Regeneration method for waste vanadium-titanium-based SCR (Selective Catalytic Reduction) flue gas denitrification catalyst

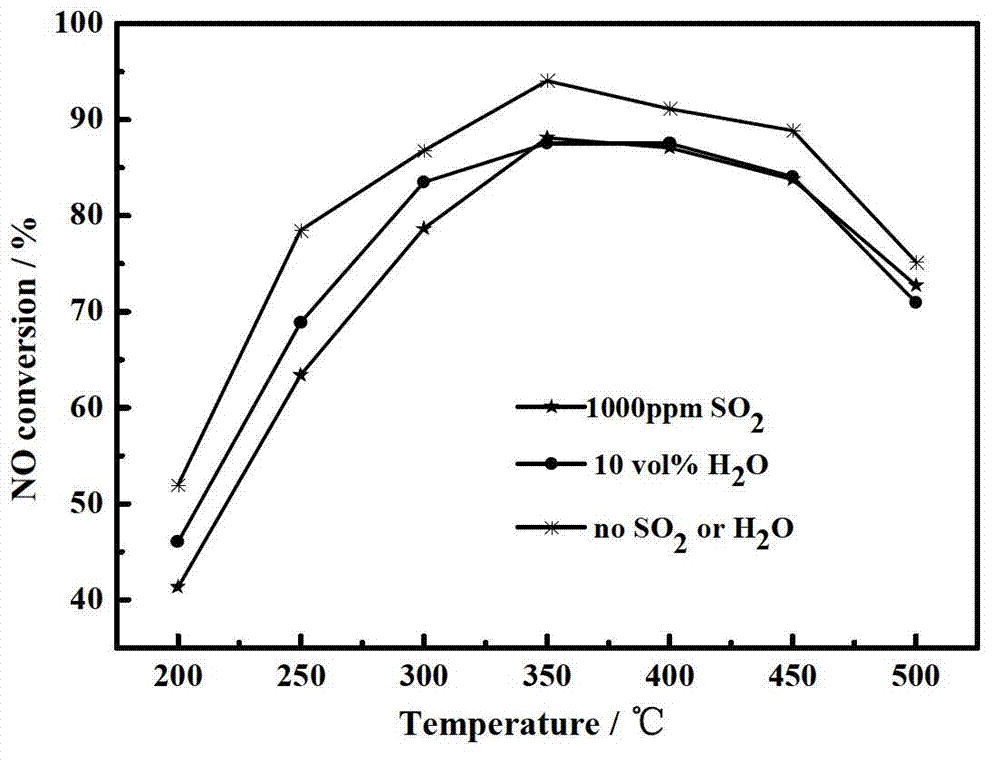

A denitrification catalyst, vanadium-titanium-based technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of low strength of regenerated catalysts, secondary pollution, Low utilization rate of waste catalysts and other issues, to achieve good anti-sulfur and anti-water poisoning performance, high utilization rate, wide active temperature window effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

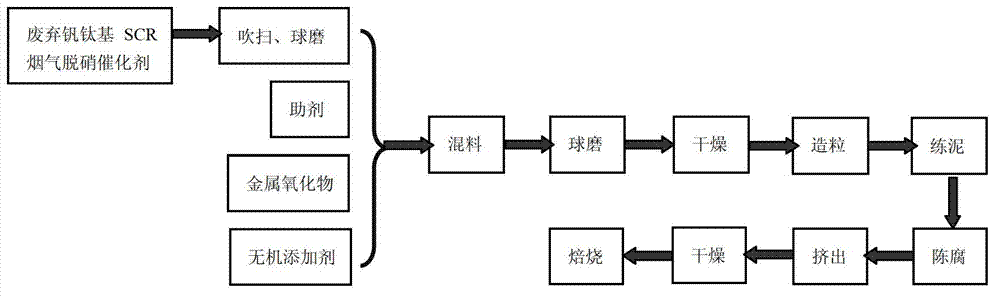

[0028] Specific steps:

[0029] (1) Blow the waste vanadium-titanium-based SCR flue gas denitrification catalyst with 0.8MPa oil-free dry compressed air for 50 minutes, put it in a ball mill tank, and then put it on a planetary ball mill with a material: agate ball mass ratio of 1:3 Ball milling for 1 hour to prepare waste vanadium-titanium-based SCR flue gas denitrification catalyst recycle material;

[0030](2) Mix ammonium sulfate, kaolin and waste vanadium-titanium-based SCR flue gas denitrification catalyst reclaimed material at a mass ratio of 0.5:9.5:90 (without adding metal oxides), and then use the mixture: agate ball: poly The mass ratio of acrylic acid: water is 1:2.5:0.5%:1, ball milled on a planetary ball mill for 15 hours, and then dried at 110°C for 24 hours to prepare the regenerated SCR flue gas denitrification catalyst powder;

[0031] (3) Mix the regenerated SCR flue gas denitrification catalyst powder with hydroxypropyl methylcellulose, glycerin, and water...

Embodiment 2

[0038] Specific steps:

[0039] (1) The waste vanadium-titanium-based SCR flue gas denitrification catalyst was purged with 0.1MPa oil-free dry compressed air for 60 minutes, then placed in a ball mill tank, and then placed on a planetary ball mill with a material: agate ball mass ratio of 1:2 Ball milled for 1.5h to prepare waste vanadium-titanium-based SCR flue gas denitrification catalyst reclaimed material;

[0040] (2) Mix cobalt oxide, ammonium phosphate, kaolin, bentonite, and waste vanadium-titanium-based SCR flue gas denitrification catalyst reclaimed materials in a mass ratio of 15:2:10:30:43, and then use the mixture: agate balls The mass ratio of acrylamide: water is 1:2:2%:0.7, ball milled on a planetary ball mill for 16 hours, and then dried at 90°C for 24 hours to prepare the regenerated SCR flue gas denitrification catalyst powder;

[0041] (3) Mix the regenerated SCR flue gas denitrification catalyst powder with polyvinyl alcohol, tung oil, and water in a mas...

Embodiment 3

[0048] Specific steps:

[0049] (1) Blow the waste vanadium-titanium-based SCR flue gas denitrification catalyst with 1MPa oil-free dry compressed air for 20 minutes, put it in a ball mill tank, and then ball mill it on a planetary ball mill with a mass ratio of material: agate ball equal to 1:3 0.5h, the waste vanadium-titanium-based SCR flue gas denitration catalyst reclaimed material was prepared;

[0050] (2) Mix cerium oxide, lanthanum oxide, cobalt oxide, diammonium hydrogen phosphate, quartz sand, and waste vanadium-titanium-based SCR flue gas denitrification catalyst reclaimed material in a mass ratio of 1:1:13:0.3:28:56.7 material, and then ball milled on a planetary ball mill for 6 hours with the mass ratio of mixture: agate ball: acrylamide: ethanolamine: water: 1:3:1%:0.5%:0.5, and then dried at 120°C for 12 hours to prepare Regenerated SCR flue gas denitrification catalyst powder;

[0051] (3) Mix the regenerated SCR flue gas denitrification catalyst powder with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com