Interface analysis apparatus for double-floating ball red mud setting tank

An analysis device and settling tank technology, which is applied in the direction of material analysis by measuring buoyancy, measuring device, analyzing materials, etc., can solve the problems of easy stuttering of the measuring probe, affecting the sensitivity of the measuring probe, and high operating costs, reducing maintenance time and cost. The effect of labor intensity, reliable measurement and investment saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

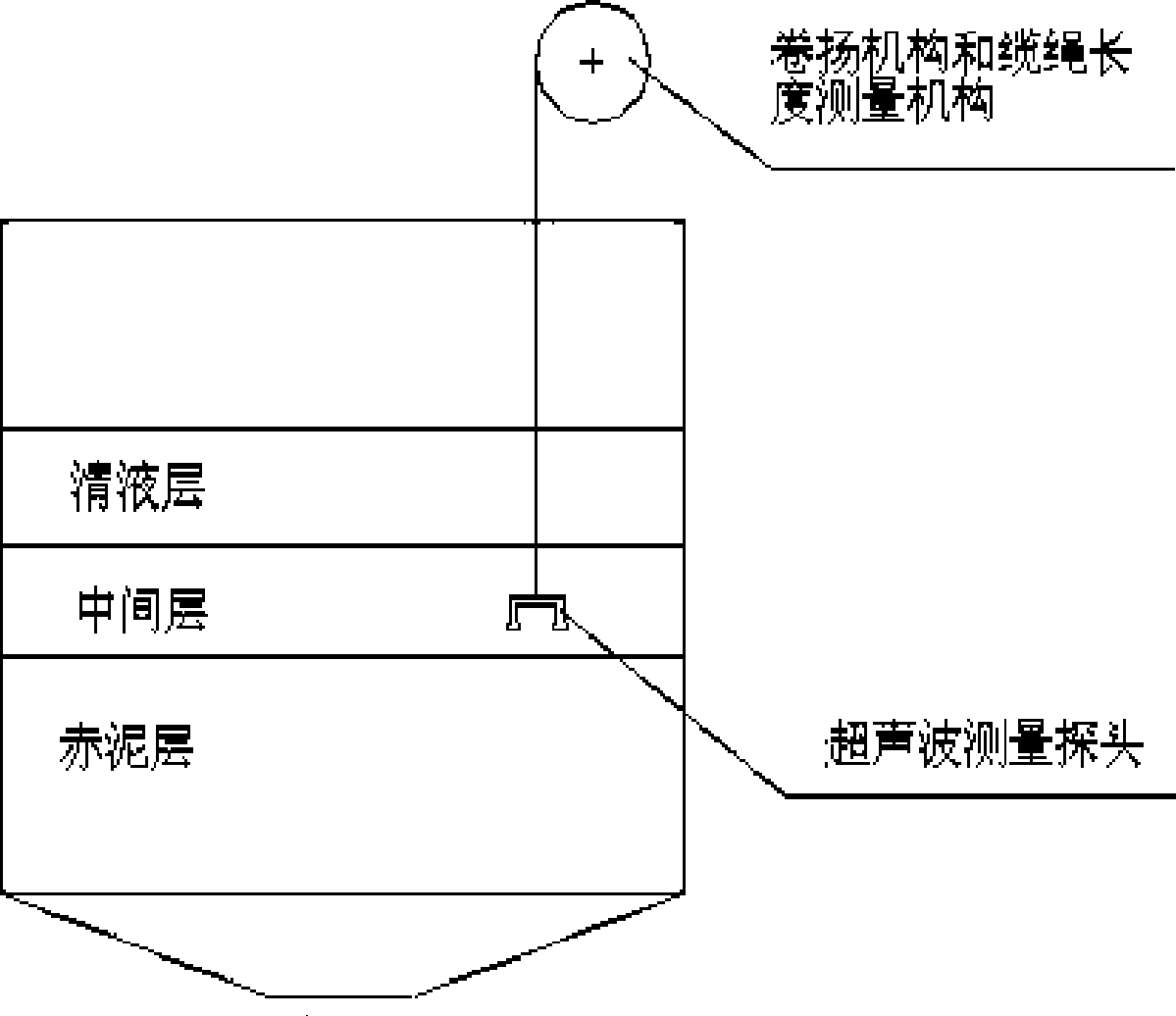

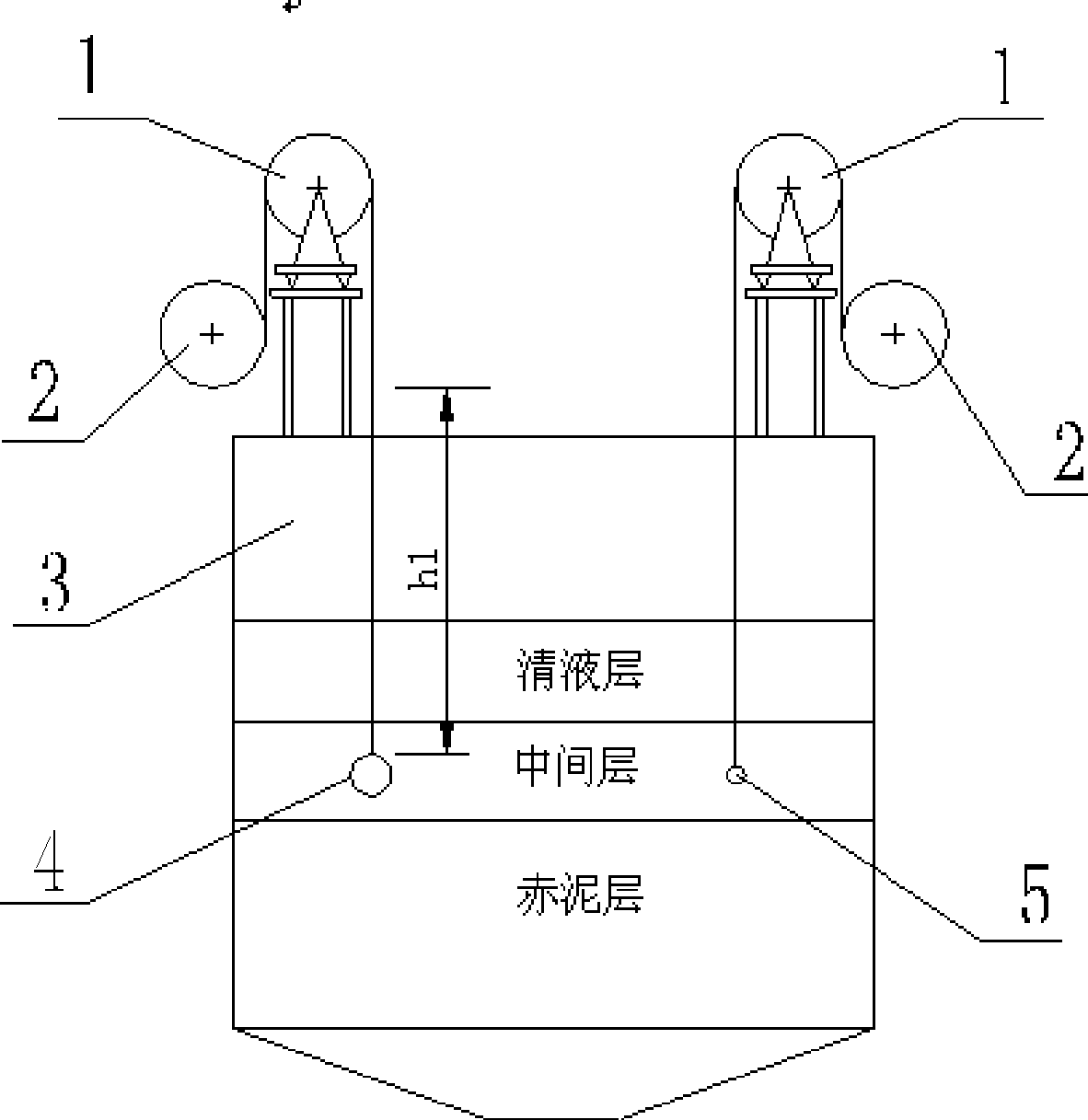

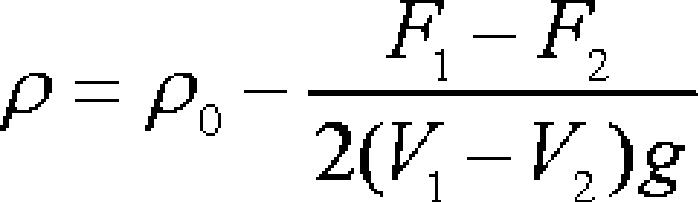

[0008] Embodiments of the present invention: the present invention is composed of the following parts: a pulley block 1 with a weighing frame, a hoisting mechanism and a cable length measuring device 2, a settlement tank 3, a large floating ball 4, a small floating ball 5 and the cables connecting the floating balls , PLC control system, in which the diameter of the large floating ball is 300mm, and the diameter of the small floating ball is 150mm, both of which are made of stainless steel, filled with lead sand in the middle, and the density is about 4000kg / m3; the cable connected to the floating ball requires a temperature resistance >100°C , acid and alkali corrosion resistance, small ductility. Section about 1.5~2.5mm 2 , good flexibility. according to figure 2 To connect, two sets of pulley blocks 1 with measuring scales, hoisting mechanism and cable length measuring device 2 are installed on the settling tank 3, and are respectively connected with the large floating b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com