Intermediate temperature efficient modified SNCR denitration device of layer-burning boiler and method

A denitrification and medium temperature technology, which is applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve the problems of unstable denitrification efficiency required by the temperature window, affecting boiler operation efficiency, etc., achieving low investment and operation costs and improving operation efficiency , The effect of improving the efficiency of denitrification reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

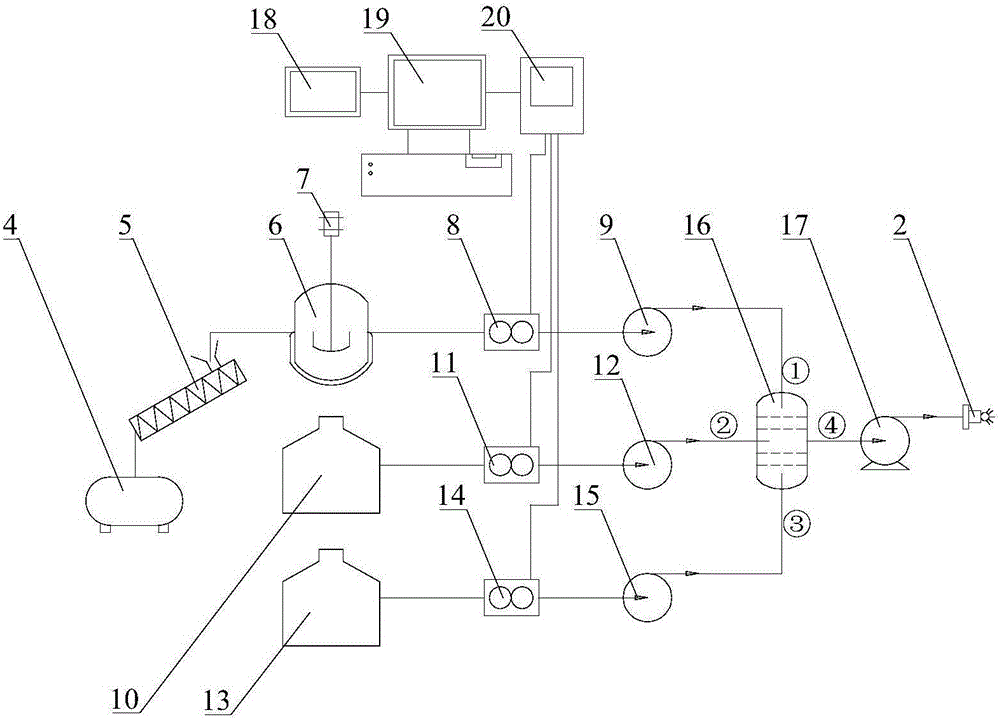

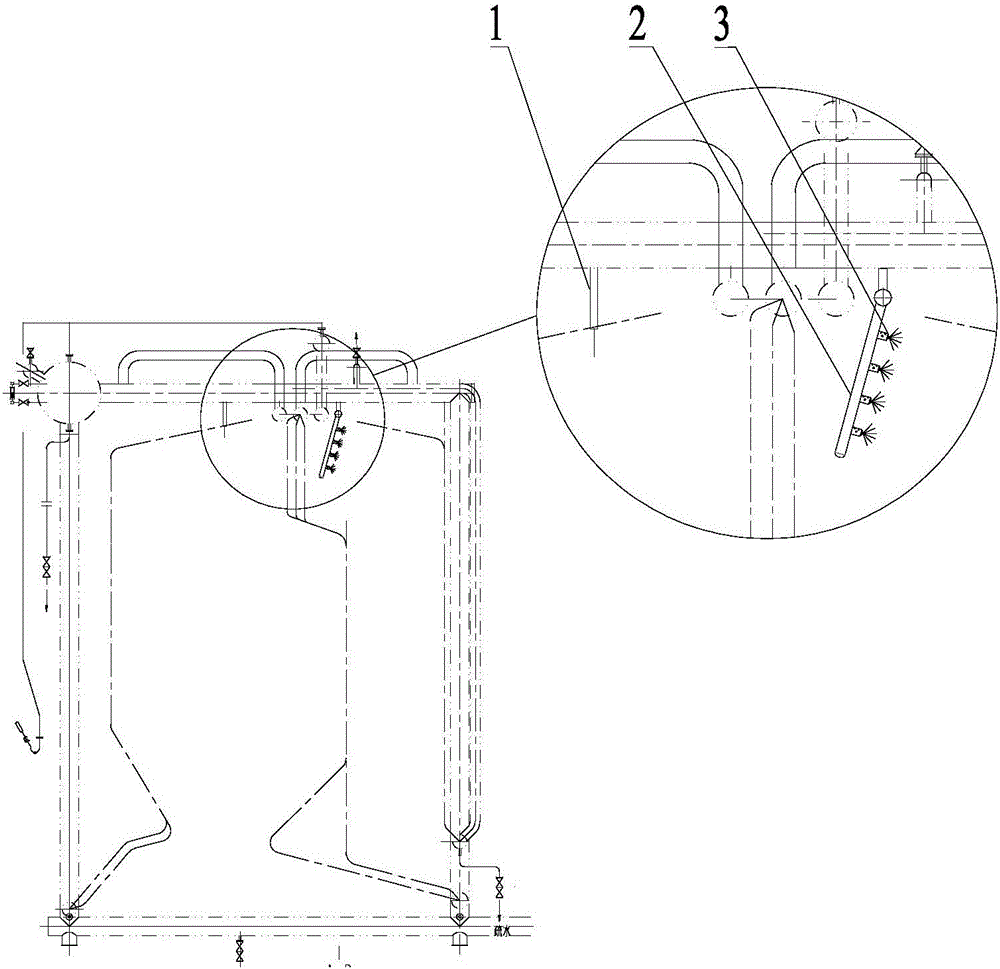

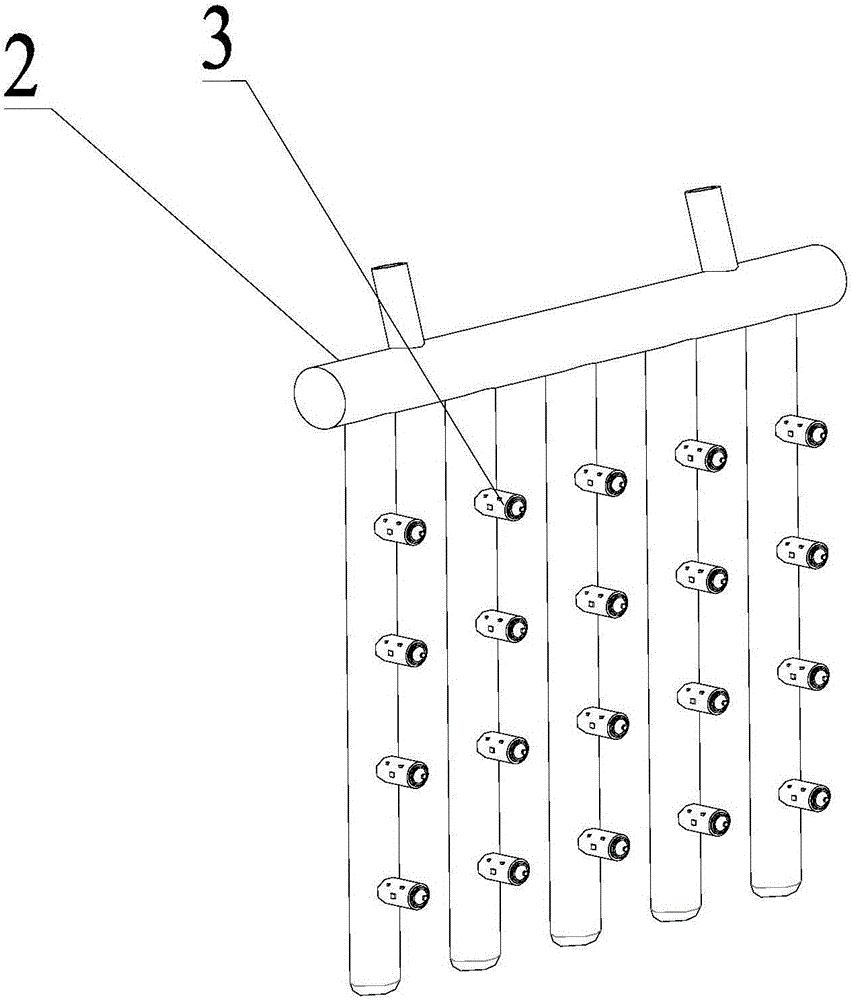

[0045] The solid urea particles are stored in the urea storage bin 4, transported to the liquid distribution tank 6 by the screw conveyor 5, and the urea particles are dissolved into a urea solution with a concentration of 25% to 60% with deionized water; H 2 o 2 The concentration of the solution is 30%, and the amount added is according to H 2 o 2 and detected NO X The molar ratio is 1:1 to determine, the organic acid additive selects formic acid solution, the concentration is 20%, urea, H 2 o 2 and formic acid solution are sent to the premixing device 16 by No. 1 delivery pump 9, No. 2 delivery pump 12 and No. 3 delivery pump 15 through No. 1 flowmeter 8, No. 2 flowmeter 12 and No. 3 flowmeter 14 respectively, and mix well The modified solution is pressurized by the booster pump 17 and sprayed through the ammonia spray grid 2 from the atomizing nozzle 3 into the turning area of the furnace outlet to form atomized droplets, where the smoke temperature at the nozzle posi...

Embodiment 2

[0047] The solid urea particles are stored in the urea storage bin 4, transported by the screw conveyor 5 to the liquid distribution tank 6, and the urea particles are dissolved into a urea solution with a concentration of 25% to 60% with deionized water; the concentration of the H2O2 solution is 30%, Add amount according to H 2 o 2 and detected NO X The molar ratio is 1:1 to determine, the organic acid additive selects acetic acid solution, the concentration is 20%, urea, H 2 o 2 and acetic acid solution are sent to the premixing device 16 by No. 1 delivery pump 9, No. 2 delivery pump 12 and No. 3 delivery pump 15 through No. 1 flowmeter 8, No. 2 flowmeter 12 and No. 3 flowmeter 14 respectively, and mix well The modified solution is pressurized by the booster pump 17 and sprayed into the turning area of the furnace outlet through the ammonia spraying grid 2 by the atomizing nozzle 3 to form atomized droplets, where the smoke temperature at the nozzle position is 595°C. ...

Embodiment 3

[0049] The solid urea particles are stored in the urea storage bin 4, transported to the liquid distribution tank 6 by the screw conveyor 5, and the urea particles are dissolved into a urea solution with a concentration of 25% to 60% with deionized water; H 2 o 2 The concentration of the solution is 30%, and the amount added is according to H 2 o 2 and detected NO X The molar ratio is 1:1 to determine, the organic acid additive selects propionic acid solution, the concentration is 20%, urea, H 2 o 2 and propionic acid solution are sent to the premixing device 16 by No. 1 delivery pump 9, No. 2 delivery pump 12 and No. 3 delivery pump 15 through No. 1 flowmeter 8, No. 2 flowmeter 12 and No. 3 flowmeter 14 respectively, mix A good modified solution is pressurized by the booster pump 17 and sprayed through the ammonia spray grid 2 from the atomizing nozzle 3 into the turning area of the furnace outlet to form atomized droplets, where the smoke temperature at the nozzle posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com