sncr flue gas denitrification device using urea as reducing agent

A reducing agent, urea technology, applied in the direction of climate sustainability, greenhouse gas capture, mixer, etc., can solve the problems of restricting the application of SNCR technology, water wall corrosion, etc., to prevent corrosion, ensure the effect of concentration and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with drawings and embodiments.

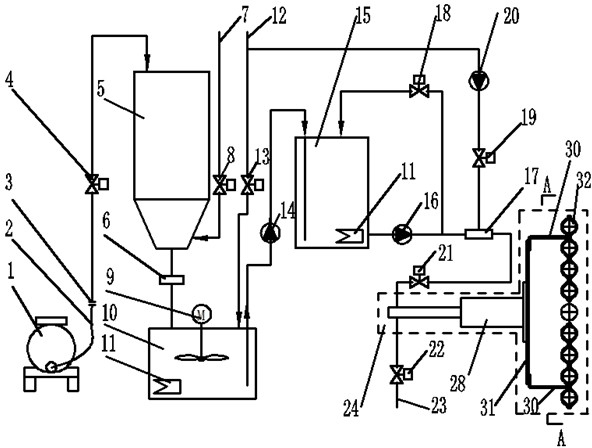

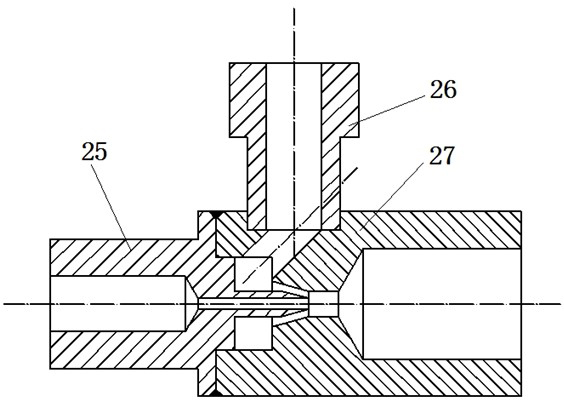

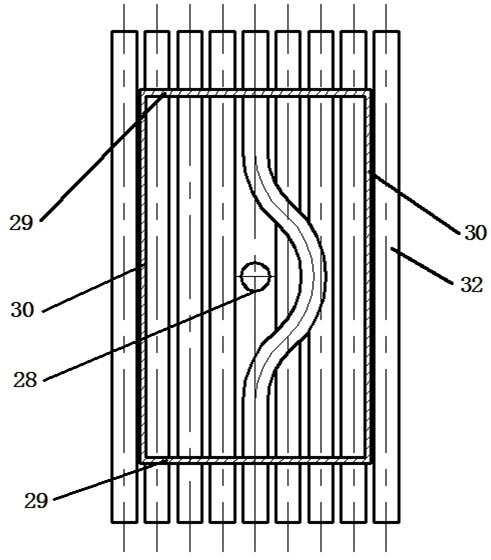

[0017] Such as figure 1 , figure 2 , image 3 As shown, the present invention comprises agitator 9, urea solution preparation tank 10, heater 11, industrial water main pipe 12, industrial water regulating valve 13, urea delivery pump 14, urea solution storage tank 15, urea injection pump 16, mixer 17 , Urea reflux regulating valve 18, pressurized industrial water regulating valve 19, industrial water pump 20, urea dilute solution regulating valve 21, atomizing steam regulating valve 22, atomizing steam main pipe 23, urea injection unit 24. The upper part of the urea solution preparation tank 10 communicates with the industrial water main pipe 12 through an industrial water regulating valve 13 and corresponding pipelines. A first heater 11 and an agitator 9 are installed in the urea solution preparation tank 10 . The communication between the urea solution preparati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com