Telescopic in-furnace denitration device arranged at top of boiler

A telescopic technology on the top of the boiler, which is applied in the direction of gas treatment, membrane technology, and dispersed particle separation, can solve the problems of poor mixing effect and low out-of-stock efficiency, achieve enhanced mixing effect, save consumption, save equipment investment and operating costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

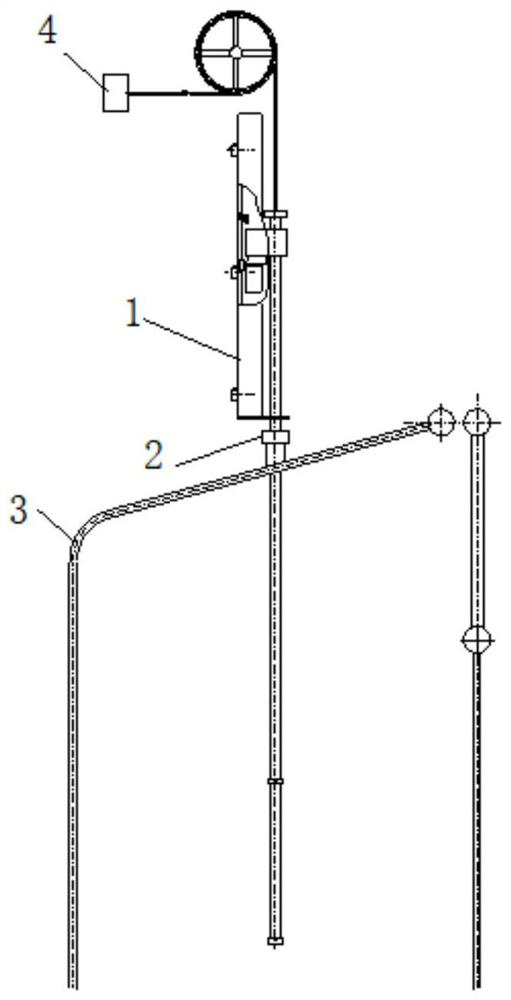

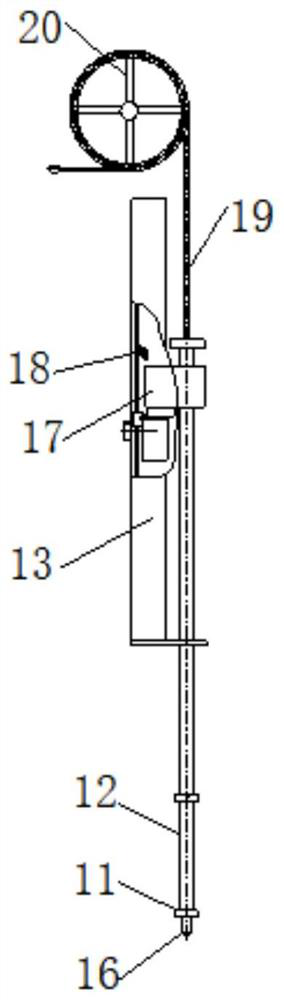

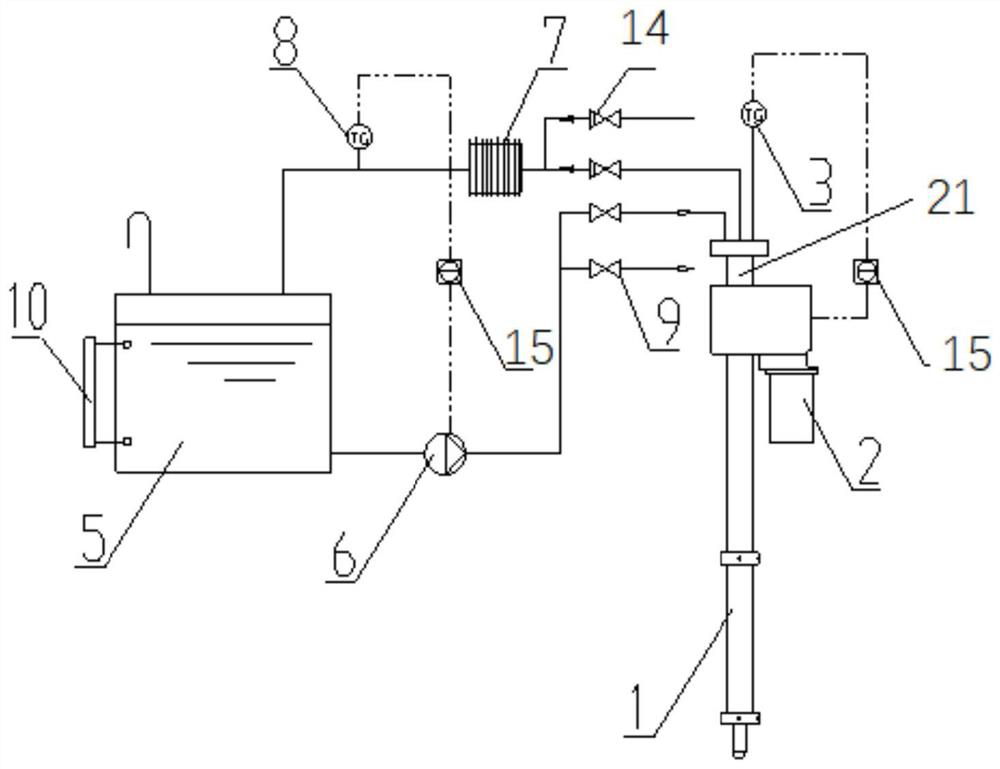

[0030] Such as Figure 1 to Figure 3 As shown, the present invention proposes a retractable furnace denitrification device arranged on the top of the boiler. The main body is conveyed by a retractable spray gun 1, a spray gun height control system, a spray gun cooling system, a positive pressure sealing device 2, a reducing agent and compressed air. The distributing device 4 is composed. The retractable spray gun 1 of the present invention comprises an annular spray head 11, a gun barrel 12 and a spray gun beam body 13, and the gun tube 12 extends into the furnace interior through a reserved hole in the furnace roof, so that the retractable spray gun 1 is vertically arranged on the top of the boiler, A single telescopic spray gun 1 sprays and covers a radius of about 2 meters, and multiple telescopic spray guns 1 can be arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com