High temperature resistant matte acrylic adhesive

An acrylic glue, high temperature resistant technology, applied in adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve poor temperature resistance and reliability, product viscosity and performance attenuation, uniformity of lamp tube fog surface Poor and other problems, to achieve the effect of improving reliability, soft light, improving viscosity and adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

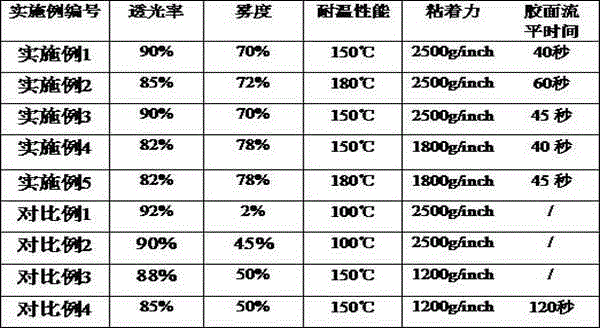

Examples

Embodiment 1

[0040] The diluent of embodiment 1 is toluene; The diluent of embodiment 2 is ethyl acetate; The diluent of embodiment 3 is acetone; The diluent of embodiment 4 is toluene and ethyl acetate according to the mixed diluent of 1:1; The diluent in Example 5 is a 1:1 mixed diluent of toluene and acetone.

[0041] The coupling agent of embodiment 1 is a silane coupling agent, the coupling agent of embodiment 2 is aluminate, the coupling agent of embodiment 3 is a titanate coupling agent; the coupling agent of embodiment 4 is chromium-containing Organic complex; The coupling agent of embodiment 5 is a chromium-containing organic complex.

[0042] According to the above components, mix an appropriate amount of azo compound and N-nitroso compound in the acrylic adhesive, add diluent and coupling agent, stir at high speed for 30 minutes, then add rosin resin, paste in order Vinyl resin, isocyanate cross-linking agent, epoxy cross-linking agent, acrylic polymer with a viscosity of 2000-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com