Concrete mixing device for water conservancy engineering

A technology of water conservancy projects and mixing devices, which is applied in the direction of cement mixing devices, clay preparation devices, chemical instruments and methods, etc., can solve problems such as poor performance, large impact area, uneven mixing, etc., and achieve uniform and stable concrete, large Three-dimensional effect of stirring driving force and motion trajectory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

[0015] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

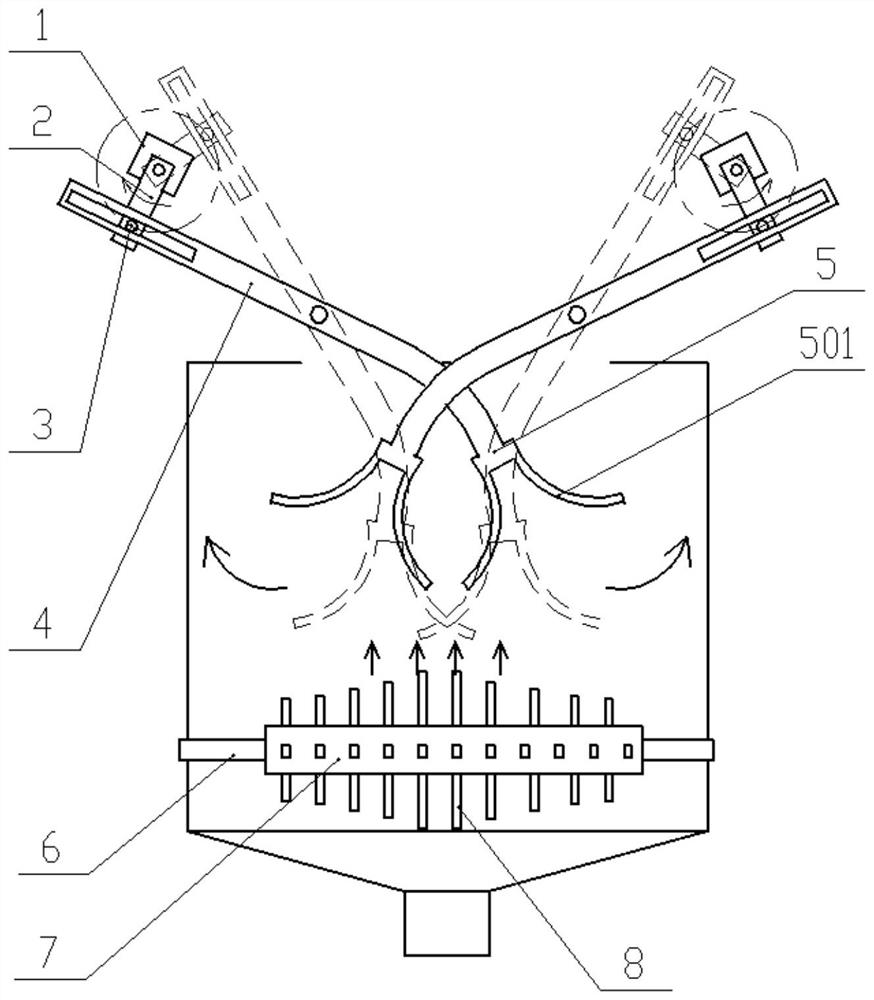

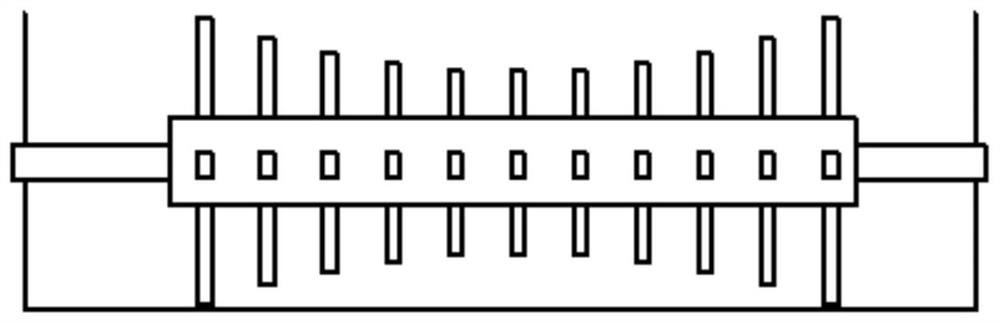

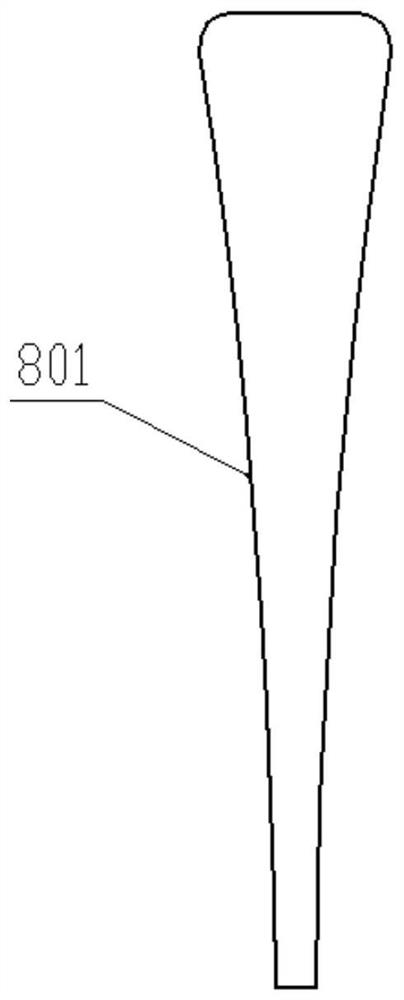

[0016] like figure 1 Shown in -2, a concrete mixing device for water conservancy projects, it specifically includes a mixing bucket for mixing various raw materials of concrete, the mixing bucket is a vertical mixing bucket with an opening facing upwards, and a mixing bucket for mixing is installed in the mixing bucket The stirring part, the mixing barrel is a cuboid structure, and its opening is arranged along its length direction; the stirring part includes a digging stirring part and a rotating part from top to bottom, and the specific structure of these parts is as follows:

[0017] For the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com