SNCR (selective non-catalytic reduction) and SCR (selective catalytic reduction) combined process flue gas denitrification system of CFB (circulating fluidized bed) boiler

A hybrid method and denitrification technology, applied in separation methods, chemical instruments and methods, and dispersed particle separation, etc., can solve problems such as high dust and low temperature at the outlet of economizers, and achieve reduced operating costs, good economy and environmental protection performance , reduce the effect of investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following non-limiting examples illustrate the invention.

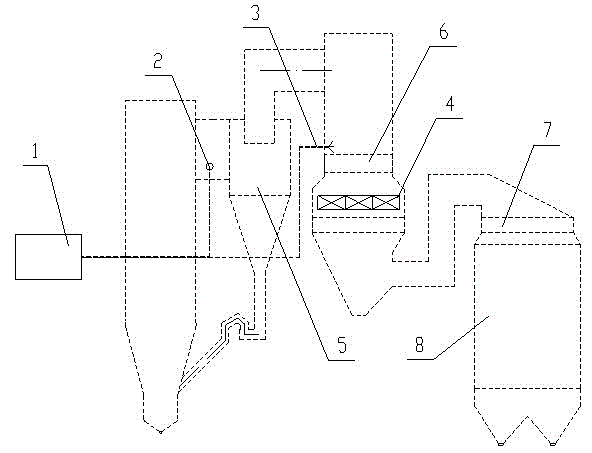

[0019] Such as figure 1 As shown, the reducing agent prepared by the reducing agent preparation system 1 is sprayed through the SNCR reducing agent injection device 3 at the inlet of the CFB boiler cyclone separator 5, and the NOx in the high-temperature flue gas at the outlet of the CFB boiler furnace is in the cyclone separator The 5 positions are strongly mixed, and part of the NOx in the flue gas undergoes a reduction reaction with the reducing agent to generate harmless and pollution-free N2 and water, which can achieve a denitrification efficiency of 50%. The incompletely reacted NOx and escaping ammonia enter the heating surface at the tail of the boiler, and then further undergo a catalytic reduction reaction through the denitrification reactor 4 arranged between the primary economizer 7 and the secondary economizer 8, and the NOx in the flue gas It is further reduced, and the denitrification effic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com