Novel biomass pellet fuel and preparation method thereof

A technology for biomass particles and fuels, which is applied in the fields of biofuels, waste fuels, and fuels, can solve the problems of non-use and high pollution, and achieve the effects of uniform and stable mixing, easy preparation, and solving indigestion treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

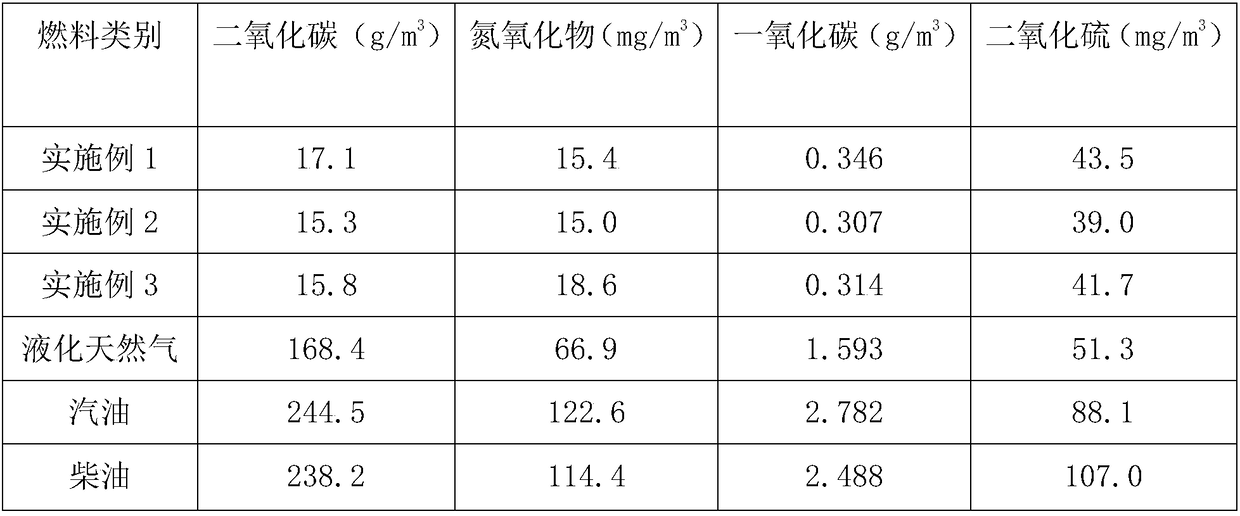

Examples

Embodiment 1-3

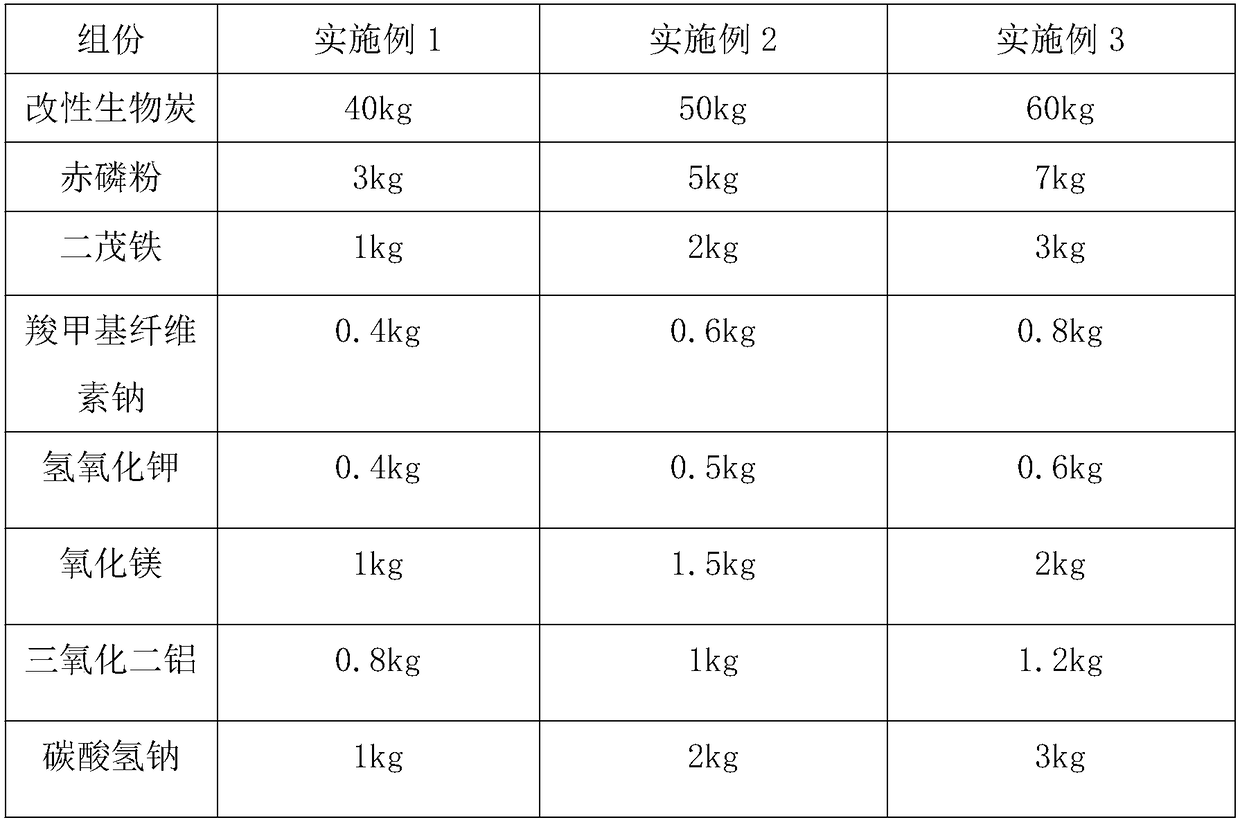

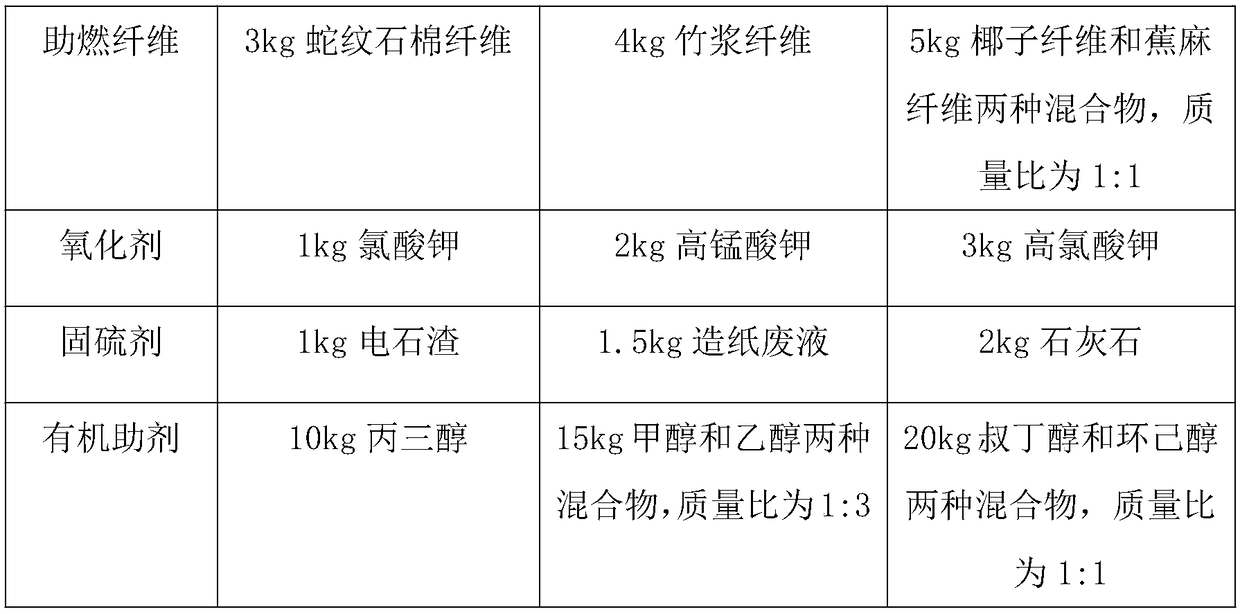

[0028] Embodiment 1-3, a kind of novel biomass particle fuel, takes the raw material of following table 1:

[0029] Table 1

[0030]

[0031]

Embodiment 1

[0033] The modified biochar in the raw material is prepared through the following steps:

[0034] (1) Weigh the following raw materials: Spartina alterniflora 15kg, camellia oleifera husk 8kg, cottonseed husk 8kg, rice husk 8kg, corn stalk 4kg, expanded perlite powder 2kg and melon seed stone powder 2kg;

[0035] (2) Dry Spartina alterniflora, camellia husks, cottonseed husks, rice husks and corn stalks until the water content is below 20%, then cut them into 2cm segments and mix them evenly, and add hard Zinc fatty acid, 1% liquid paraffin, expanded perlite powder and melon seed stone powder are mixed evenly to obtain a mixed material;

[0036] (3) Put the mixed material into the carbonization furnace, raise the temperature to 440°C at a rate of 10°C / min under oxygen-limited conditions, keep the temperature for carbonization for 2.5 hours, and then remove the charcoal, filter it with water and cool it down to room temperature, then It is dried and pulverized to less than 500...

Embodiment 2

[0041] The modified biochar in the raw material is prepared through the following steps:

[0042] (1) The following raw materials are taken in parts by weight for subsequent use: 20 kg of Spartina alterniflora, 10 kg of camellia oleifera husk, 10 kg of cottonseed husk, 10 kg of rice husk, 6 kg of corn stalk, 3 kg of expanded perlite powder and 3 kg of melon seed stone powder;

[0043] (2) Dry Spartina alterniflora, camellia husks, cottonseed husks, rice husks and corn stalks until the water content is below 15%, then cut them into 3cm segments and mix them evenly, and add hard Zinc fatty acid, 2% liquid paraffin, expanded perlite powder and melon seed stone powder are mixed uniformly to obtain a mixed material;

[0044] (3) Put the mixed material into the carbonization furnace, raise the temperature to 450°C at a rate of 15°C / min under oxygen-limited conditions, keep the temperature for carbonization for 3 hours, and then produce charcoal. Water is filtered and cooled to room...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com