Mold core for manufacturing high-temperature alloy hollow blade

A hollow blade and superalloy technology, which is applied to cores, manufacturing tools, casting and molding equipment, etc., can solve the problems of core 2 expansion and contraction, failure to fix cores, and core 2 deformation, etc., and achieve core making work. Easy, remove exposure, simplify shape effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

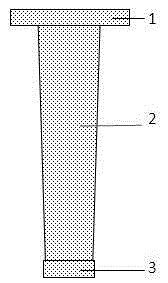

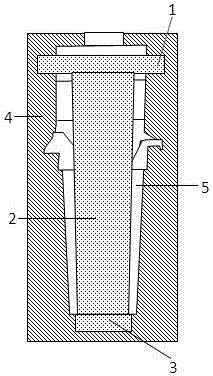

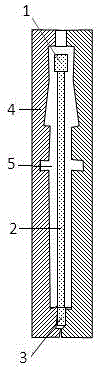

[0026] like Figure 5-12 As shown, the present invention is a core 2 for manufacturing superalloy hollow blades. The core 2 is placed in a wax pressing mold 4 to make a wax mold, and the wax mold wrapped around the core 2 is used to make a ceramic mold shell 6 . According to the shape and size of the hollow blade and the core 2, the present invention designs a core 2 and a wax-pressing mold 4 by using the new core head structure concept, so that the core 2 can be oriented in the ceramic mold shell 6 to carry out the orientation of the superalloy hollow blade During the solidification process, the blade tip core 3 has a certain degree of freedom of rotation, and the blade root core 1 can freely expand and contract in the vertical direction. specific:

[0027] Two positioning grooves are arranged on the central positions of the front and rear sides of the blade top core head 3 of the core 2, and the positioning grooves are inner tapered grooves, i.e. the core blade top groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com