Catalyst for performing selective catalytic reduction on nitrogen oxide by ammonia

A nitrogen oxide, selective catalysis technology, applied in physical/chemical process catalysts, molecular sieve catalysts, chemical/physical processes, etc., to achieve the effect of wide range of raw materials, low reaction temperature, and excellent nitrogen oxide purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Preparation of Fe-Ce / Beta Catalyst

[0021] 1) Preparation of 1M Ce(NO 3 ) 3 Aqueous solution, the Beta molecular sieve (Si / Al=25, purchased from Tianjin Shenneng Technology Co., Ltd.) that has been removed from the template is added to the above solution, and the mass fraction of Ce / beta molecular sieve is controlled according to the metering ratio to be 5%. After stirring at room temperature, The remaining moisture was dried at 80°C, and then calcined at 500°C for 6 hours to obtain 5% Ce / beta.

[0022] 2) with 1M ferrous sulfate solution as precursor, introduce Fe in 5% Ce / Beta by ion exchange method, exchange method is: take by weighing 5% Ce / Beta sample 100g and place in the round bottom flask of 250ml, then according to Add 50ml of ferrous sulfate solution in a metered ratio, then add deionized water to 200ml, stir in a water bath at 80°C for 12h, then suction filter, wash and dry. The above steps were repeated three times, and finally the mass content of Fe was...

Embodiment 2

[0025] Preparation of Fe-La / ZSM-5-Beta Catalyst

[0026] 1) Weigh a certain amount of La(NO 3 ) 3 Completely soluble in water, 1M La(NO 3 ) 3 Aqueous solution, ZSM-5 (Si / Al=25, purchased from Tianjin Shenneng Technology Co., Ltd.) and Beta molecular sieve were added to the above solution according to the mass ratio of 1 / 1 (Si / Al=30), and the control The mass fraction of La / molecular sieve was 0.1, and the remaining moisture was dried at 80°C after stirring at room temperature, and then calcined at 550°C for 6 hours to obtain 10% La / ZSM-5-Beta.

[0027] 2) Using 1M ferrous sulfate solution as a precursor, introduce Fe into 10% La / ZSM-5-Beta by ion exchange method, the exchange method is: weigh 100g of 10% La / ZSM-5-Beta sample and place it in 250ml Then add 50ml of ferrous sulfate solution according to the metering ratio, then add deionized water to 200ml, stir for 18h under the condition of 80°C water bath, then suction filter, wash and dry. The above steps were repeated t...

Embodiment 3

[0030] Application of Fe-Ce / Beta Catalyst in Selective Catalytic Reduction of Nitrogen Oxide and Ammonia

[0031] Put 5g of 1.6%Fe-5%Ce / Beta / cordierite monolithic catalyst into a stainless steel fixed-bed reactor with a length of 50cm and an inner diameter of 2cm. The catalyst is placed in the central constant temperature zone of the reactor. At the reaction inlet: nitrogen oxide =1000ppm; Ammonia = 1050ppm; Oxygen = 5%; Water vapor = 8%; Sulfur dioxide = 25ppm; -1 .

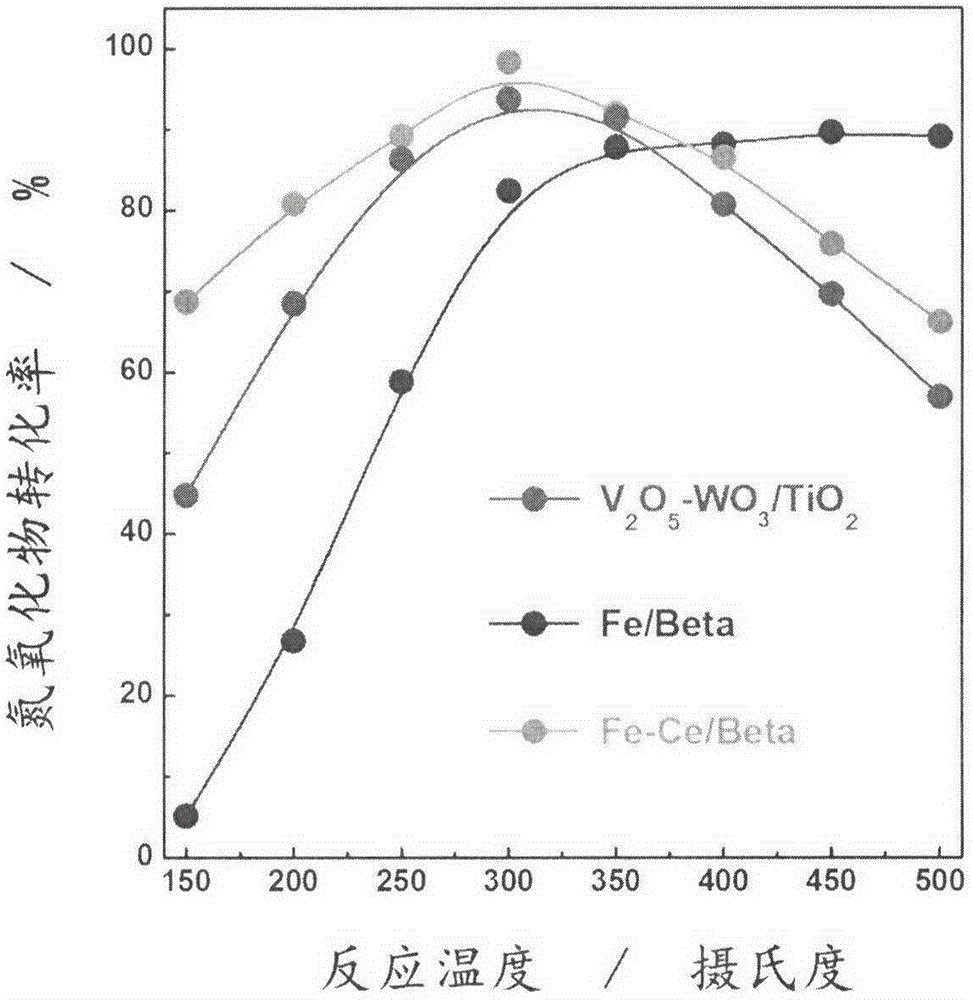

[0032] 4) The product is analyzed online with a nitrogen oxide analyzer and a small mass spectrometer. The model of nitrogen oxide analyzer used is Swiss Eco Physics CLD62, the model of mass spectrometer is German Pfeiffer Omnistar, and the test results of catalytic reaction are shown in figure 1 .

[0033] Catalytic results show that: 1.6%Fe-5%Ce / Beta has excellent NH3 -SCR performance, the conversion rate of nitrogen oxides can reach 97% at 300°C, and the concentration of nitrogen oxides at the outlet is lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com