Aerosol type rubber conveyer belt releasing agent, preparation method thereof and spraying system thereof

An aerosol, conveyor belt technology, applied in additives, injection devices, petroleum industry, etc., to reduce labor costs, high lubricity, and ensure uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

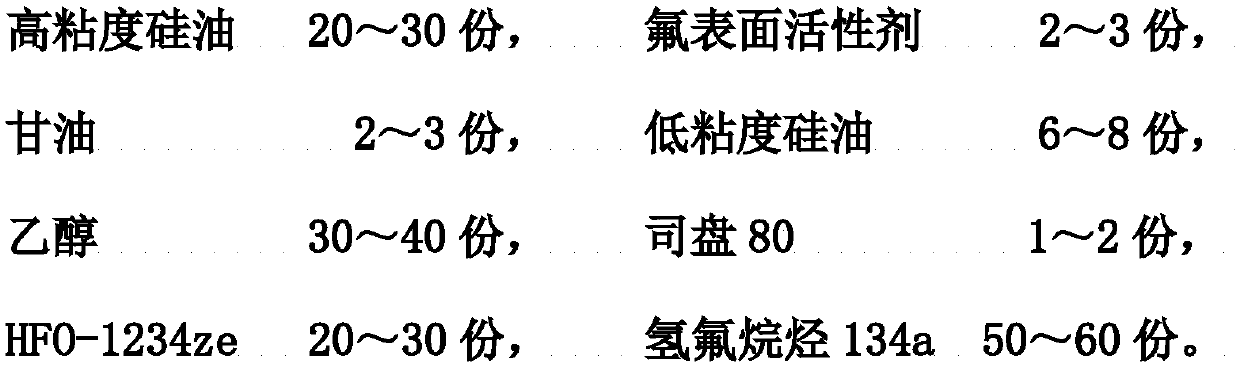

Embodiment 1

[0045] 1) Build an aerosol-type rubber conveyor belt release agent spraying device

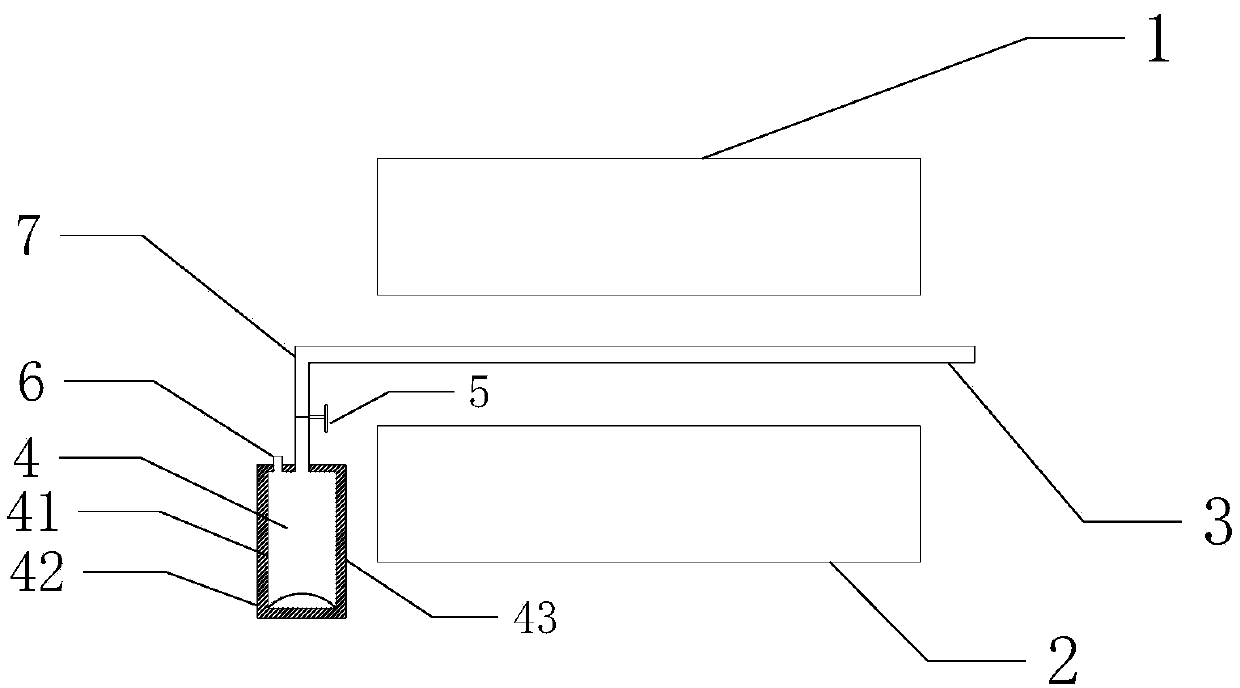

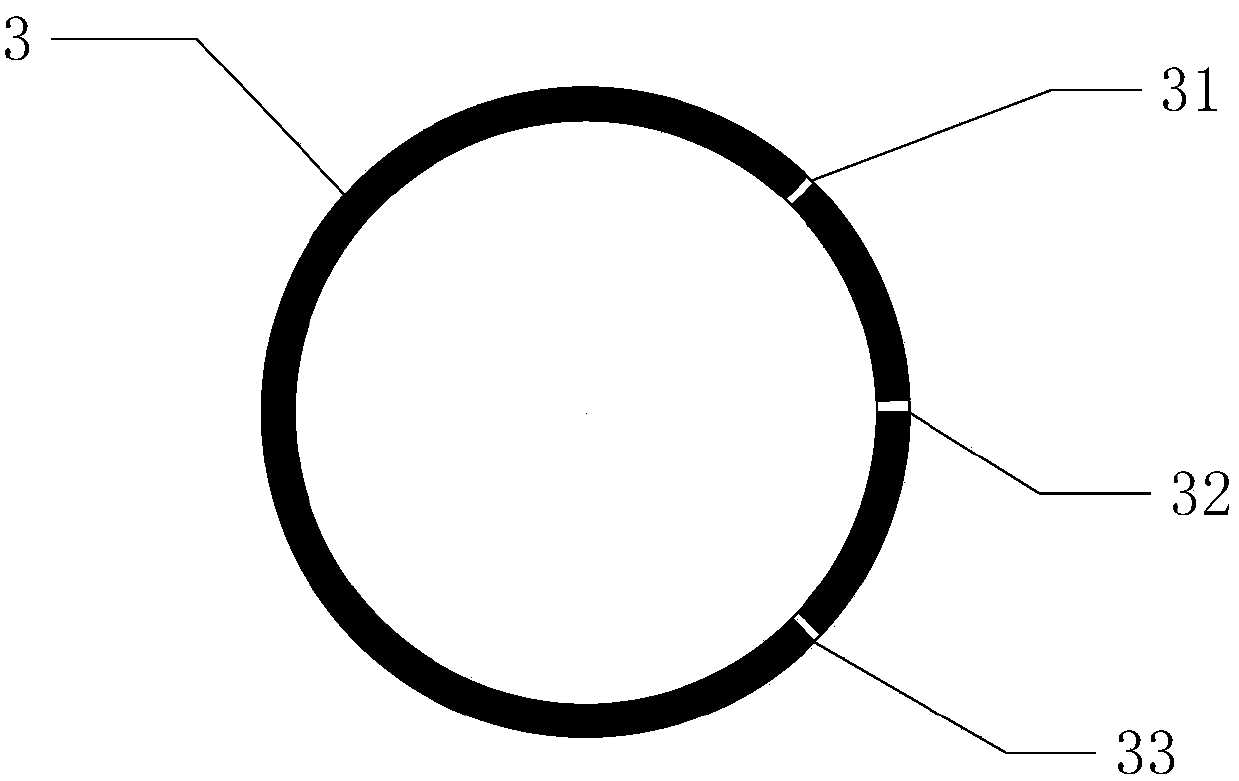

[0046] see figure 1 and figure 2 , as a specific embodiment, the aerosol-type rubber conveyor belt release agent spraying device of the present invention includes an aerosol pipeline 3 arranged on the side of the vulcanizer along the length direction of the vulcanizer, and the aerosol pipeline 3 is in the height direction of the vulcanizer Located in the middle of the upper vulcanization plate 1 and the lower vulcanization plate 2 when it is in an open state; one end of the aerosol pipeline 3 is sealed, and the other end communicates with the aerosol tank 4 through a connecting pipe 7; , on the side facing the vulcanizing machine, a set of spray hole groups is arranged every 300mm along the length direction, and the spray hole groups include upper, middle and lower distribution of upper spray holes 31 and middle spray holes arranged radially toward the gas mist pipeline 3 32 and the lower s...

Embodiment 2

[0053] The difference from Example 1 is that in this example, the amount of each raw material component of the release agent is: 23 parts of high-viscosity polyether silicone oil, 2.4 parts of fluorosurfactant, 2.3 parts of glycerin, 7.5 parts of low-viscosity silicone oil, 36 parts of ethanol, 1.5 parts of Span 80, 25 parts of HFO-1234ze, 55 parts of hydrofluoroalkane 134a. In the spraying system: the length of the aerosol pipeline 3 is 3.2m, the middle spray hole 32 is located in the middle of the aerosol pipeline, the circumferential interval angle between the lower spray hole 33 and the middle spray hole 32 is 25 degrees, and the upper spray hole 31 and the middle spray hole The circumferential interval angle of the holes 32 is 40 degrees, the aperture of the upper spray hole 31 is 0.9mm, the aperture of the middle spray hole 32 is 0.7mm, the aperture of the lower spray hole 33 is 0.58mm, and the spray hole group interval is 310mm .

Embodiment 3

[0055] The difference from Example 1 is that in this example, the amount of each raw material component of the release agent is: 28 parts of high-viscosity polyether silicone oil, 2 parts of fluorosurfactant, 2.7 parts of glycerin, 6 parts of low-viscosity silicone oil, 30 parts of ethanol, 1 part of Span 80, 20 parts of HFO-1234ze, 53 parts of hydrofluoroalkane 134a. In the spraying system: the length of the aerosol pipeline 3 is 3.5m, the middle spray hole 32 is located in the middle of the aerosol pipeline, the circumferential interval angle between the lower spray hole 3 and the middle spray hole 2 is 20 degrees, and the upper spray hole 31 and the middle spray hole The circumferential interval angle of the holes 32 is 35 degrees, the hole of the upper spray hole 31 is 0.8mm, the aperture of the middle spray hole 32 is 0.6mm, the aperture of the lower spray hole 3 is 0.5mm, and the spray hole group interval is 350mm .

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com