Low-resistance internal mixing type gas nucleus atomization oil gun

An internal mixing, low-resistance technology, applied in the direction of lighting and heating equipment, burners, etc., can solve the problems of flame trailing, affecting fuel utilization, endangering boiler safety, etc., and achieve the effect of ensuring the atomization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, the purpose of which is to enable those skilled in the art to understand and implement the present invention, rather than to limit the present invention. It should be understood that the protection scope of the present invention shall be determined by the claims, and any structure similar to the present invention or an equivalent replacement shall be included in the protection scope of the present invention. In the following, the flow direction of the combustion medium is taken as the front, and the commas all represent the relationship between sum and sum.

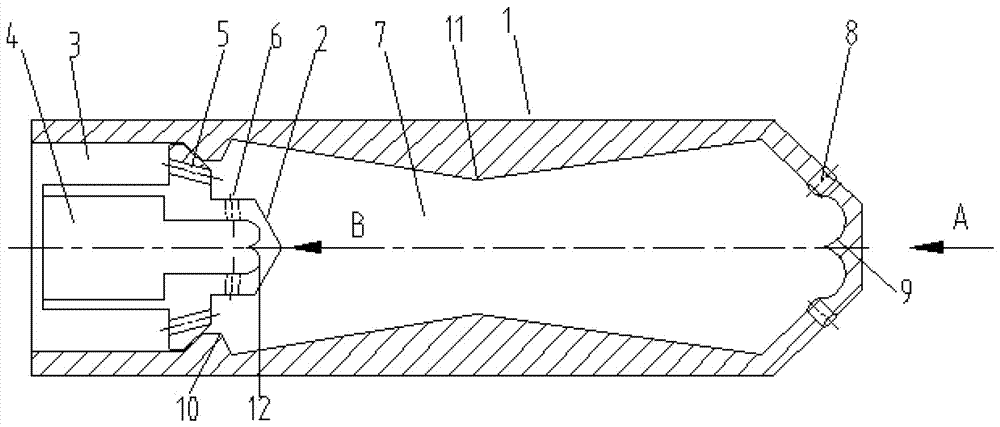

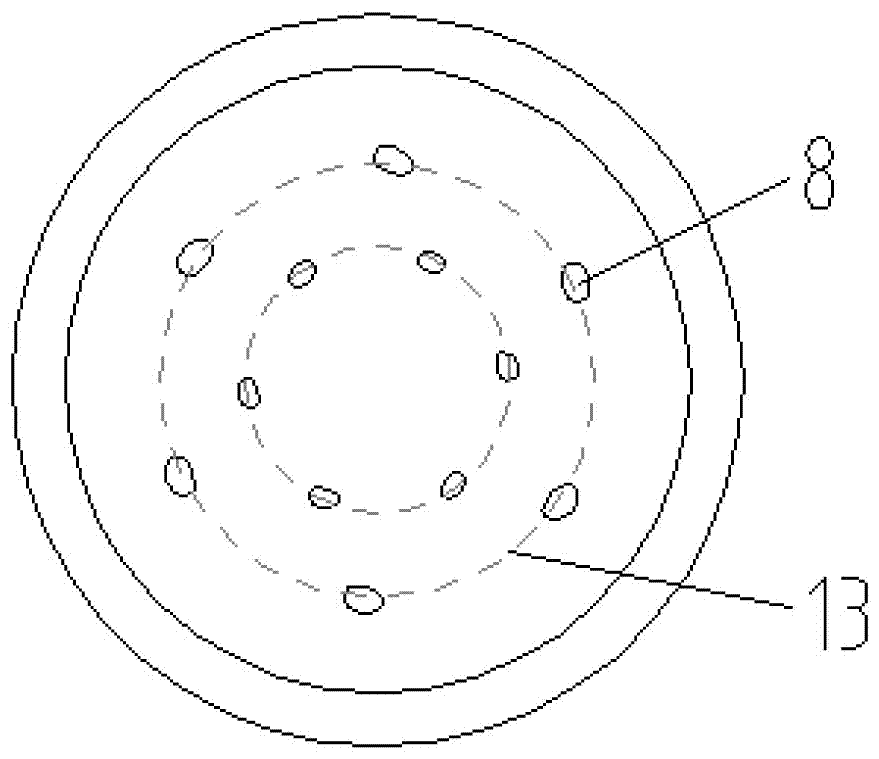

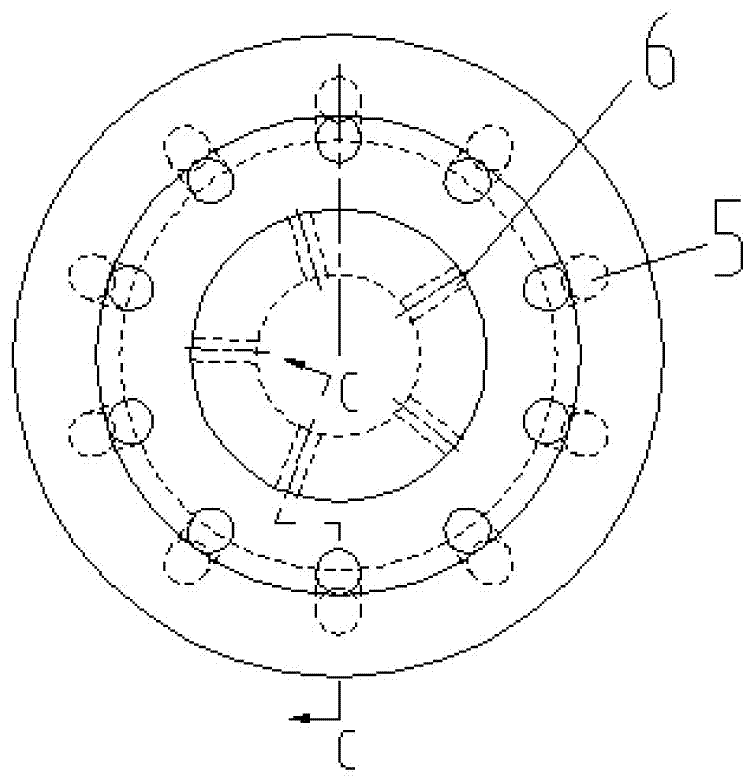

[0018] figure 1 It is a schematic diagram of the structure of a low-resistance internal-mixing air-nucleus atomizing oil gun. figure 1 It can be seen that a low-resistance internal mixing gas core atomizing oil gun includes a Venturi oil gun housing 1 and a mixing core 2 placed inside the V...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com