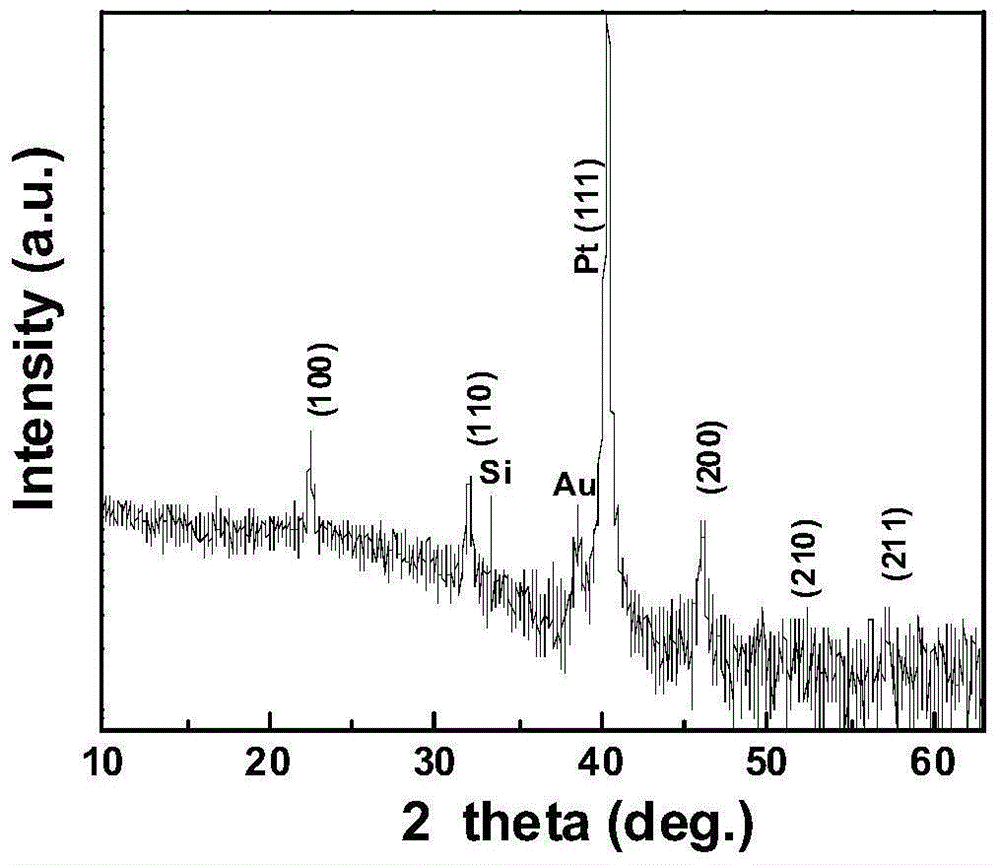

Preparation method of potassium-sodium niobate-barium zirconate-sodium bismuth titanate lead-free piezoelectric film with vertical phase boundary

A lead-free piezoelectric, potassium sodium niobate technology, applied in the direction of solid-state chemical plating, metal material coating process, coating, etc., can solve the problems of temperature instability, KNN-BZ ceramic piezoelectric performance decline, etc., to achieve Better structure, excellent electrical performance, and structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

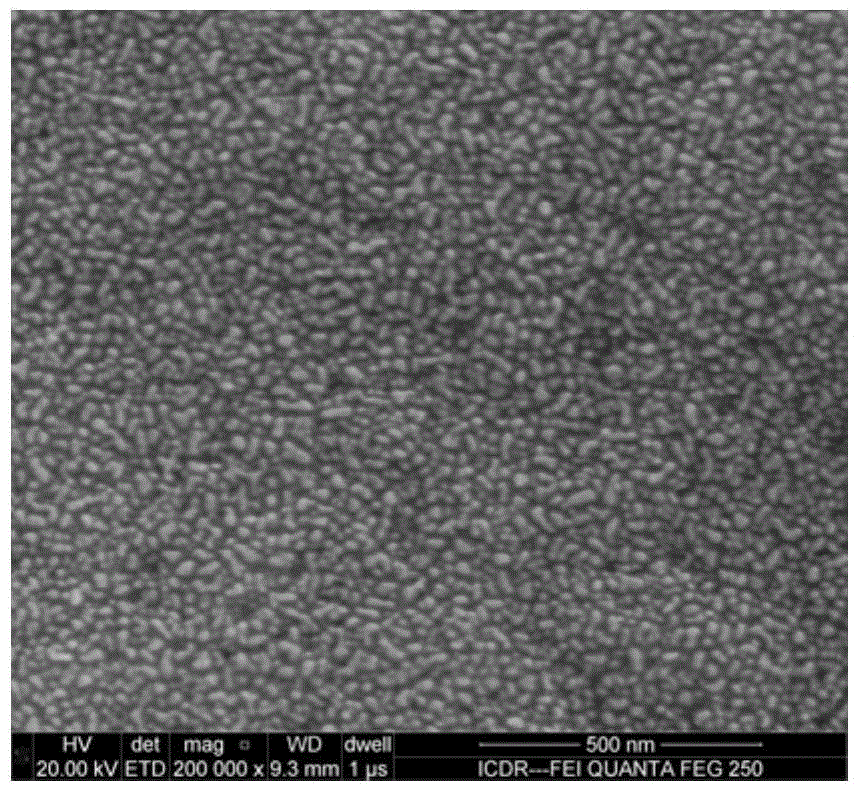

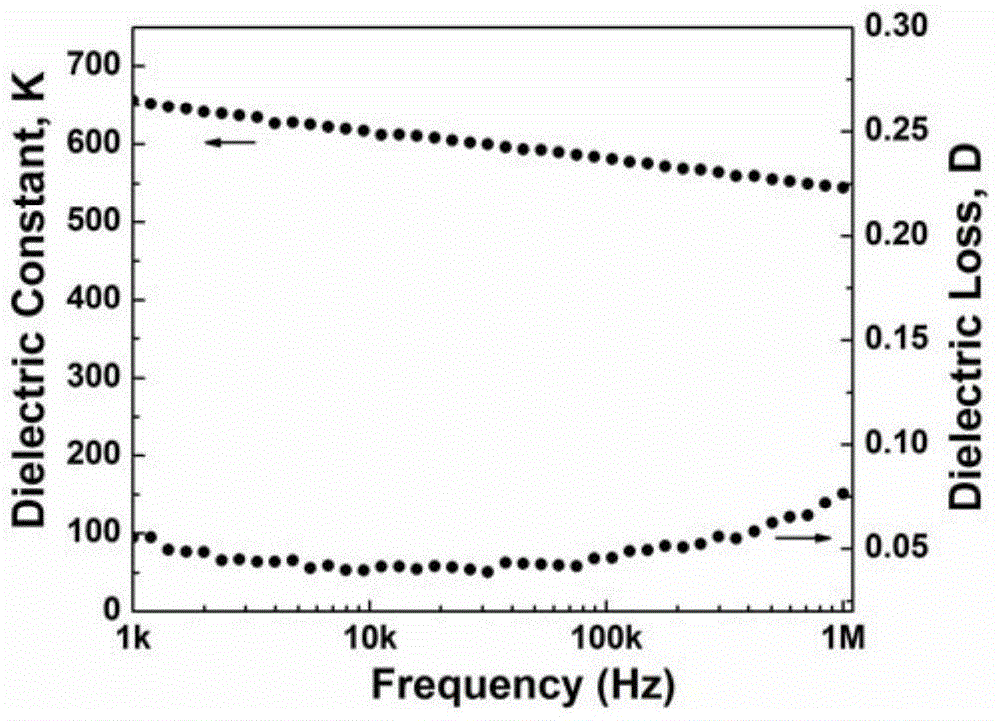

Embodiment 1

[0042] 1) Press 0.910K 0.5 Na 0.5 NbO 3 -0.080BaZrO 3 -0.01Bi 0.5 Na 0.5 TiO 3 The stoichiometric ratio, respectively excess (in moles) 10% of potassium acetate and sodium acetate was added to ethylene glycol methyl ether, magnetically stirred at room temperature until dissolved, forming a solution containing K, Na. Add barium acetate and bismuth acetate into a mixture of ethylene glycol methyl ether and glacial acetic acid (volume ratio 3:7), heat to 100°C and cool to room temperature after completely dissolving to form a solution containing Bi and Ba. Then tetra-n-butoxyzirconium is added dropwise into the solution containing Bi and Ba to form a solution containing Zr, Bi and Ba. Add tetrabutyl titanate into ethylene glycol methyl ether, and at the same time add acetylacetone whose molar number is twice that of tetrabutyl titanate as a stabilizer, stir magnetically at room temperature for 40 minutes to obtain a Ti-containing solution, and then add the Ti-containing Th...

Embodiment 2

[0046] 1) by 0.9125K 0.5 Na 0.5 NbO 3 -0.0775BaZrO 3 -0.01Bi 0.5 Na 0.5 TiO 3 The stoichiometric ratio, respectively excess (in moles) 10% of potassium acetate and sodium acetate was added to ethylene glycol methyl ether, magnetically stirred at room temperature until dissolved, forming a solution containing K, Na. Add barium acetate and bismuth acetate into a mixture of ethylene glycol methyl ether and glacial acetic acid (volume ratio 3:6), heat to 80°C and cool to room temperature after completely dissolving to form a solution containing Bi and Ba. Then tetra-n-butoxyzirconium is added dropwise into the solution containing Bi and Ba to form a solution containing Zr, Bi and Ba. Add tetrabutyl titanate into ethylene glycol methyl ether, and at the same time add acetylacetone whose molar number is 1.5 times that of tetrabutyl titanate as a stabilizer, stir magnetically at room temperature for 40 minutes to obtain a Ti-containing solution, and then add the Ti-containing ...

Embodiment 3

[0051] 1) by 0.915K 0.5 Na 0.5 NbO 3 -0.075BaZrO 3 -0.01Bi 0.5 Na 0.5 TiO 3 The stoichiometric ratio, respectively excess (in moles) 10% of potassium acetate and sodium acetate was added to ethylene glycol methyl ether, magnetically stirred at room temperature until dissolved, forming a solution containing K, Na. Add barium acetate and bismuth acetate into a mixture of ethylene glycol methyl ether and glacial acetic acid (volume ratio 3:5), heat to 80°C and cool to room temperature after completely dissolving to form a solution containing Bi and Ba. Then tetra-n-butoxyzirconium is added dropwise into the solution containing Bi and Ba to form a solution containing Zr, Bi and Ba. Add tetrabutyl titanate to ethylene glycol methyl ether, and at the same time add acetylacetone whose molar number is twice that of tetrabutyl titanate as a stabilizer, stir magnetically at room temperature for 50 minutes to obtain a Ti-containing solution, and then add the Ti-containing The solu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com