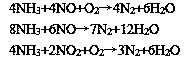

Novel SNCR (selective non-catalytic reduction) and SCR (selective catalytic reduction) hybrid denitrification system

An SCR reactor and denitrification technology, applied in chemical instruments and methods, nitrous oxide capture, greenhouse gas capture, etc., can solve the problems of unsatisfactory denitration effect, waste of reducing agent, escape of ammonia gas, etc. Small area, increased droplet number, and the effect of reducing ammonia escape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0037] Such as figure 1 As shown, a new SNCR and SCR mixed denitrification system, including preparation storage module, delivery circulation module, metering dilution module, NO X Online monitoring module, automatic control module, distribution module, injection module, boiler, SCR reactor.

[0038] The preparation and storage module, the conveying cycle module, and the metering and dilution module are connected in sequence through pipelines, and the metering and dilution module, distribution module, and injection module are connected in sequence through pipelines. The automatic control module is connected to the temperature, pressure and other signals from the boiler through the circuit, and obtained through the circuit. from NO X Monitor the signal of the module online, and output the control signal to the metering dilution module through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com