Fruit and vegetable cleaning agent and preparation method thereof

A fruit and vegetable cleaning agent and technology of cleaning agent, applied in the field of daily necessities, can solve the problems of many kinds of raw materials, high production cost, poor decontamination effect, etc., and achieve the effects of good pesticide residue removal, pesticide residue removal, and peculiar smell elimination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

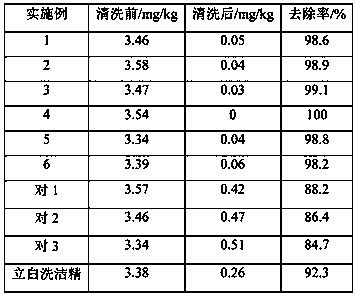

Examples

Embodiment 1

[0024] A fruit and vegetable cleaner, made of the following raw materials in parts by weight:

[0025] 15 parts of citrus peel extract, 5 parts of Morus alba extract, 1 part of tea polyphenol, 5 parts of coconut fatty acid diethylamide, 10 parts of sodium secondary alkyl sulfonate, 6 parts of cocamidopropyl betaine, bamboo charcoal 10 parts of powder, 2 parts of hydroxyethyl cellulose and 60 parts of water.

[0026] The preparation method of described orange peel extract comprises the following steps:

[0027] Grind the citrus peel to 20 mesh powder, add ethanol solution 8 times the weight of the raw material, the volume concentration of the ethanol solution is 75%, soak for 1h, then ultrasonic extraction 3 times, each 10h, the ultrasonic extraction condition is : The temperature is 50°C, the ultrasonic power is 300 W, centrifuged, and the supernatant is collected.

[0028] The preparation method of described Morus alba extract comprises the following steps:

[0029] Vacuum...

Embodiment 2

[0035] A fruit and vegetable cleaner, made of the following raw materials in parts by weight:

[0036] 16 parts of citrus peel extract, 6 parts of Morus alba extract, 2 parts of tea polyphenols, 6 parts of coconut oil fatty acid diethylamide, 12 parts of sodium secondary alkyl sulfonate, 7 parts of cocamidopropyl betaine, bamboo charcoal 11 parts of powder, 2.5 parts of hydroxyethyl cellulose and 65 parts of water.

[0037] The preparation method of described orange peel extract comprises the following steps:

[0038] Grind the citrus peel to 30 mesh powder, add ethanol solution 10 times the weight of the raw material, the volume concentration of the ethanol solution is 80%, soak for 2 hours, then ultrasonically extract 2 times, each time for 5h, the ultrasonic extraction conditions are : The temperature is 55°C, the ultrasonic power is 400 W, centrifuged, and the supernatant is collected.

[0039] The preparation method of described Morus alba extract comprises the followin...

Embodiment 3

[0046] A fruit and vegetable cleaner, made of the following raw materials in parts by weight:

[0047] 18 parts of citrus peel extract, 7 parts of Morus alba extract, 3 parts of tea polyphenols, 8 parts of coconut fatty acid diethylamide, 15 parts of sodium secondary alkyl sulfonate, 9 parts of cocamidopropyl betaine, bamboo charcoal 13 parts of powder, 3 parts of hydroxyethyl cellulose and 70 parts of water.

[0048] The preparation method of described orange peel extract comprises the following steps:

[0049]Grind the citrus peel to 40 mesh powder, add an ethanol solution 12 times the weight of the raw material, the volume concentration of the ethanol solution is 70%, soak for 1h, and then ultrasonically extract 3 times, each time for 6h, the ultrasonic extraction conditions are: : The temperature is 60°C, the ultrasonic power is 500 W, centrifuged, and the supernatant is collected.

[0050] The preparation method of described Morus alba extract comprises the following st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com