Flue gas dust removal, denitration and waste heat utilization integrated device and treatment method thereof

A denitration catalyst and flue gas technology, applied in the field of flue gas purification, can solve the problems of high investment cost and operating cost, difficult process control, poor stability of purification effect, etc., and achieve high efficiency, good dust removal effect, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

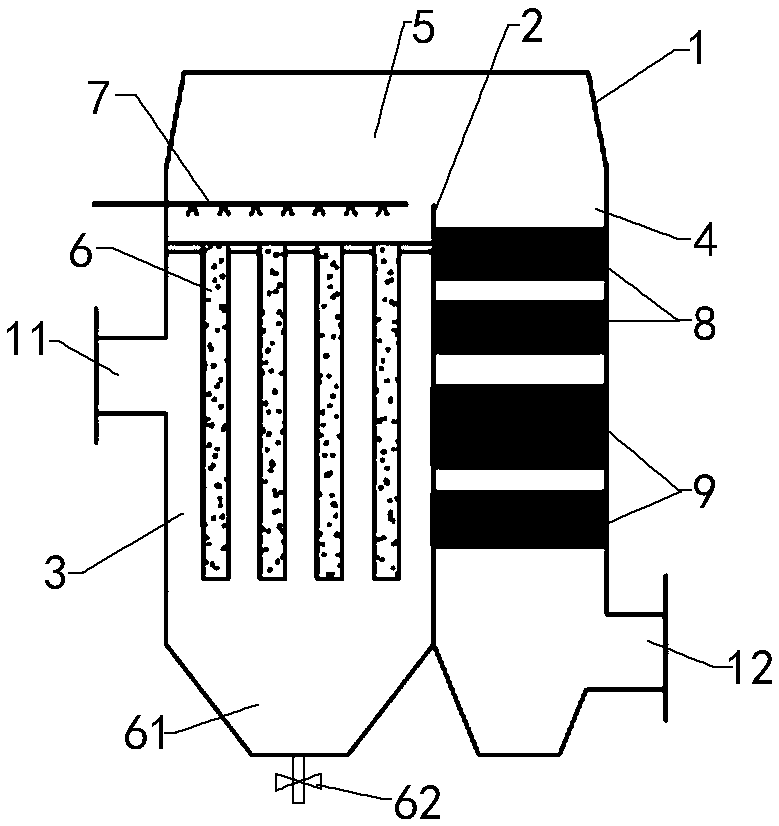

[0036] like figure 1 As shown, the flue gas dedusting and denitrification waste heat utilization integrated device of the present invention is connected between the boiler economizer and the desulfurization tower, including a shell 1, and the inside of the shell 1 is divided by a baffle plate 2 into a dust removal area 3 arranged in parallel and horizontally The comprehensive reaction zone 4 is provided with a denitrification zone and an air preheating zone sequentially along the flue gas flow direction in the comprehensive reaction zone 4.

[0037] The baffle plate 2 in the housing 1 is arranged vertically, the bottom edge is sealed and fixed with the bottom plate of the housing 1, and the two side edges are sealed and fixed with the side wall of the housing 1, and there is a horizontal gap between the top edge and the top plate of the housing 1. The flue gas channel 5 is for flue gas circulation in the dust removal area 3 and the comprehensive reaction area 4; the side wall ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com