Robotic assembly line for powder dispensing

A robot and assembly line technology, applied to medical containers, mixers, pharmaceutical packaging, etc., can solve problems such as low efficiency, instability, pollution, etc., and achieve the effects of preventing drug contamination, uniform and stable mixing, and high preparation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

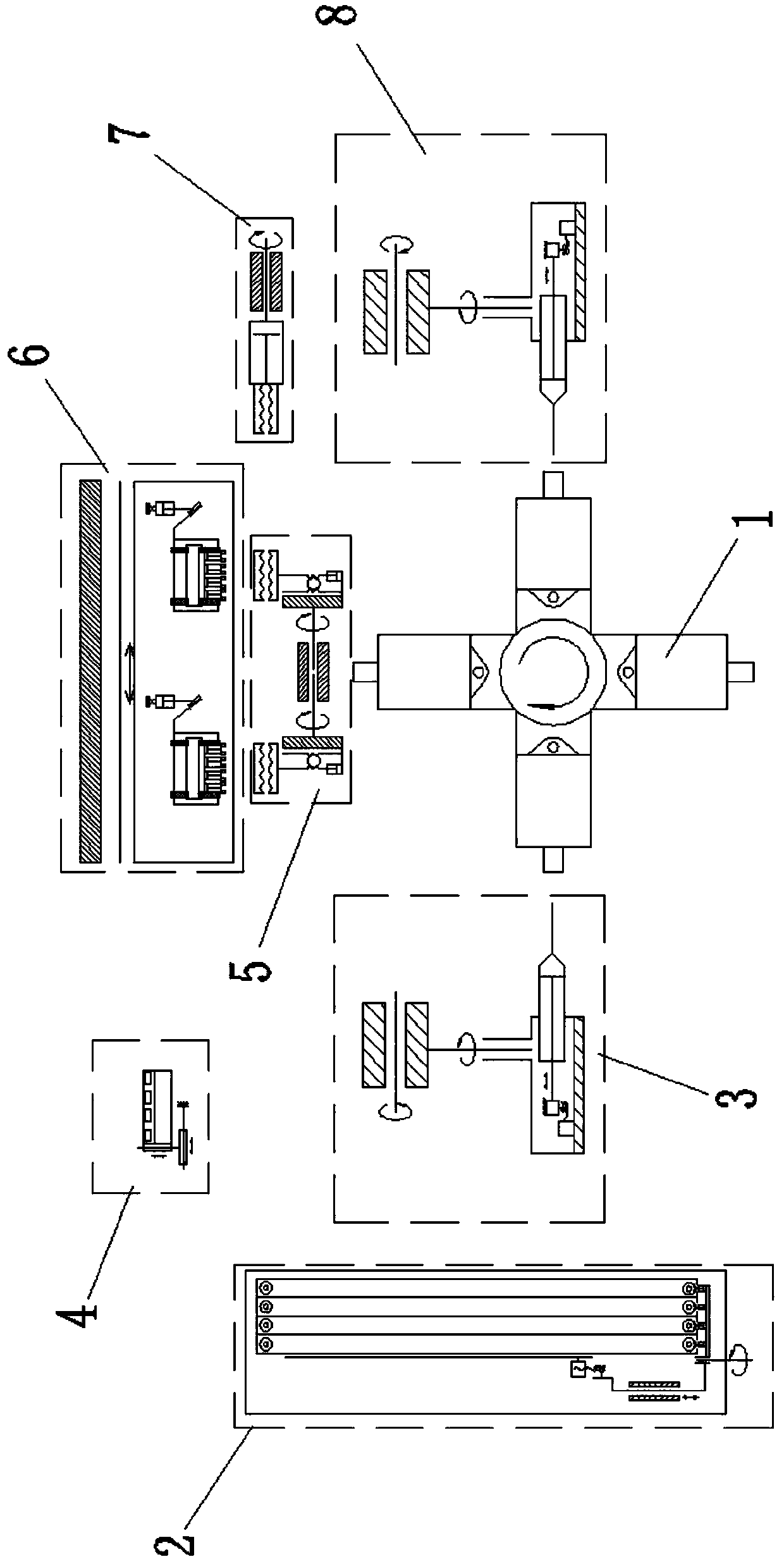

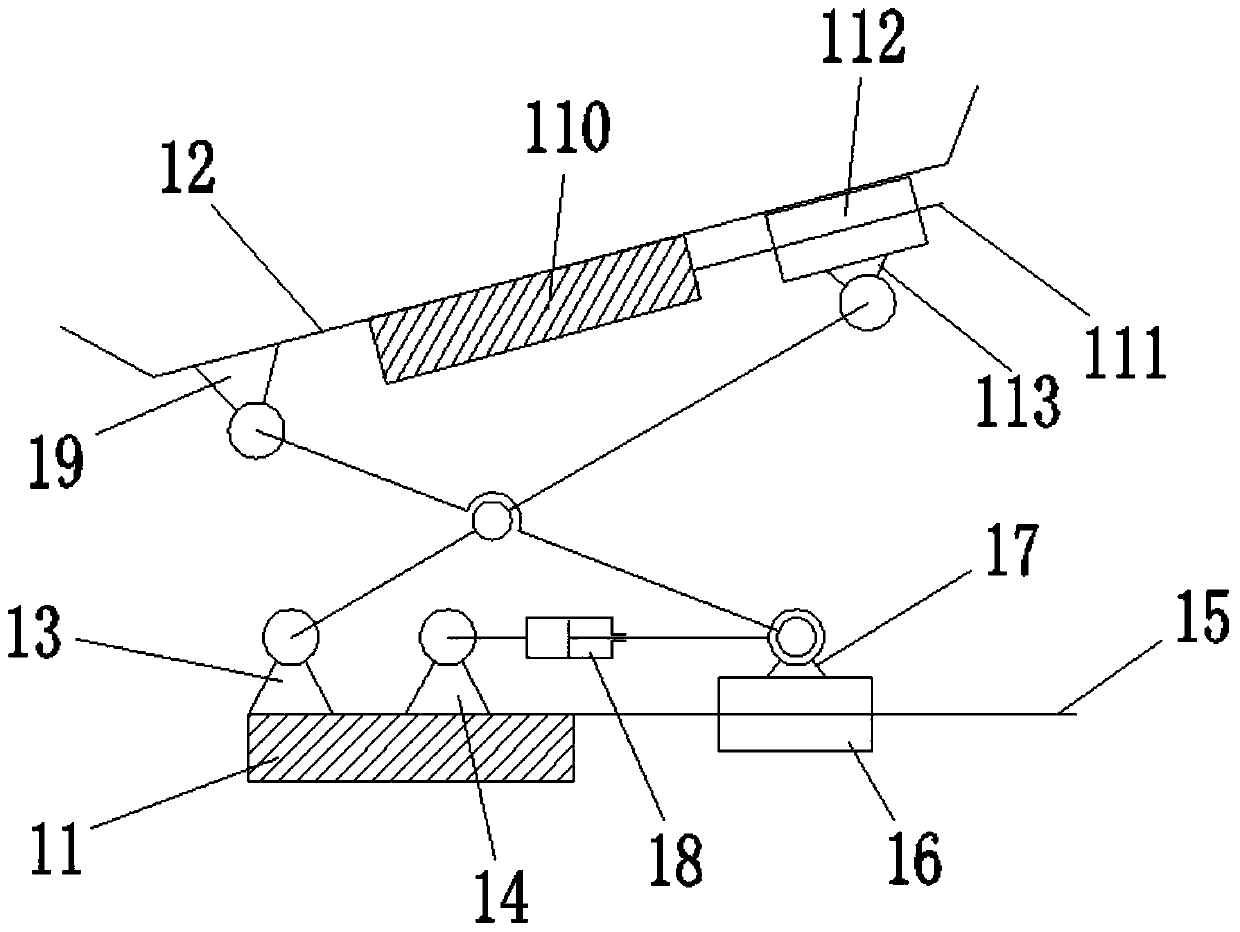

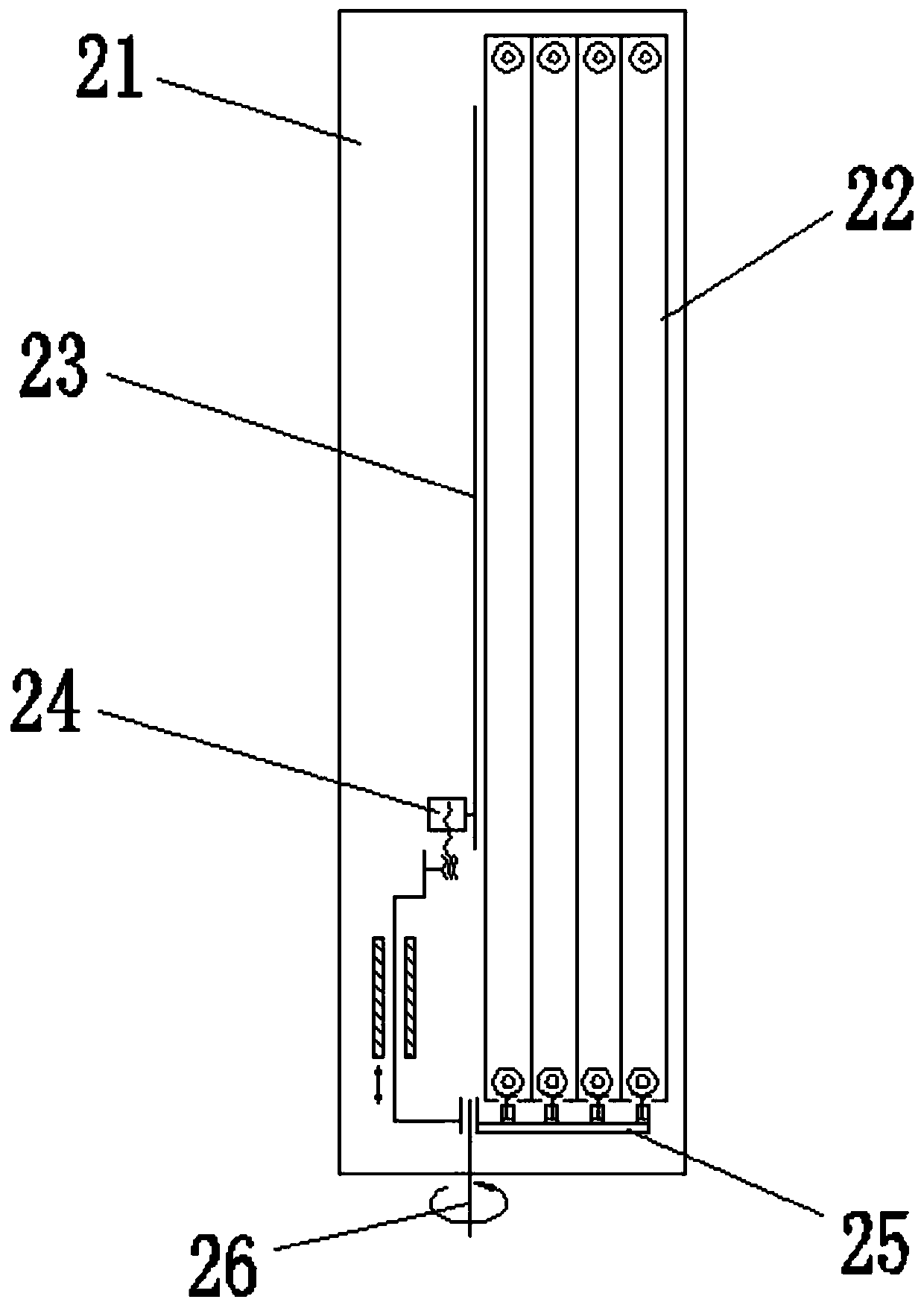

[0026] Such as Figure 1-8 As shown, a robot assembly line for powder dispensing includes a rotary platform 1 for holding mother solution bags; a powder bottle feeding device 2 for pushing and arranging powder bottles; The manipulator suction device 3 for injecting the liquid medicine into the powder bottle; the solution bottle transfer steering device 4 used to grab the powder bottle and cooperate with the manipulator suction device to complete the injection of the medicine liquid to obtain the original solution bottle; A solution bottle swing mixing device 5 for mixing medicinal liquid; a solution bottle delivery device 6 for grabbing and transporting a mixed solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com