A kind of potassium permanganate sustained-release agent and its preparation method and application

A technology of potassium permanganate and slow-release agent, which is applied in application, chemical instruments and methods, agriculture, etc., can solve problems such as unstable release concentration, permeability problems, and adsorption problems, and achieve good treatment effects and adsorption properties. Enhanced, long-release effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

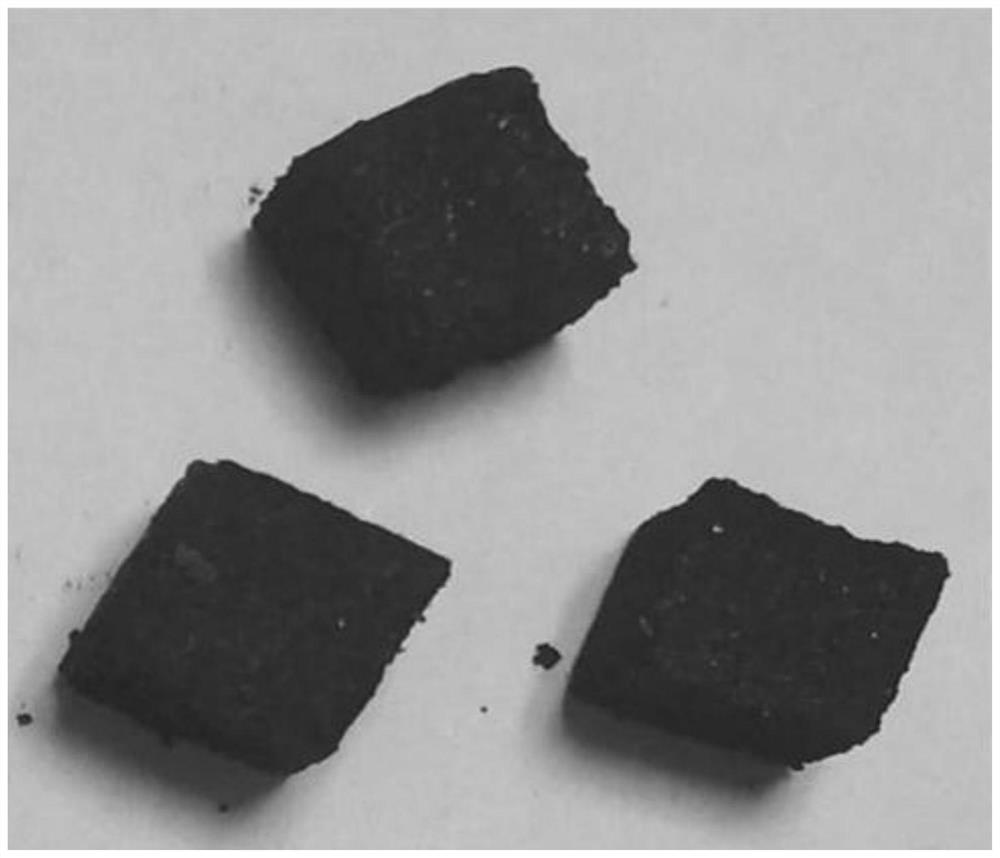

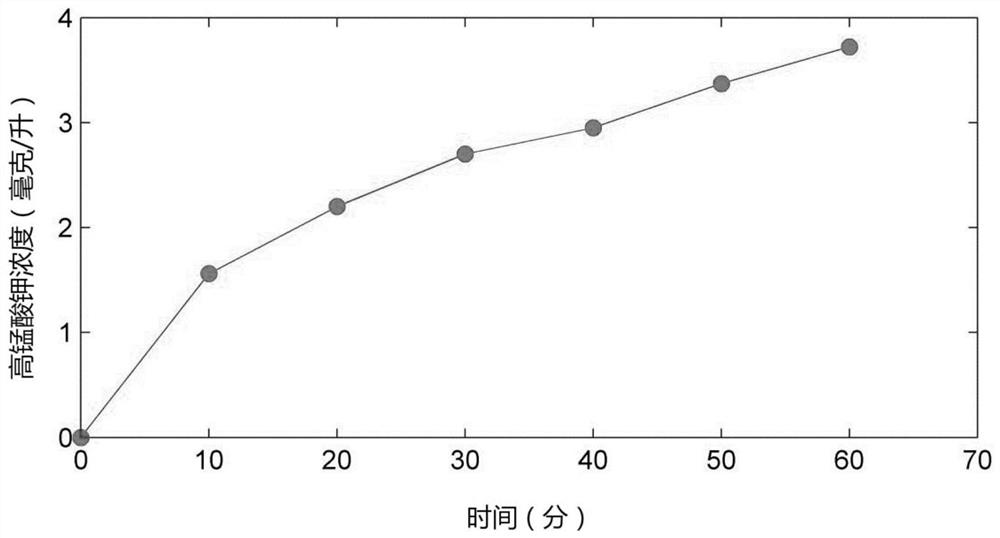

[0038] Use slow release agent as KMnO 4 , paraffin, quartz sand and activated carbon mass ratio of 2:10:10:2 mixed adsorption slow-release agent.

[0039] (1) Preparation of sustained release agent

[0040] Based on microcapsule technology, the sustained-release agent is prepared by melting condensation dispersion method. Take 10g of paraffin in a Erlenmeyer flask, add 20mL of absolute ethanol, and heat in a water bath to 75°C; when the paraffin is completely melted, add 1g of polyethylene glycol-4000 and 1 drop of Span-80, and stir thoroughly; press 2:10 : Add 10g of quartz sand, 2g of activated carbon and 2g of potassium permanganate powder in sequence at a mass ratio of 10:2, stir to disperse evenly; pour it into a prepared mold with a size of 1.0cm×1.0cm×1.0cm while it is hot; After cooling and drying, the cube-shaped solid potassium permanganate slow-release agent can be obtained.

[0041] figure 1 for KMnO4 , paraffin, quartz sand and activated carbon mass ratio of 2...

Embodiment 2

[0062] Use slow release agent as KMnO 4 , paraffin, quartz sand and activated carbon mass ratio of 2:10:10:3 mixed adsorption slow-release agent.

[0063] Preparation of sustained-release formulations:

[0064] Based on microcapsule technology, the sustained-release agent is prepared by melting condensation dispersion method. Take 10g of paraffin in a Erlenmeyer flask, add 20mL of absolute ethanol, and heat in a water bath to 75°C; when the paraffin is completely melted, add 1g of polyethylene glycol-4000 and 1 drop of Span-80, and stir thoroughly; press 2:10 : Add 10g of quartz sand, 3g of activated carbon and 2g of potassium permanganate powder in sequence at a mass ratio of 10:3, stir to disperse evenly; pour it into a prepared mold with a size of 1.0cm×1.0cm×1.0cm while it is hot; After cooling and drying, the cube-shaped solid potassium permanganate slow-release agent can be obtained.

Embodiment 3

[0066] Use slow release agent as KMnO 4 , paraffin, quartz sand and activated carbon mass ratio of 2:10:10:4 mixed adsorption slow-release agent.

[0067] Preparation of sustained-release formulations:

[0068] Based on microcapsule technology, the sustained-release agent is prepared by melting condensation dispersion method. Take 10g of paraffin in a Erlenmeyer flask, add 20mL of absolute ethanol, and heat in a water bath to 75°C; when the paraffin is completely melted, add 1g of polyethylene glycol-4000 and 1 drop of Span-80, and stir thoroughly; press 2:10 Add 10g of quartz sand, 4g of activated carbon and 2g of potassium permanganate powder in sequence at a ratio of 10:4, stir to disperse evenly; pour it into a prepared mold with a size of 1.0cm×1.0cm×1.0cm while it is hot; After cooling and drying, the cube-shaped solid potassium permanganate slow-release agent can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| osmotic coefficient | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com