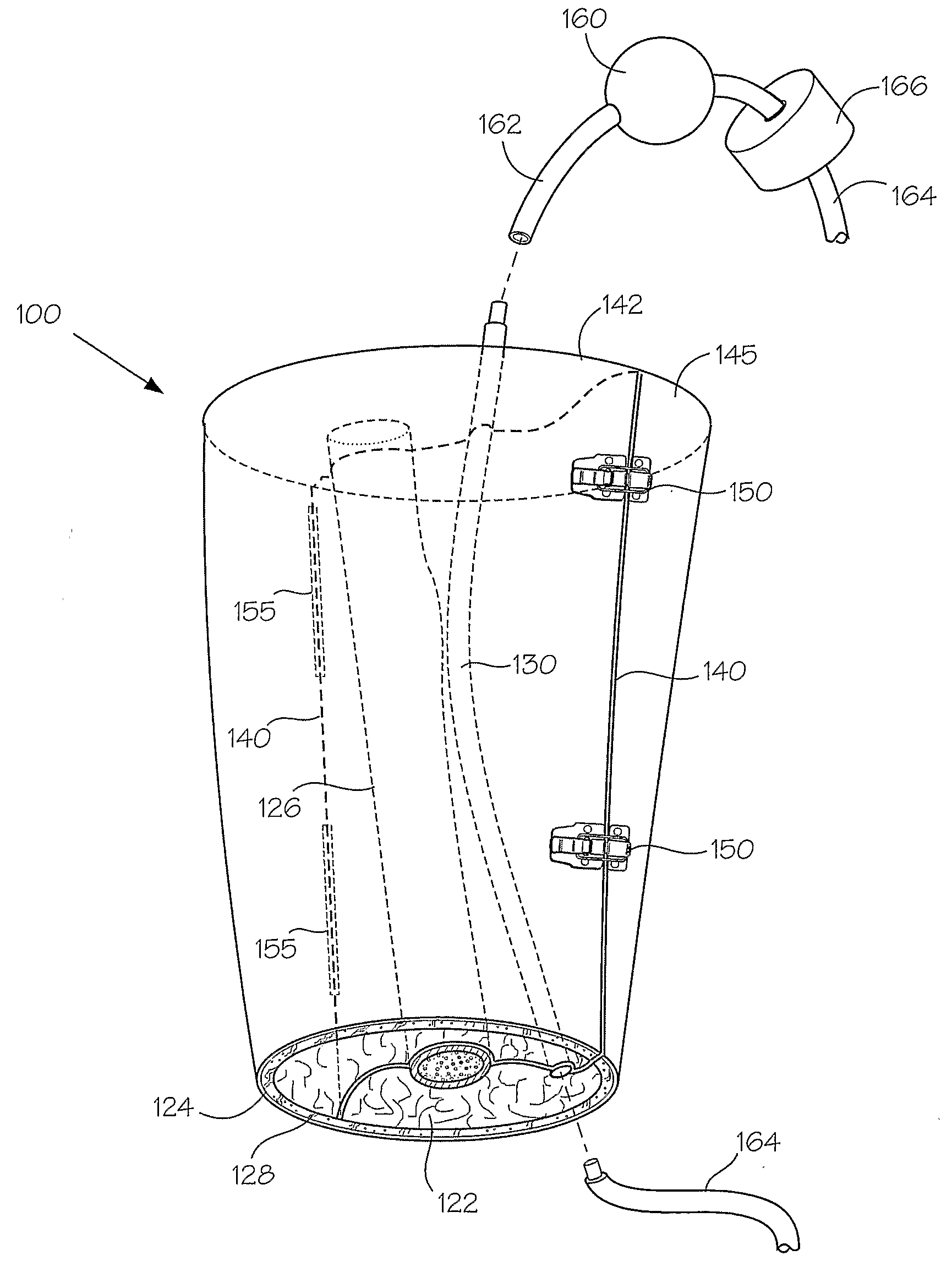

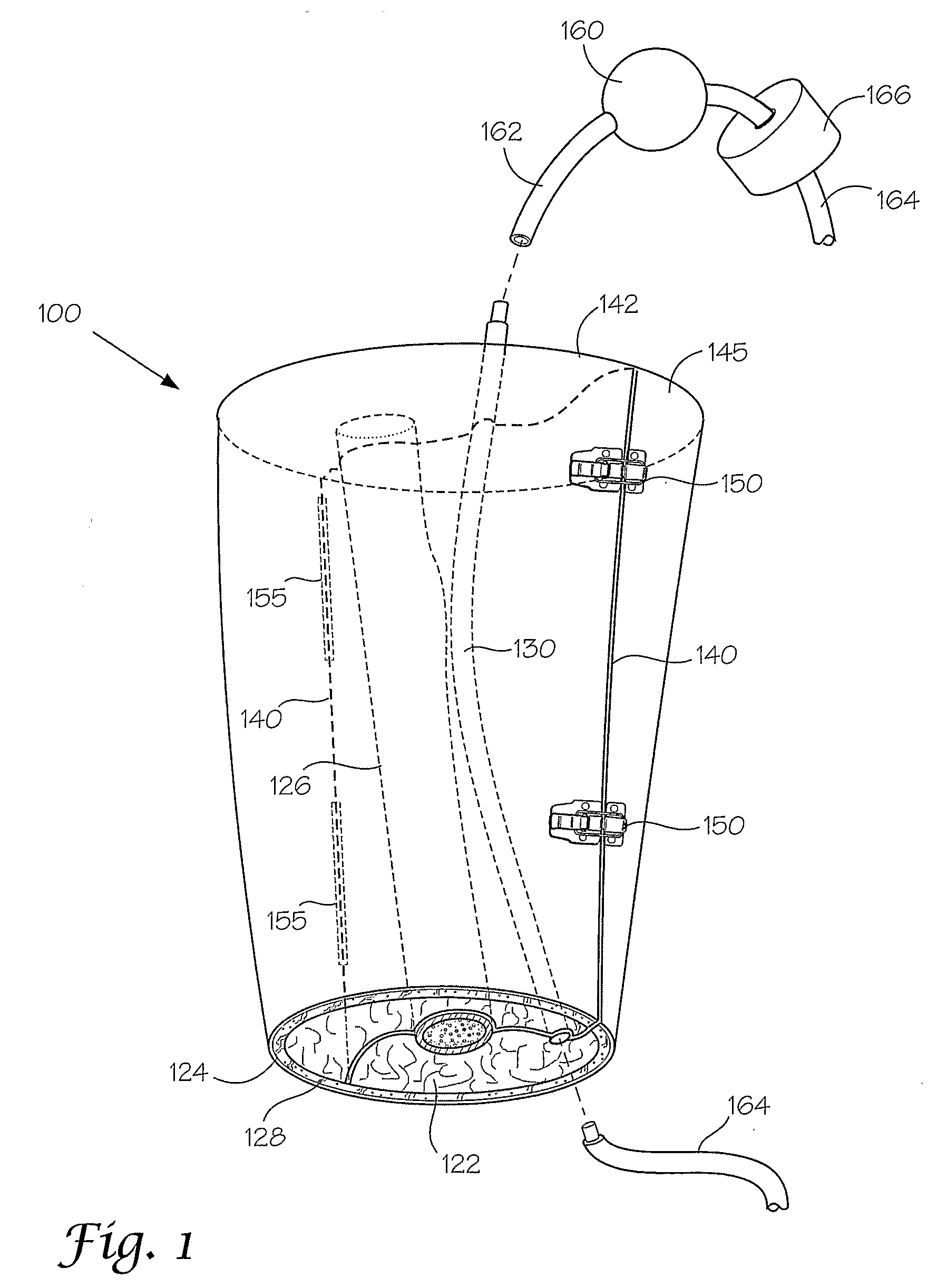

Models And Methods Of Using Same For Testing Medical Devices

ActiveUS20080187895A1Avoid product qualityIncreased development costAdditive manufacturing apparatusEducational modelsHuman bodyAnatomical structures

Disclosed herein are synthetic anatomical models that are designed to enable simulated use testing by medical device compam'es, medical device designers, individual inventors, or any other entity interested in the performance of medical devices. These models are unique in possessing a level of complexity that allows them to be substituted for either a live animal, an animal cadaver, or a human cadaver in the testing of these devices. These models are further characterized by a similarity of geometry, individual component physical properties, and component-to-component interfacial properties with the appropriate target tissue and anatomy.

Owner:SAKEZLES CHRISTOPHER

Computer-assisted manipulation of catheters and guide wires

InactiveUS20050004579A1Eliminating radiation exposurePermit separationEar treatmentCatheterGraphicsGraphical user interface

Owner:TELECATH

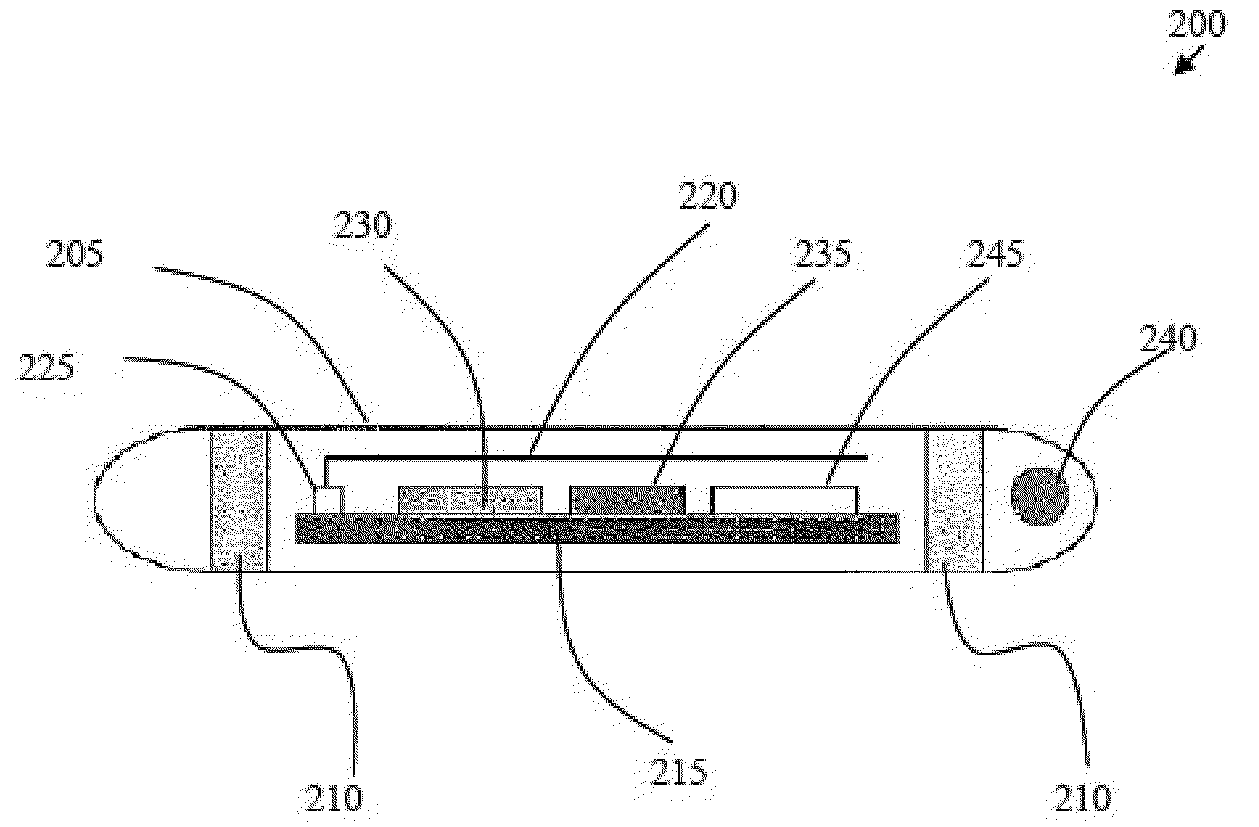

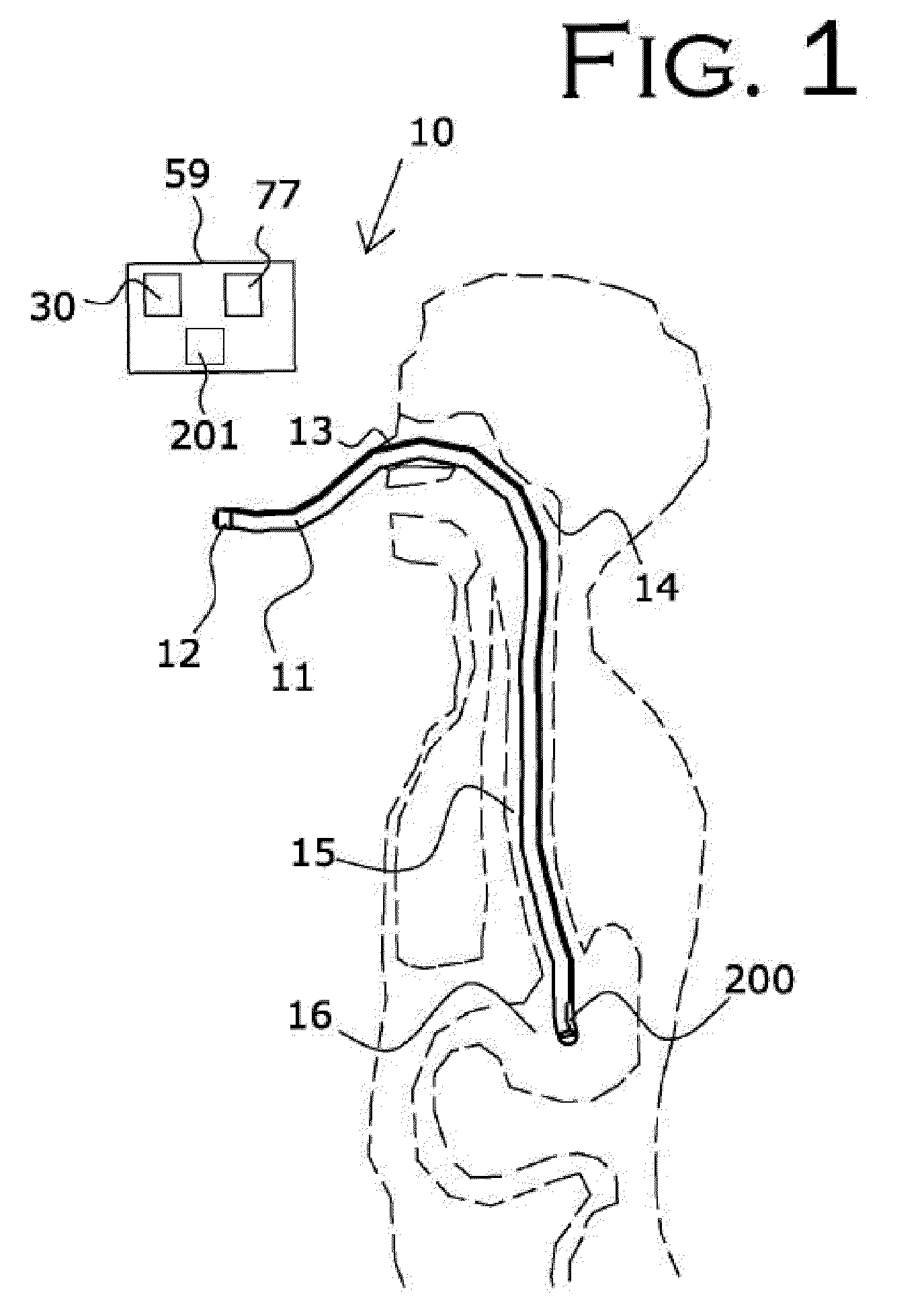

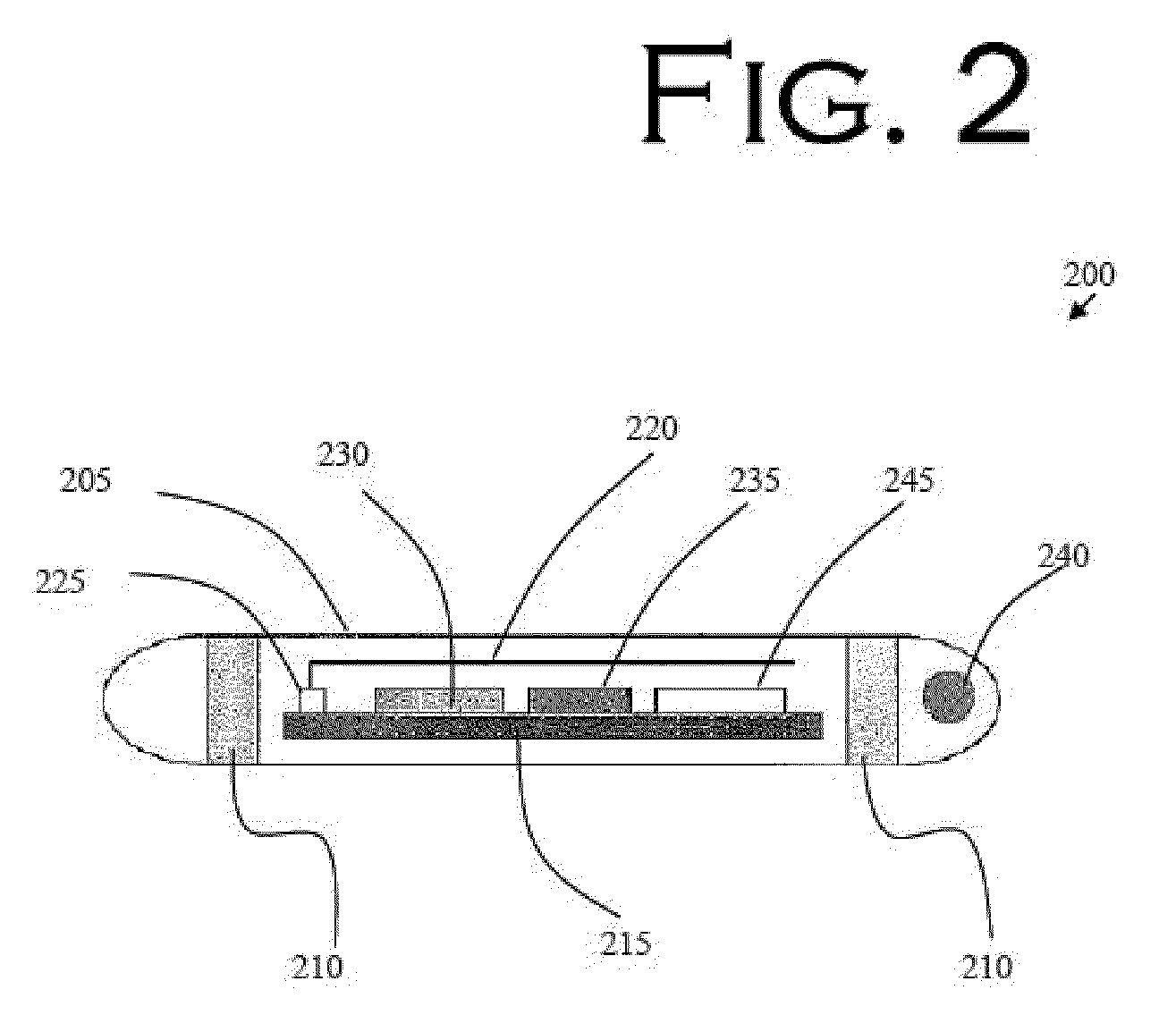

Medical Device Placement and Monitoring System Utilizing Radio Frequency Identification

InactiveUS20090209849A1Improve staff efficiencyEliminate exposureElectric/electromagnetic visible signallingSensorsMonitoring systemCatheter

A medical device placement and monitoring system is provided that includes numerous circuits that can be used alone or in combination. The circuits include a feedback initiator, a feedback receiver, and a clinician notifying device. By various means in the provided circuits, the feedback initiator provides information about the location of a radio frequency identification tag secured to a medical device inserted within a patient. This information or data is received and analyzed by the feedback receiver that monitors the circuit, which then transmits an output to the clinician notifying device to alert or advise the attending clinician of this information. The data that is output supplies information about the location of the radio frequency identification tag to the clinician, thereby assisting the clinician in placement of a variety of medical devices including nasogastric or endotracheal tubes, as well as in monitoring proper device placement after initial insertion.

Owner:NG ET OPTIMIZER

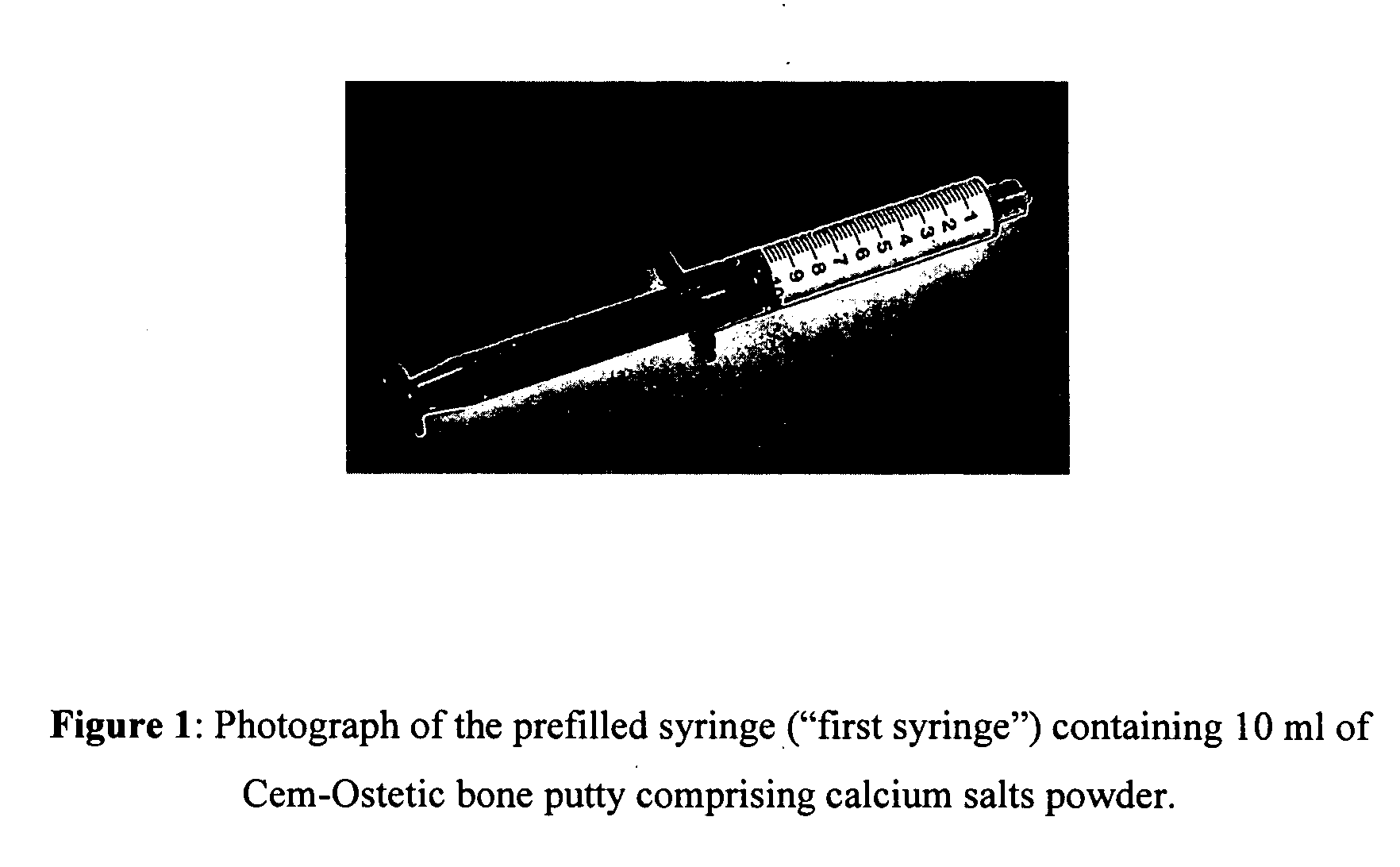

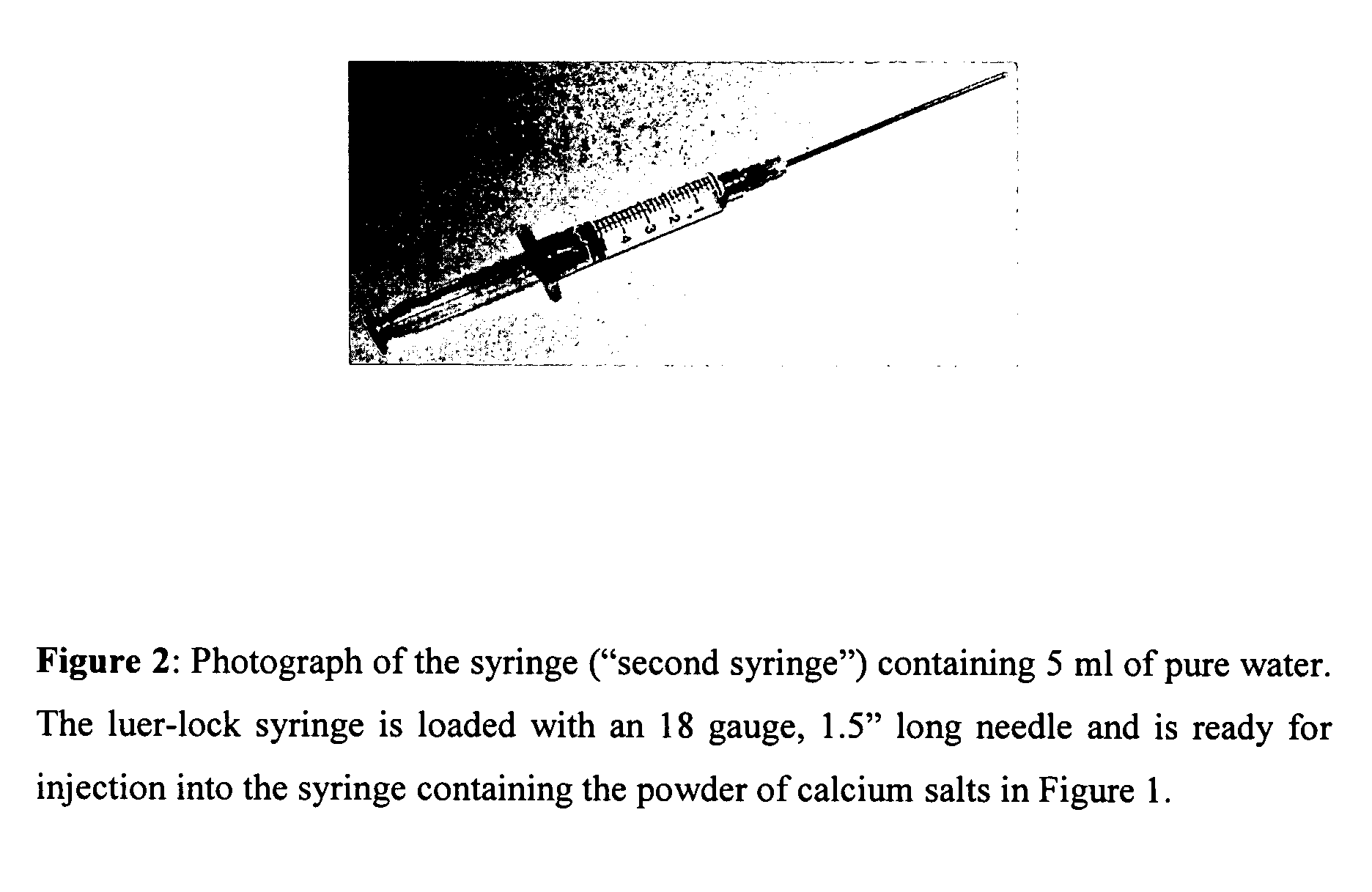

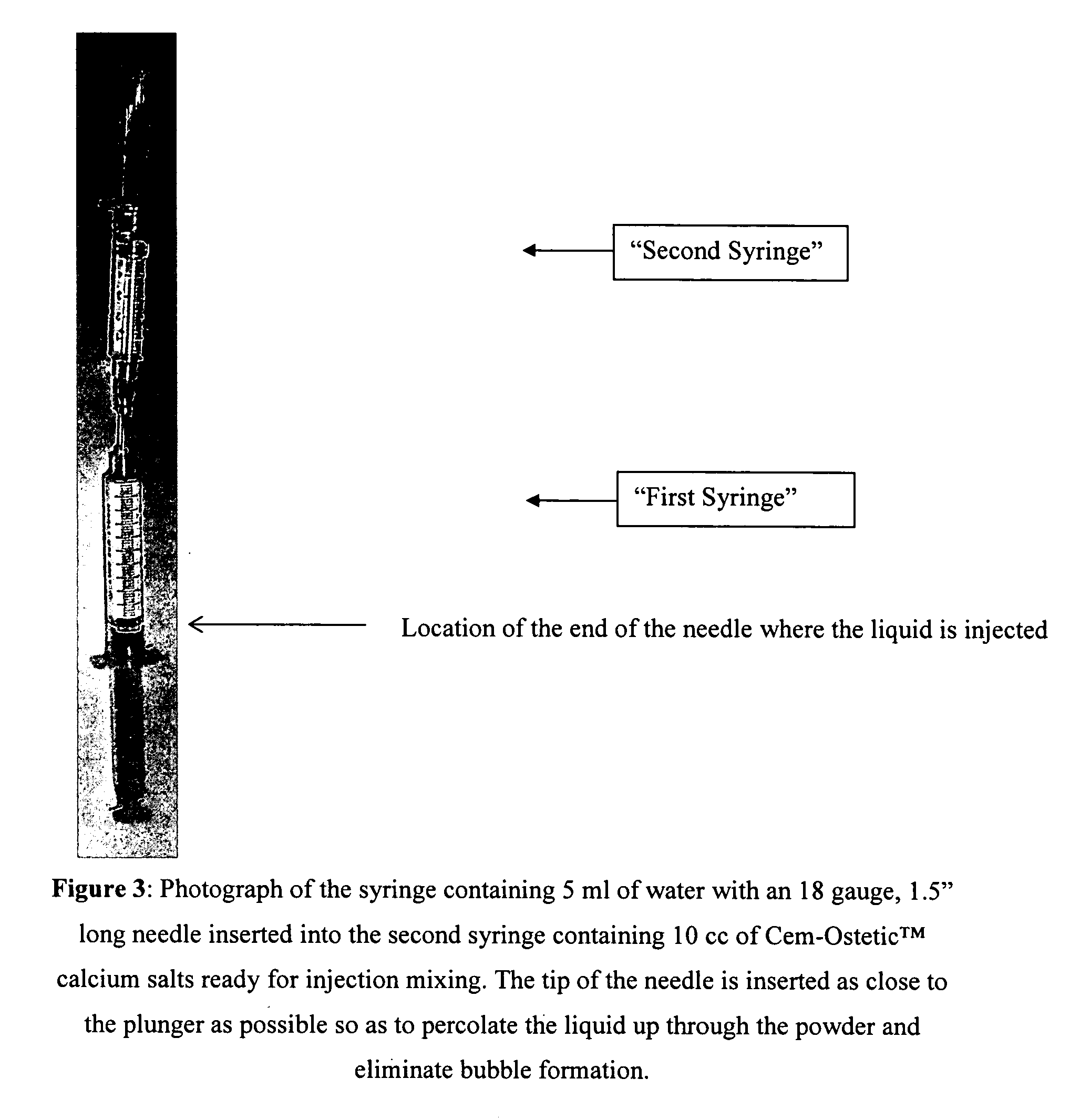

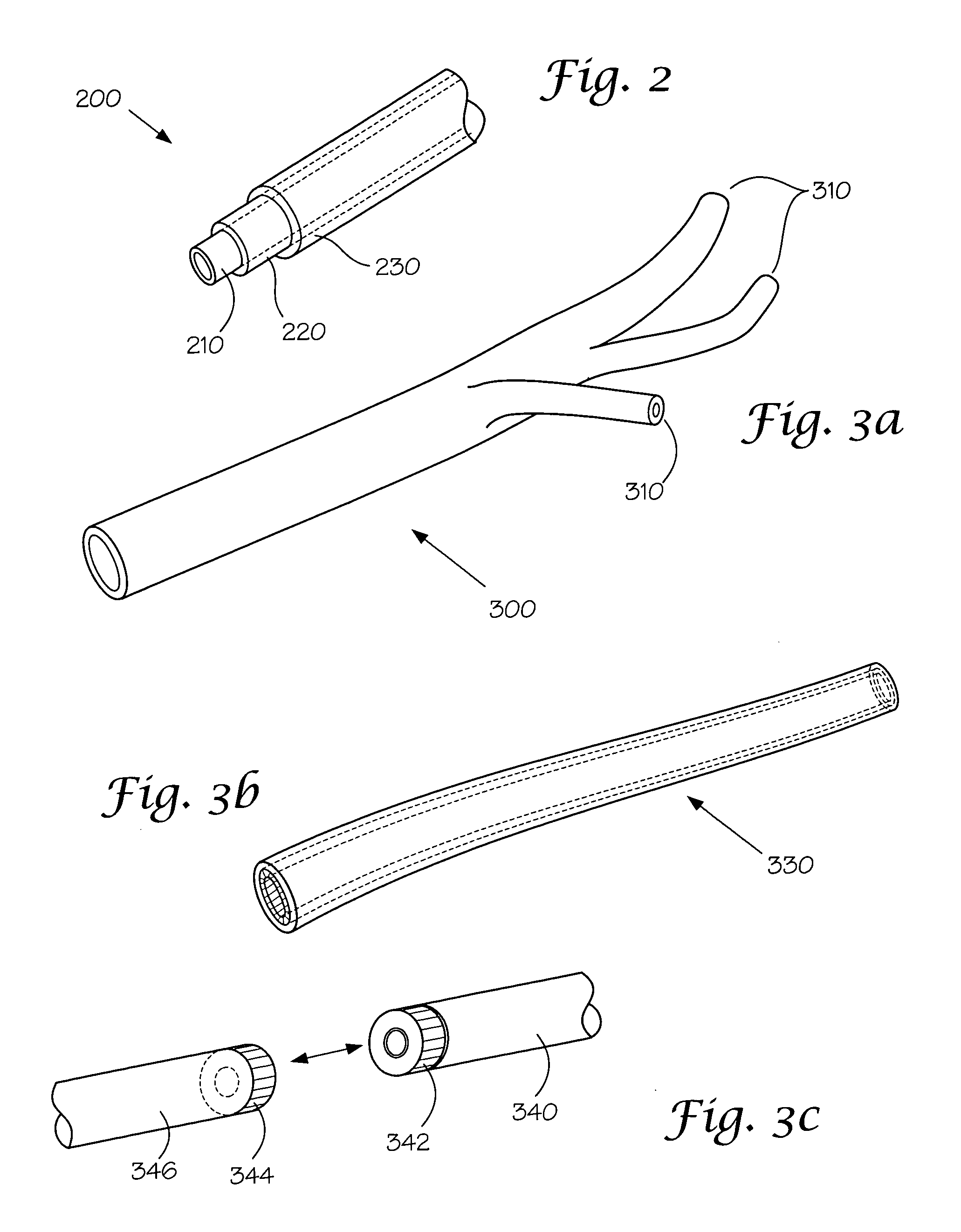

Method of preparing rheological materials for bone and cartilage repair

InactiveUS20070026030A1Volume maximizationEliminate exposureBiocideInternal osteosythesisCartilage repairAnimal body

Methods of mixing delivering biocompatible cement, paste, putty, or gel for bone and cartilage repair are described in this invention. Powder-like solid materials are loaded into a first syringe. Liquids are loaded into one or multiple syringes. The liquids are injected into the first syringe containing the solid materials. To force the liquids through the solid, prevent bubble formation and provide intimate intermixing, the liquids are injected in the very proximity of the plunger end of the syringe containing the solid materials. The first syringe is preferably held vertical with the tip facing up so as to avoid bubble formation that in turn could cause back-pressure build-up and plug the first syringe during injection. The described methods of mixing the liquids with the solids allows to form a rheological paste, cement, putty, or gel in the first syringe. As injection into the human or animal body proceeds, the paste then flows without complications often caused by entrapped bubbles or improper / heterogeneous mixing. The preparation and injection processes can be conducted at temperatures that do not damage live tissue or denature proteins. The paste, cement, putty, or gel can be injected into bone through the cannula by hand or with a pressurizing system. The method reduces the amount of time needed to prepare the paste and load it into the syringe and provides a device that is easily prepared for injection.

Owner:BERKELEY ADVANCED BIOMATERIALS

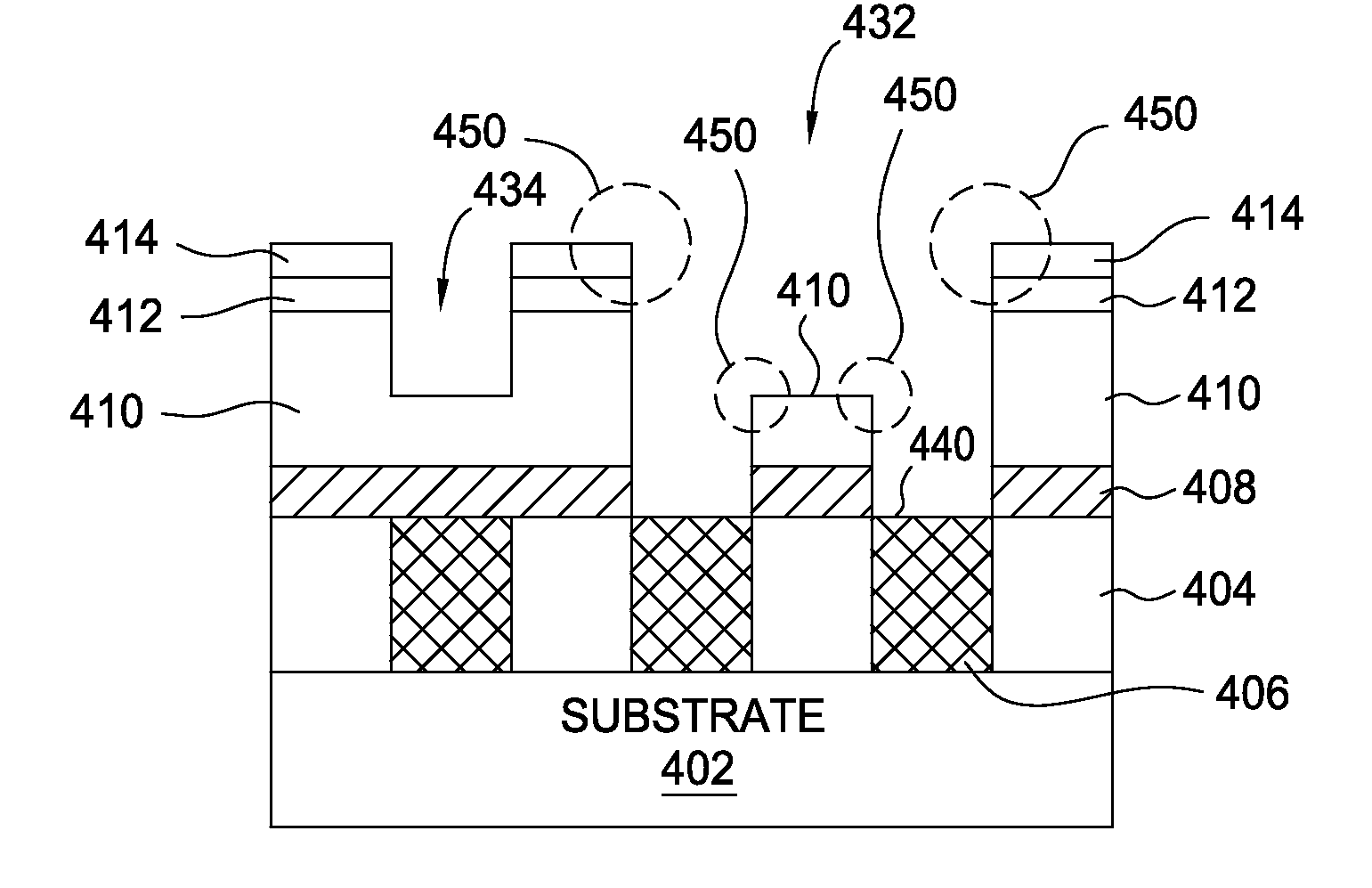

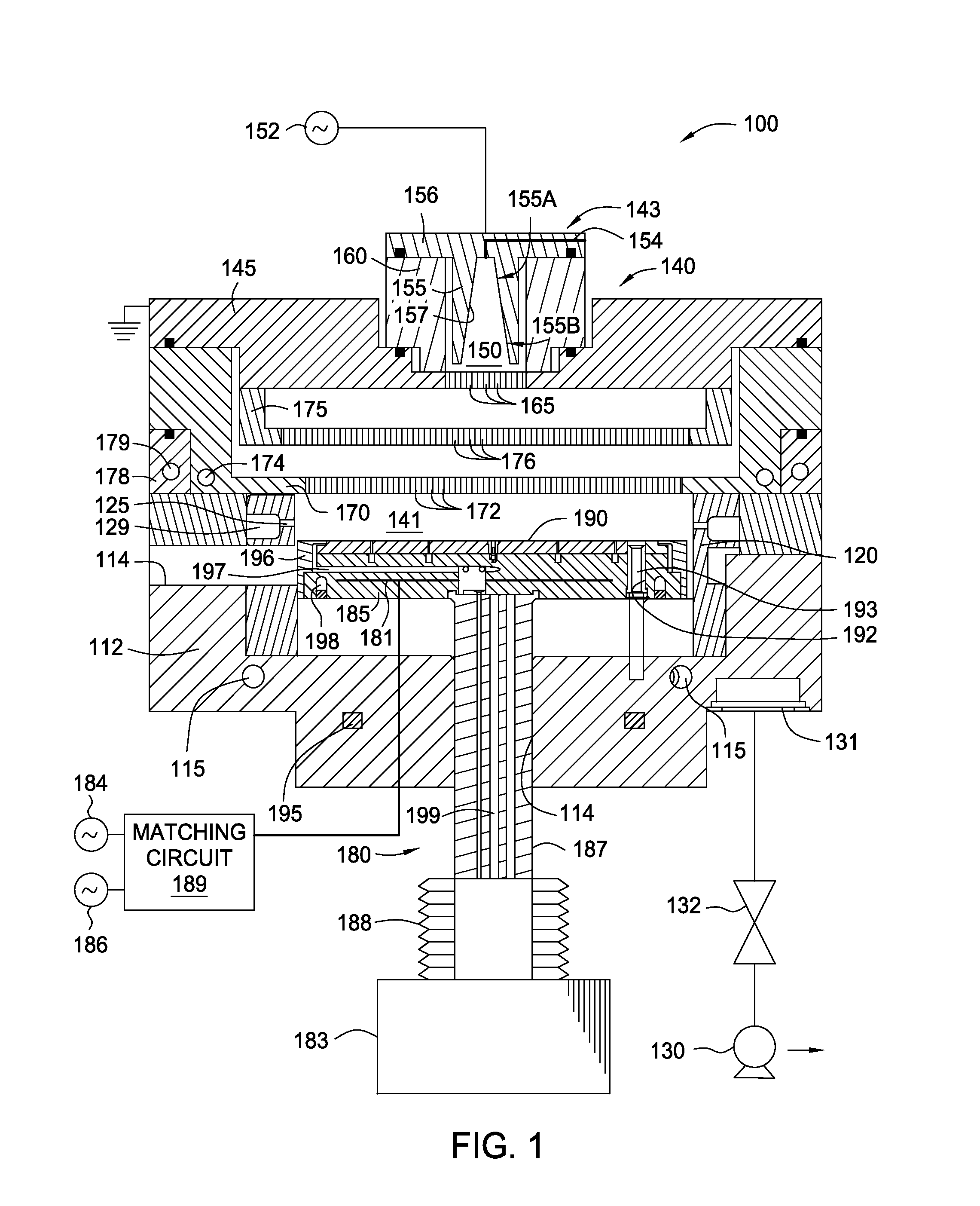

Methods for etching a dielectric barrier layer in a dual damascene structure

ActiveUS20150214101A1Eliminate exposureElectric discharge tubesSemiconductor/solid-state device manufacturingDielectricPhysics

Methods for eliminating early exposure of a conductive layer in a dual damascene structure and for etching a dielectric barrier layer in the dual damascene structure are provided. In one embodiment, a method for etching a dielectric barrier layer disposed on a substrate includes patterning a substrate having a dielectric bulk insulating layer disposed on a dielectric barrier layer using a hardmask layer disposed on the dielectric bulk insulating layer as an etching mask, exposing a portion of the dielectric barrier layer after removing the dielectric bulk insulating layer uncovered by the dielectric bulk insulating layer, removing the hardmask layer from the substrate, and subsequently etching the dielectric barrier layer exposed by the dielectric bulk insulating layer.

Owner:APPLIED MATERIALS INC

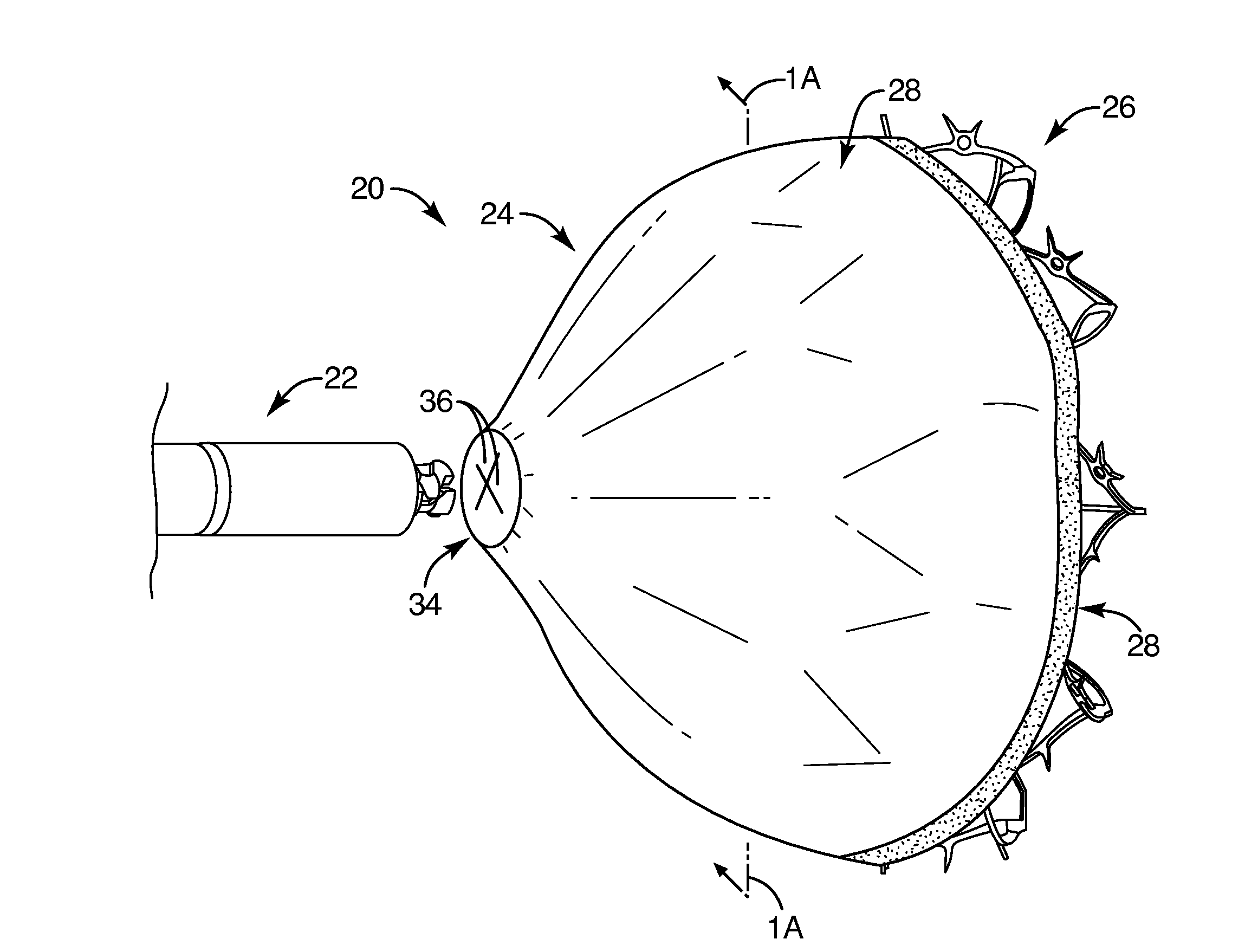

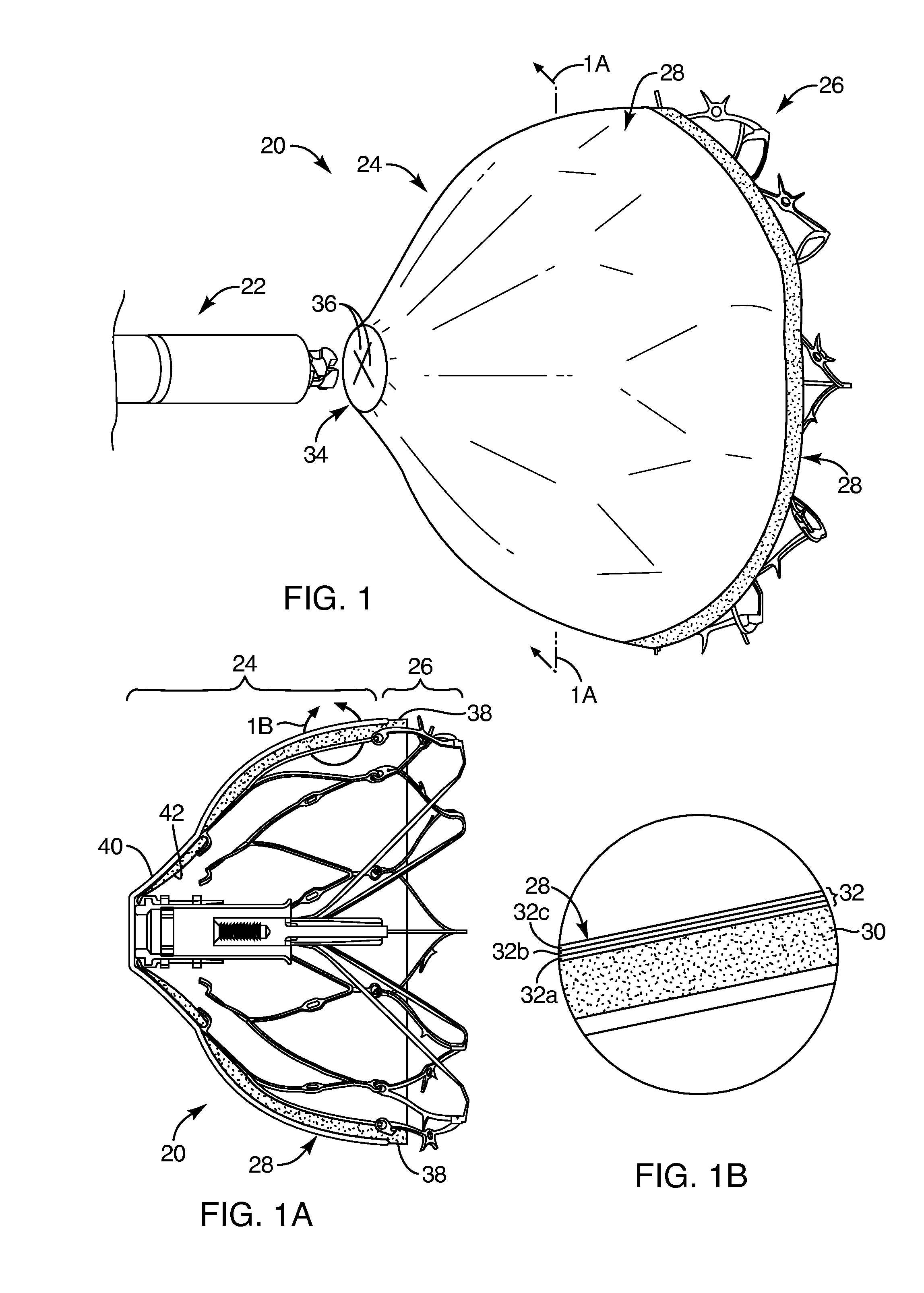

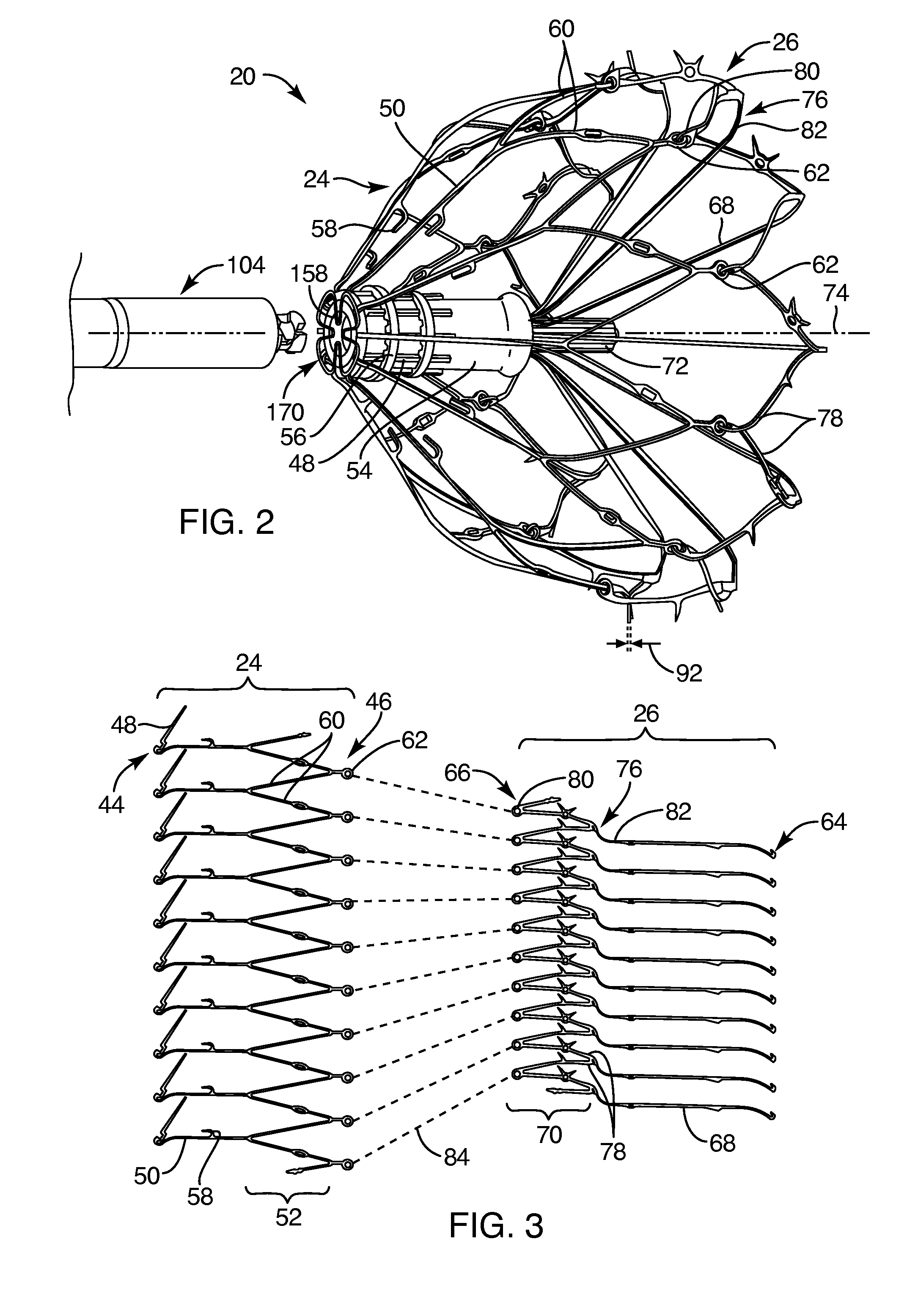

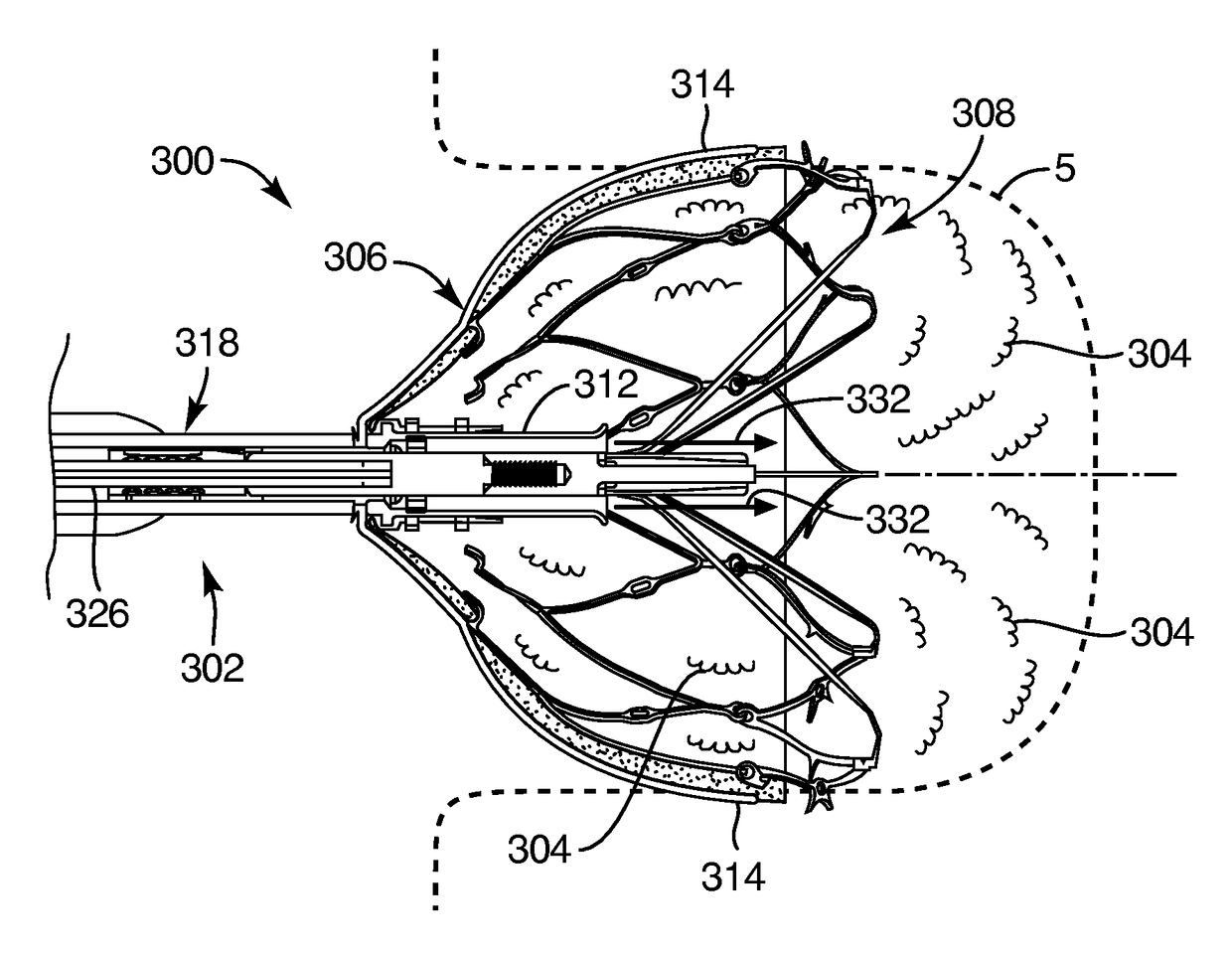

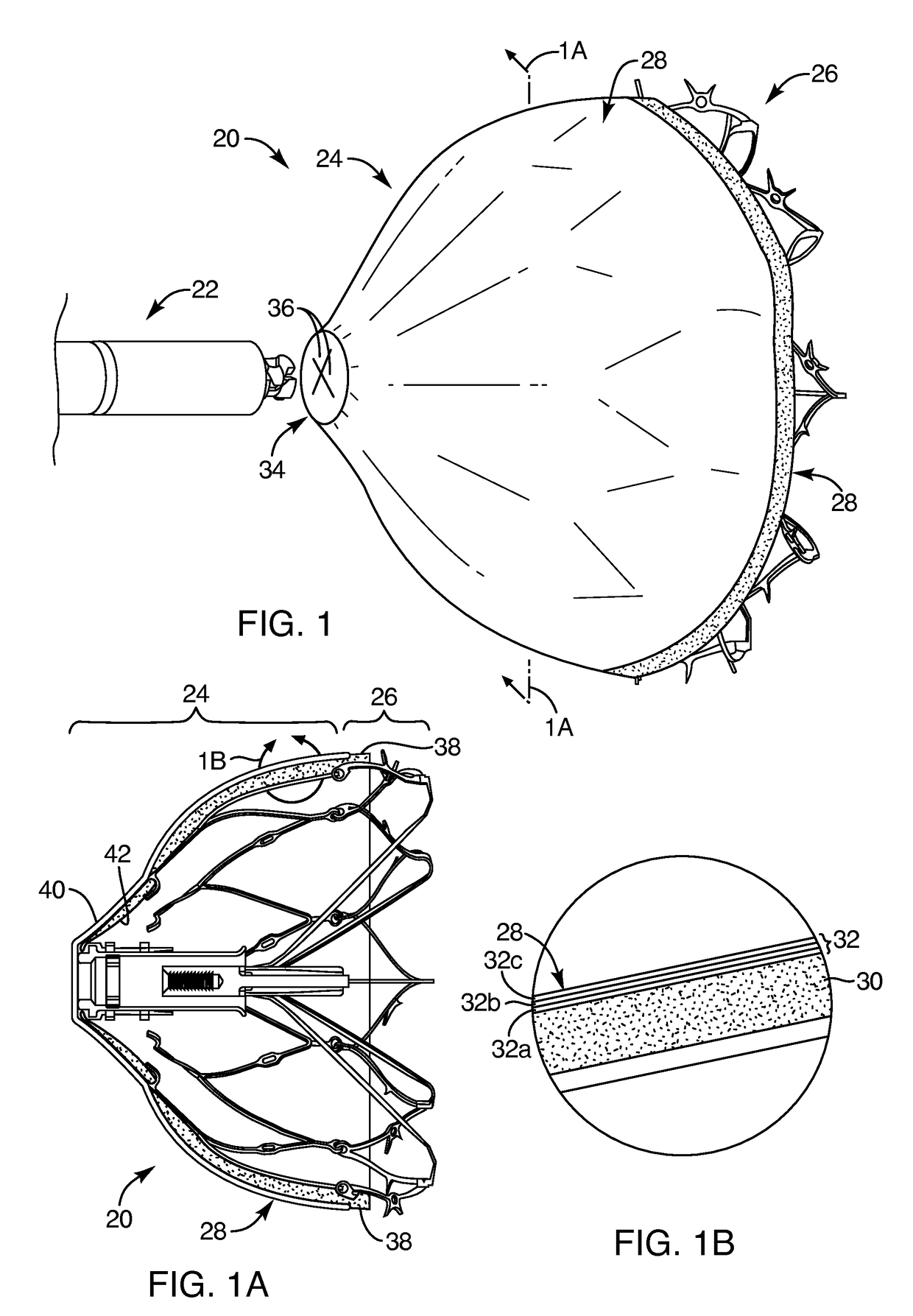

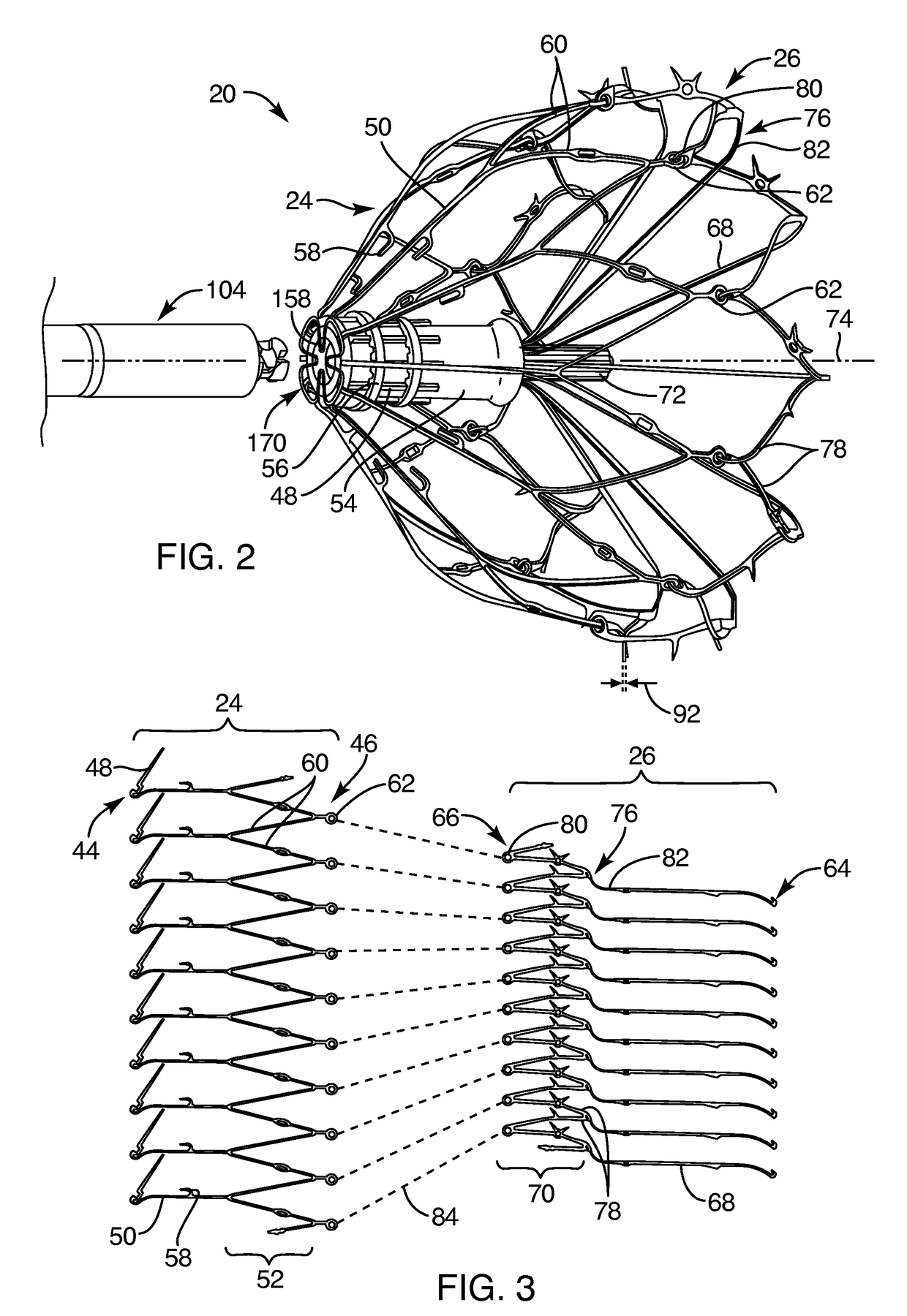

Medical device for modification of left atrial appendage and related systems and methods

Devices, methods and systems are provided for occluding an opening within the tissue of a body, such as a left atrial appendage. In one embodiment, a medical device coupled to a delivery catheter includes a fluid flow path that facilitates contrast fluid to pass through the delivery catheter and the medical device to a distal side thereof to provide imaging information as to the position of the medical device positioned in the opening, such as the left atrial appendage. In another embodiment, a medical device is coupled to a delivery catheter, the medical device including flaps adjacent a hub of the medical device that close-off a bore of the hub upon the catheter being detached from the medical device.

Owner:COHEREX MEDICAL

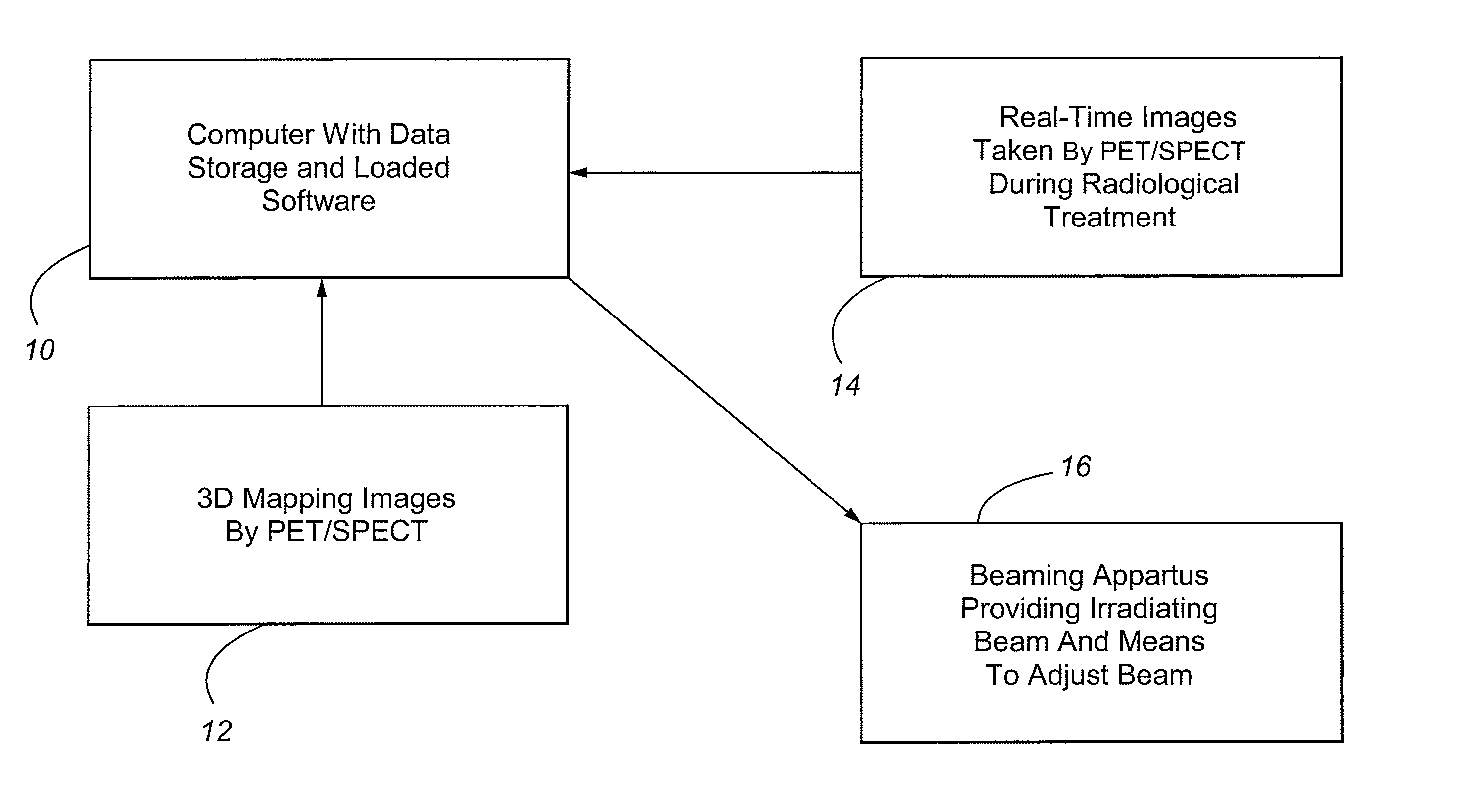

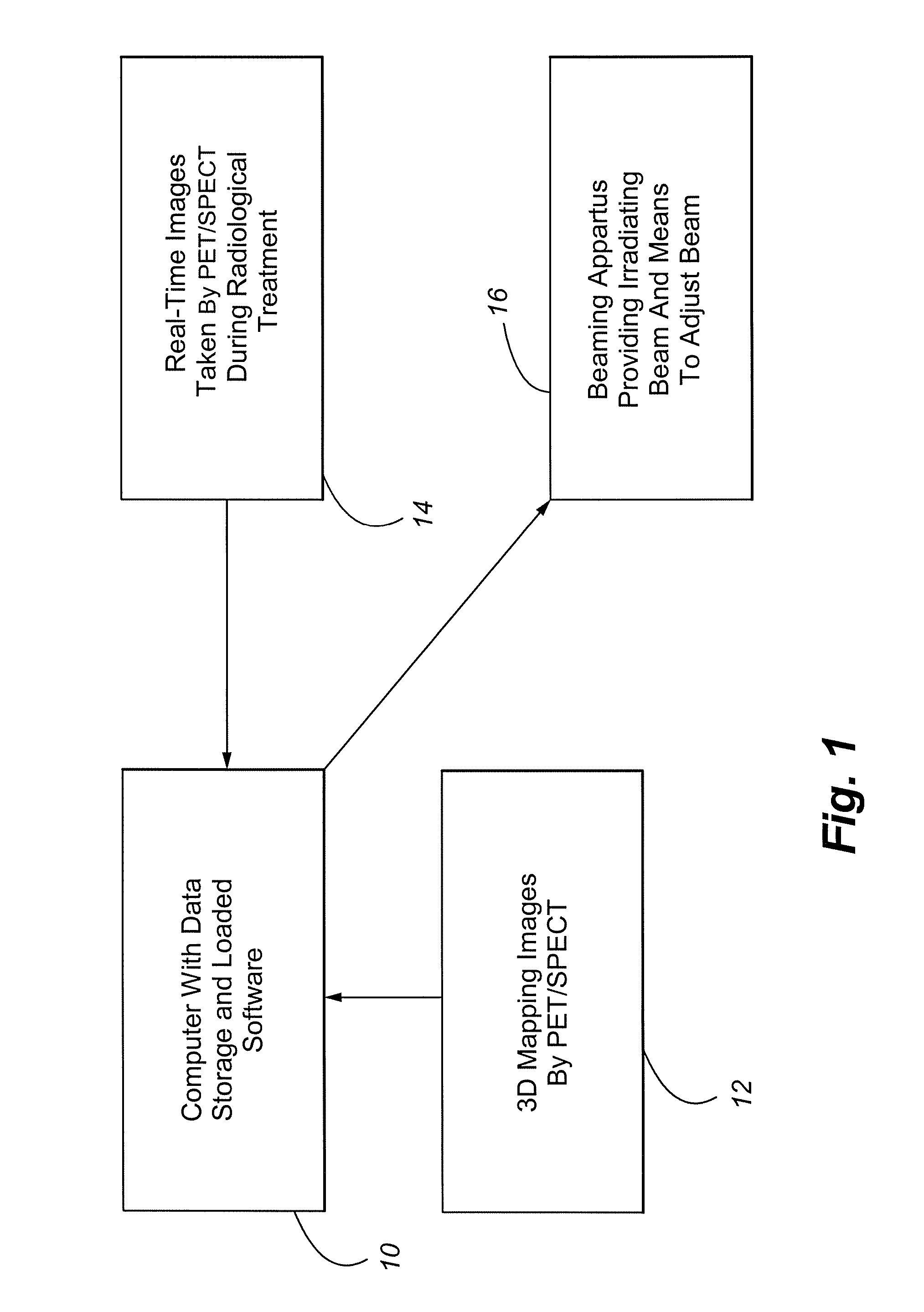

Method and Apparatus Including Use of Metalloporphyrins for Subsequent Optimization of Radiosurgery and Radiotherapy

InactiveUS20070043289A1Selective uptakeEfficient deliveryTelevision system detailsTelevision system scanning detailsRadiosurgeryDual delivery

Owner:ADAIR

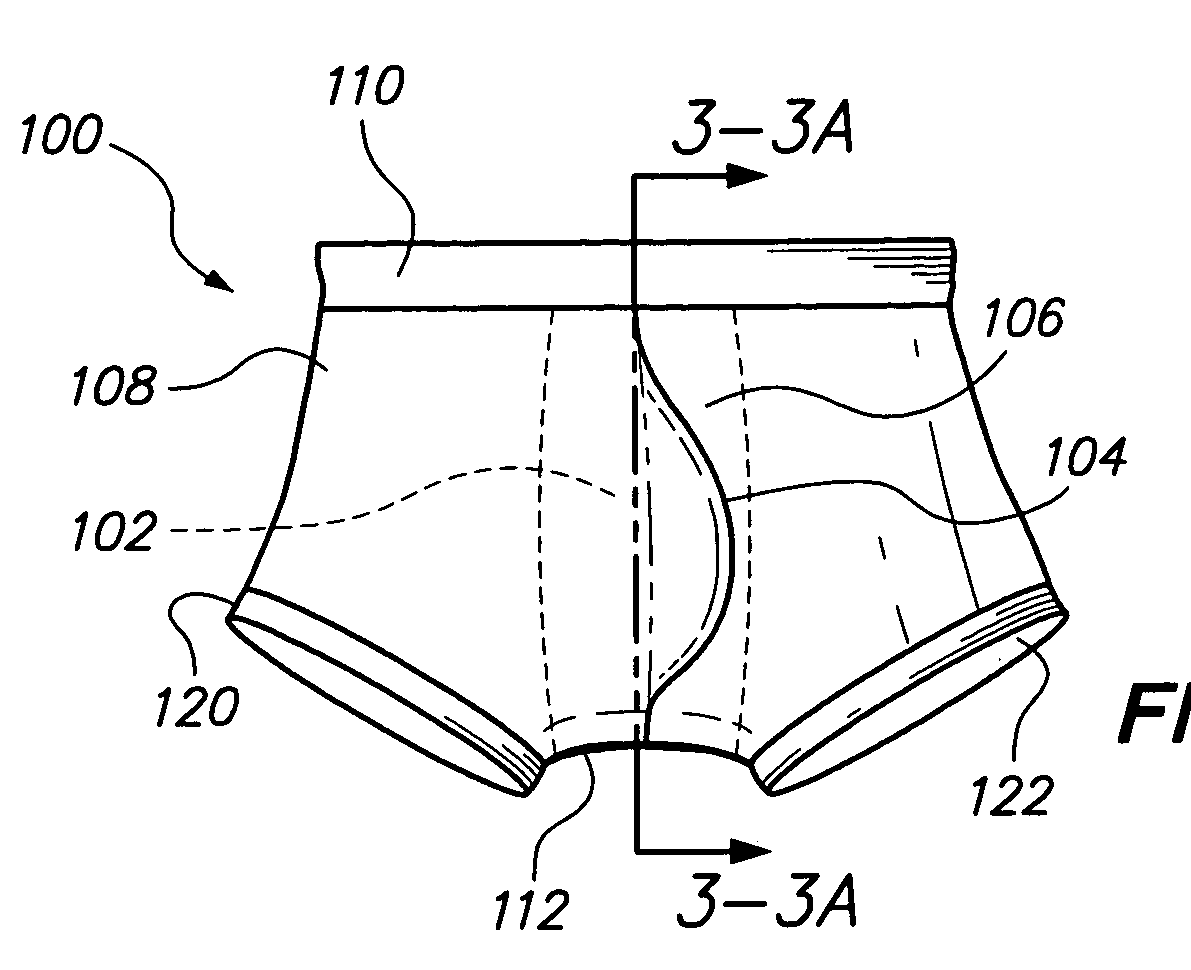

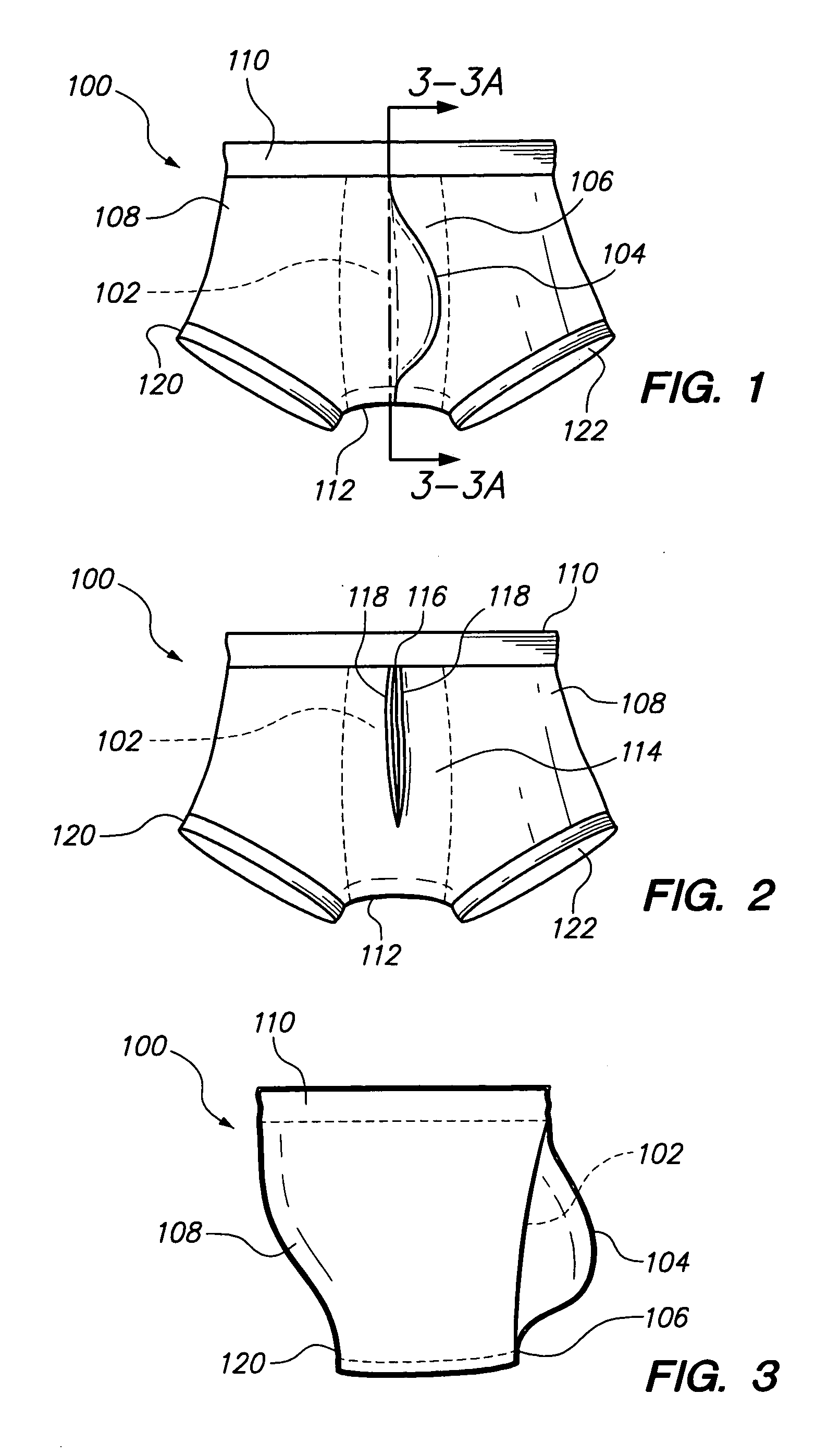

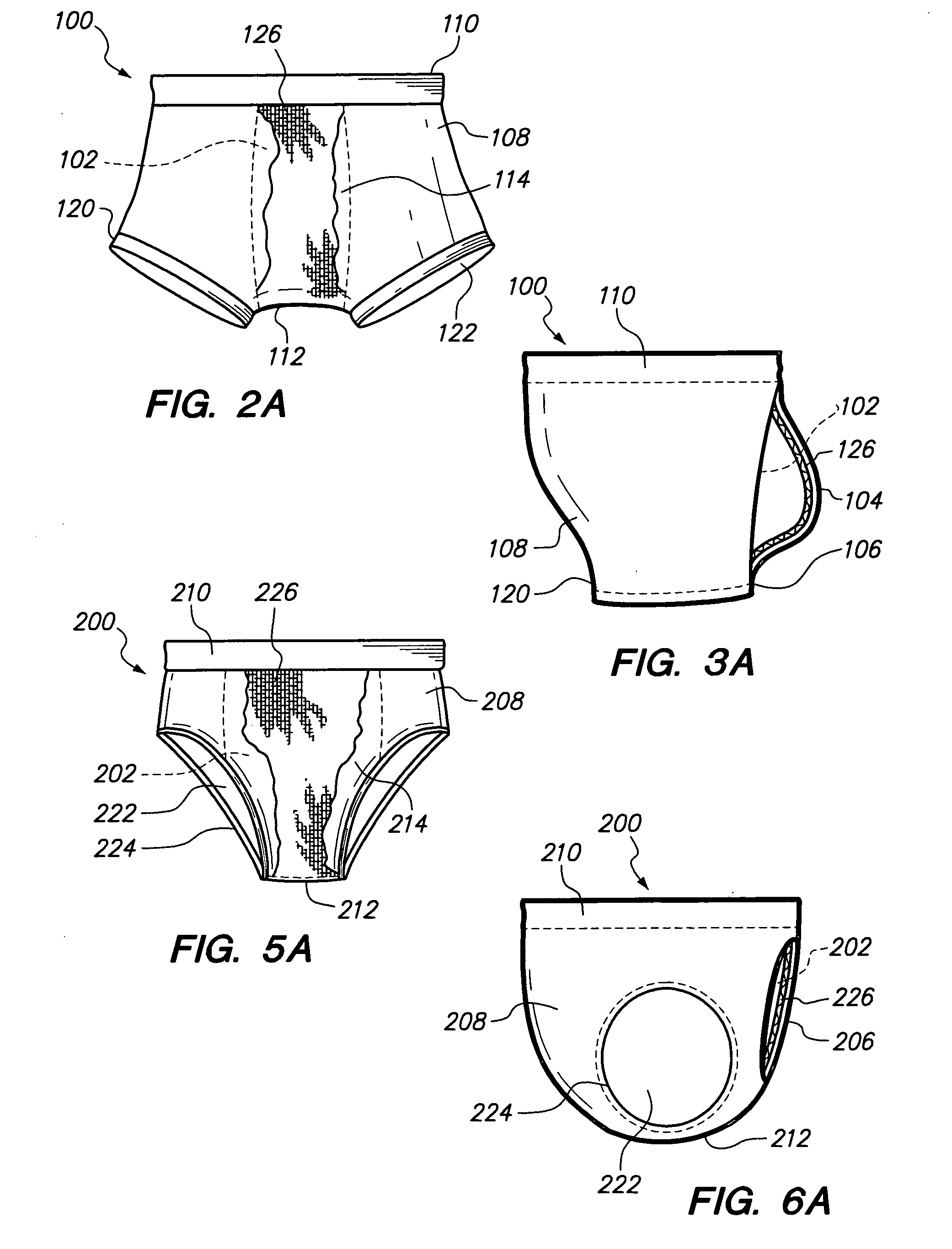

Underwear having internal pocket and pouch

A pair of underwear for use by a male includes a fabric fashioned to form a boxer-brief type undergarment, the fabric having a bilateral symmetry and including a front panel. A rear panel is formed within the fabric and positioned immediately behind the front panel to form an internal pocket. A slit-shaped portal is formed within the rear panel for providing access to the internal pocket for depositing a scrotum and genitalia of the male. Finally, an external pouch extending outward from the front panel is provided as a depository for the genitalia of the male. The boxer-brief type undergarment minimizes perspiration and irritation, absorbs accidental leakage of fluid body waste, and eliminates exposure to the fluid body waste and stains on the body of the male. A thin layer of absorbent material can be included to minimize the effects of accidental leakage.

Owner:SHLUSH JACOB

Composition and method for cream bleach product

ActiveUS20110038818A1Safe application methodEnvironment safetyCosmetic preparationsHair cosmeticsEmulsionPersulfate

This invention relates to compositions and methods for hair bleaching. In particular, the invention concerns stabilized hair bleach products that contain at least one persulfate salt, and an oil gel. The composition of the present invention forms an emulsion where the oil and salt do not separate providing a consistent and stable hair bleach formulation.

Owner:HAIR SYST

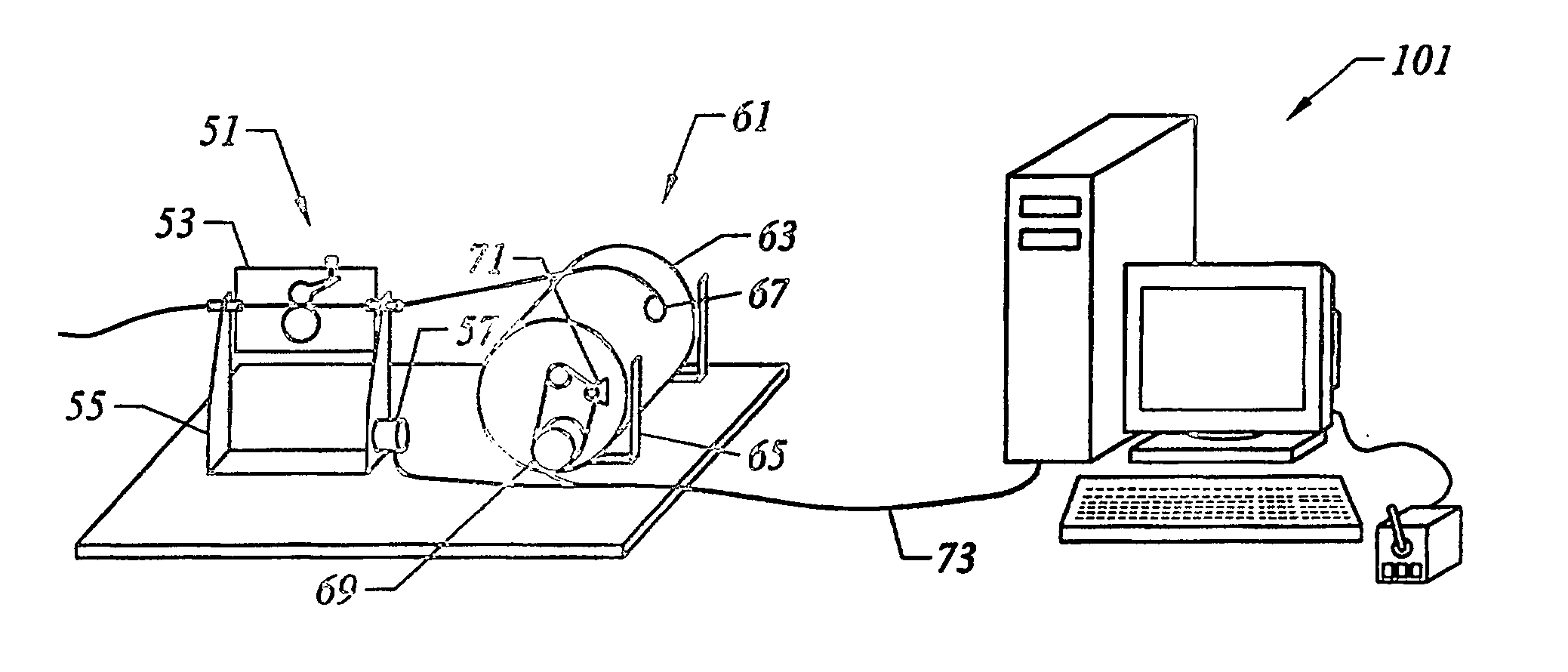

Models and methods of using same for testing medical devices

ActiveUS20060184005A1Avoid product qualityIncreased development costAdditive manufacturing apparatusDiagnostic recording/measuringAnatomical structuresLiving body

Disclosed herein are synthetic anatomical models that are designed to enable simulated use testing by medical device companies, medical device designers, individual inventors, or any other entity interested in the performance of medical devices. These models are unique in possessing a level of complexity that allows them to be substituted for either a live animal, an animal cadaver, or a human cadaver in the testing of these devices. These models are further characterized by a similarity of geometry, individual component physical properties, and component-to-component interfacial properties with the appropriate target tissue and anatomy.

Owner:SAKEZLES CHRISTOPHER

Laser marking system

InactiveUS20070199930A1Small footprintLow costDuplicating/marking methodsLaser beam welding apparatusEngineeringLaser

Owner:MECCO PARTNERS

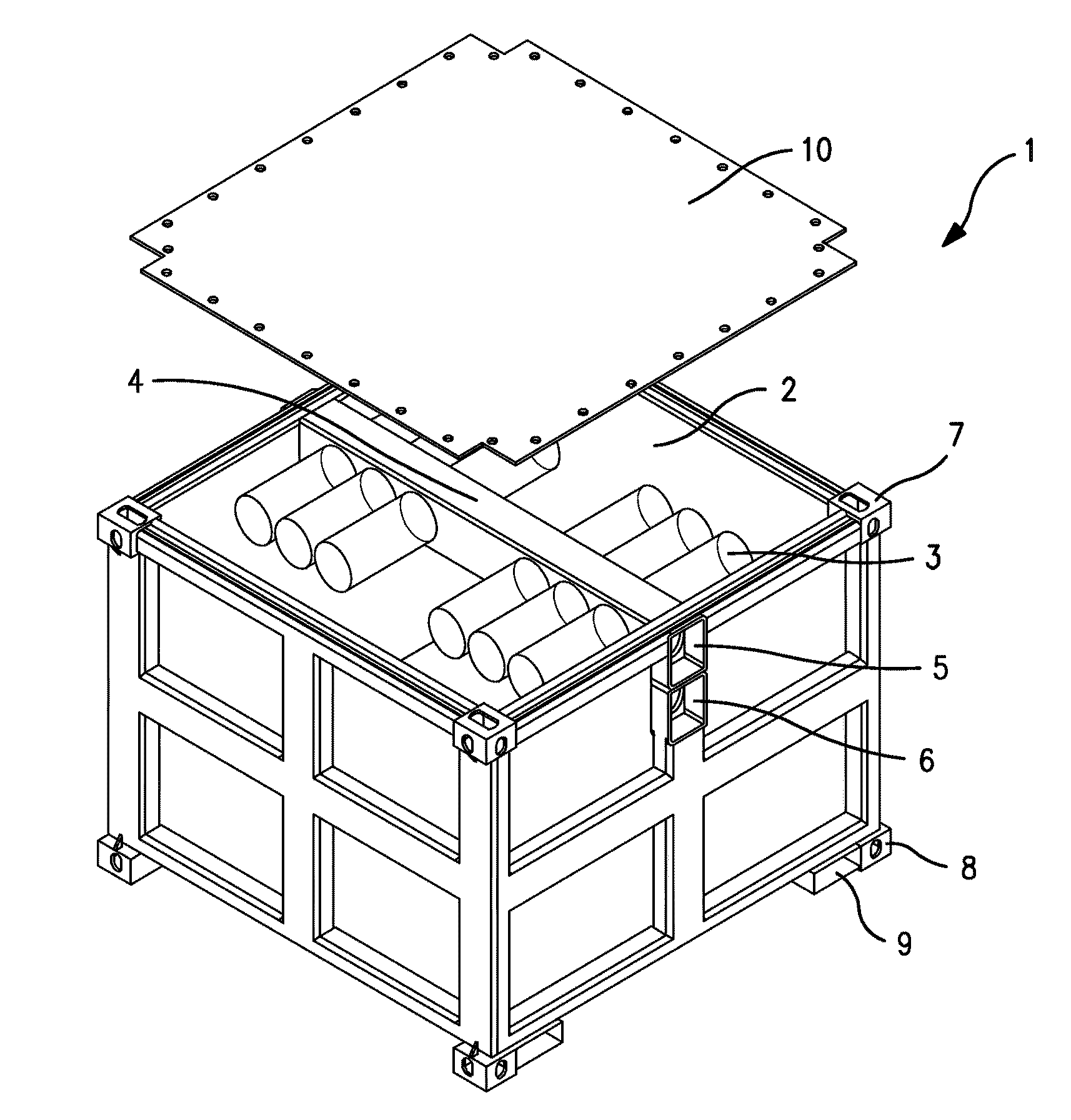

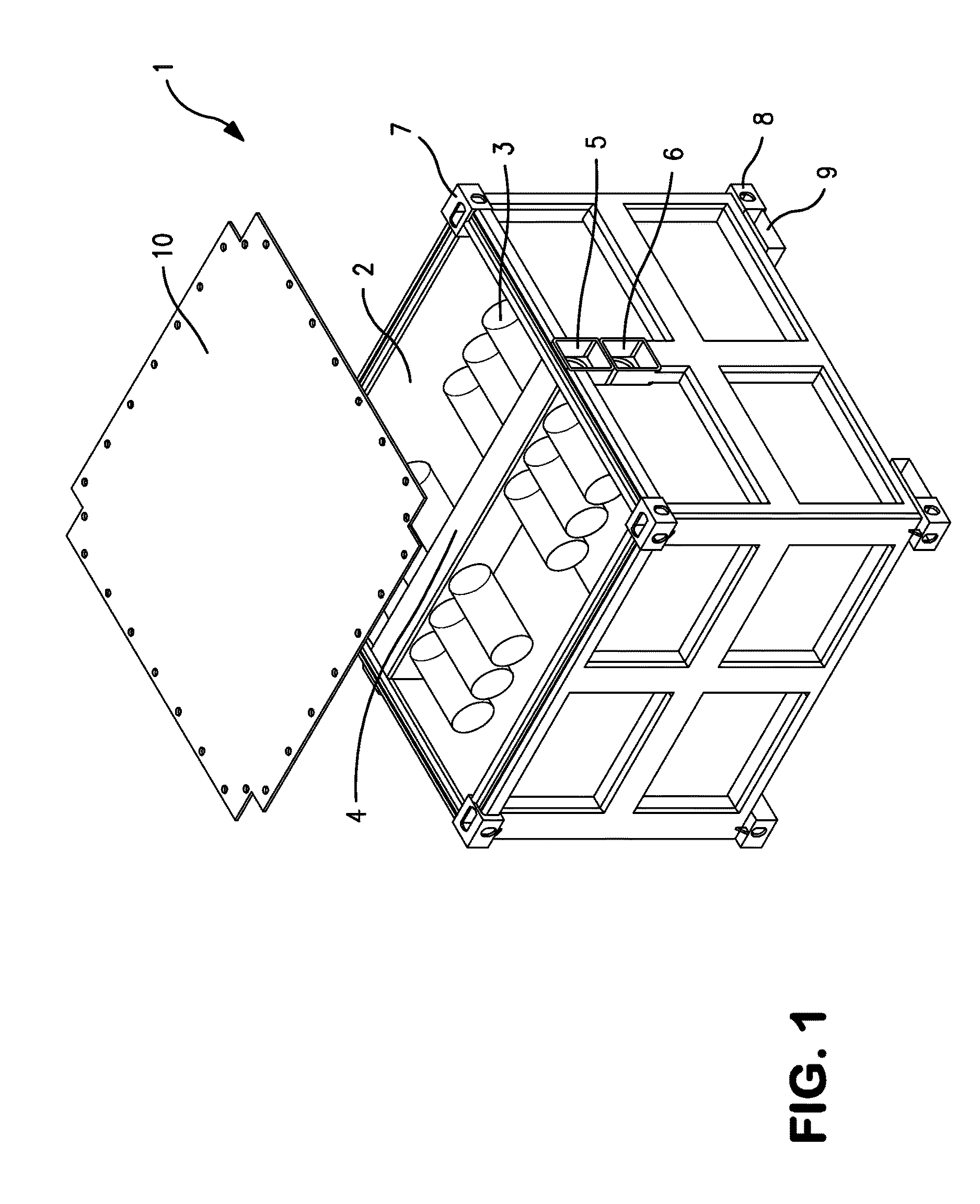

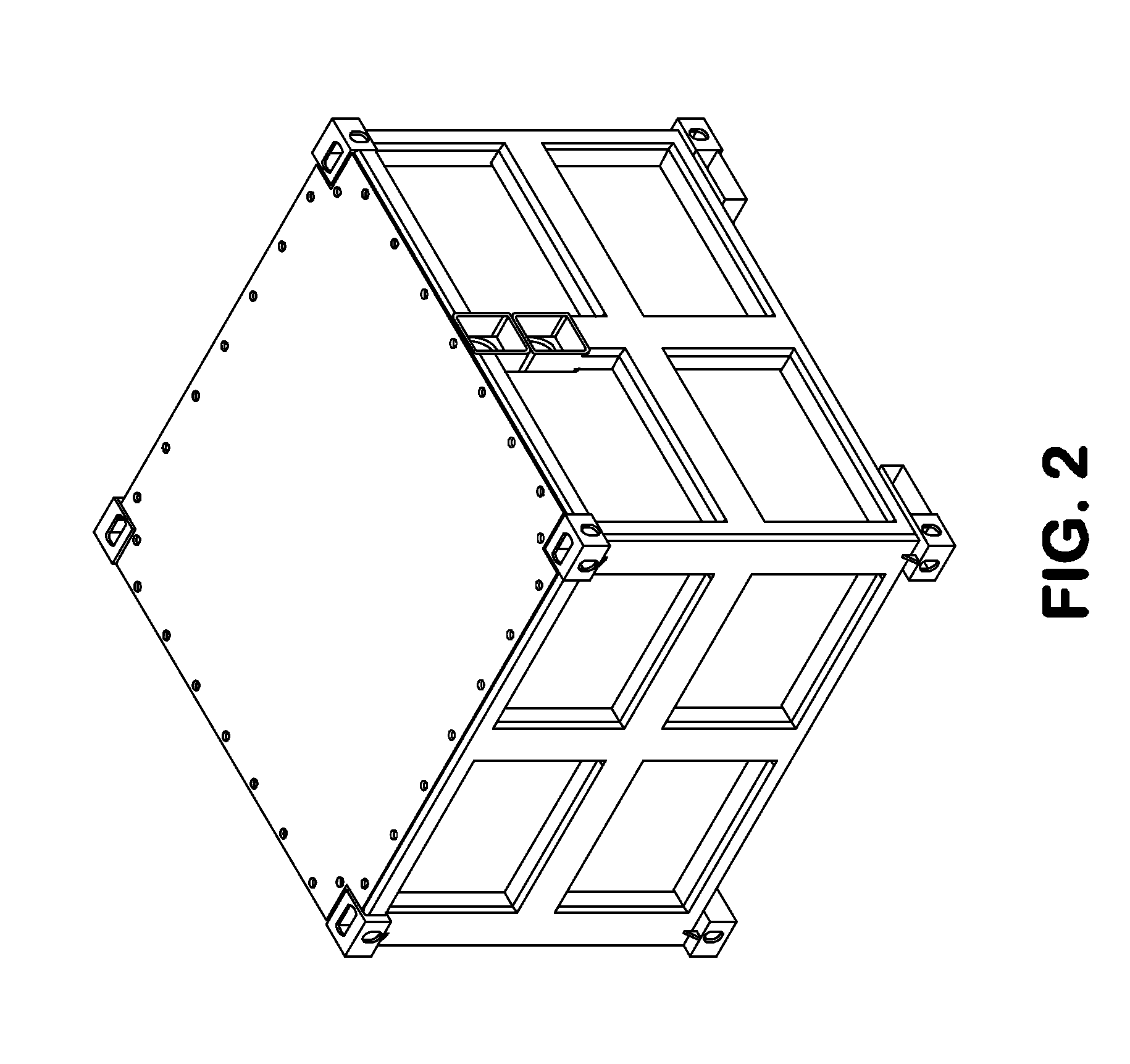

Waste container for collecting hazardous material

InactiveUS20160372225A1Eliminate exposureDispersed particle filtrationLarge containersEngineeringFilter material

A container is provided for collecting and filtering material. The container includes an inlet penetration through at least one surface of the container, and an outlet penetration through at least one surface of the container. The container further includes at least one filter being integral to the container such that the at least one filter is disposed of together with the container. The at least one filter is connected to the outlet. The material enters the container through the inlet, the material conveyed by a media (filtrate) is passed through the at least one filter resulting in a clean media stream (permeate), and the clean media exits the container through the outlet.

Owner:PENTEK

Medical device for modification of left atrial appendage and related systems and methods

Devices, methods and systems are provided for occluding an opening within the tissue of a body, such as a left atrial appendage. In one embodiment, a medical device coupled to a delivery catheter includes a fluid flow path that facilitates contrast fluid to pass through the delivery catheter and the medical device to a distal side thereof to provide imaging information as to the position of the medical device positioned in the opening, such as the left atrial appendage. In another embodiment, a medical device is coupled to a delivery catheter, the medical device including flaps adjacent a hub of the medical device that close-off a bore of the hub upon the catheter being detached from the medical device.

Owner:COHEREX MEDICAL

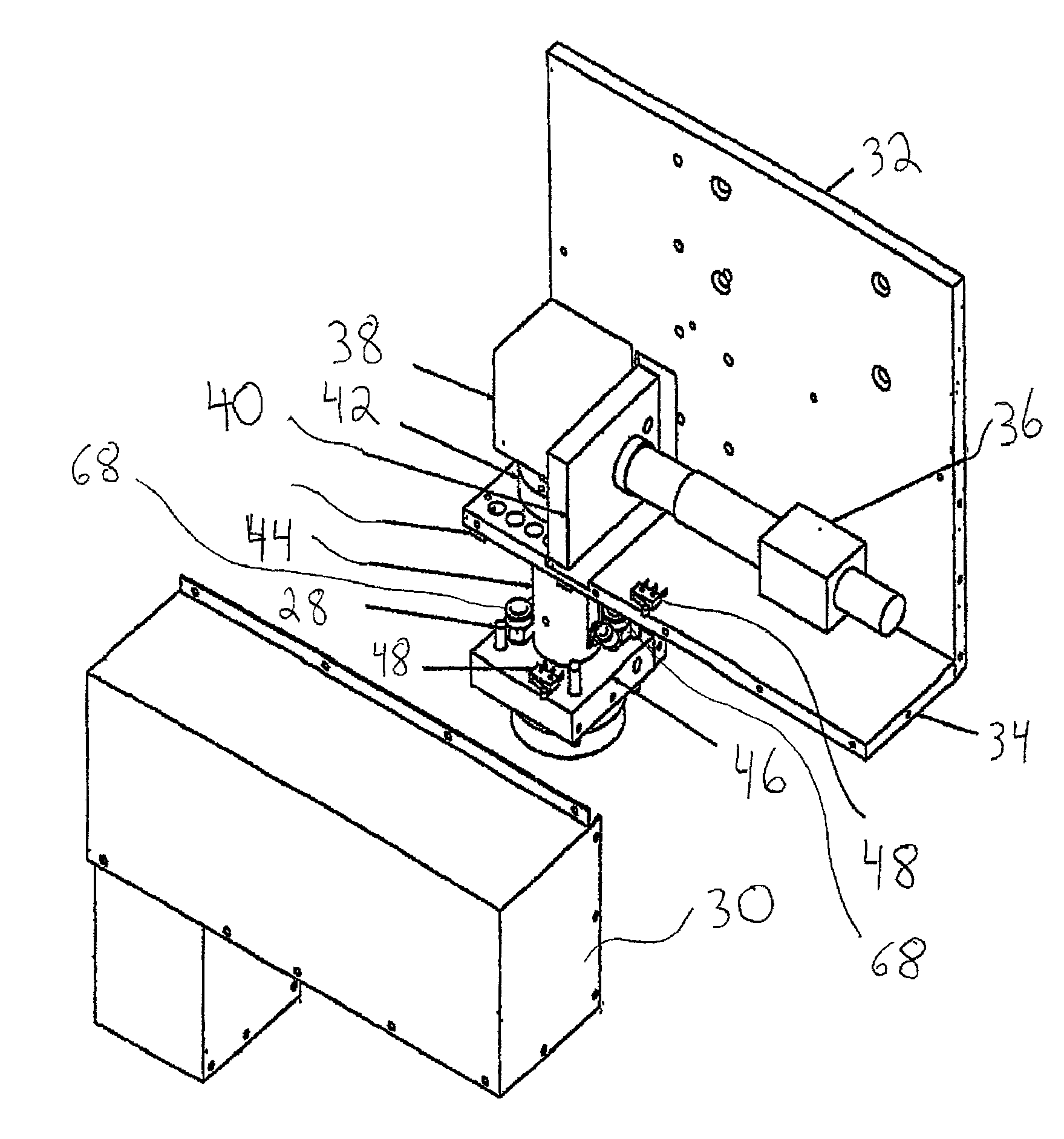

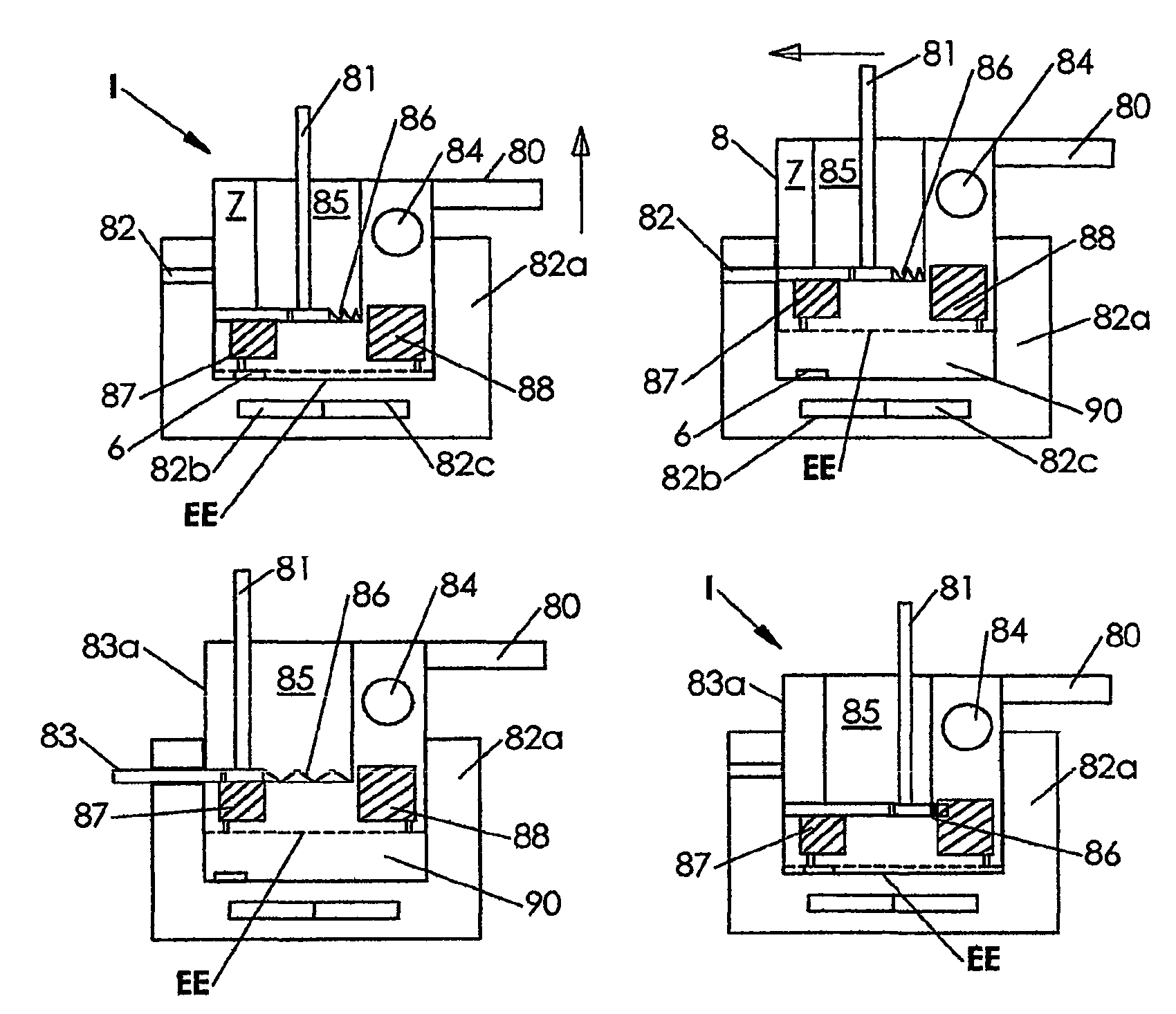

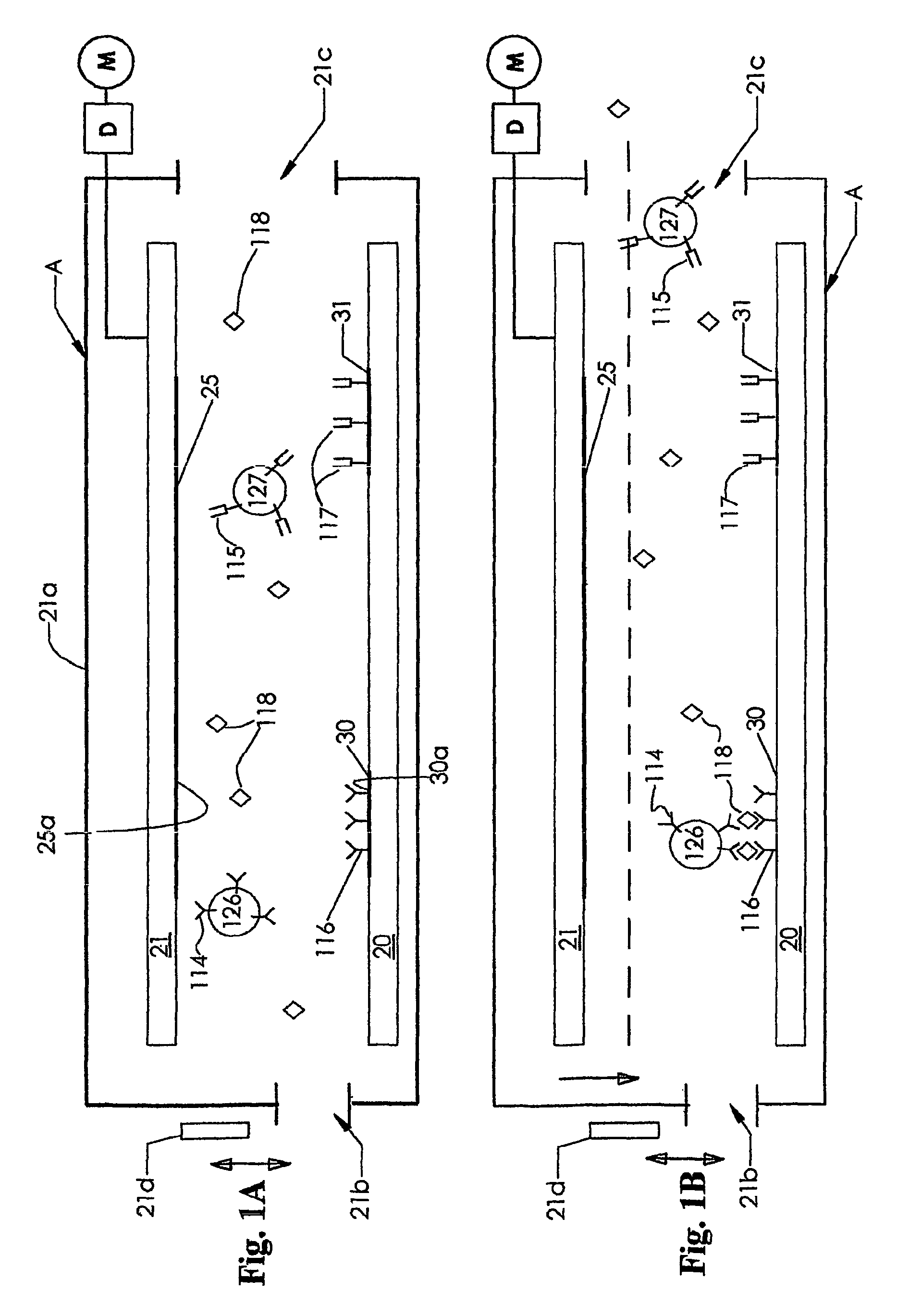

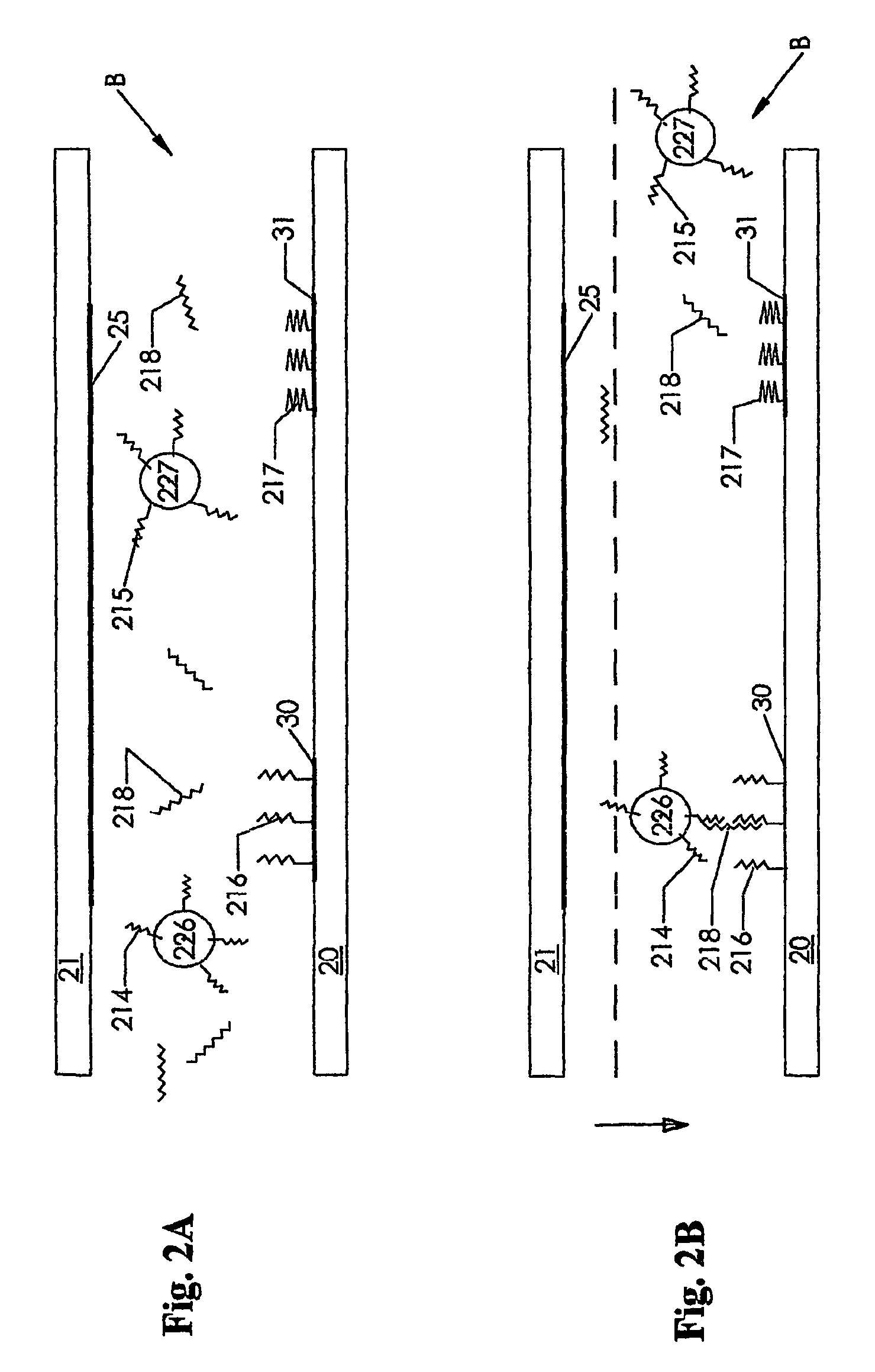

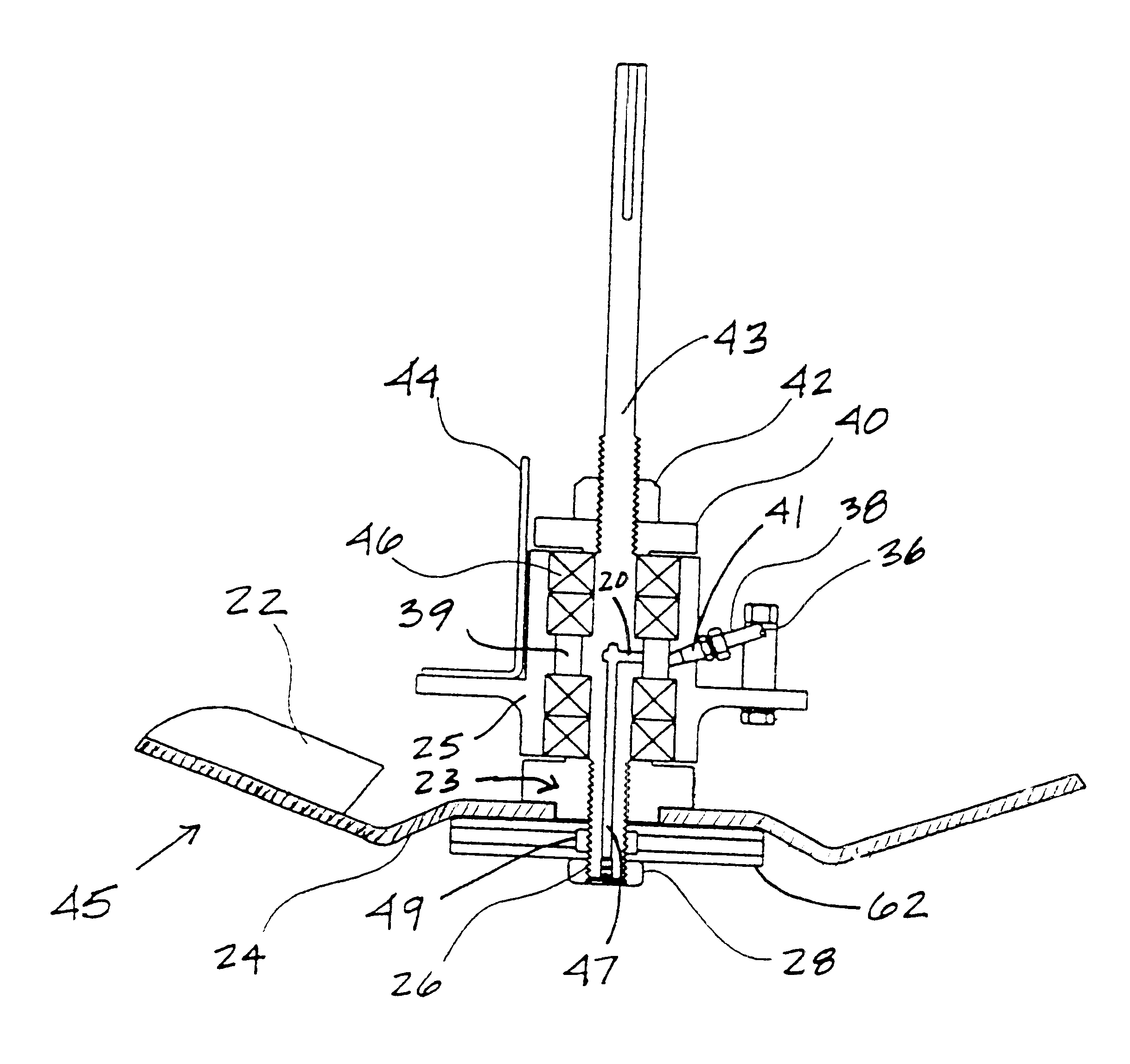

Diagnostic instrument with movable electrode mounting member and methods for detecting analytes

InactiveUS7435384B2High-precision detectionEliminate exposureMaterial nanotechnologyMaterial analysis by optical meansEngineeringDiagnostic instrument

An instrument (A) detects in a sample the presence of an analyte. The sample includes electrically readable particles (126) with an agent attached thereto that binds with the analyte or is an analog of the analyte. The instrument includes a port for the sample and a pair of electrodes (25, 30), one of which has a surface portion (30a) with an agent thereat that binds with the analyte or is an analog of the analyte. The electrodes have a first position where they are separated a sufficient distance apart to enable the sample to move between the electrodes and a second position where the electrodes are in close proximity. A detection circuit, including the electrodes, has a first state when the analyte is absent and a second state when the analyte is present. A signaling device provides an indication of the state of the detection circuit.

Owner:FISH LEONARD

Method and apparatus for a sanitizable mixing nozzle

ActiveUS20120037662A1Enhanced interactionEliminate exposureLiquid transferring devicesLiquid dispensingDiluentEngineering

A mixer assembly includes a mixer body and a mixer cover coupled to the mixer body. The mixer body includes an inner wall defining a mixing chamber having an inlet and an outlet. The inner wall includes a plurality of protrusions disposed on top of the inner wall that form a plurality of passes therebetween. The mixer body further includes a shell disposed around the inner wall that forms a diluent chamber between the inner wall and the shell. Diluent entering the diluent chamber flows through the plurality of passes and into the mixing chamber for mixing with product entering from the inlet of the mixing chamber. Mixed product exits the mixer body from the outlet of the mixing chamber. The mixer cover includes an angled shelf that closes out the diluent chamber and extends over the plurality of passes such that diluent entering the diluent chamber moves through the plurality of passes along the angled shelf and into the mixing chamber.

Owner:LANCER PARTNERSHIP

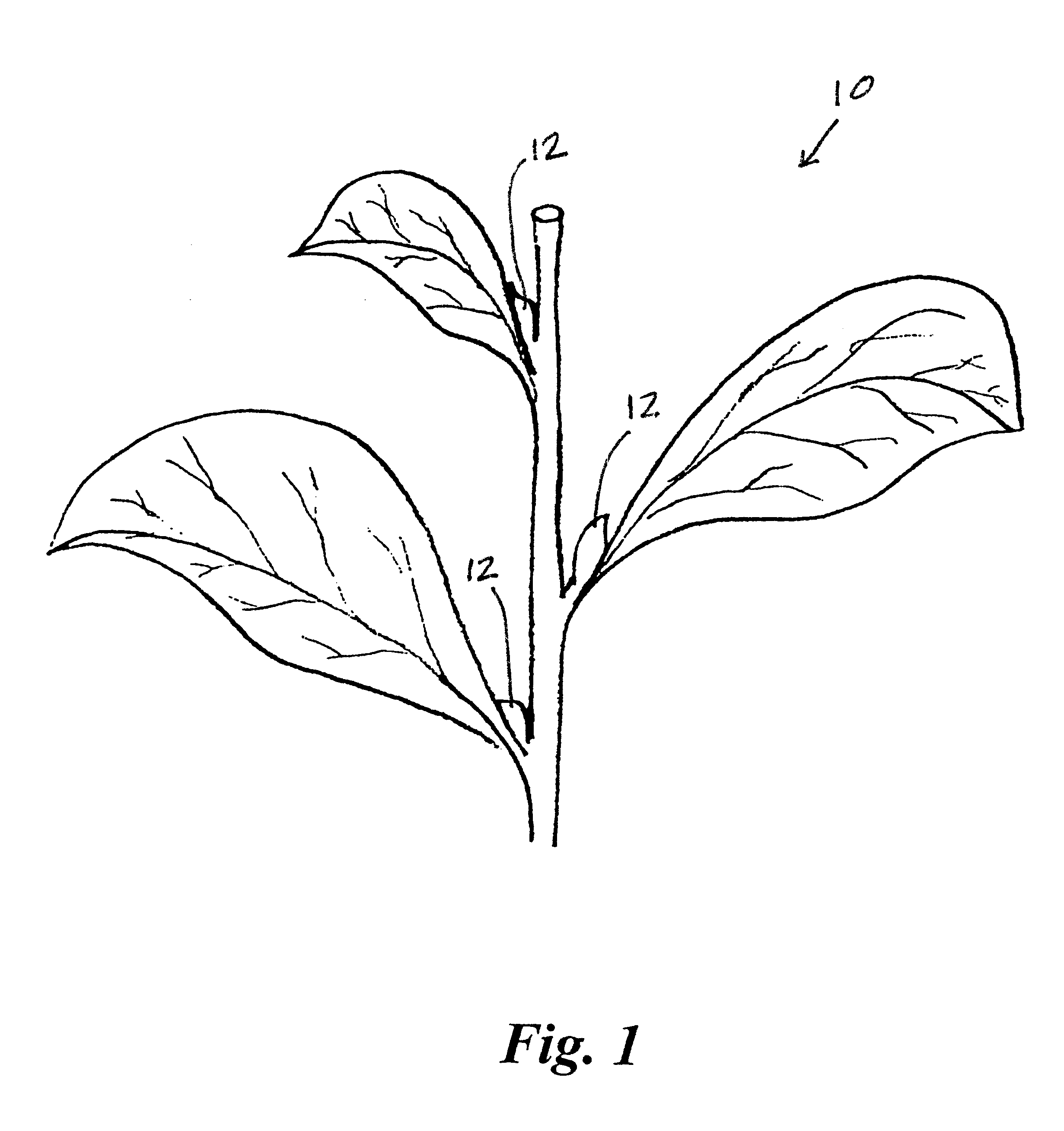

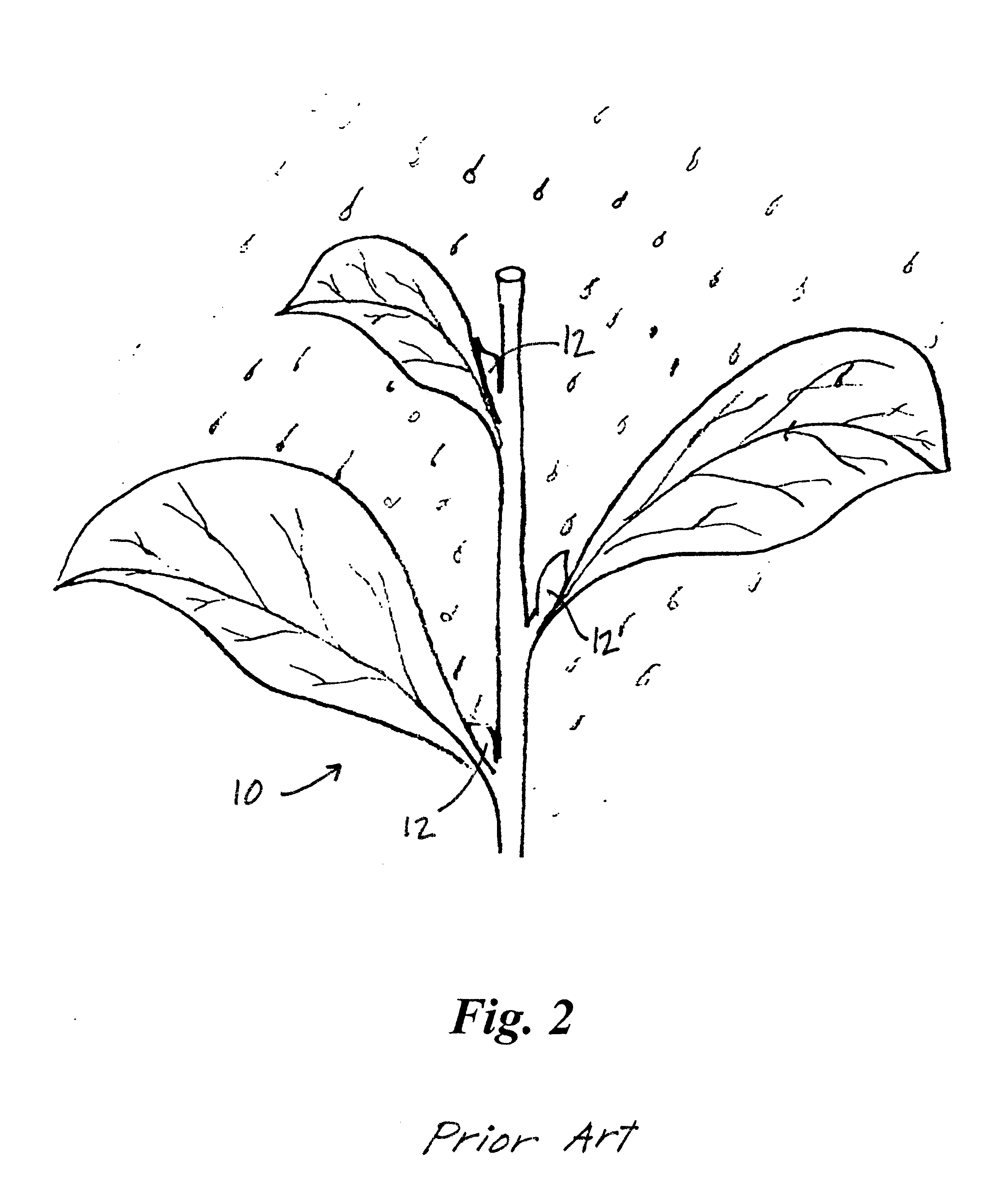

Method and apparatus for simultaneously topping tobacco and controlling suckers with chemicals applied to cut stems by mechanical means

InactiveUS6446420B1Reducing maleic hydrazide residueEliminates existing maleic hydrazide sprayingLawn-mowersDiggersMechanical engineeringChemical substance

A method and apparatus for simultaneously cutting and directing fluid into the stem of a tabacco plant, the apparatus including having a liquid delivery blade, a source of fluid communicating with to the underside of the blade, an associated power source for rotating the liquid delivery blade at a sufficiently high speed "top" tobacco plants.

Owner:BURCH CO +1

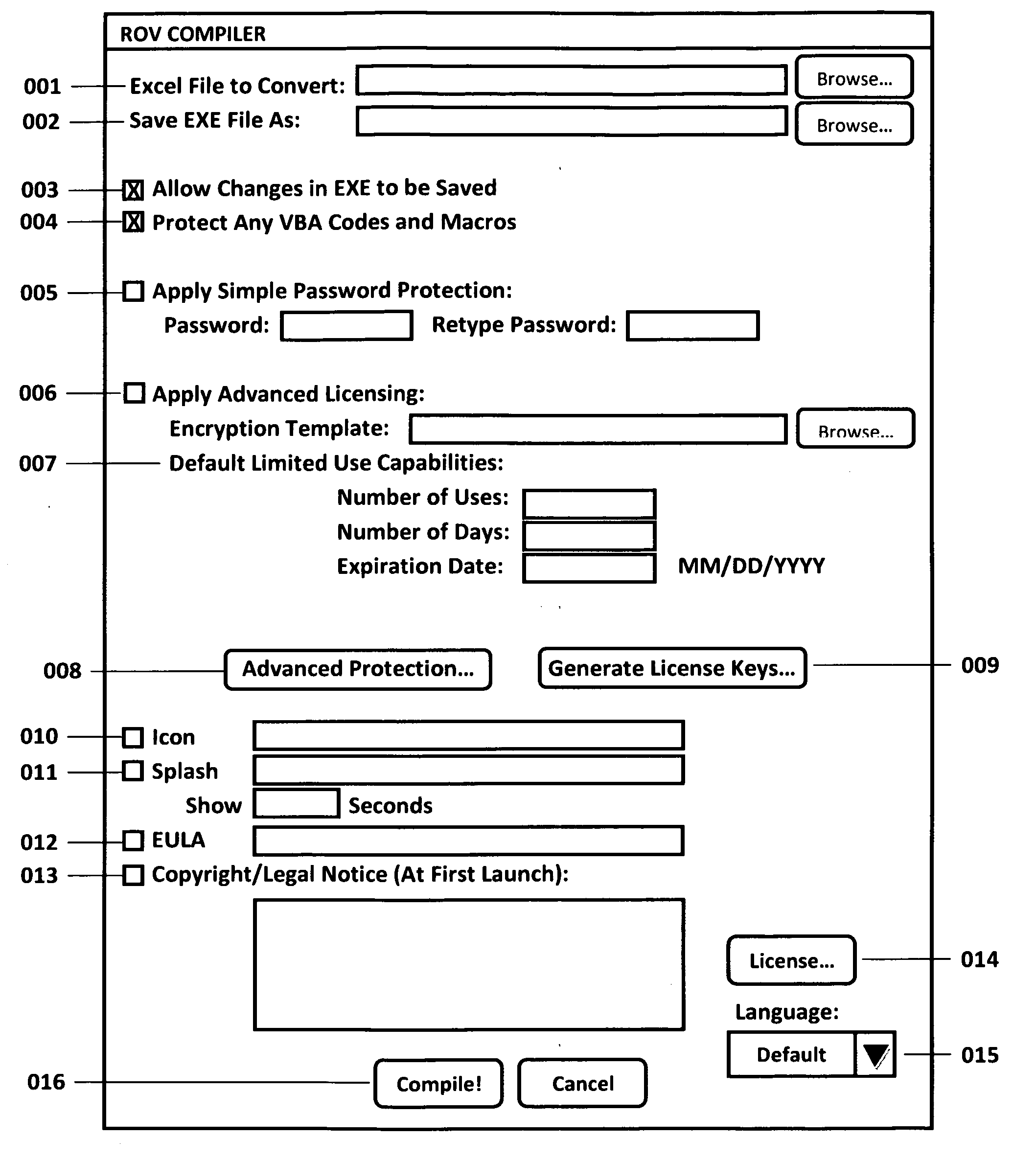

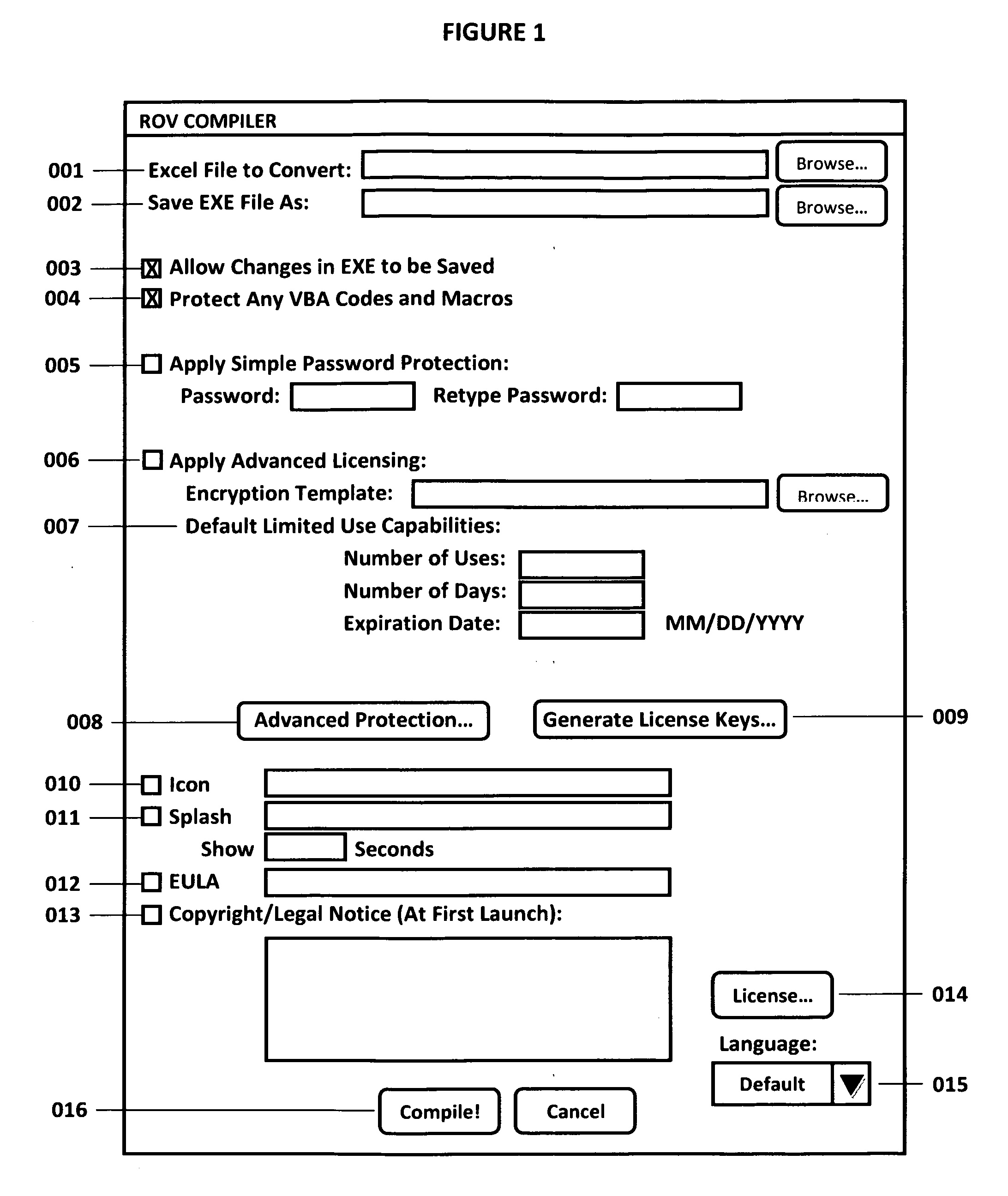

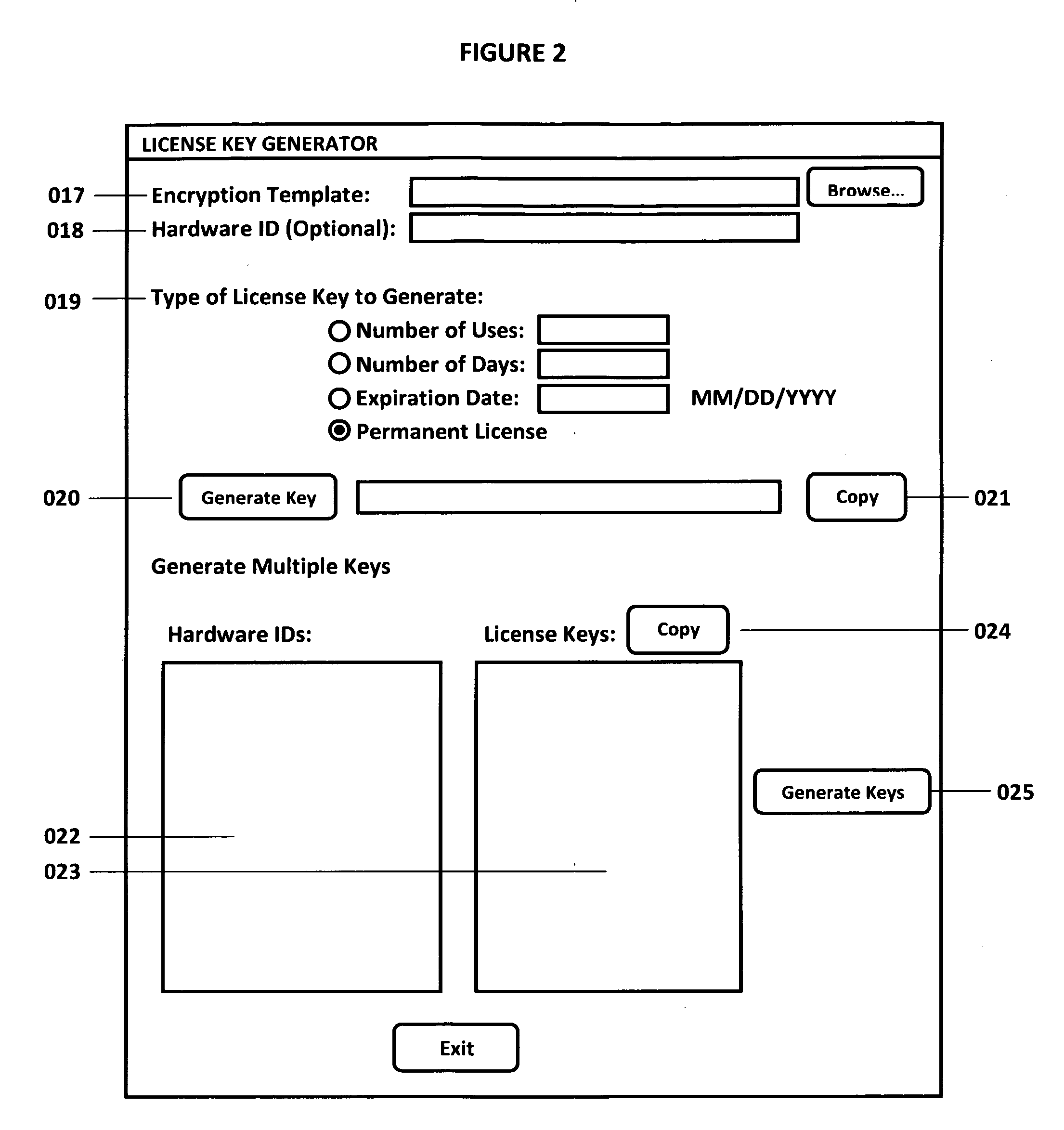

Evaluation compiler method

ActiveUS20100205586A1Save precious computing resource time moneyHigh speedLink editingDigital data processing detailsSoftware systemTheoretical computer science

A method and software system allowing the ability to use an existing Excel model and extract the business intelligence, relationships, computations and model into pure mathematical relationships and codes such that the business intelligence in the original model is completely protected and the model can be run at extremely high speed and advanced simulations of hundreds of thousands to millions of trials can be run.

Owner:MUN JOHNATHAN C

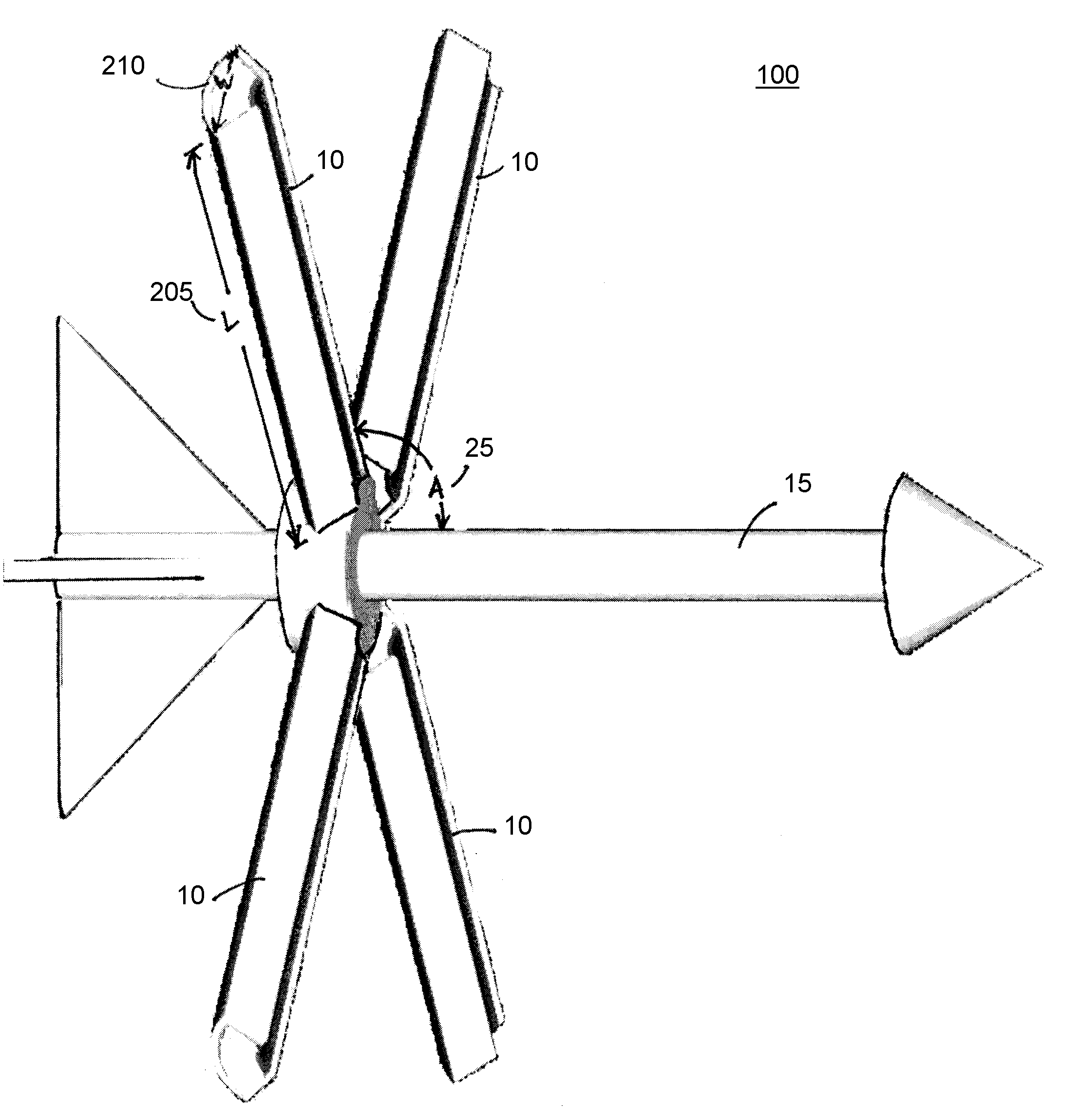

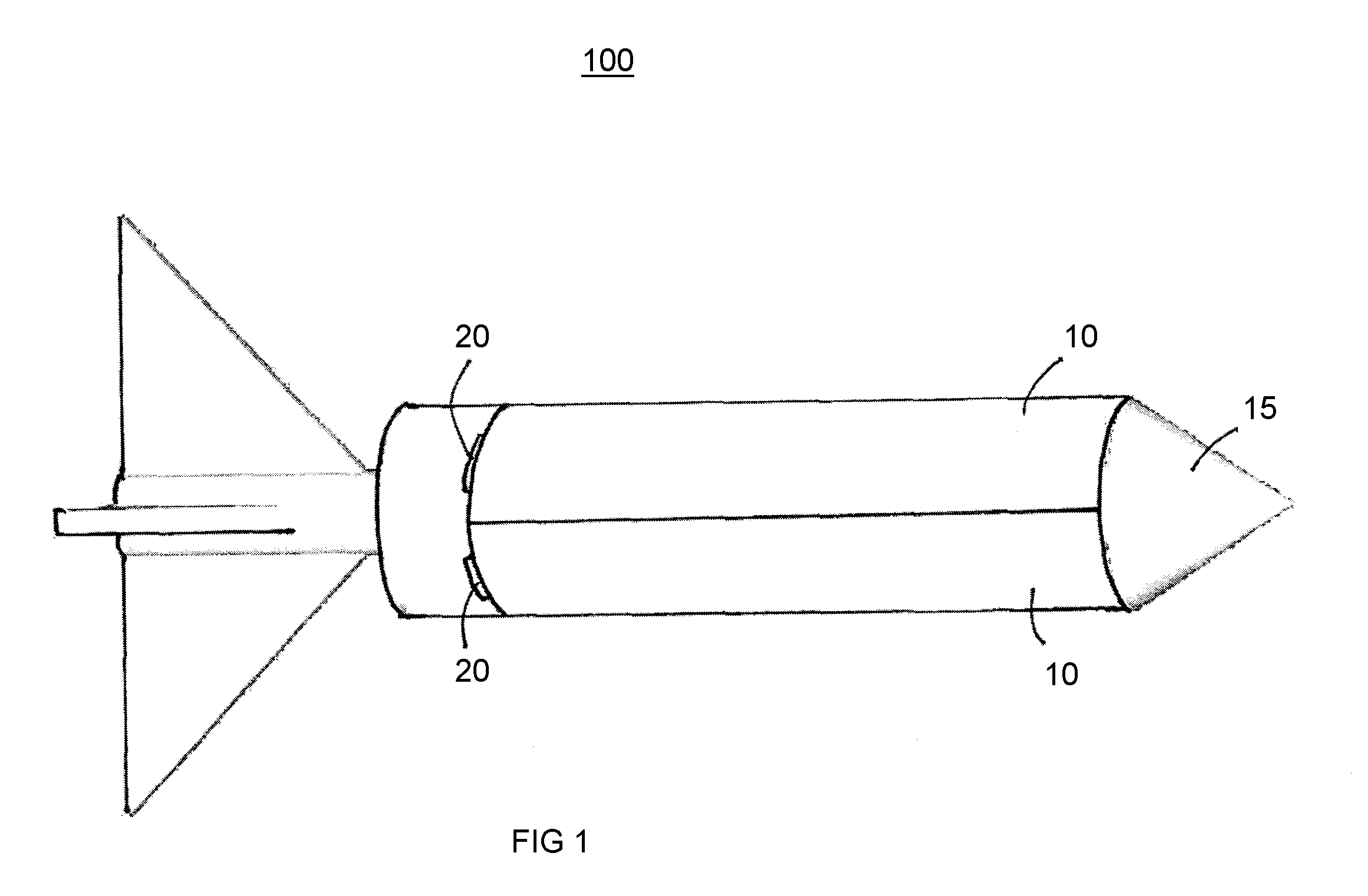

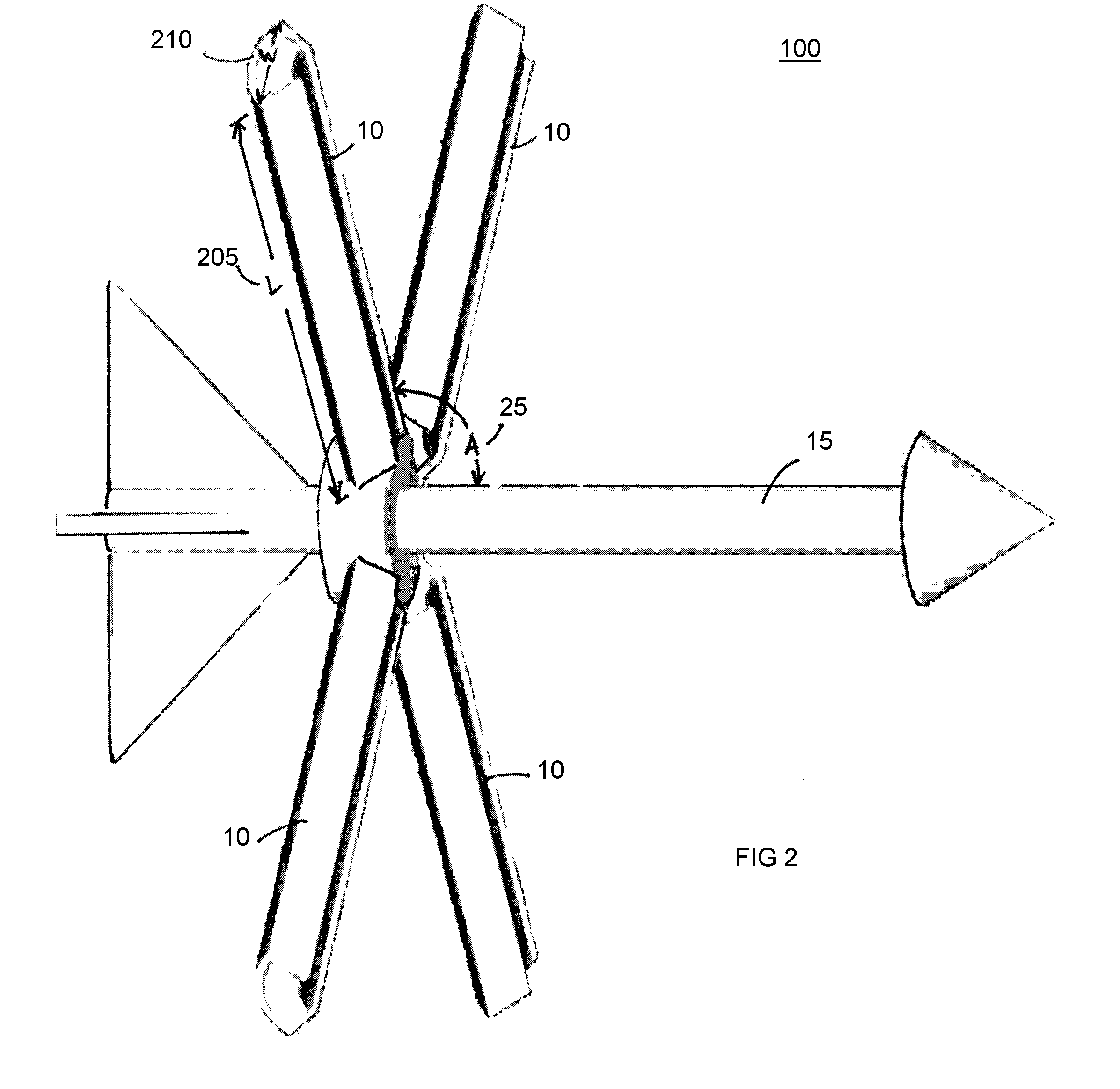

Missile system for breaching reinforced concrete barriers utilizing hinged explosively formed projectile warheads

InactiveUS7007607B1Improve penetrationWide areaAmmunition projectilesTraining ammunitionMissile systemRebar

A hinged explosively formed projectile warhead system eliminates exposure of soldiers to harm in wall breaching operations by providing a lethal mechanism that can be deployed at safe distances, simultaneously breaching a man-sized hole and removing one or more rows of rebar in reinforced concrete structures or barriers. The warhead system employs both a missile system and explosively formed projectile warhead technology delivered to the target from a tube launched platform. A set of warhead arms is attached to the aft end of a missile body by means of a set of hinges. The warhead arms are initially folded against the missile body. After launch of the warhead system, the warhead arms fold away from the missile body. The angle at which the warhead arms are folded from the missile body determines the area of a hole breached by the warhead system in a reinforced concrete target.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

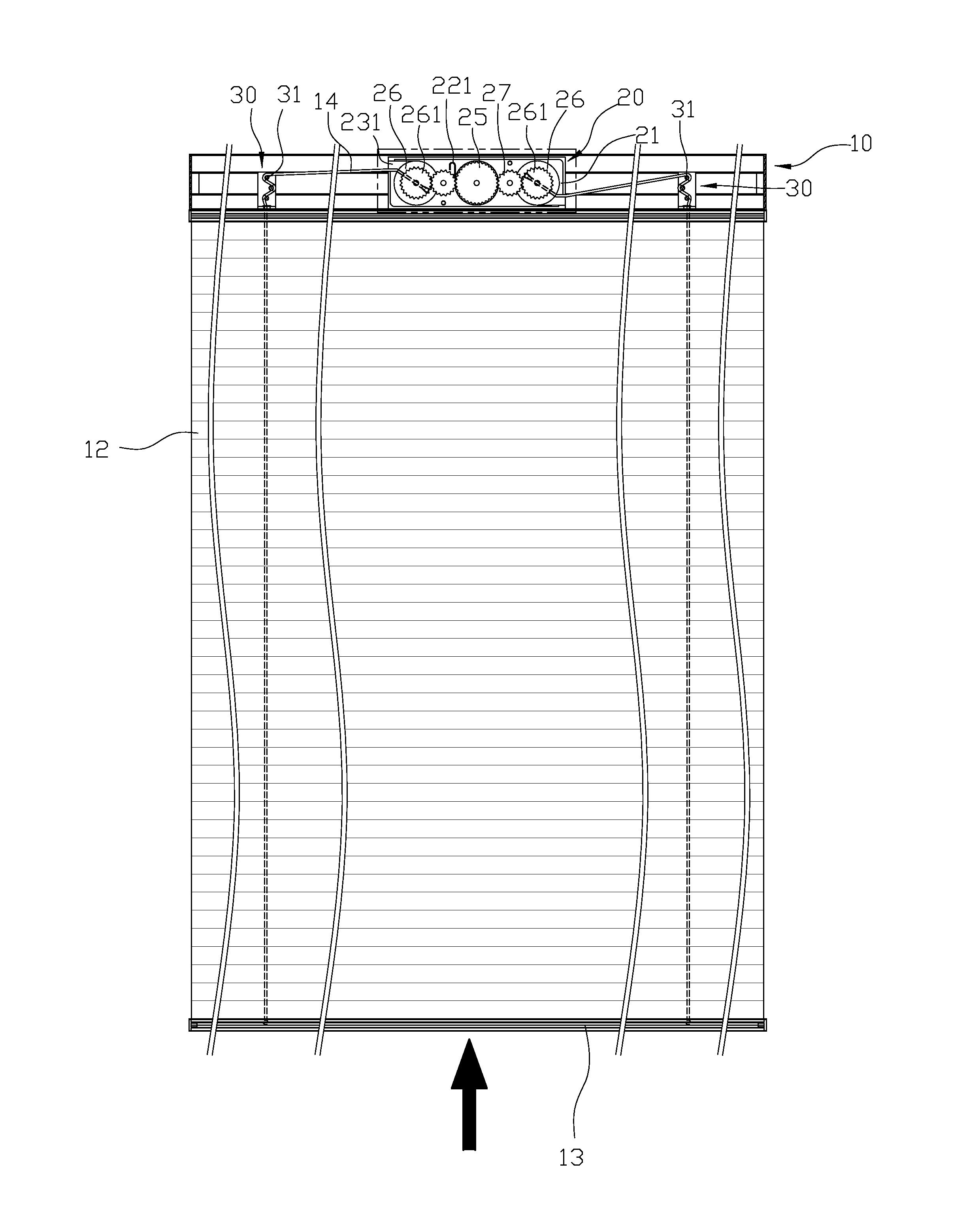

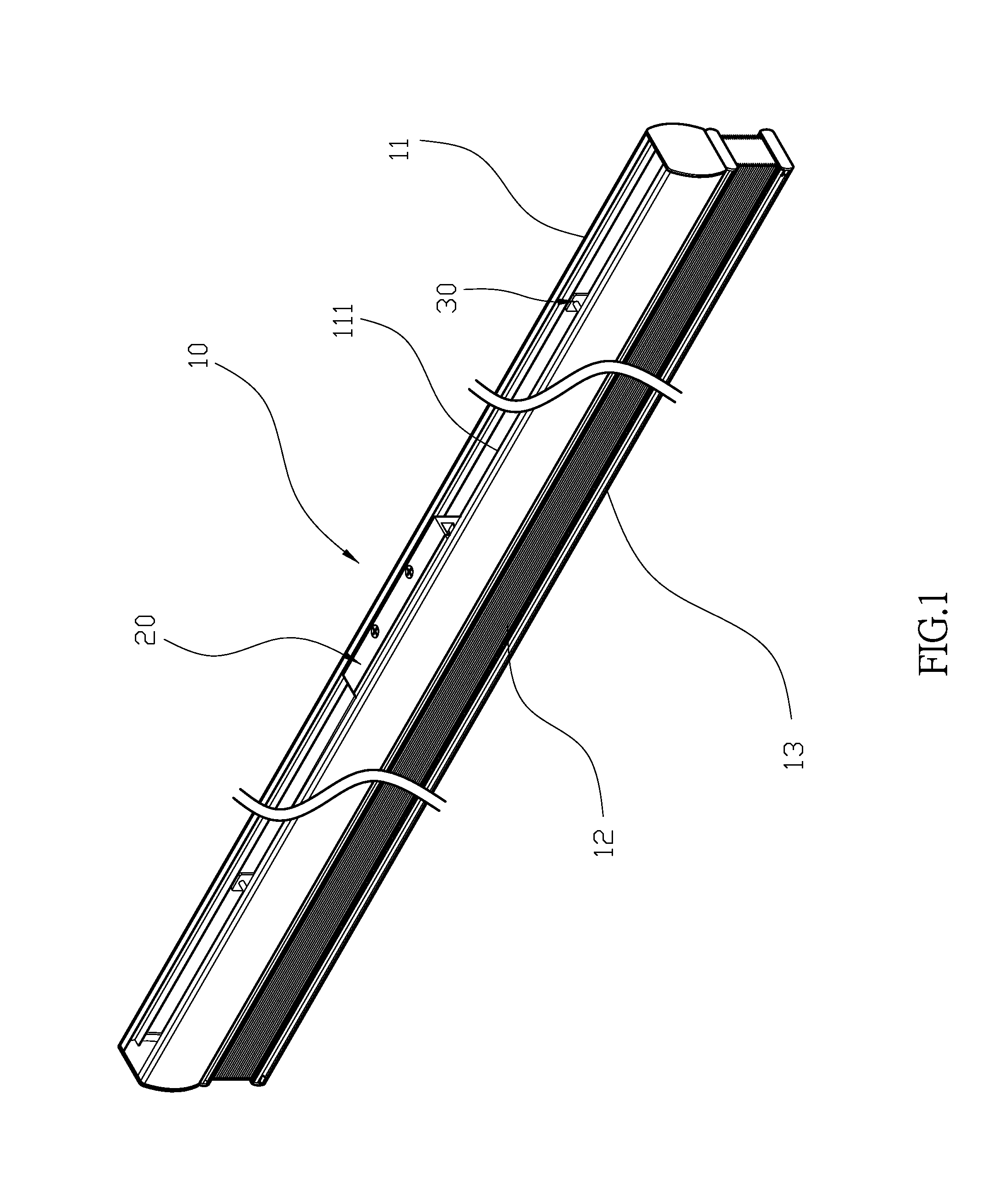

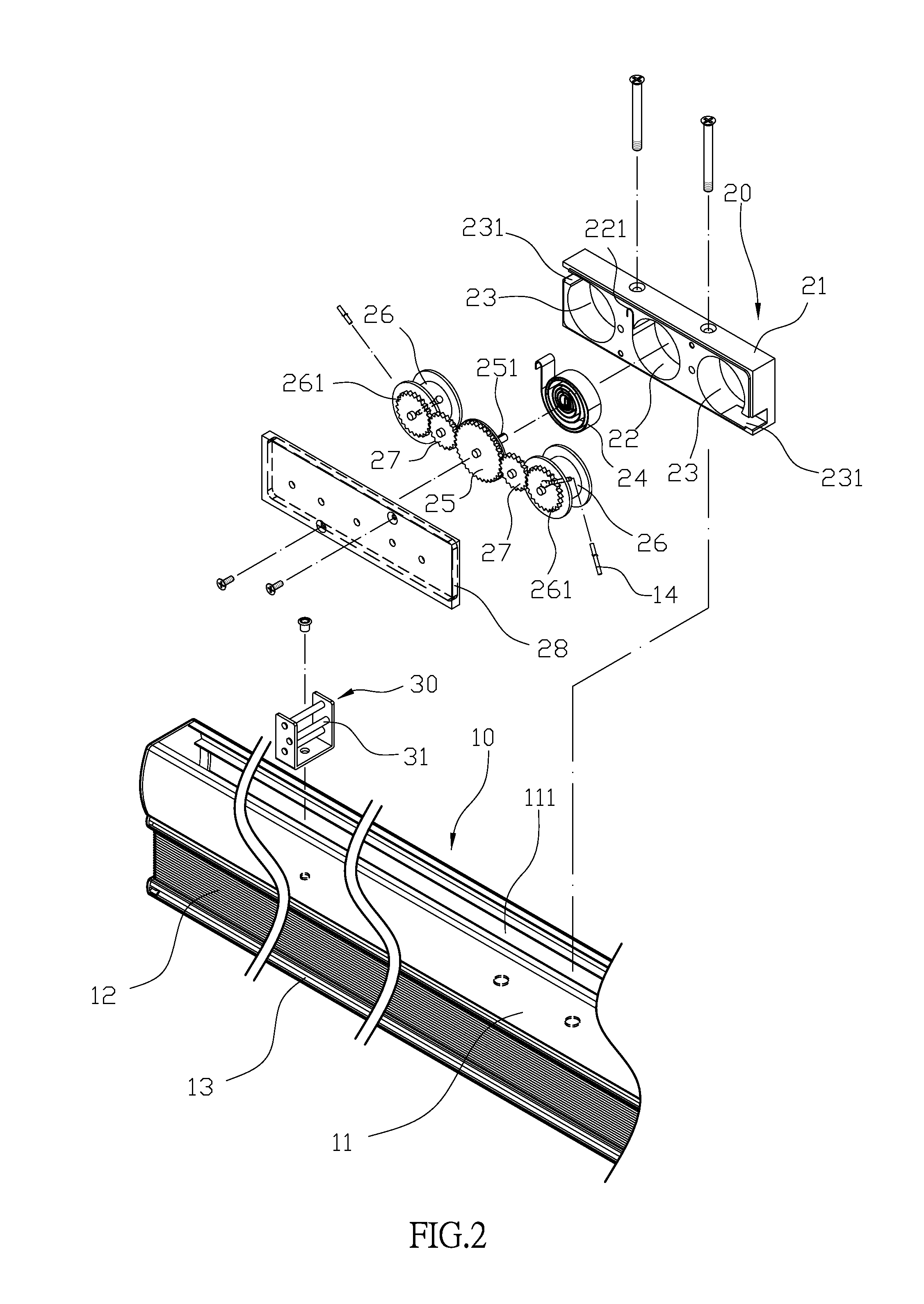

Stringless curtain structure

InactiveUS20150129142A1Eliminate exposureHigh precisionDoor/window protective devicesCurtain suspension devicesEngineeringMechanical engineering

A stringless curtain structure has a curtain body, a string rolling mechanism and two breaking units, wherein weight of a spring in the string rolling mechanism and a weighted lower beam is balanced, the user can push / pull the weighted lower beam to control a curtain of the curtain body to eliminate the exposure of the string, so little children would not play with the string to lead to dangerous situation. Furthermore, the breaking unit is disposed at each sides of the string rolling mechanism, so when the curtain needs to be positioned, the friction between the string and the breaking units can be used to enhance the precision of the positioning of the curtain body.

Owner:HUANG HUA CHI

Mold core for manufacturing high-temperature alloy hollow blade

The invention provides a mold core for manufacturing a high-temperature alloy hollow blade. The mold core is placed in a wax injection mold to fabricate a wax pattern and the wax pattern covered with the mold core is used for fabricating a ceramic mold case; two positioning grooves are formed at the center positions of the front and rear two surfaces of the blade tip core head of the mold core; the positioning grooves are internally tapered grooves and the center lines of the positioning grooves are coincident with each other; and a pair of convex pins matched with the blade tip is arranged corresponding to the blade tip position of the wax injection mold. The mold core for manufacturing the high-temperature alloy hollow blade provided by the invention is characterized in that in mold core design, the shape of the core head part is simplified, and exposure of the blade root core head is eliminated so as to reduce involvement with the wax injection mold and the ceramic mold case, so that core making work becomes easy and the damage of the mold core is reduced. The mold core has certain degree of rotation freedom at the blade top core head in the directional solidification process of the high-temperature alloy hollow blade in the ceramic mold case, and the blade root core head is capable of completely and freely stretching in the vertical direction; therefore, the deformation and breakage of the mold core are greatly reduced, and the yield of the hollow blade is obviously improved.

Owner:DONGFANG TURBINE CO LTD

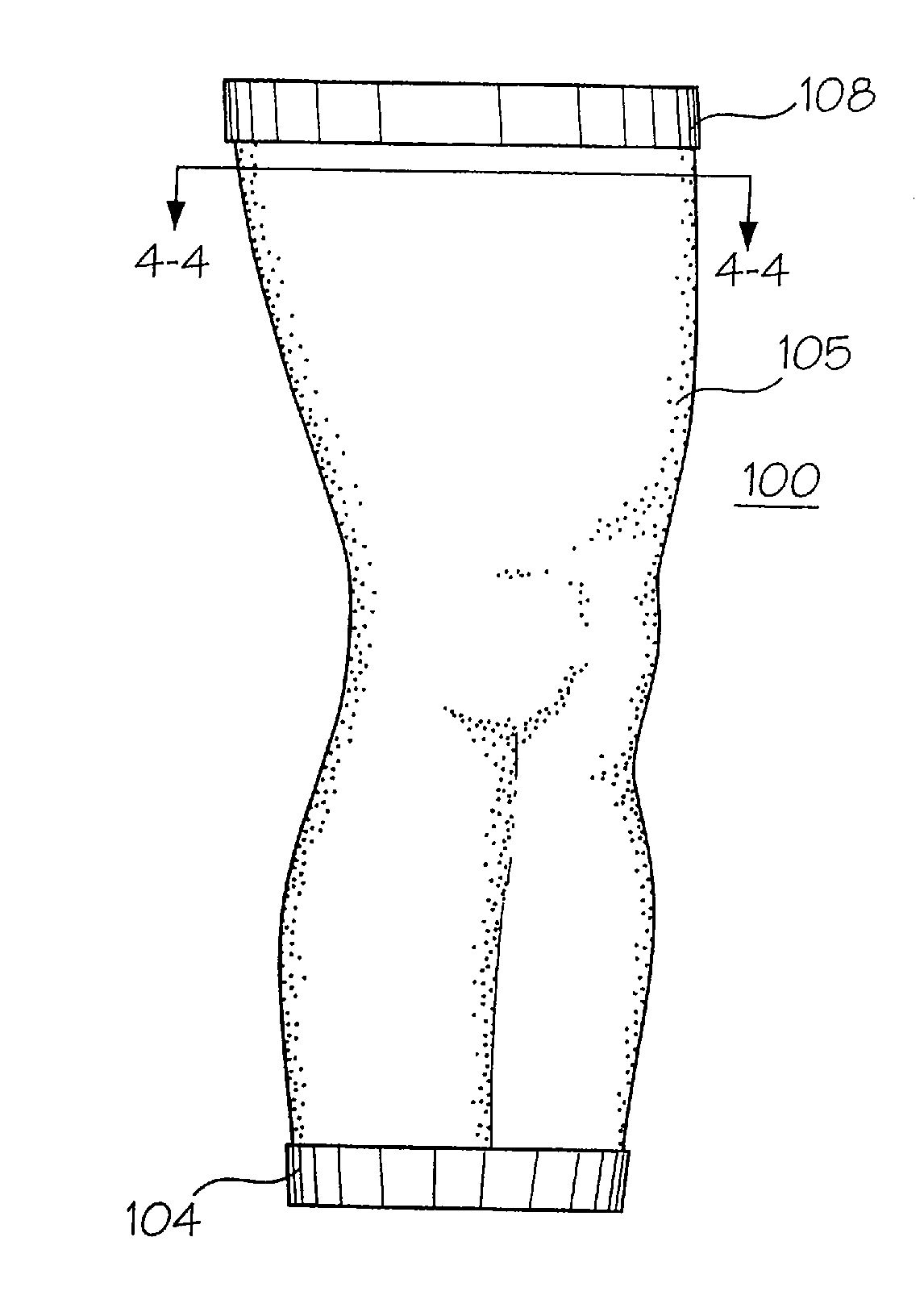

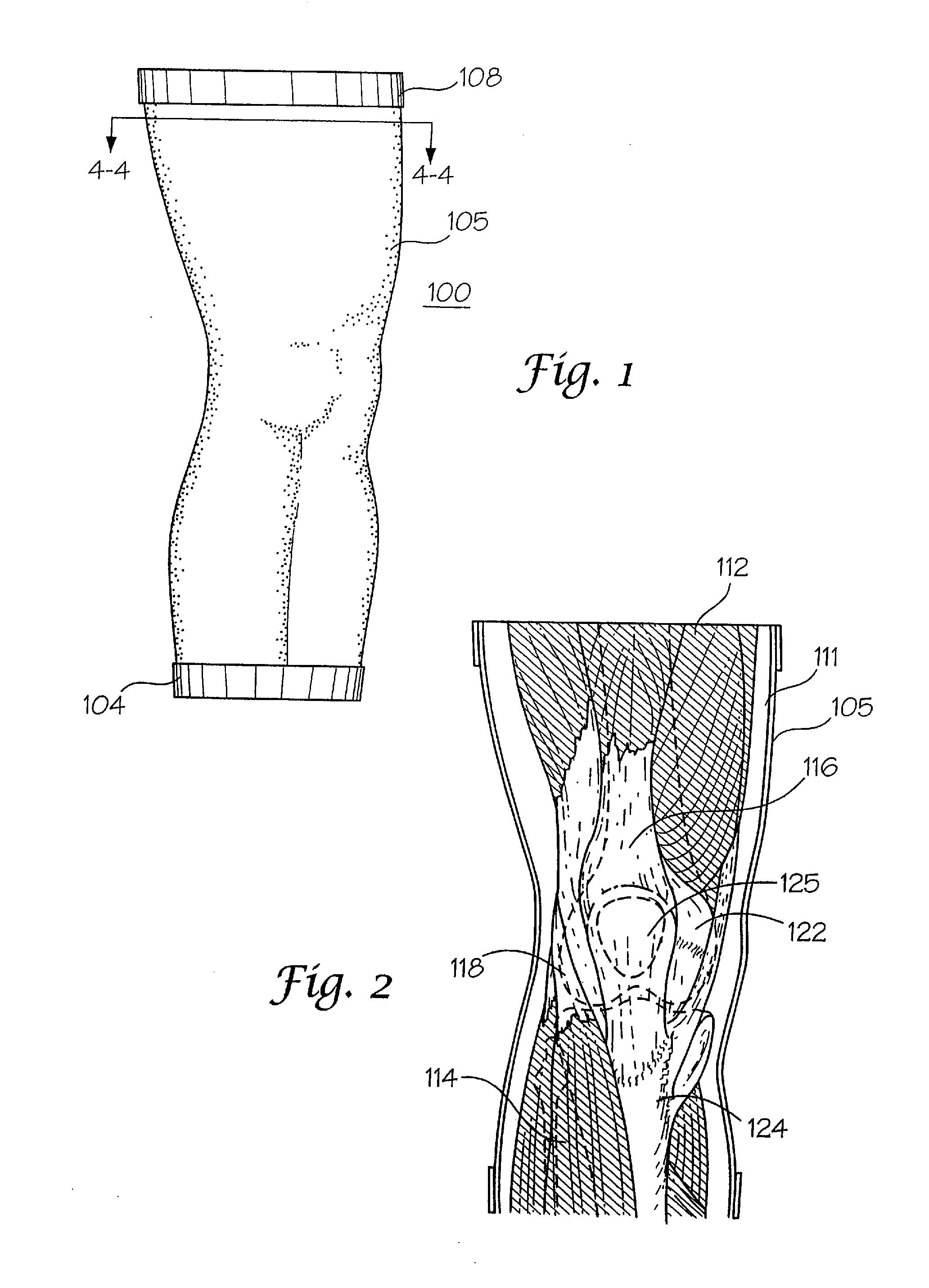

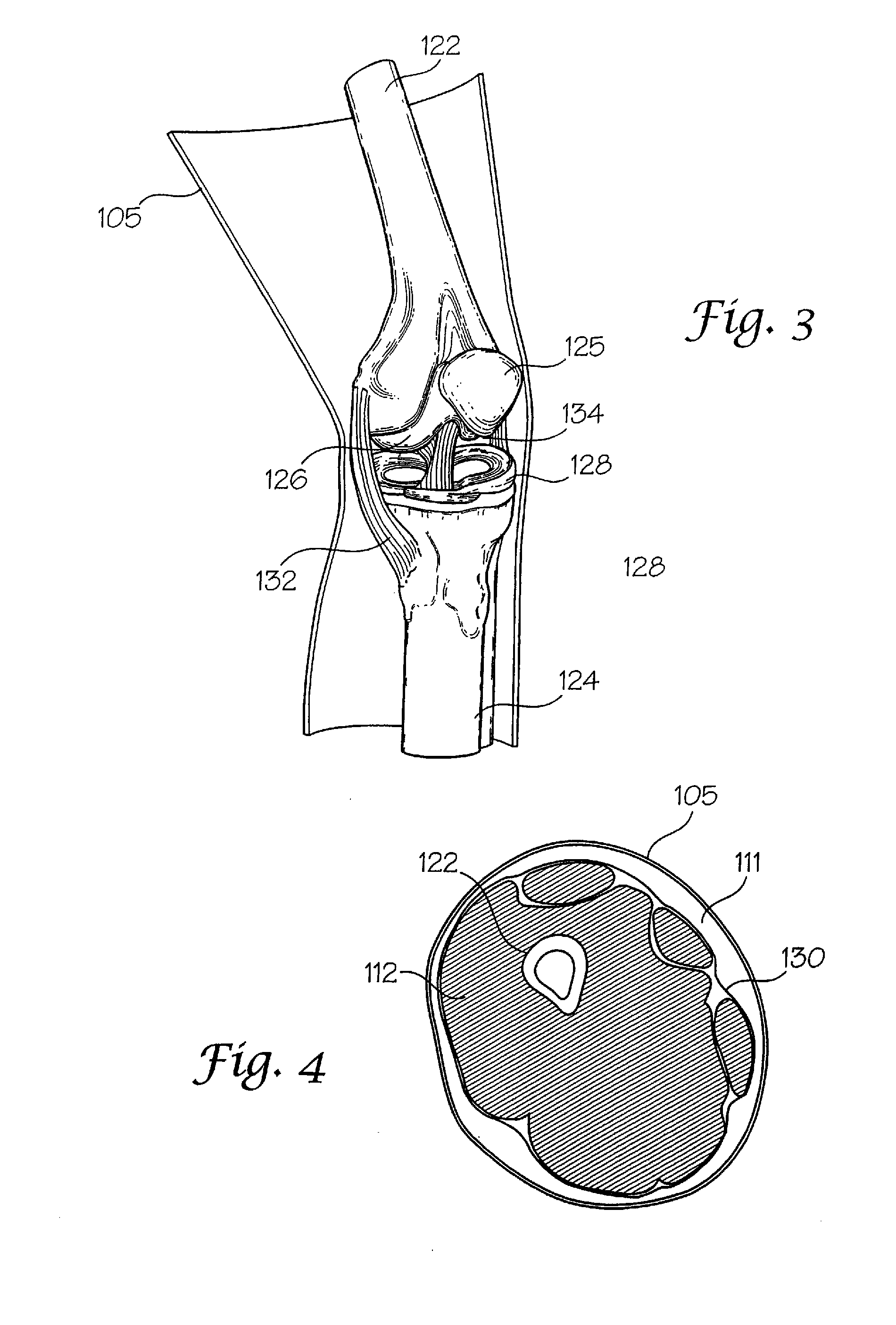

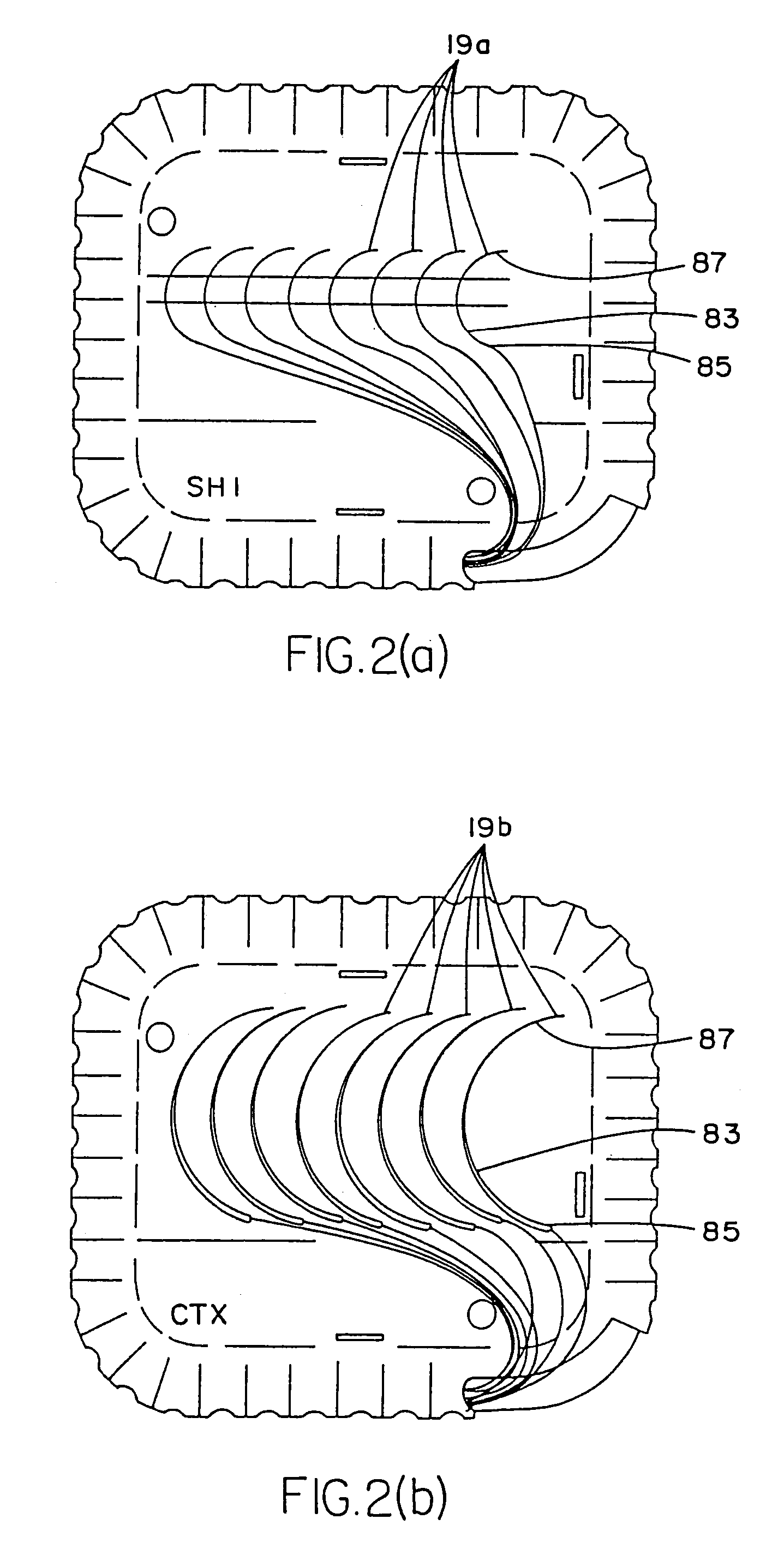

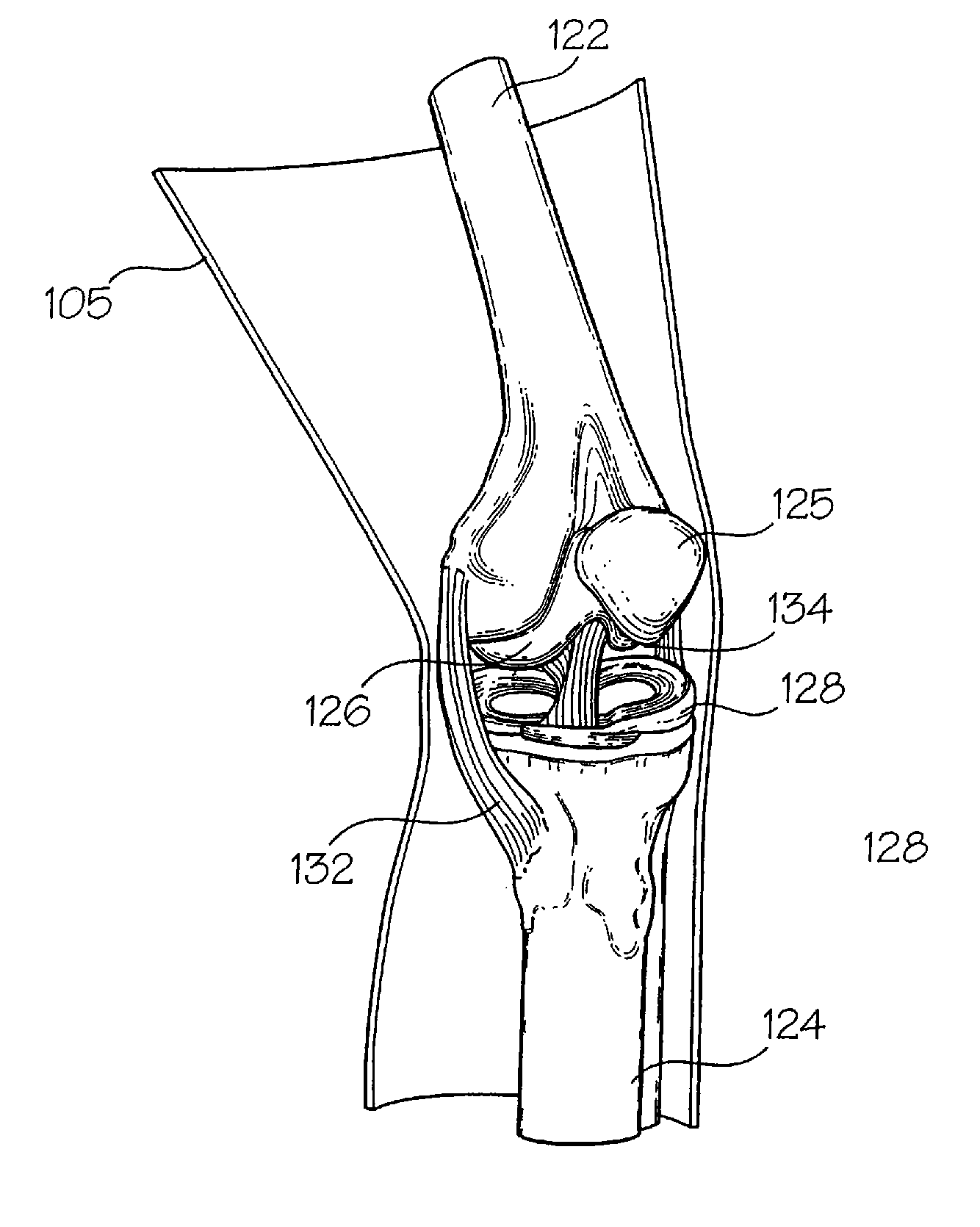

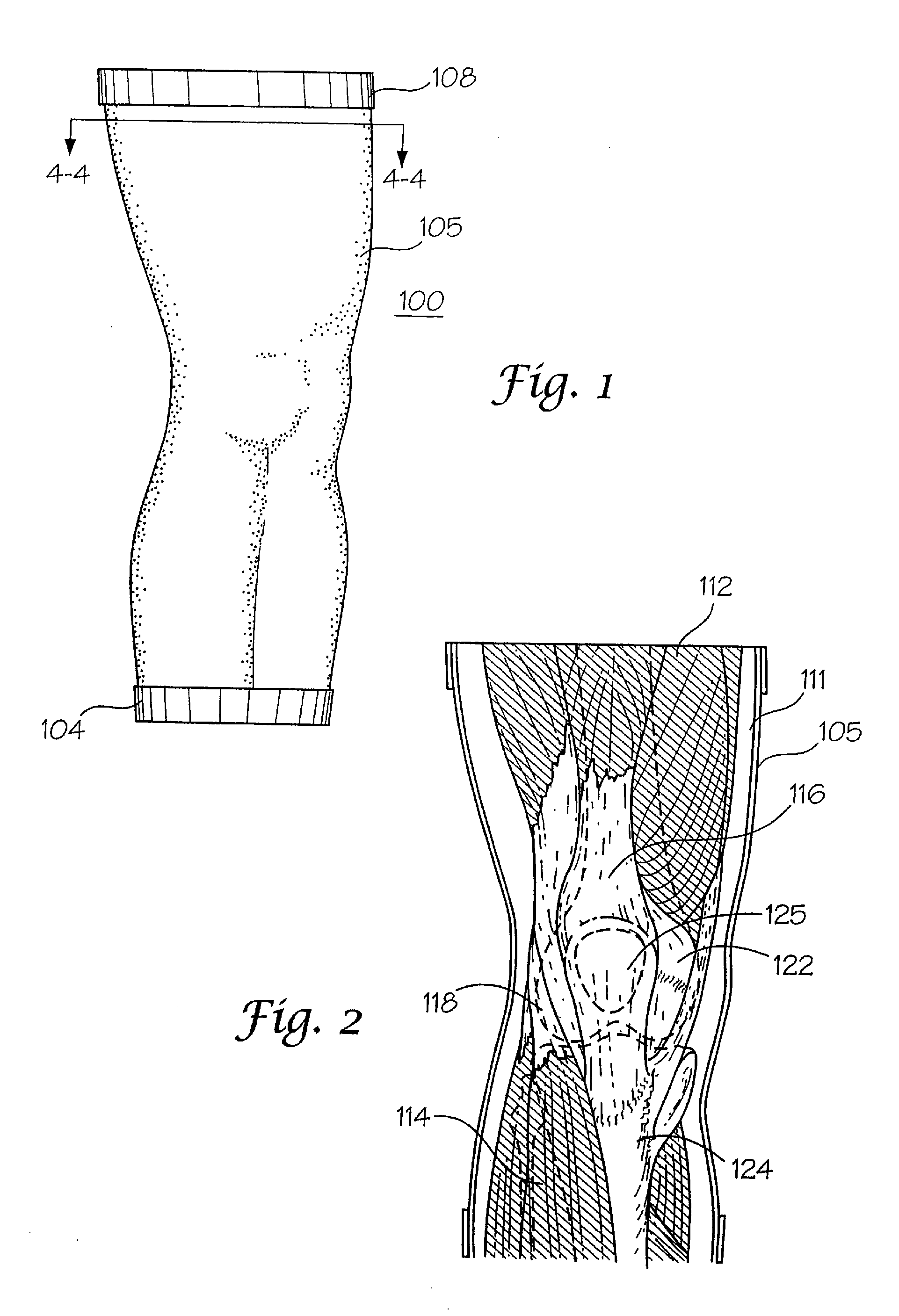

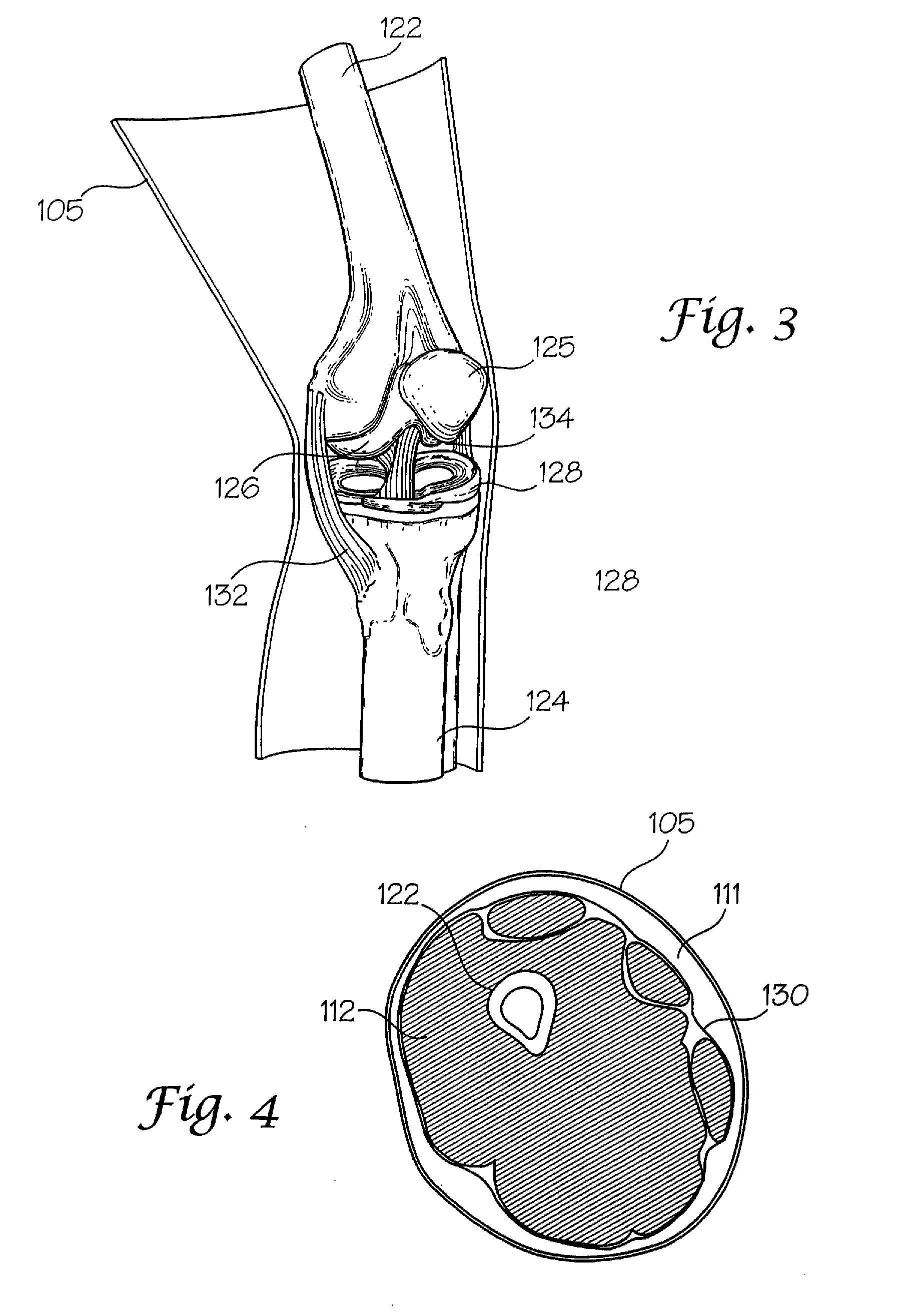

Joint replica models and methods of using same for testing medical devices

ActiveUS20100136510A1Avoid product qualityLengthened product timelinesAdditive manufacturing apparatusEducational modelsAnatomical structuresTarget tissue

Disclosed herein are joint replica models that are designed to enable simulated use testing by medical device companies, medical device designers, individual inventors, or any other entity interested in the performance of medical devices. These models are unique in possessing a level of complexity that allows them to be substituted for either a live animal, an animal cadaver, or a human cadaver in the testing of these devices. These models are further characterized by a similarity of geometry, individual component physical properties, and component-to-component interfacial properties with the appropriate target tissue and anatomy.

Owner:SAKEZLES CHRISTOPHER

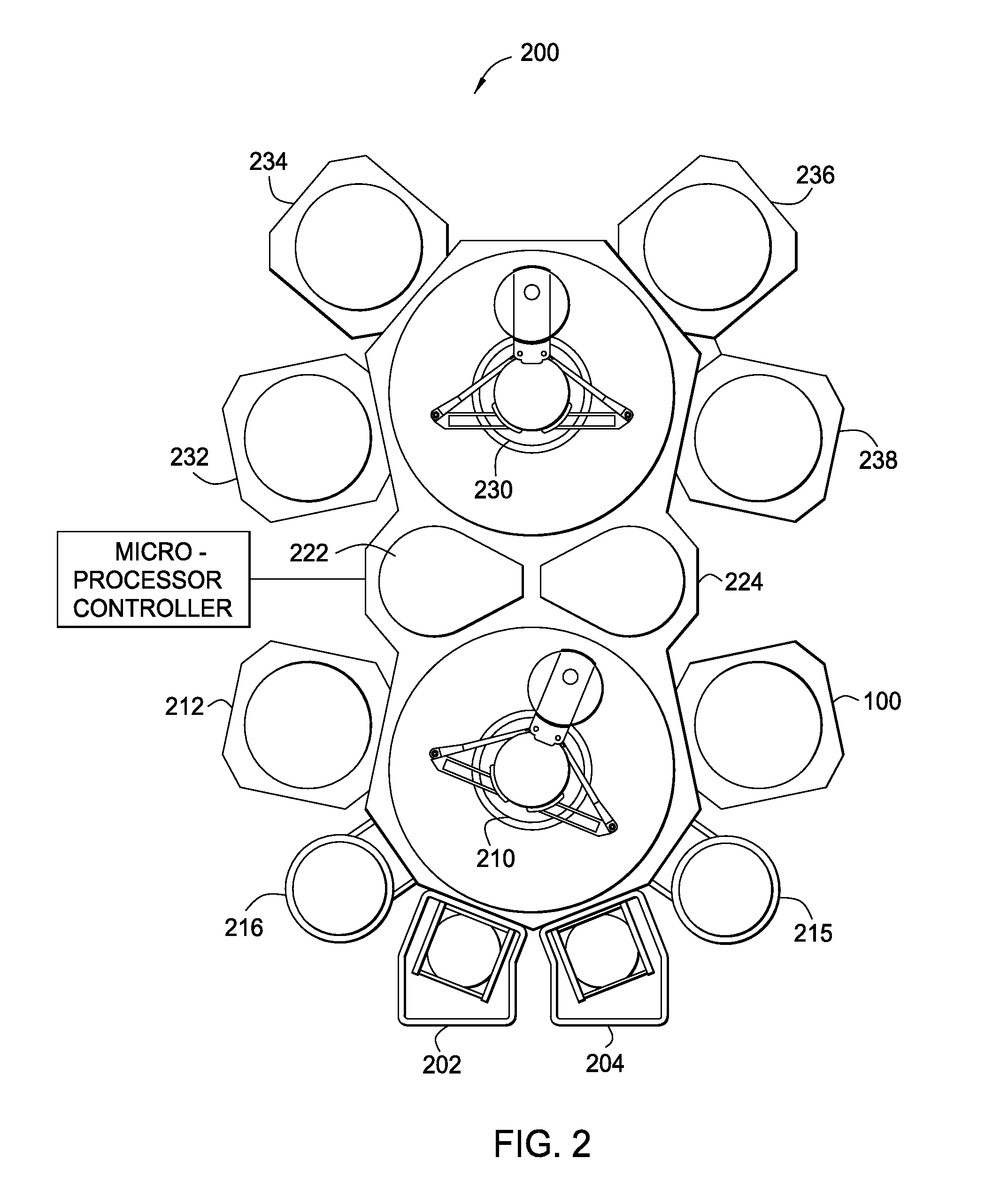

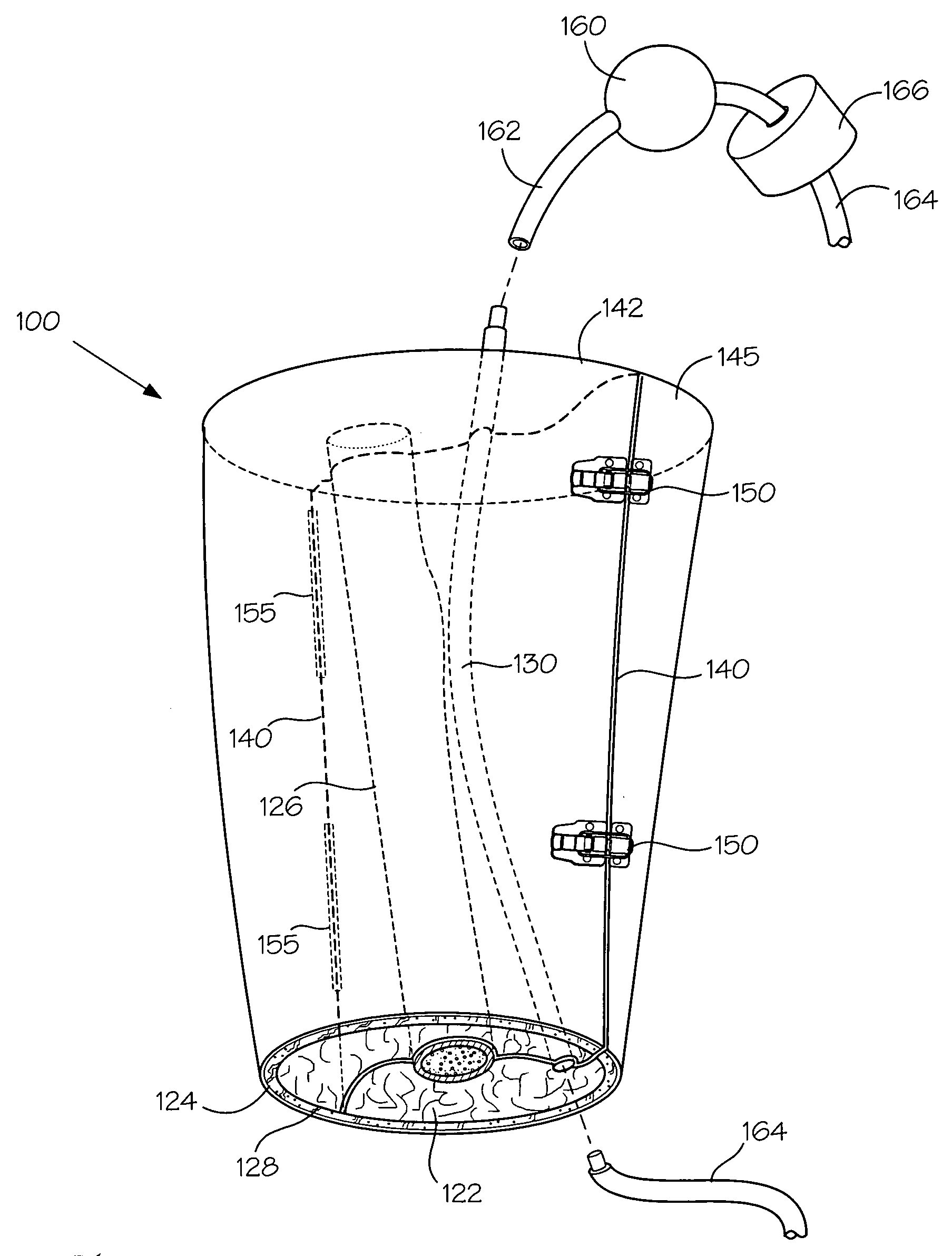

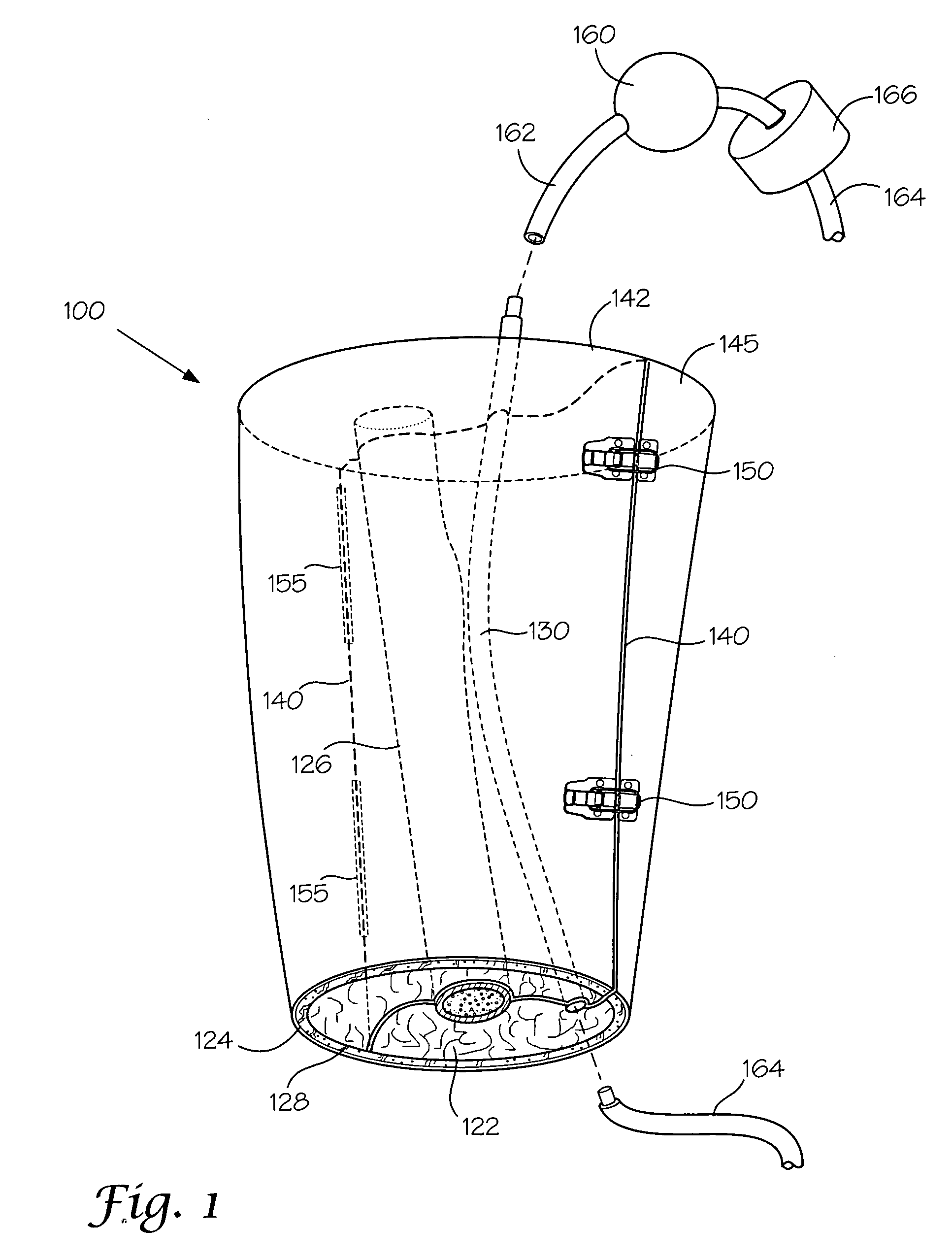

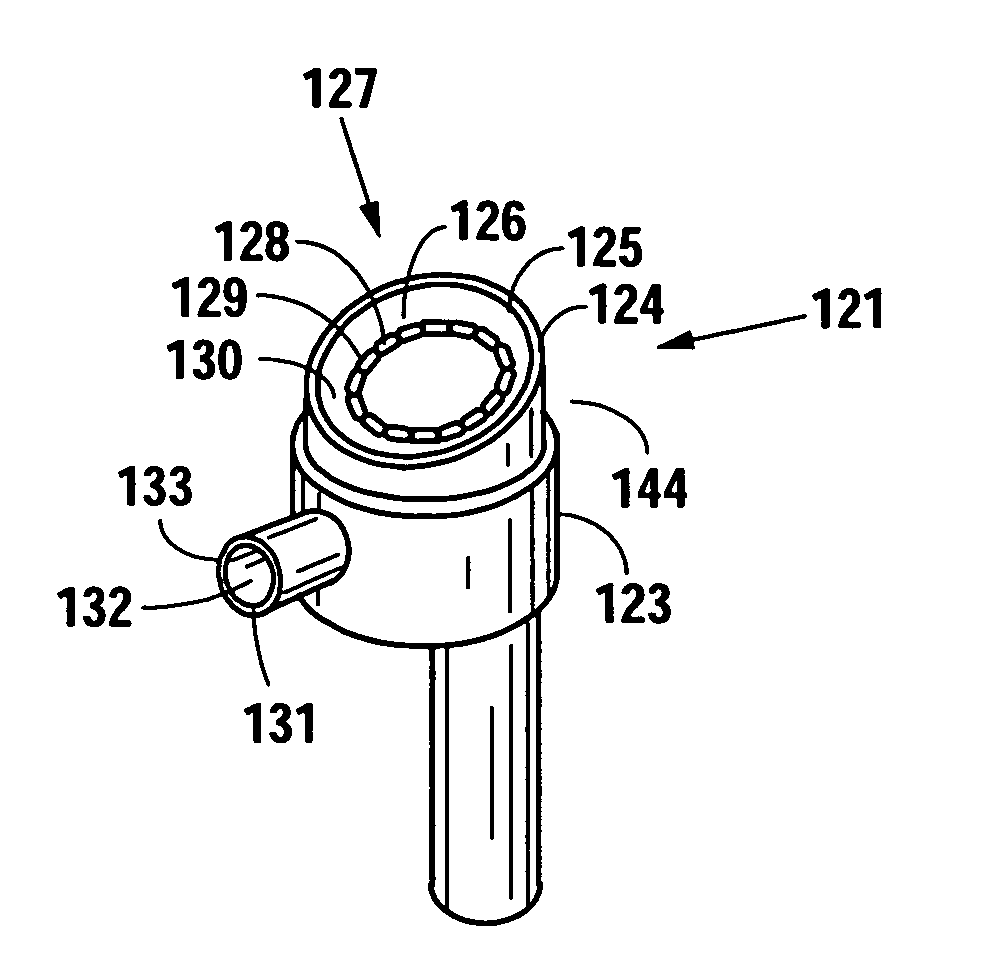

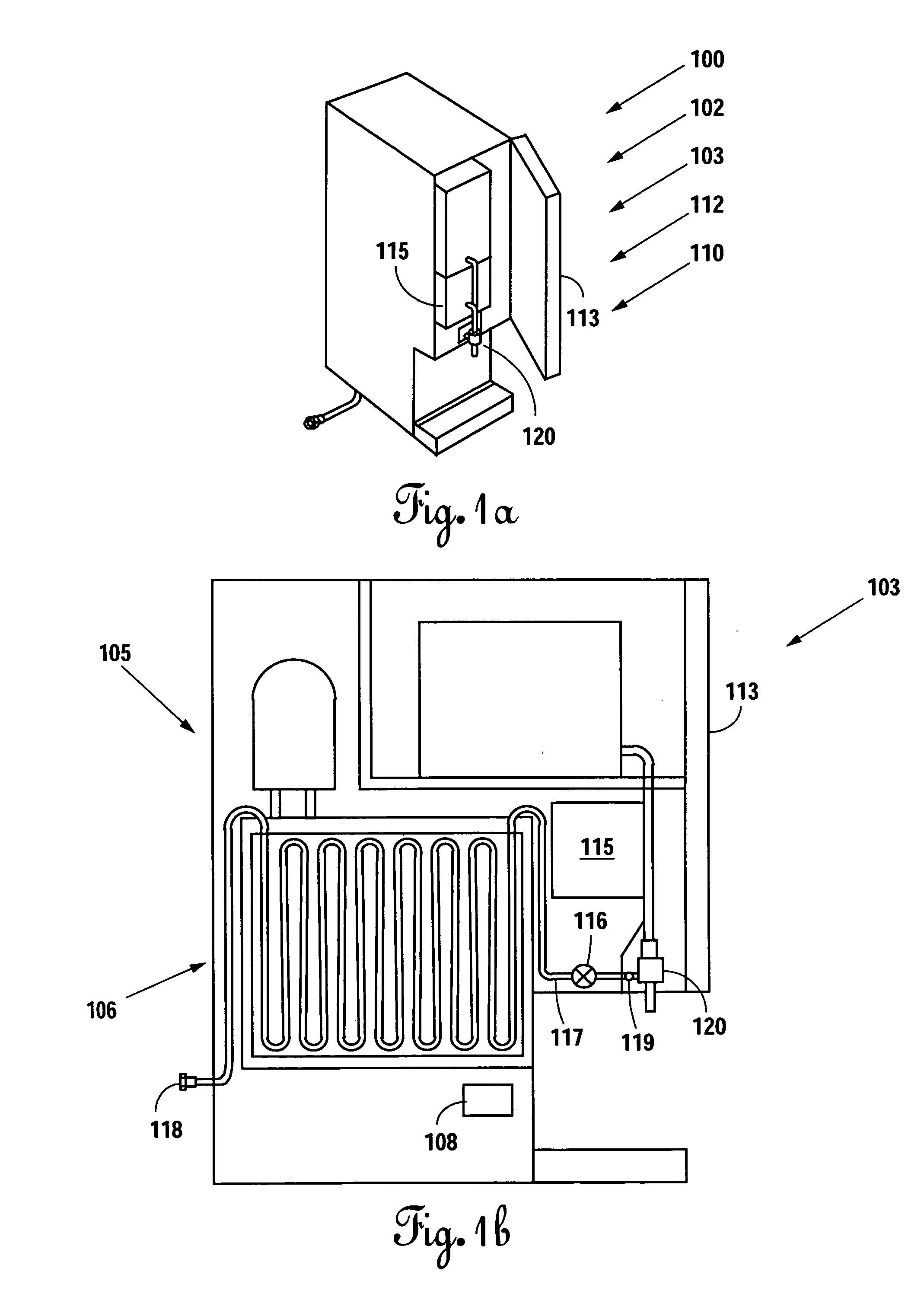

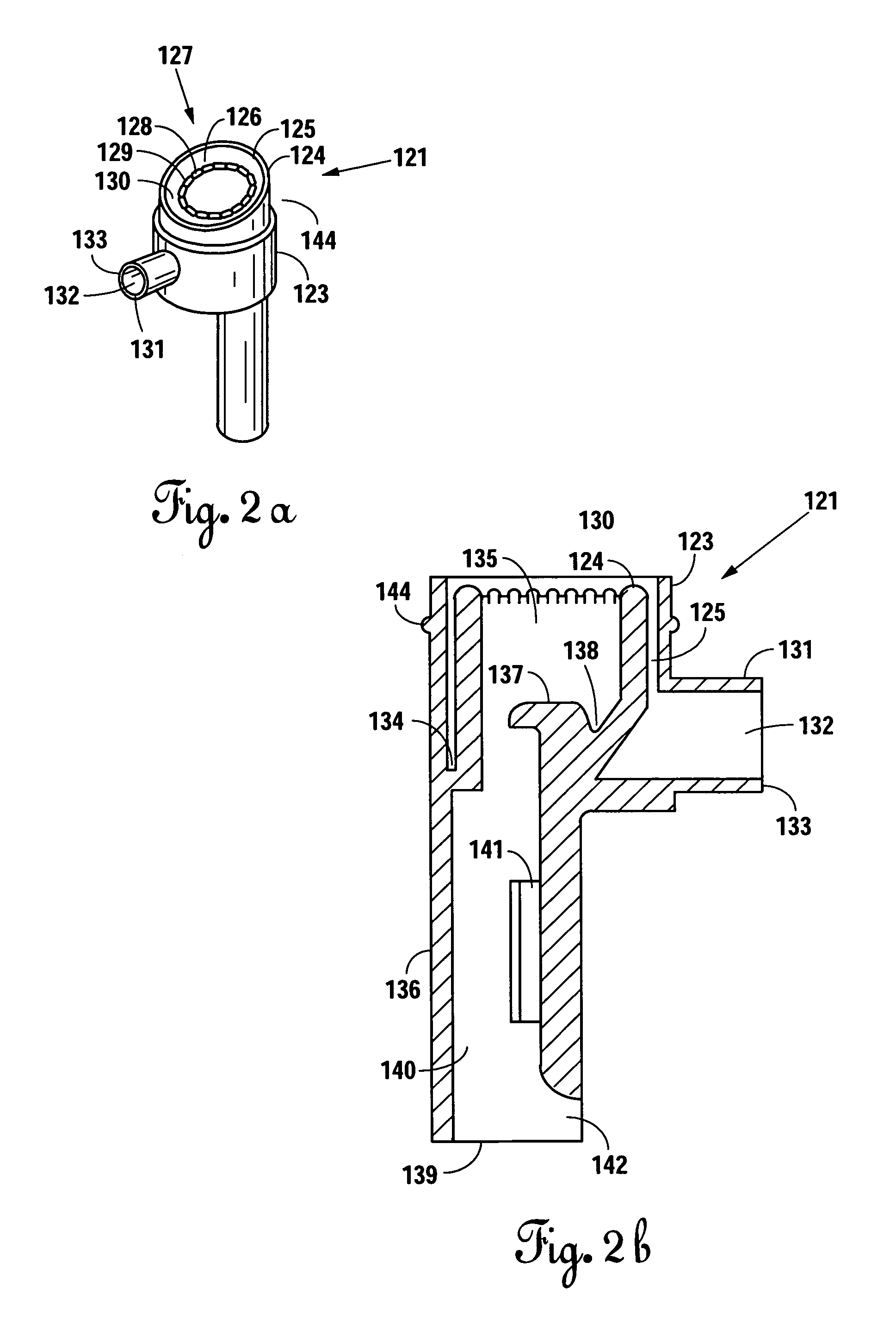

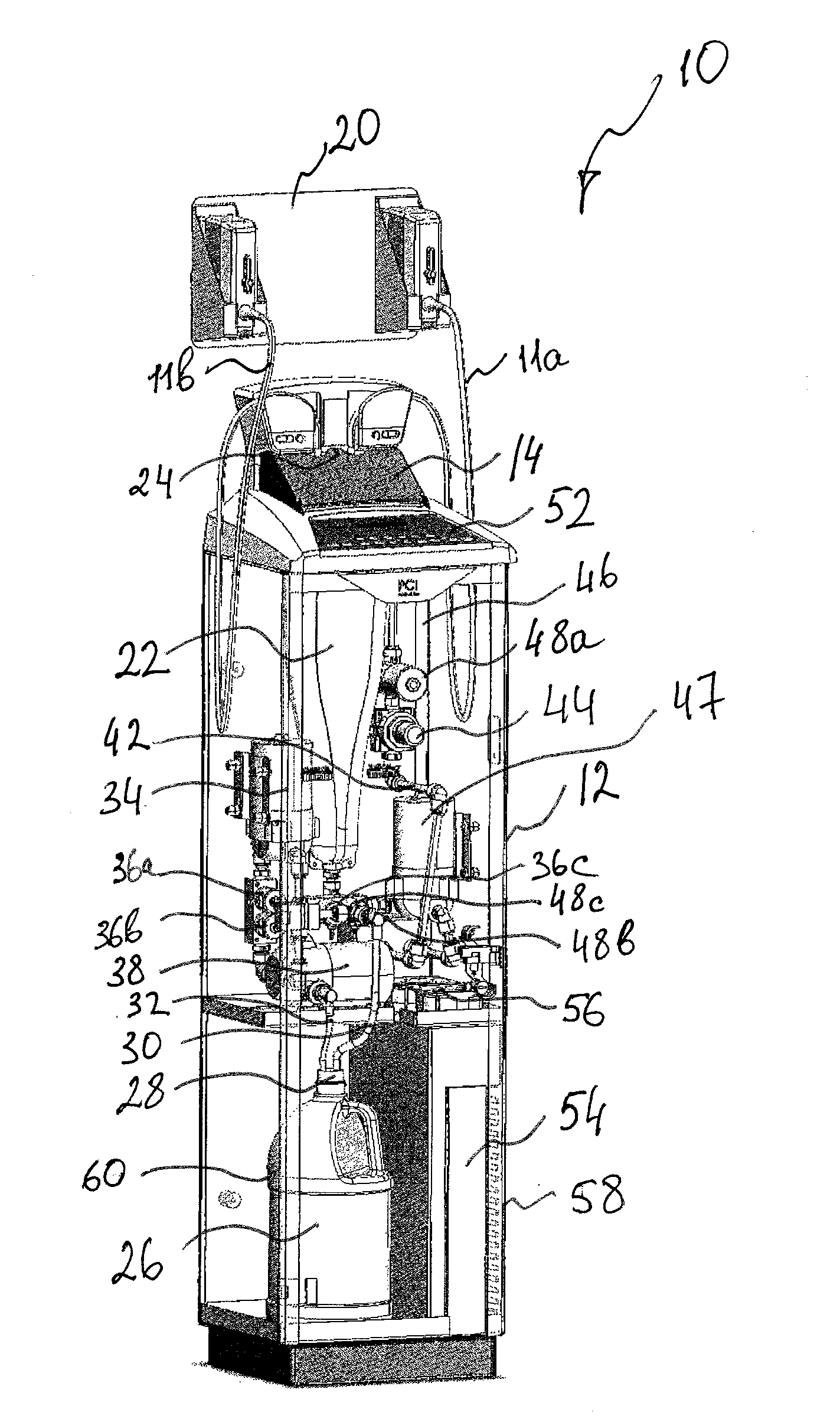

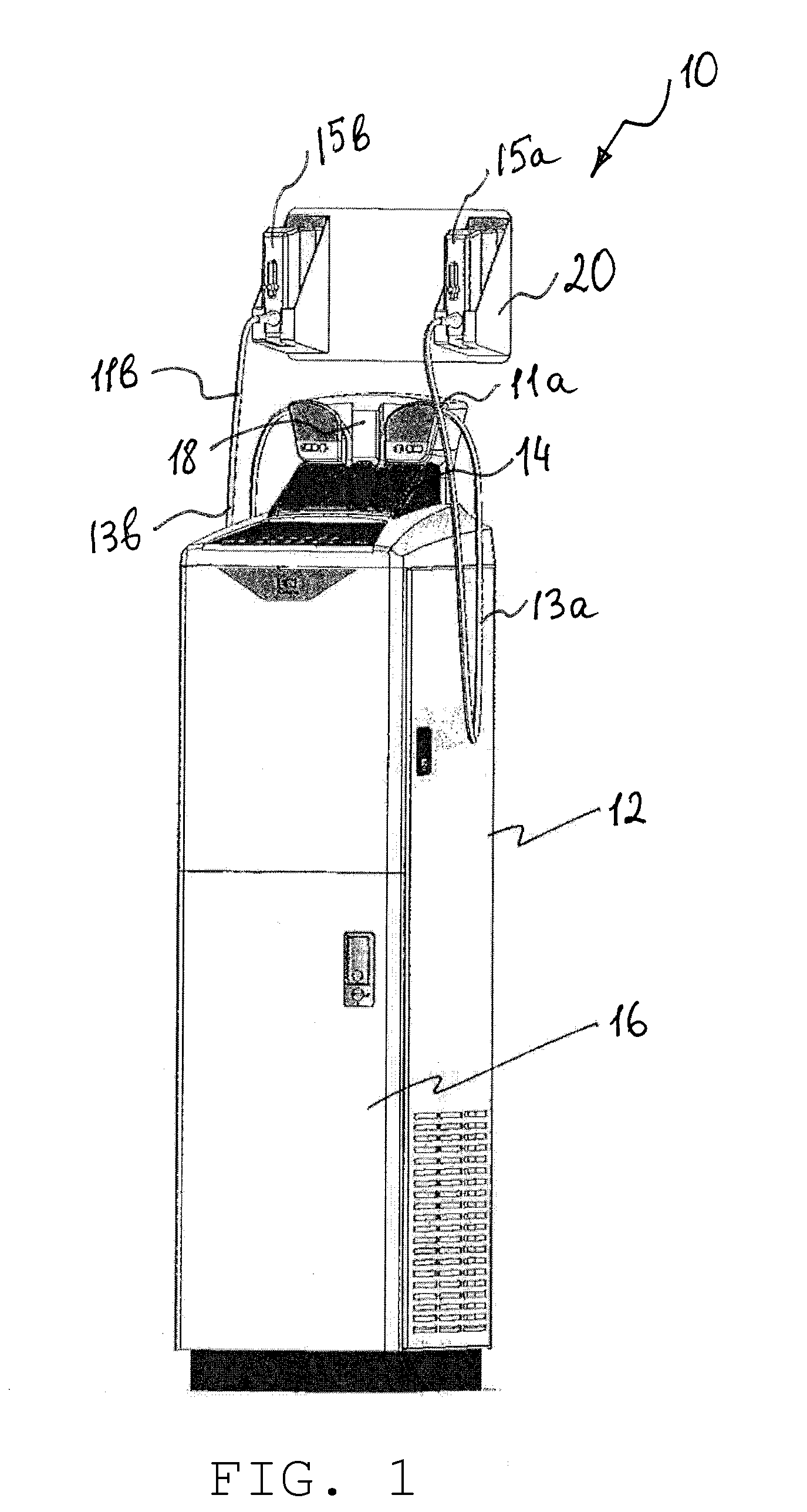

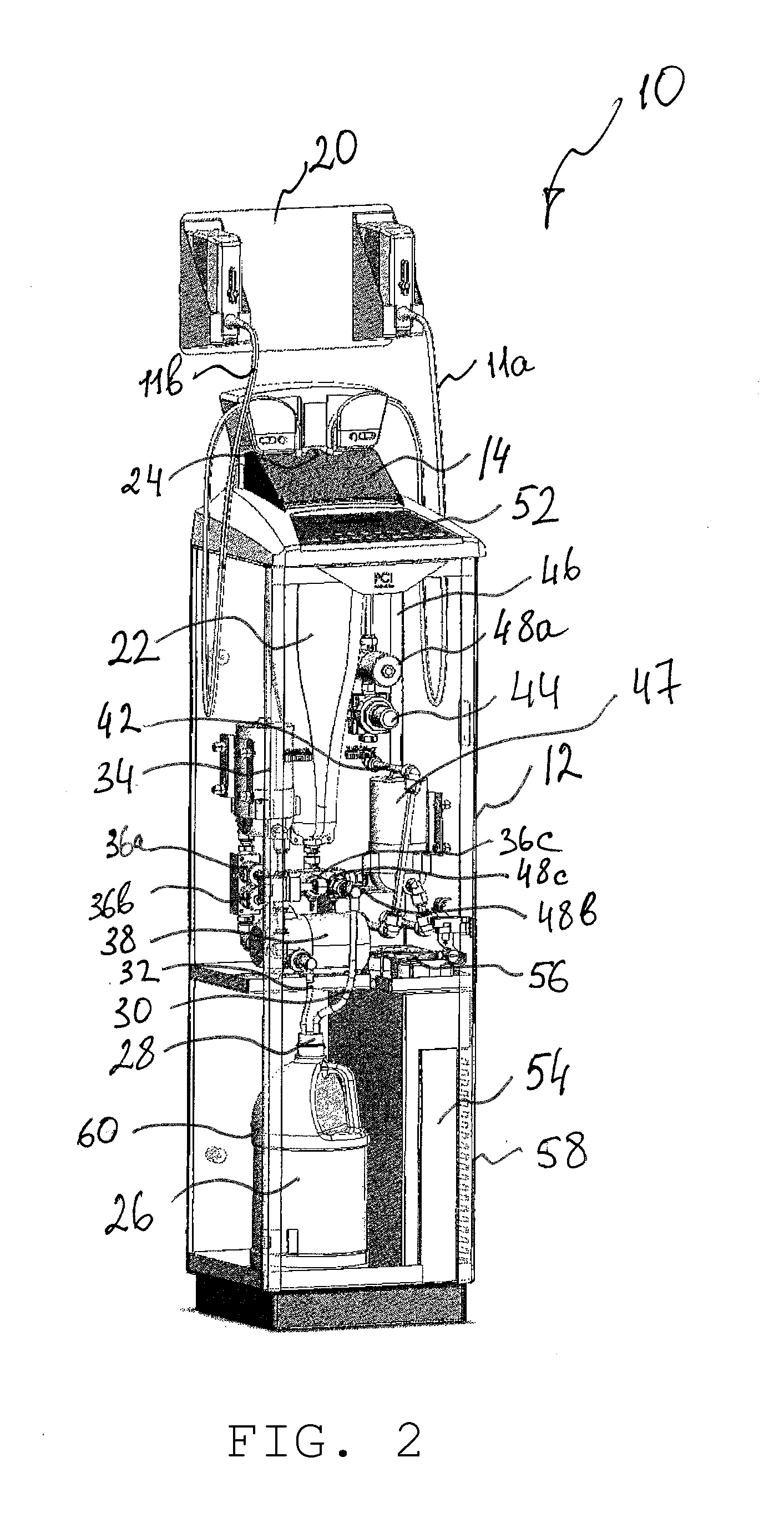

Intracavity Ultrasound Probe Disinfectant System

ActiveUS20120020834A1More reliableEliminate exposureUltrasonic/sonic/infrasonic diagnosticsCosmetic preparationsDisinfectantEngineering

A disinfectant system for intracavity ultrasound probes in disclosed generally including a housing, a disinfectant chamber positioned in the housing and receiving at least one ultrasound probe, a container for containing a disinfectant solution fluidly coupled to the disinfectant chamber, at least one pump for supplying the disinfection solution from the container to the disinfection chamber and from the disinfection chamber to the container, and a controller for automated operation of the disinfectant system, wherein the disinfectant solution is a multi-use disinfectant solution. A method for disinfecting intracavity ultrasound probes is also disclosed generally including placing at least one ultrasound probe into a disinfectant chamber, supplying a disinfectant solution from a container to the disinfectant chamber via a pump, and returning the solution to the container via the pump, wherein the steps of supplying and returning the disinfectant solution are controlled by a controller.

Owner:CIVCO MEDICAL INSTR CO

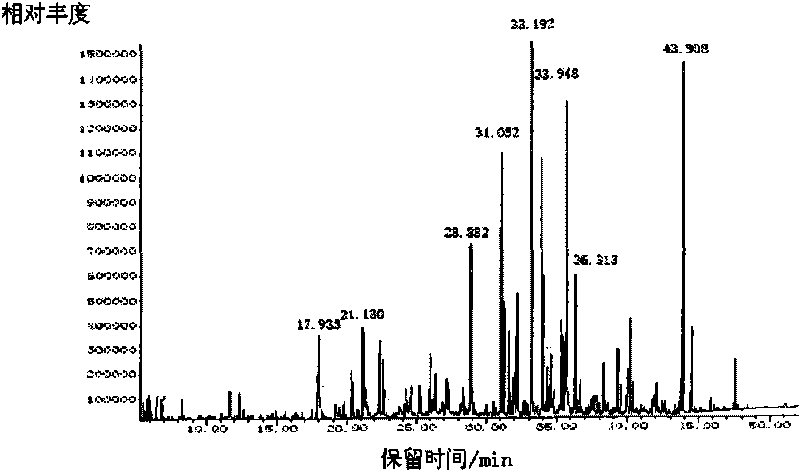

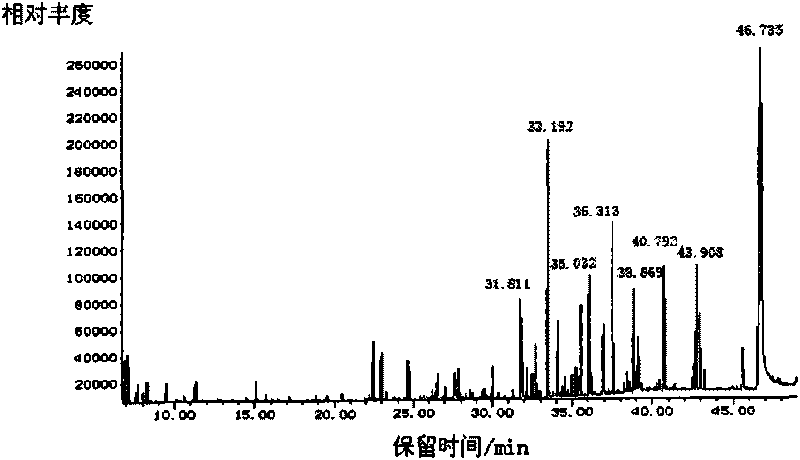

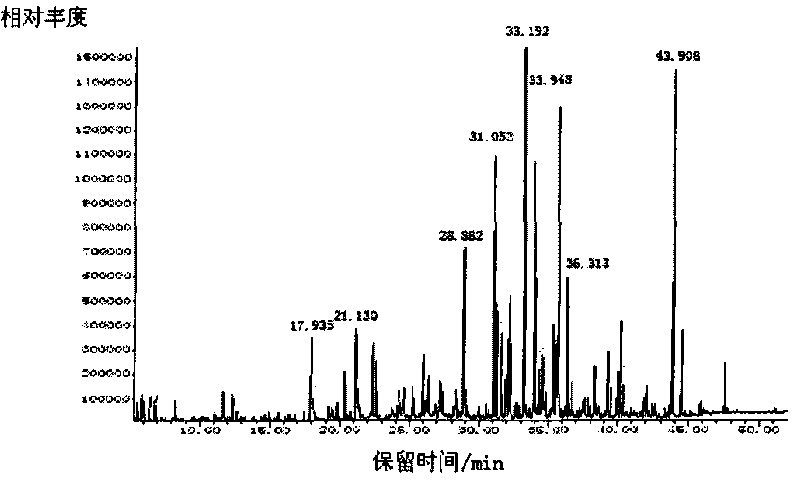

Detecting method for trace amount aroma components in natural aromatic product

The invention discloses a detecting method for trace amount aroma components in a natural aromatic product. The detecting method mainly comprises steps of: puffing and trapping pre-treatment, puffing and trapping of volatile components, thermal desorption cold hydrazine system enrichment components, GC-MS analyzing and the like. The detecting method enriches substances of the natural product by a sample pretreatment technique-puffing and trapping / thermal desorption; compared with the traditional static headspace, the puffing and trapping technique can analyze volatility and semi-volatile compound with high molecular weight, has stronger analytical capacity on the identification of olefine, is particularly suitable for analyzing trace amount terpene compound with volatility components such as essential oil and the like, does not need using a dissolvent for extraction, can cause experimenters not to expose in potential hazardous chemicals and does not need to carry out waste treatment on the dissolvent. The detecting method has simple operation, high automation degree, environmental friendly, good enrichment effect and high sensitivity.

Owner:SHANGHAI INST OF TECH

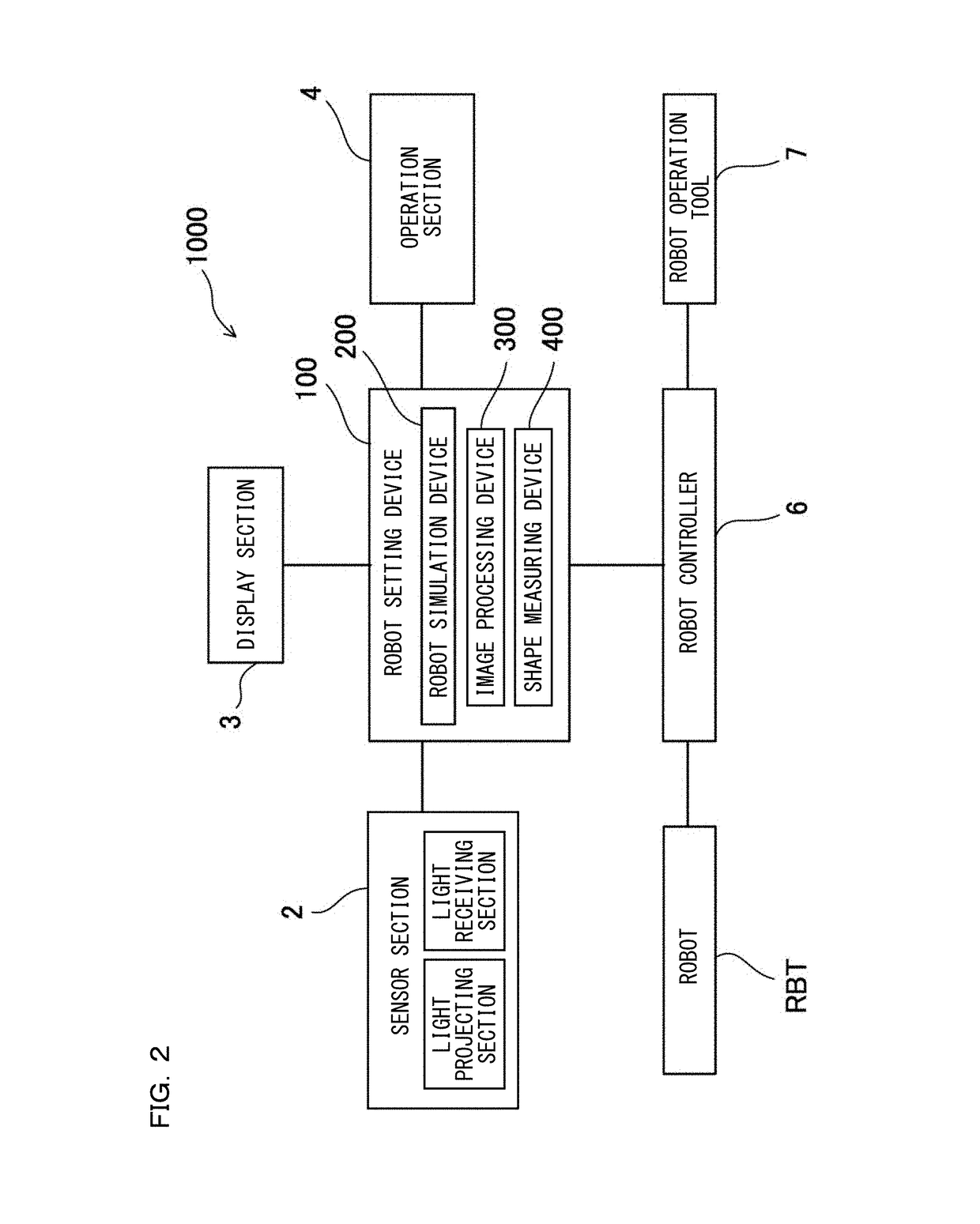

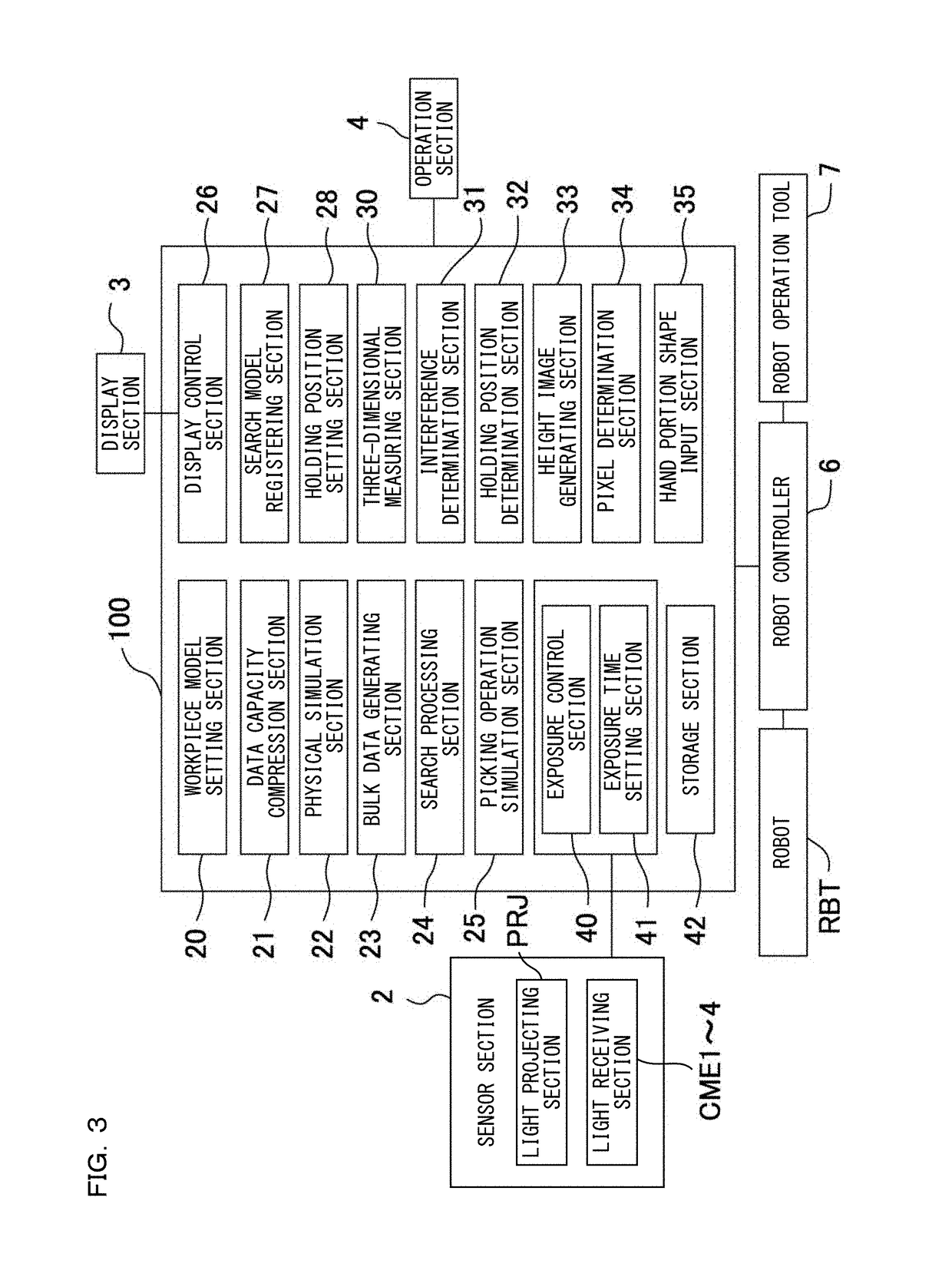

Shape measuring device and shape measuring method

ActiveUS10190873B1Reduce in quantityEliminate exposureUsing optical meansMeasurement deviceImaging data

An exposure time is changed stepwise, a light receiving amount output from a light receiving section is obtained at each exposure time, which is changed stepwise, and height image data, in which each pixel value indicates a height of each portion of a surface of a measuring object, is generated based on the obtained light receiving amount. It is determined whether each pixel constituting each height image is valid or invalid based on the obtained light receiving amount. An exposure time, which corresponds to a height image in which the number of pixels determined to be valid satisfies a predetermined condition, is set as a set value.

Owner:KEYENCE

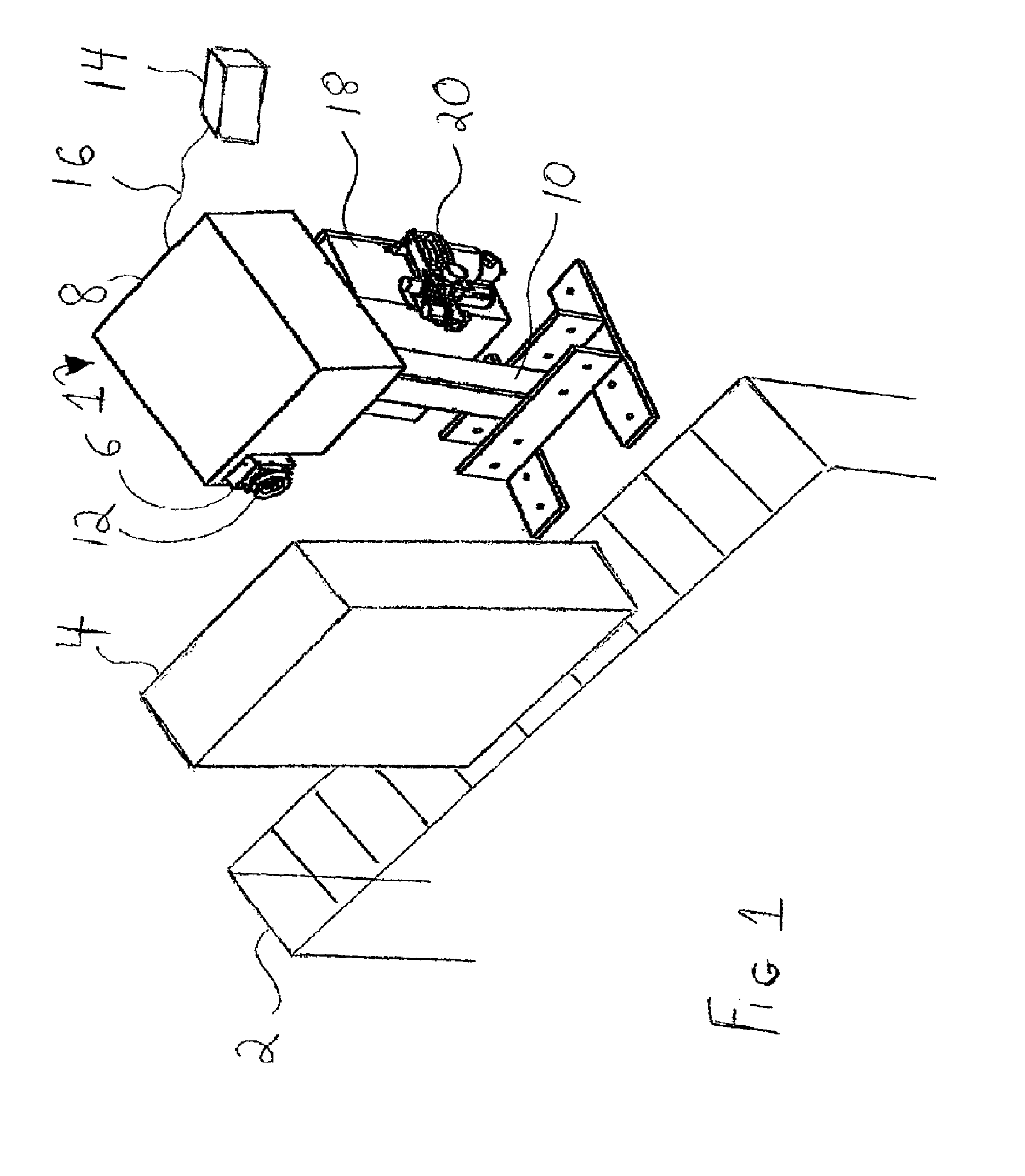

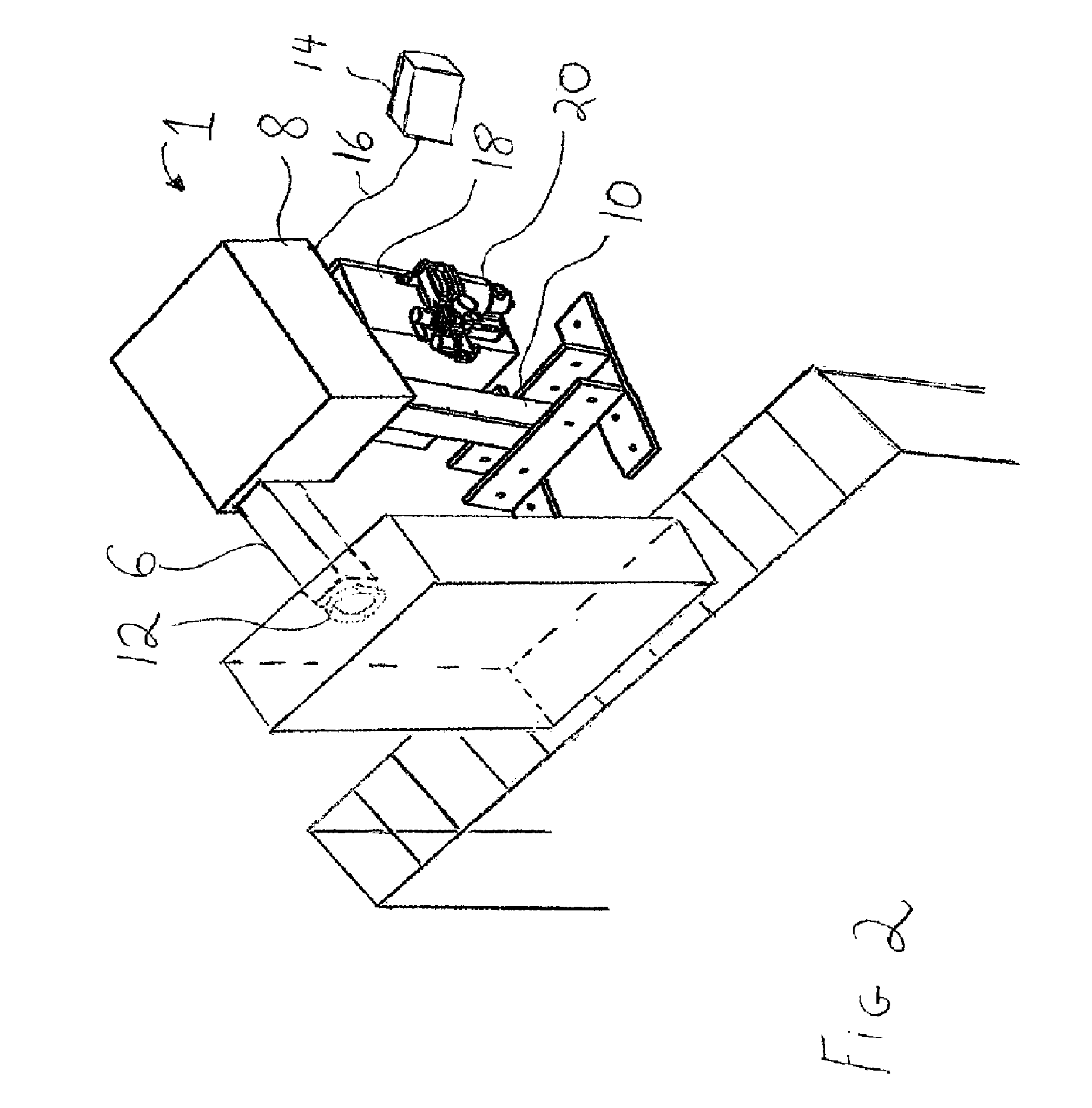

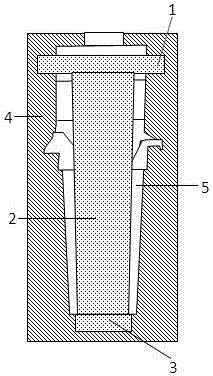

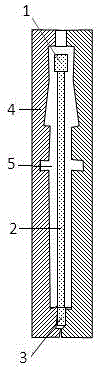

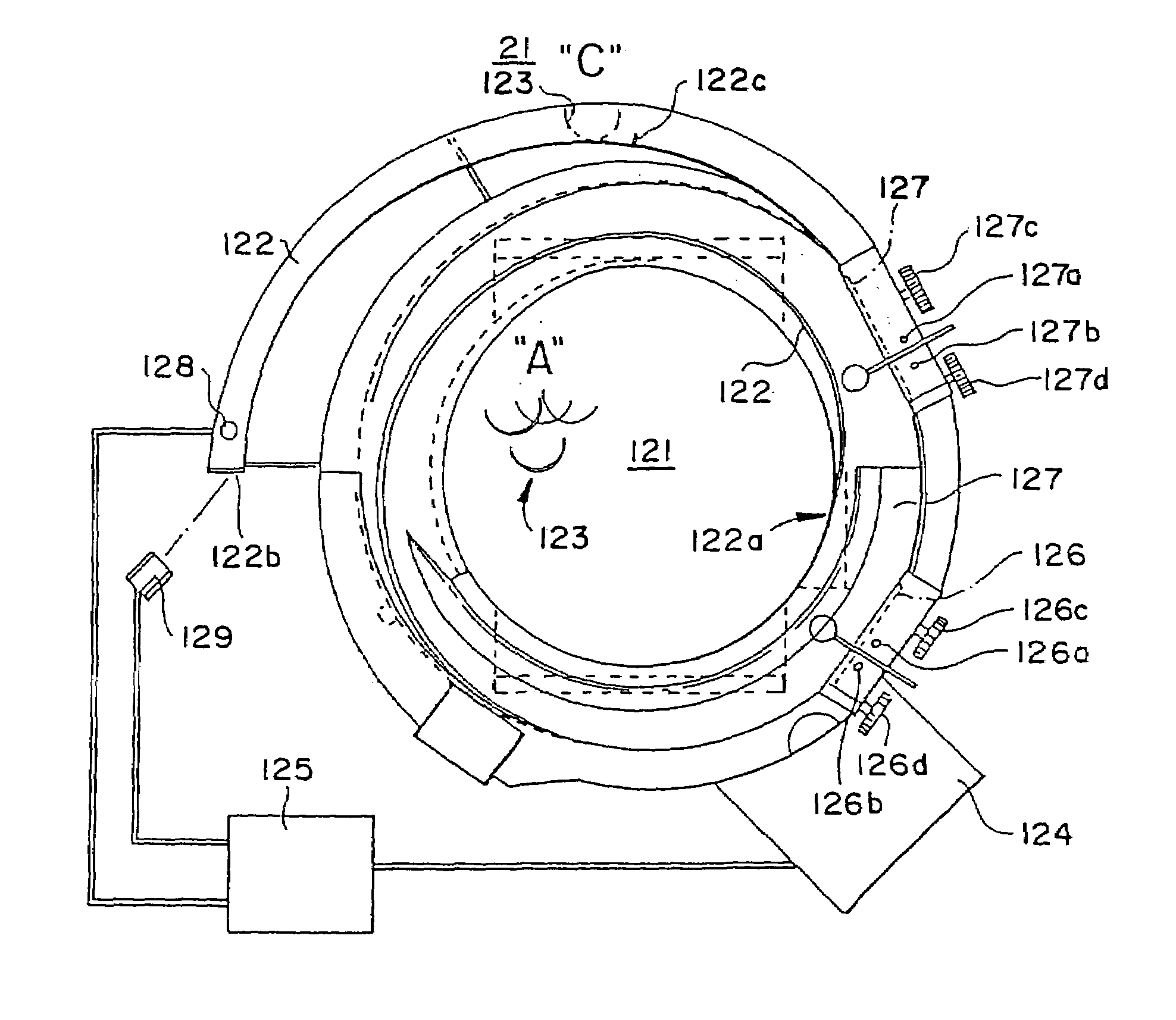

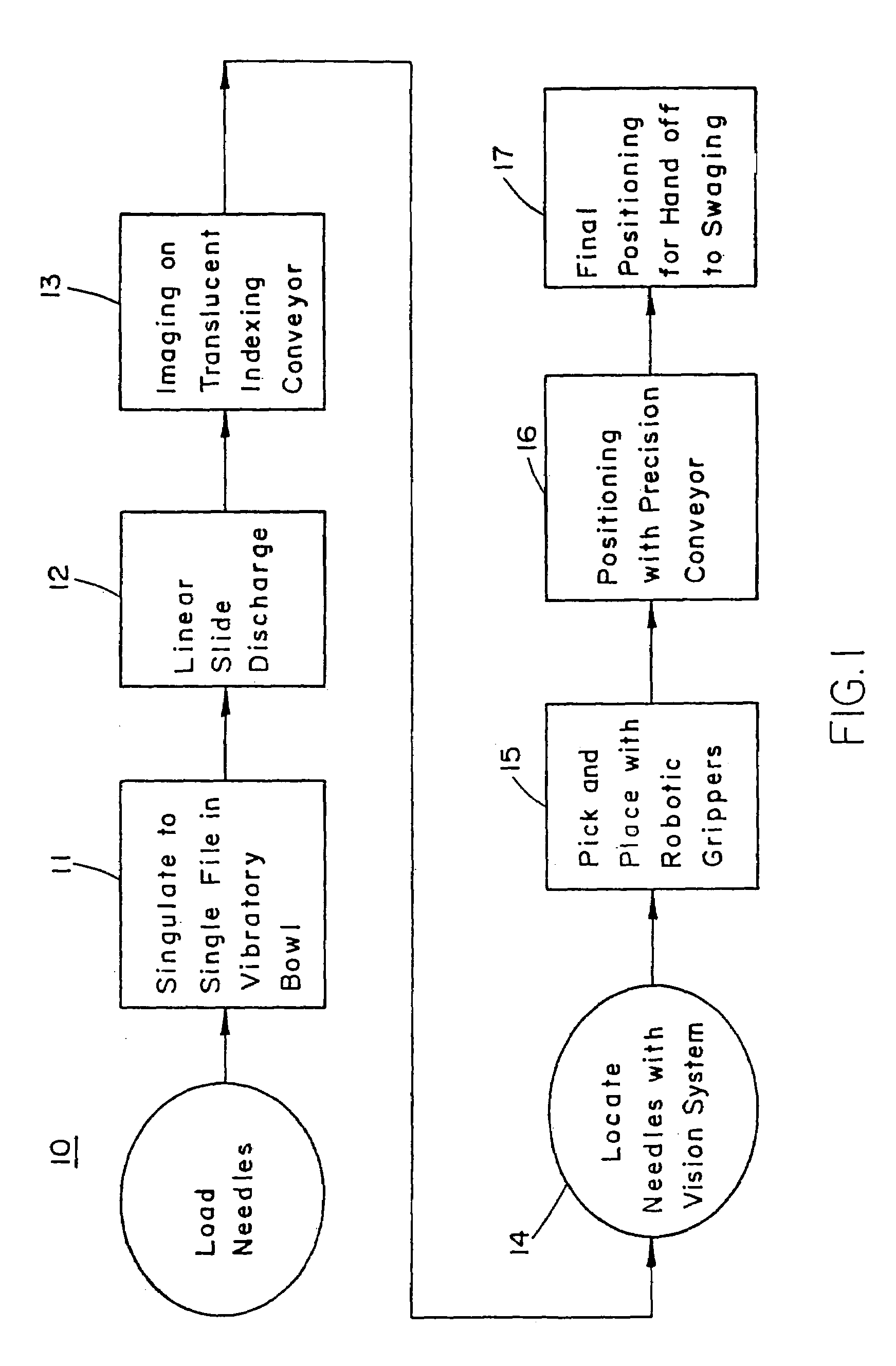

Needle sorting device

InactiveUS6997305B2Eliminate exposureCost effectiveSuture equipmentsProgramme controlBiomedical engineeringDischarger

A device for singulating surgical needles from a bulk supply of needles includes a vibratory bowl for receiving the supply of needles. The bowl has a floor to receive the needles, a track extending from the floor to a needle discharge point and a selectively vibrating motor to vibrate the surgical needles into a single file along the track. A discharge device has first and second needle receiving pockets, and positions the first and the second needle receiving pockets below the needle discharge point. A controller selectively vibrates the vibratory bowl and selectively positions the first and second needle pockets below the needle discharge point, the controller singulating individual needles from the single file of needles into the first and second needle receiving pockets. A discharger discharges the singulated needles in a spaced relationship on a conveyor for subsequent imaging at an inspection station.

Owner:ETHICON INC

Joint Replica Models and Methods of Using Same for Testing Medical Devices

ActiveUS20070166670A1Avoid product qualityImprove timelinessAdditive manufacturing apparatusEducational modelsAnatomical structuresMedicine

Disclosed herein are joint replica models that are designed to enable simulated use testing by medical device companies, medical device designers, individual inventors, or any other entity interested in the performance of medical devices. These models are unique in possessing a level of complexity that allows them to be substituted for either a live animal, an animal cadaver, or a human cadaver in the testing of these devices. These models are further characterized by a similarity of geometry, individual component physical properties, and component-to-component interfacial properties with the appropriate target tissue and anatomy.

Owner:SAKEZLES CHRISTOPHER

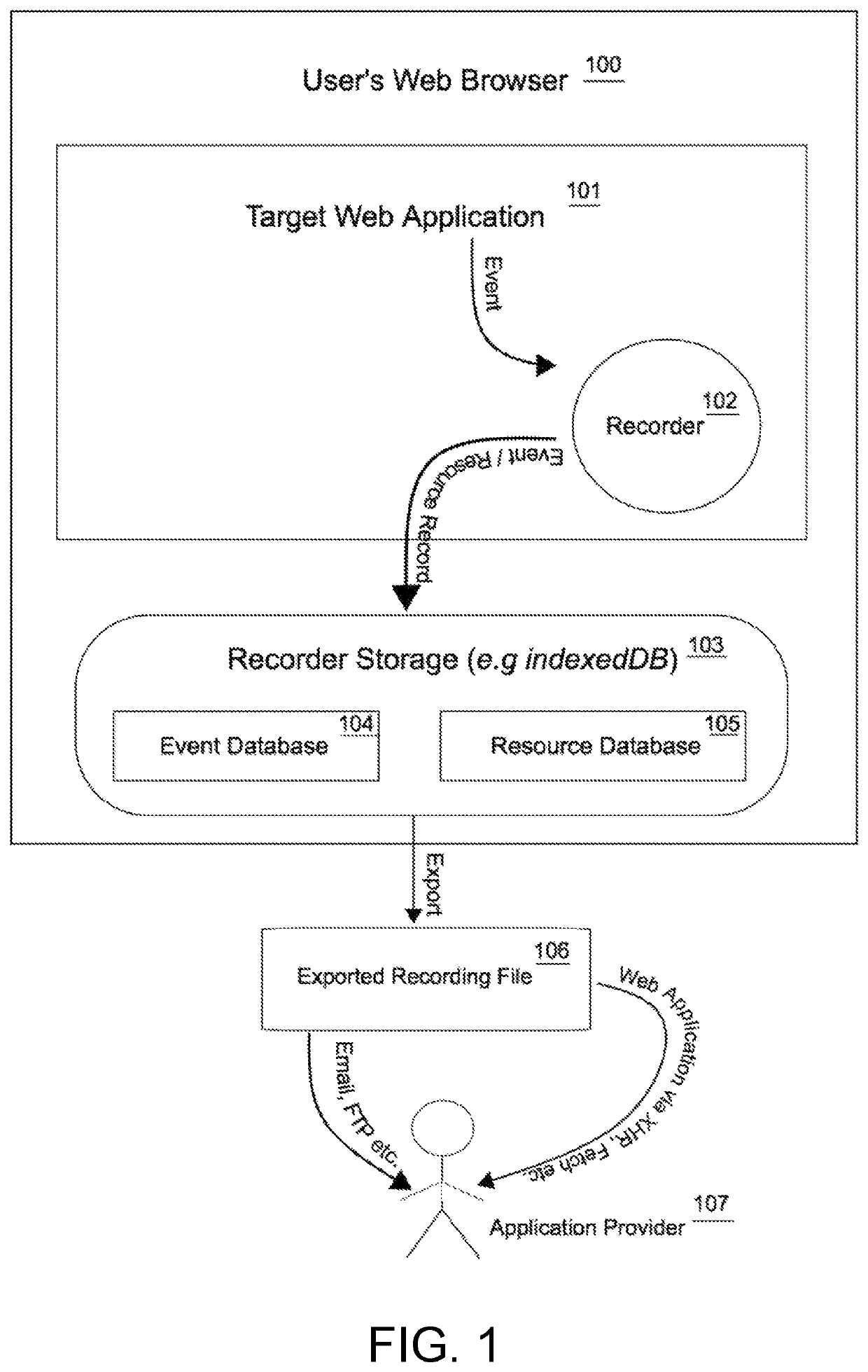

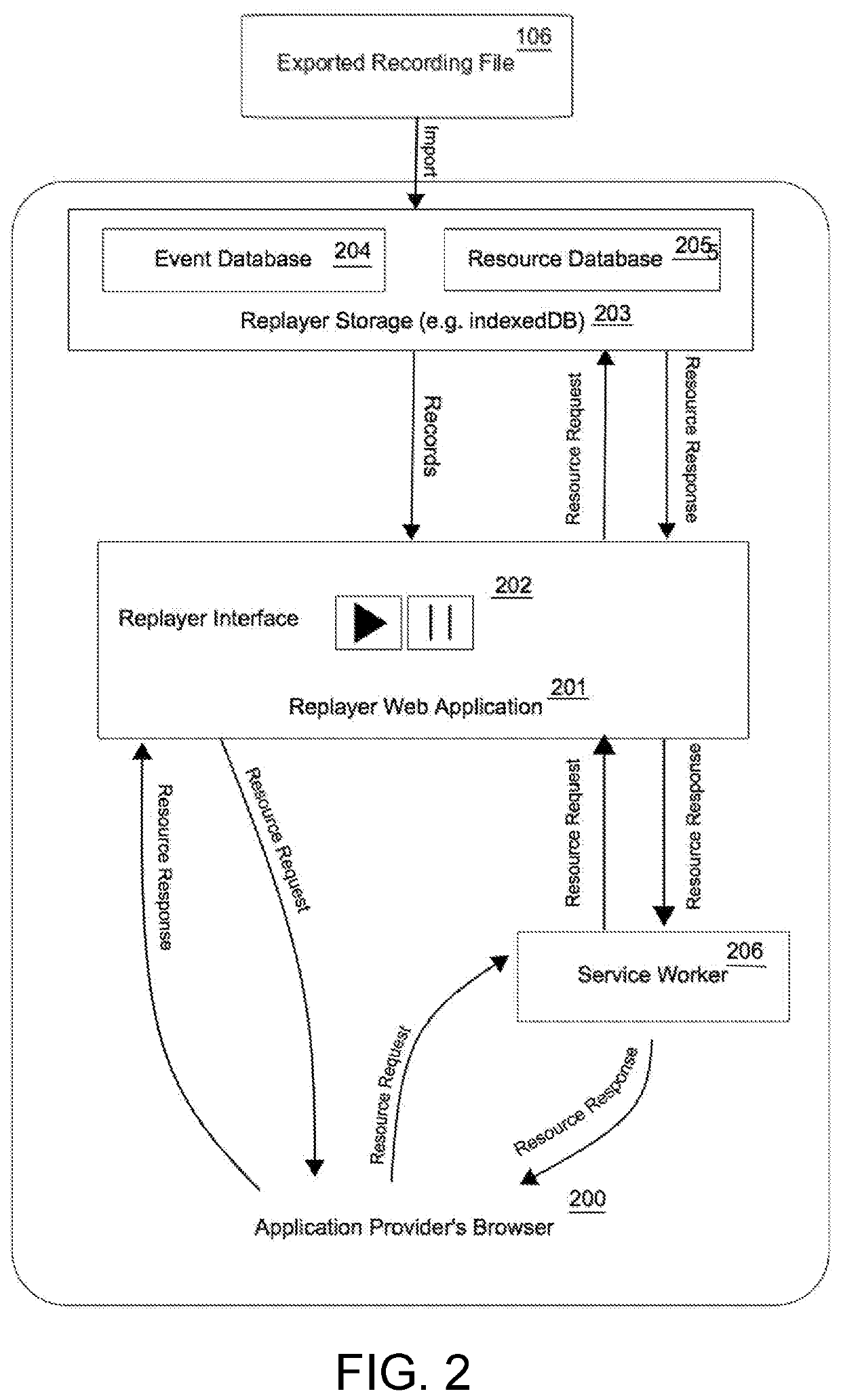

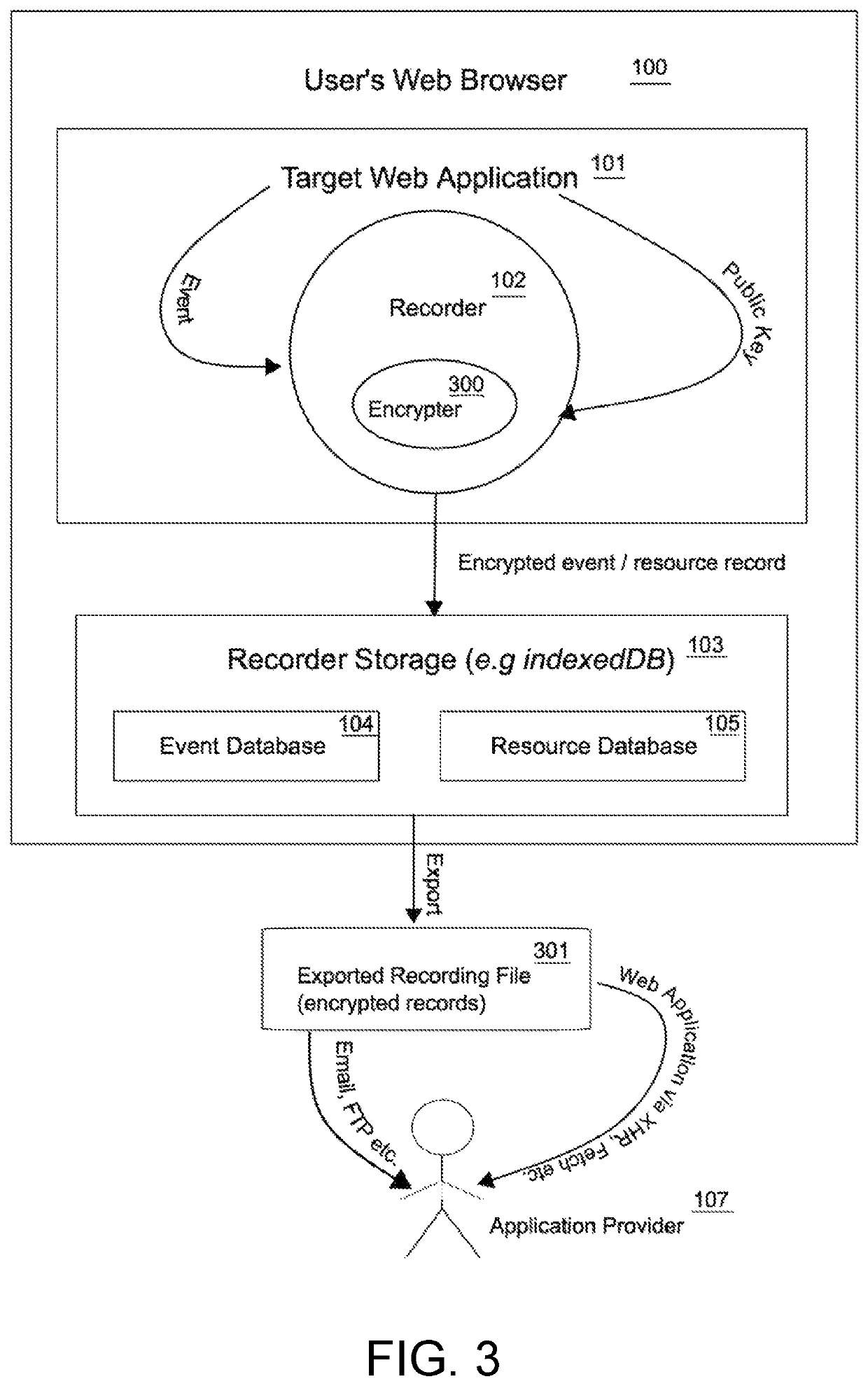

System and methods for secure user interface session recording, transmission, and replay without third party disclosure

ActiveUS11184406B1Eliminate exposureRisk minimizationError detection/correctionComputer security arrangementsWeb siteThird party

A user's session of a web application or a website in a web browser is recorded and replayed while protecting private and sensitive data from unauthorized access. All the captured data needed to re-create (replay) the user's session in the browser itself is recorded and exported on demand. The need to transmit potentially sensitive and private data continuously to external server(s) is eliminated while still guaranteeing availability of a record of user activity leading up to any point of interest during the user's session. By encrypting recording information and redacting all non-layout content (e.g. text nodes, images, inputs) from the browser DOM before capturing the DOM, the visual layout of the page is maintained and the probability of leaking the user's sensitive or private information is reduced. The replaying user is still able to derive meaningful information about the user's interaction with the web application or website without jeopardizing privacy.

Owner:SHASHANK

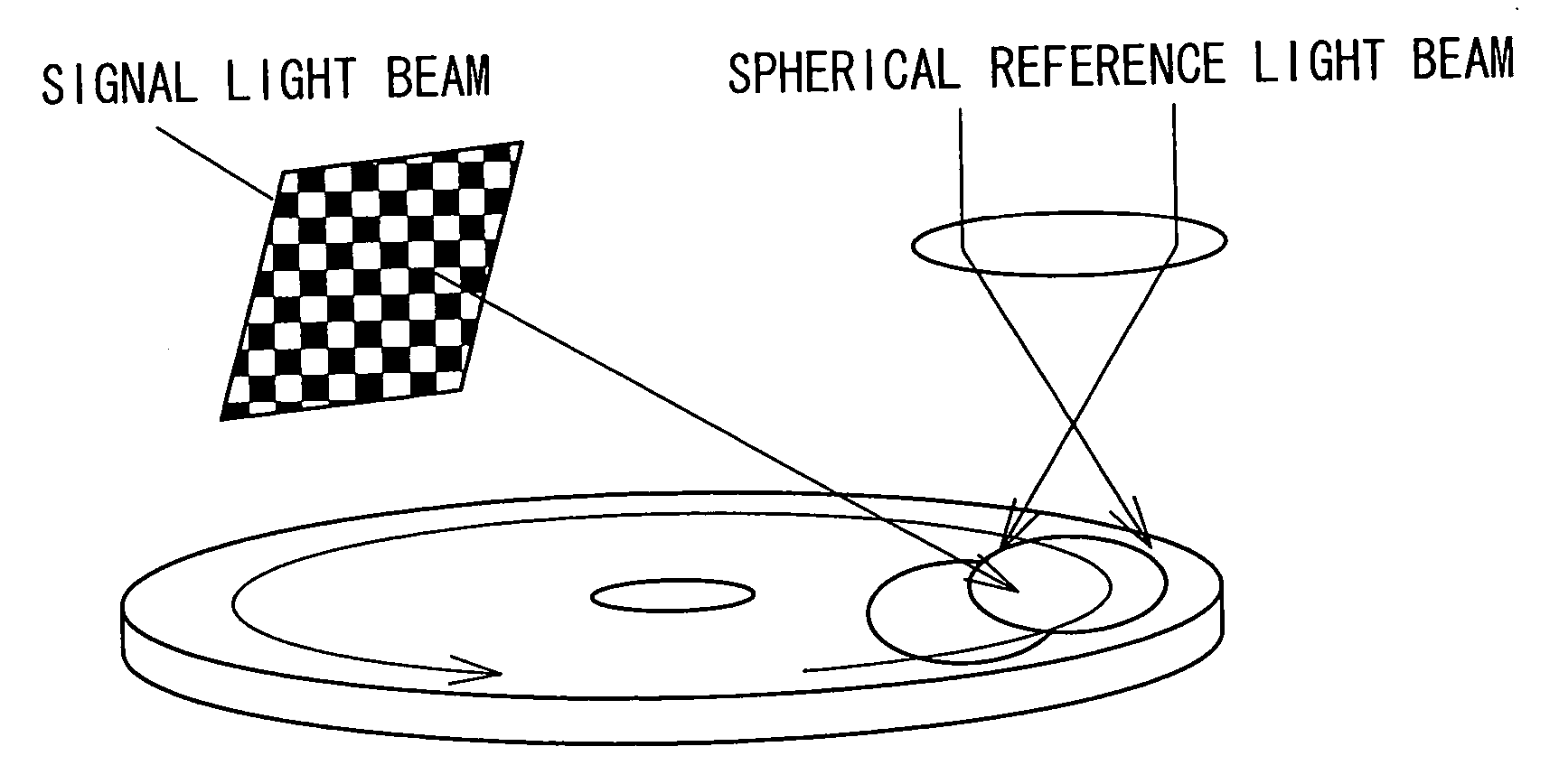

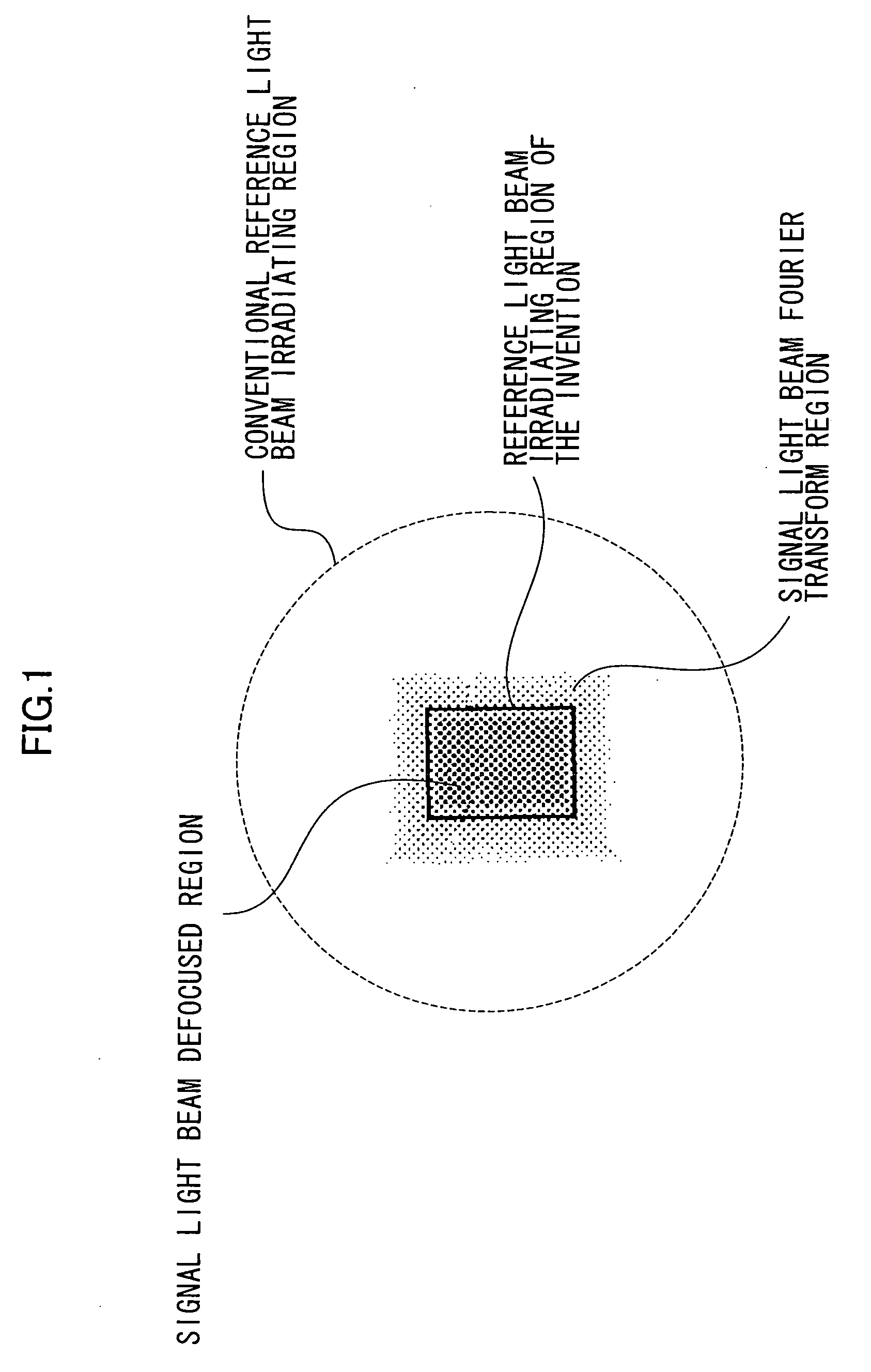

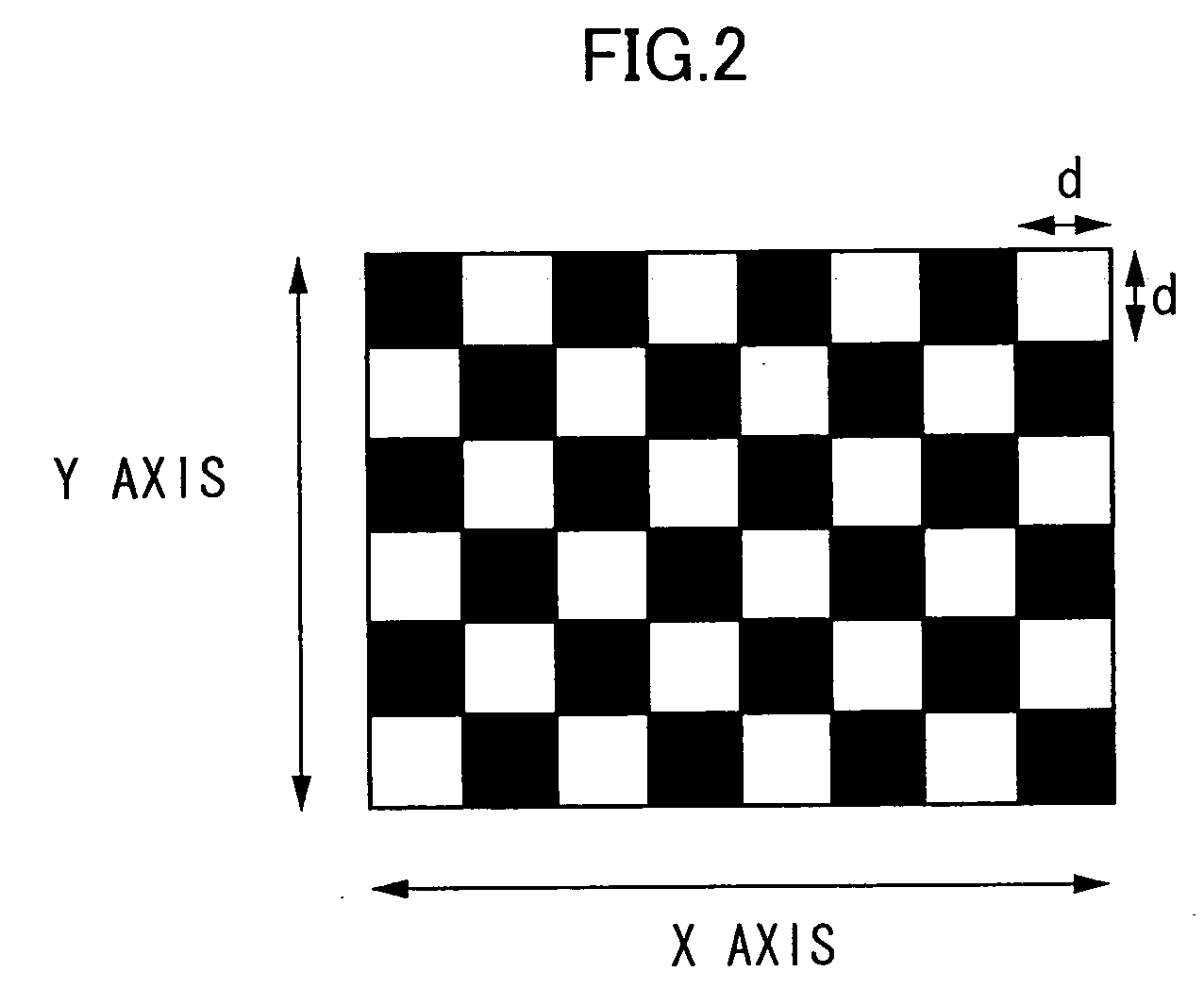

Hologram recording method and hologram recording apparatus

InactiveUS20050012971A1High-density recordingHigh-density recording can reliably be realizedPhotomechanical apparatusRecord information storageHigh densityLight beam

A hologram is recorded by irradiating, with a reference light beam, a region corresponding to an intensity distribution of a signal light beam on an optical recording medium. For example, the reference light beam having the intensity distribution which substantially coincides with the intensity distribution of the signal light beam is generated, and only the region which substantially coincides with the region irradiated by the signal light beam (i.e., the signal light beam defocused region) is irradiated with the reference light beam. This enables only the necessary region to be exposed and the regions which need not be exposed not to be exposed. Accordingly, the hologram can be recorded without losing information of the signal light beam and thus high-density recording can be realized.

Owner:FUJIFILM BUSINESS INNOVATION CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com