Reducing agent atomization spray gun for selective non-catalytic reduction denitration process

An atomizing spray gun, non-catalytic technology, applied in the direction of spraying devices, liquid spraying devices, chemical instruments and methods, etc., can solve the problems of increasing operating costs, easy generation of liquid droplets, enlarged gun body diameter, etc., to achieve atomization effect Good, simple structure, no consumables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

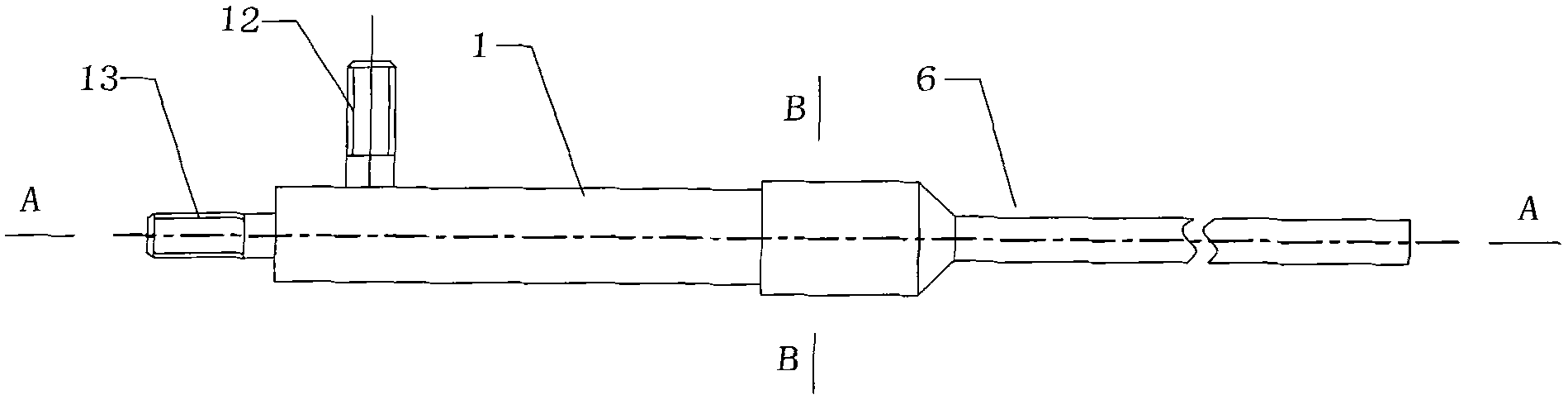

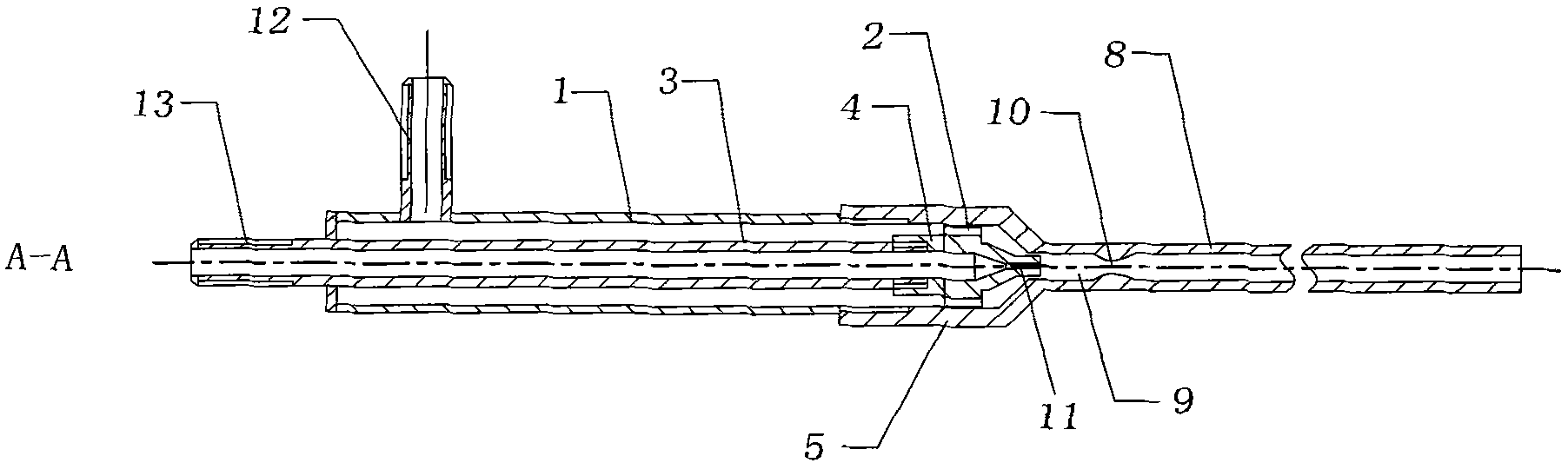

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

[0021] like Figures 1 to 3 as shown,

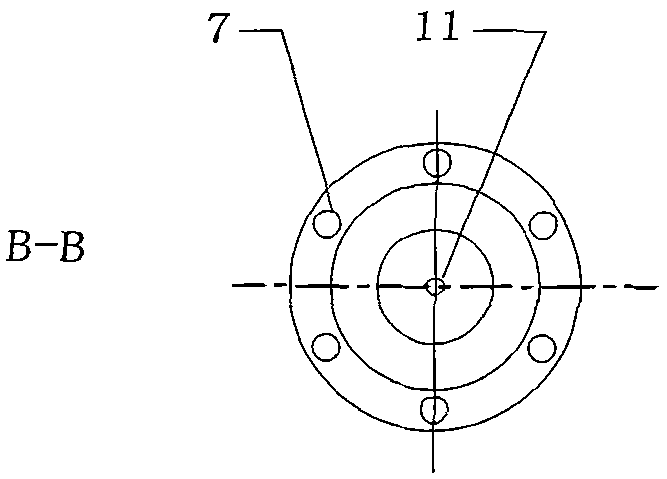

[0022] The reductant atomizing spray gun used for the selective non-catalytic reduction denitrification process of the present invention comprises a gas pipe 1, a liquid pipe 3, a liquid nozzle 4 and a spray pipe 6, the side of the gas pipe 1 is provided with an air inlet port 12, and the liquid pipe One end of 3 protrudes from the gas pipe 1, and a liquid inlet port 13 is provided at this end, and a gas channel is formed between the inner wall of the gas pipe 1 and the outer wall of the liquid pipe 3. The liquid nozzle 4 is threadedly connected to the other end of the liquid pipe 3, and the periphery of the liquid nozzle 4 is provided with a flange 2, and the flange 2 is provided with a plurality of ventilation holes 7; the spray pipe 6 is composed of a connecting part 5 and a pipe body 8 , the connection part 5 is threadedly ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com