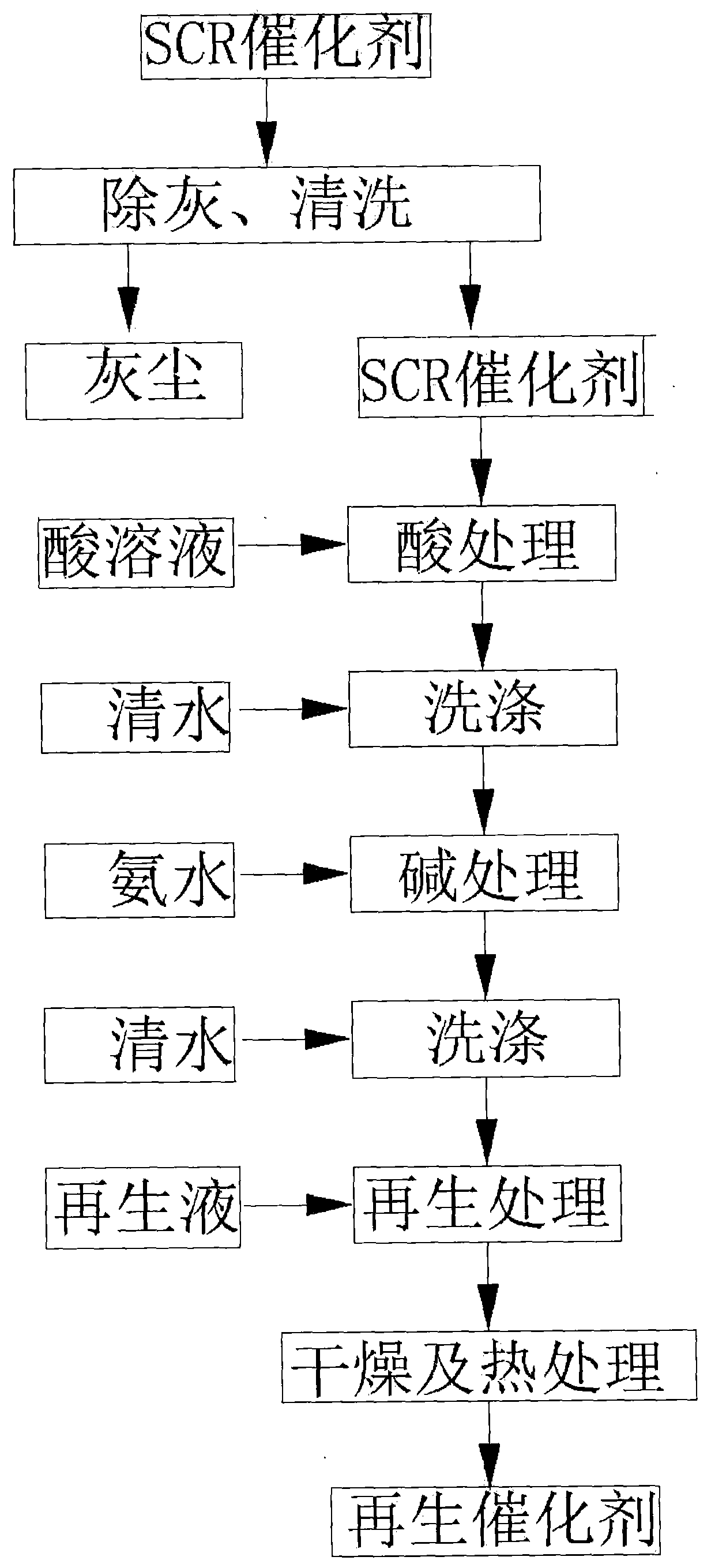

Method for regenerating titanium-based vanadium-series SCR (Selective Catalytic Reduction) denitration catalyst

A technology of SCR catalyst and denitration catalyst, which is applied in the field of titanium-based vanadium-based SCR denitration catalyst regeneration, can solve problems such as the lag in catalyst regeneration and resource recovery research, and achieve the effects of easy automation and continuity, low price and low processing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Take a waste honeycomb SCR catalyst from a power plant. 90% of the pores of the catalyst are blocked, but the appearance is intact and the mechanical strength is high. First, 5MP high-pressure air was used to remove dust in the channels, and then the activity and mechanical strength of the catalyst were measured. The activity of the catalyst was 65.3% of that of the new catalyst, and the mechanical strength was 89.6%.

[0024] Add the de-ashed SCR denitrification catalyst into a solution of 10% hydrochloric acid and 0.5% hydrofluoric acid, oscillate ultrasonically for 30 minutes at a temperature of 60°C, and then soak for 10 hours. Take out the catalyst, drain the acid solution, add clean water, oscillate ultrasonically for 10 minutes, wash with clean water at room temperature twice, drain the SCR denitrification catalyst and add it to 20% ammonia solution, oscillate ultrasonically for 30 minutes, raise the temperature to 90°C and continue soaking for 4.0h, Sonicate wit...

Embodiment 2

[0028] Take a waste honeycomb SCR catalyst from a power plant. 80% of the pores of the catalyst are blocked, but the appearance is intact and the mechanical strength is high. First, 3MP high-pressure air was used to remove dust in the channels, and then the activity and mechanical strength of the catalyst were measured. The activity of the catalyst was 72% of that of the new catalyst, and the mechanical strength was 92%.

[0029] Add the SCR denitrification catalyst after ash removal to 10% hydrochloric acid solution, oscillate ultrasonically for 30 minutes at a temperature of 80°C, and then soak for 20 hours. Take out the catalyst, drain the acid solution, add water, oscillate ultrasonically for 10 minutes, wash with clean water at room temperature twice, drain the SCR denitrification catalyst, add it to 15% ammonia water and 5% ammonium carbonate solution, oscillate ultrasonically for 30 minutes, and raise the temperature to 90°C Continue soaking for 5.0h, ultrasonically sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com