Garbage incineration fume ultralow emission purifying system

A waste incineration and purification system technology, applied in the direction of gas treatment, chemical instruments and methods, combined devices, etc., can solve the problems of low deacidification efficiency, limited pollutant removal effect, and difficulty in meeting emission requirements, etc., to achieve improved Remove the effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

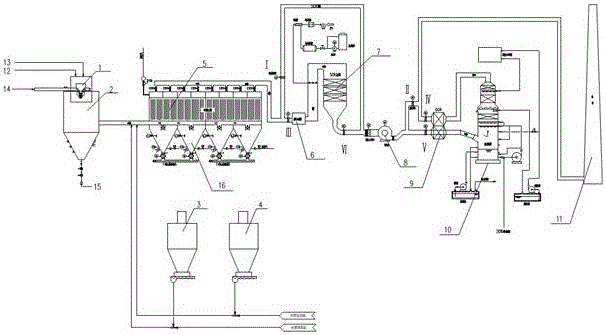

[0044] A waste incineration flue gas ultra-low emission system, its structure diagram is as follows figure 1 As shown, including SNCR denitrification device (not shown in the schematic diagram, which belongs to furnace denitrification), semi-dry reaction tower 2, slaked lime injection device 3, activated carbon injection device 4, bag filter 5, steam heater 6, SCR reactor 7. Induced fan 8, flue gas / flue gas heat exchanger 9, wet scrubber 10, chimney 11;

[0045]The upper part of the semi-dry reaction tower 2 is equipped with a rotary spraying device 1, which is connected with a lime slurry pipeline 12 and an atomizing cooling water pipeline 13, and the inlet 14 of the flue gas is set under the rotary spraying device 1, and the bottom is provided with a discharge port 15. There is a flue gas outlet on the side wall;

[0046] A slaked lime injection device 3 and an activated carbon injection device 4 are connected to the flue between the flue gas outlet on the side wall of the ...

Embodiment 1

[0064] That is to say, the flue gas combination treatment process of "semi-dry deacidification + activated carbon injection adsorption of dioxin + bag filter" is adopted in the existing technology, the pollutant discharge meets the standard requirements, and the smoke content is 80mg / m 3 , sulfur dioxide 260 mg / m 3 , hydrogen chloride 75 mg / m 3 , the average value of mercury and cadmium is 0.15 mg / m 3 , the average value of lead determination is 1.6 mg / m 3 , Dioxins 1.0ngTEQ / m 3 , in which dust, dioxins and acid substances failed to meet the EU 2000 emission standards.

[0065] By comparing the above application implementation example 1 with the comparison implementation example 1, it can be seen that a kind of waste incineration flue gas ultra-low emission purification system of the present invention, its treatment effect has been greatly improved compared with the prior art, and the smoke content and sulfur dioxide emissions are reduced by 1 / 8 and 1 / 26 times of the exist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com