Heat exchanger

A heat exchanger and elbow technology is applied in the manufacturing field of air-cooled tube-fin heat exchangers. Cost and effect of reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

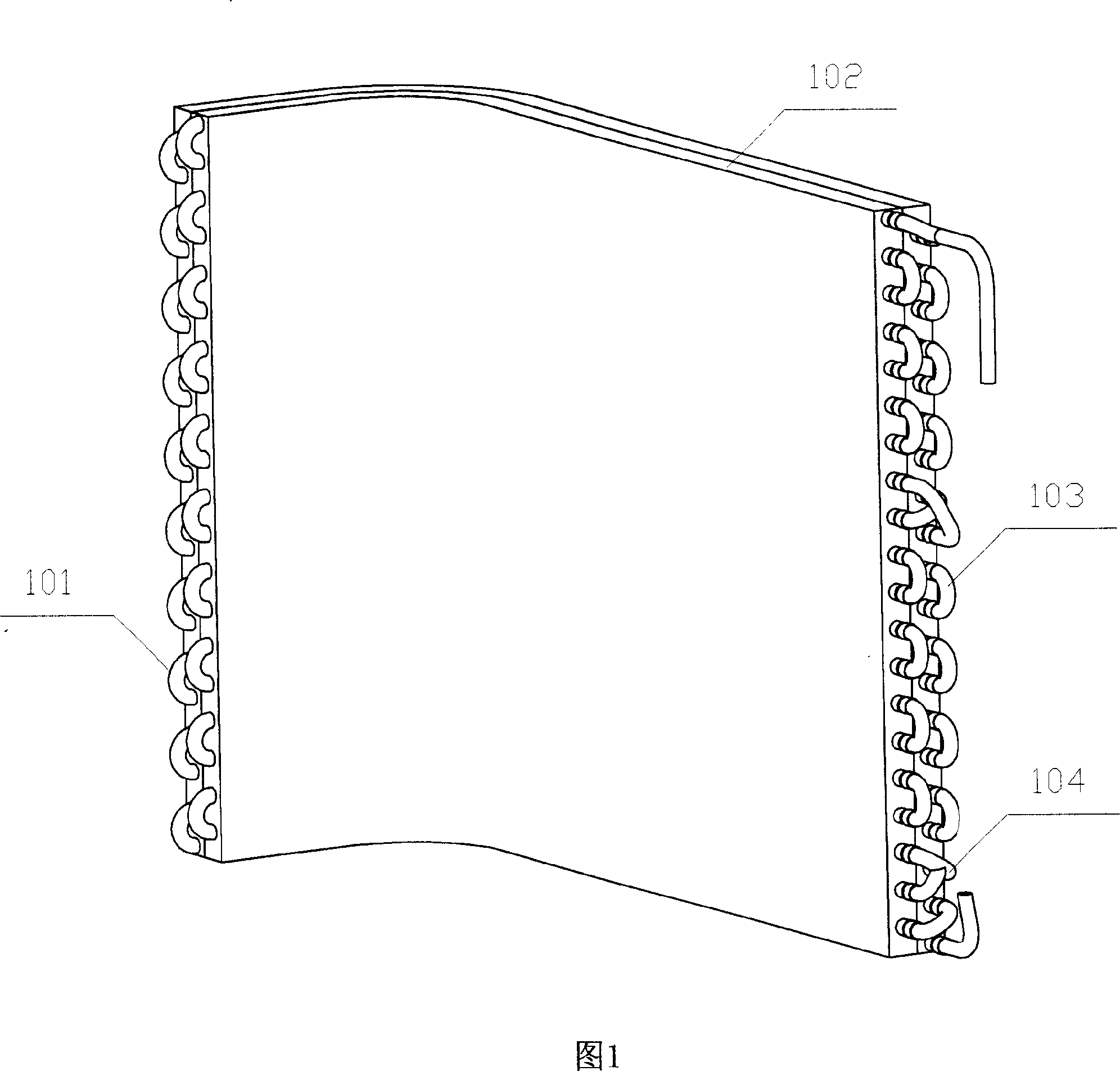

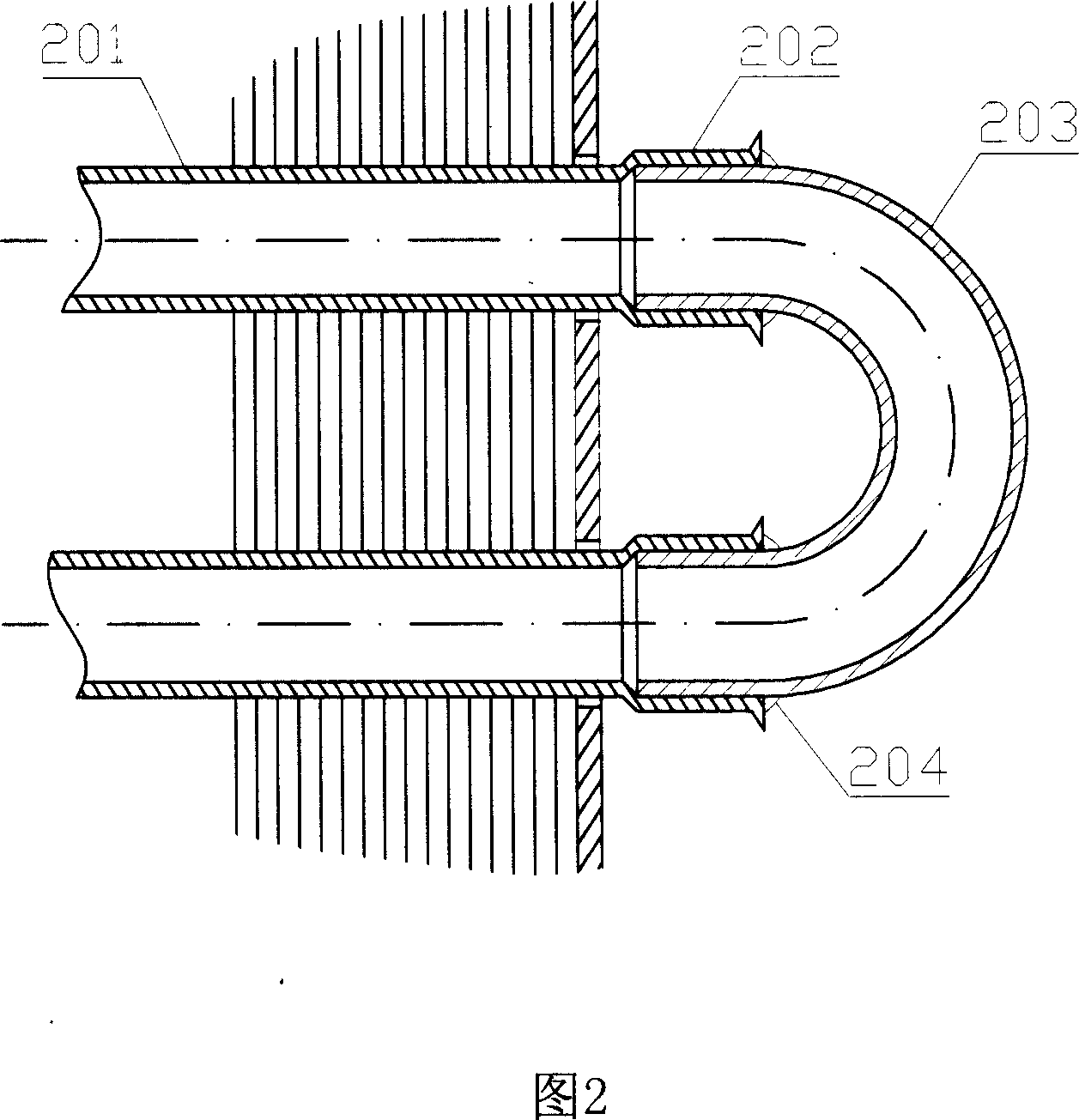

[0012] As shown in Figure 1, it is a schematic structural diagram of an air-cooled tube-fin heat exchanger. The heat exchanger comprises several U-shaped tubes 101 with two parallel straight tube parts and a plurality of fin groups 102 arranged at certain intervals along the longitudinal direction of the straight tube parts, and each fin has a certain distance from each other. The two parallel straight tube parts of the U-shaped tube are inserted into and pass through the corresponding tube insertion holes of each fin, and the U-shaped tubes are connected by welding by elbows 103 or other connectors 104 .

[0013] Due to the needs of the installation structure and air duct design, the heat exchanger can be bent and formed after the tube is expanded. Commonly, the evaporator is bent with an axis parallel to the straight tube part of the U-shaped tube after the fins are cut at an appropriate position to form a multi-fold heat exchanger. The condenser is bent on an axis perpendi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com