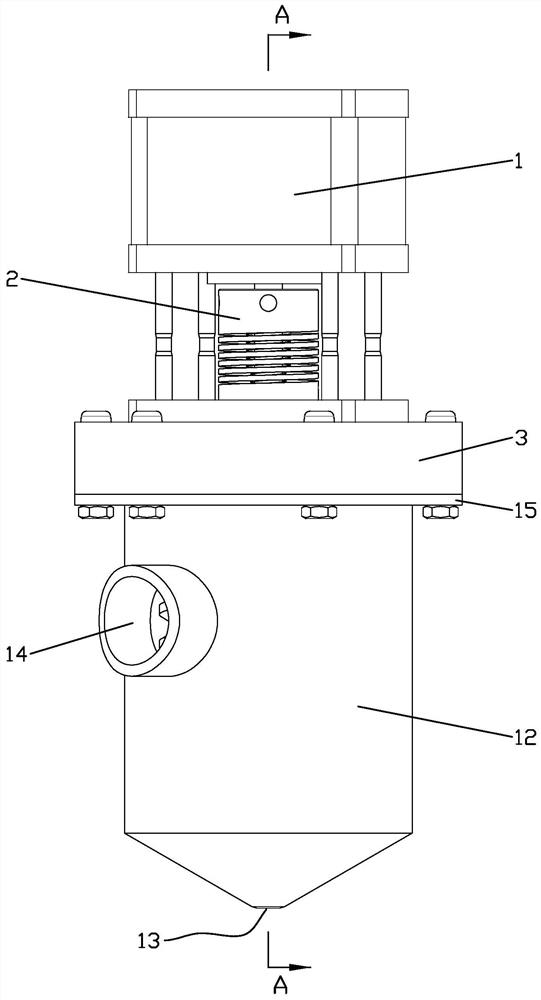

Planetary mixed extrusion molding device

An extrusion molding, planetary technology, applied in the field of planetary mixing extrusion molding devices, can solve the problems of insufficient mixing of cement, hydration and solidification, thin slurry, etc., and achieve compact structure, stable product molding, and overall light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

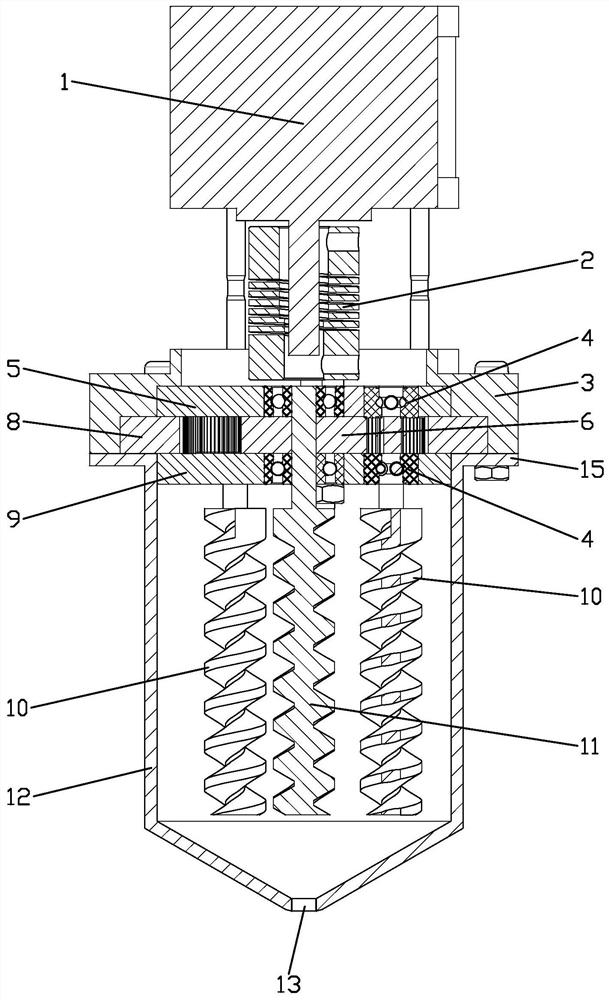

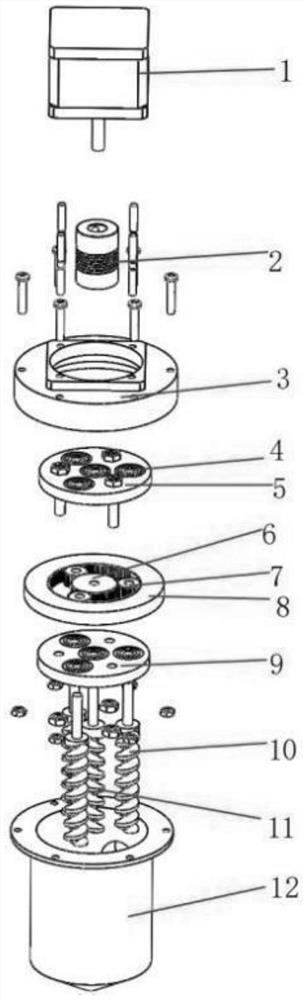

Embodiment 1

[0054] Embodiment 1 uses cement-based materials to form products, and the screw groove depths of the sun screw 11 and the planetary screw 10 are both 4mm. The sun screw 11, the planetary screw 10, and the mixing drum 12 are all made of stainless steel. The mixing drum 12 and the fixing plate 3 are connected with bolts and nuts, and the upper clamping plate 5 and the lower clamping plate 9 are fixed between the two. The distance between the planetary screw 10 and the inner wall of the mixing drum 12 is 2mm. The diameter of the sun screw 11 is 20 mm, the diameter of the planetary screw 10 is 10 mm, the diameter of the sun gear 6 is 24 mm, and the diameter of the planetary gear 7 is 6 mm. The helical blade of the sun screw 11 is a right-handed helix, and the helical blade of the planetary screw 10 is a left-handed helix. The mixing drum 12 and the branch cylinder form a branch cylinder with a "bu"-shaped structure. The branch part of the cylinder is connected with the conveying...

Embodiment 2

[0060] The principle of this embodiment is the same as that of Embodiment 1, but the details are different.

[0061] Embodiment 2 uses chocolate material to mold the product, and the screw groove depths of the sun screw 11 and the planetary screw 10 are both 2 mm. Sun screw 11, planetary screw 10, and mixing drum 12 all adopt food-grade plastic materials. The mixing drum 12 and the fixing plate 3 are connected with bolts and nuts, and the upper clamping plate 5 and the lower clamping plate 99 are fixed between the two. The distance between the planetary screw 10 and the inner wall of the mixing drum 12 is 1 mm. The diameter of the sun screw 11 is 10 mm, the diameter of the planetary screw 10 is 5 mm, the diameter of the sun gear 6 is 12 mm, and the diameter of the planetary gear 7 is 3 mm. The helical blade of the sun screw 11 is a right-handed helix, and the helical blade of the planetary screw 10 is a left-handed helix. The mixing drum 12 and the branch cylinder form a br...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com