Detecting method for trace amount aroma components in natural aromatic product

A detection method and aroma technology, applied in the direction of measurement device, material separation, analysis material, etc., can solve the problem of difficult to analyze non-volatile components, and achieve strong identification and analysis ability, excellent enrichment effect, and high degree of automation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

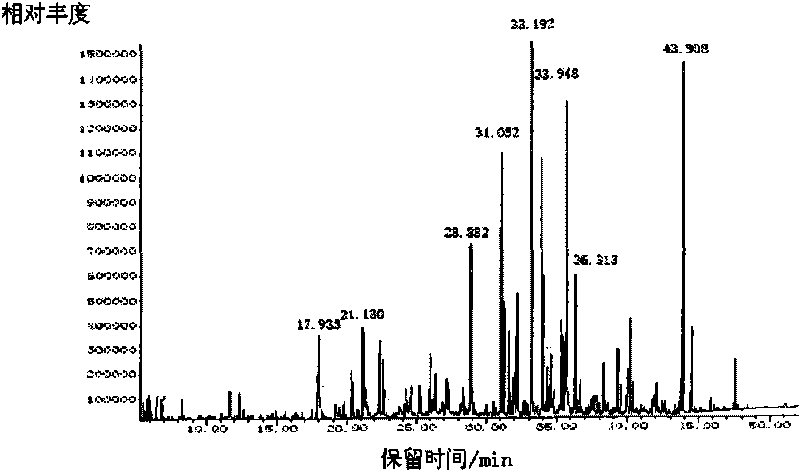

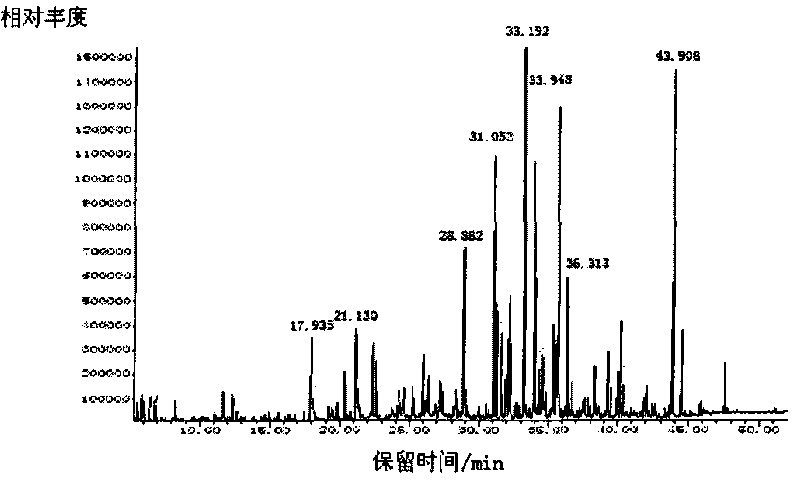

[0030] Put the clean purge and trap bottle in a constant temperature water bath at 60°C, and pass high-purity nitrogen gas for 10 minutes to remove air impurities in the bottle; weigh 2.0 g of crushed dried lotus leaves, put them into the above purge and trap bottle, and Connect the high-purity nitrogen cylinder, and the other end is connected to the Tenax-TA adsorption tube pre-loaded with 200mg Tenax-TA adsorbent (aging temperature: 300°C, aging for 3h). Put down the Tenax-TA adsorption tube and put protective caps on both ends; put the adsorption tube into the pre-stabilized TDS3 system connected to the GC-MS instrument. MS analysis.

[0031] Its thermal desorption (TDS) parameters: the initial temperature is 40°C, keep it for 2min, rapidly heat up to 260°C at a heating rate of 60°C / min, and keep it for 2min; the transfer line temperature is 280°C, and finally stabilize at 50°C, splitless injection ;

[0032] Cold hydrazine (CIS) parameters: In the standard heating mode, ...

Embodiment 2

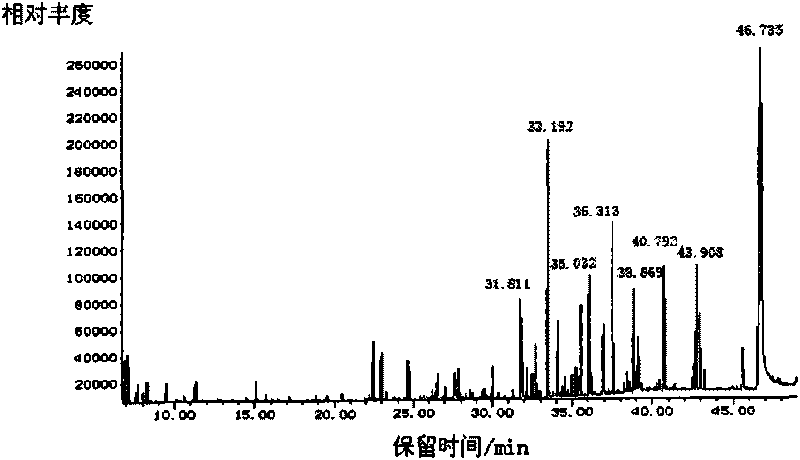

[0037]Place the clean purge and trap bottle in a constant temperature water bath at 80°C, and pass high-purity nitrogen gas for 15 minutes to remove air impurities in the bottle; weigh 2.0 g of crushed dried grass fruit, put it into the above purge and trap bottle, and connect one end to the The other end of the high-purity nitrogen cylinder is connected to a Tenax-TA adsorption tube pre-loaded with 200mg of Tenax-TA adsorbent (aging temperature 300°C, aging 3h), nitrogen gas flow is started at a pressure of 0.3MPa, and the stopwatch counts for 25 minutes; when the adsorption is completed, remove the Tenax-TA adsorption tube, with protective caps on both ends; put the adsorption tube into the pre-stabilized TDS3 system connected to the GC-MS instrument, after desorption by the thermal desorption system and enrichment by cold hydrazine, it will be used for GC-MS Analysis, its TDS parameters: initial temperature 40°C, keep 2min, rapidly heat up to 260°C at a heating rate of 60°C / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com