Emulsifying cavity device for high-pressure homogenizing emulsification equipment and method for emulsifying cavity device

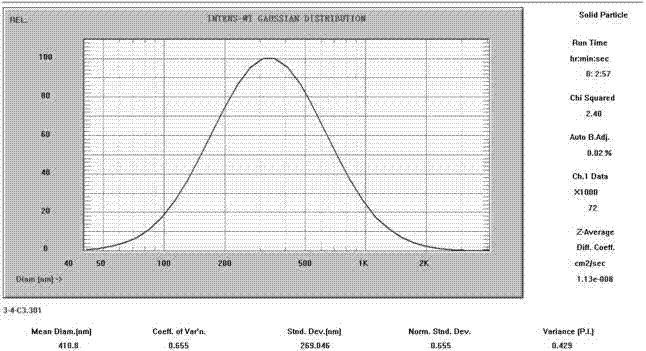

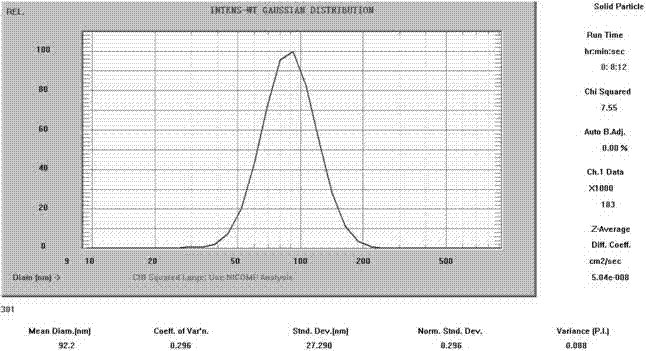

An emulsification equipment, high-pressure homogenization technology, applied in chemical instruments and methods, mixing methods, chemical/physical/physical-chemical nozzle reactors, etc., can solve problems such as low maximum working pressure, roughness, and poor dispersion of emulsions. Achieve the effect of reducing the average particle size, material particle size, and mixing uniformity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in conjunction with the accompanying drawings, and its product structure and method can be realized by those skilled in the art.

[0018] The design of the structure of the present invention is based on two technical problems. First, the pressure control method of traditional emulsification equipment cannot achieve high operating pressure; second, the particle size of traditional emulsification materials cannot achieve nanoscale dispersion.

[0019] Therefore, the internal structure of the emulsification chamber of the existing high-pressure homogeneous emulsification equipment is improved and designed into a Y-shaped spray chamber structure.

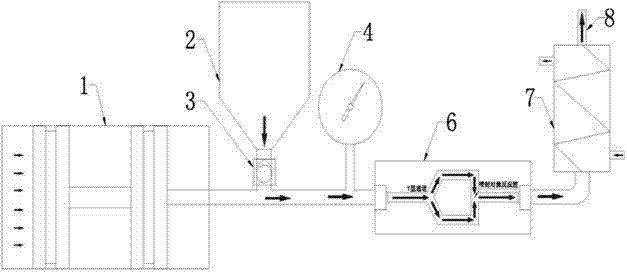

[0020] Improved high-pressure homogeneous emulsification equipment such as figure 1 As shown, it includes hydraulic plunger pump 1, check valve 3, pressure gauge 4, emulsification chamber 6, heat exchanger 7, feed cup 2, discharge port 8, and the plunger of hydraulic plunger pump 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com